H E L P

advertisement

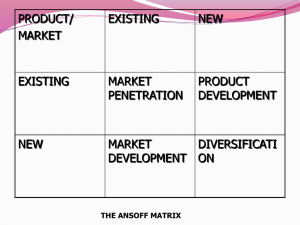

INTERNAL USE ONLY Hands-on Execution of Lean Principles - (H.E.L.P.) 1 Luis Loya Director, Operational Excellence MBB Program Master Black Belt May 14, 2014 INTERNAL USE ONLY Agenda Background / Structure 5S: A Visual Management System Lean Standard Work: SOS Takt: A Plan vs. Actual Control Lean 5S Game Q&A 2 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Background (FY 2009 – 2010) • Quarterly to semi-quarterly series of conference calls about Lean concepts. – Templates and instructional materials developed by MBBs and posted to Warehouse Operations SharePoint site. – Sites designated a “Champion” for each topic prior to national calls. 5S • Limitations – Conference call format limited depth of coverage and no one-on-one teaching. – With no “live” environment training – Operations teams were left to apply material on their own. 3 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Standard Work Takt INTERNAL USE ONLY Background (FY 2011) : How Do We Learn? Presentation - 5% Teaching Techniques Reading - 10% Retention Rate Audio-Visual - 20% Demonstration - 30% Discussion Group - 50% Practice with Feedback - 75% Teach Others / Immediate Use - 80% 4 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Learner Focused & Interactive INTERNAL USE ONLY Background (FY 2011) : The Goal • Develop & pilot an interactive hands-on learning experience for targeted Lean concepts: – 5S – Standard Work – Takt Standard Work Understand 5 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Background: The House of Lean Business Profit Impact Shareholder Satisfaction Customer Satisfaction Employee Engagement Goals: Greatest Safety Highest Quality Lowest Cost Results Shortest Lead Time Lean Roadmap To Success Right Item Right Time Right Quantity • Takt Time • Pull System • One-Piece Flow • Min Batch Size • Value Stream Map • Process Map People & Teamwork Ergonomics Empowerment Gemba 3 Level Scheduling 4 Standard Work • Managed Inventory • Smoothed demand • Build to order • Visual Management • SOS • 5S Built-In-Quality Jidoka 1 • Poke-Yoke 2 • Process Stability • Design-for-Lean • 5 Why’s • Andon Signals • Control Charts (SPC) • PDCA Leadership • Kaizen / JDI / BB • Waste Reduction • Genchi Genbutsu 5 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Foundation Culture Daily Management (1) Automation with human interaction, (2) Error proofing, (3) Go to where the value is, (4) Heijunka, (5) Go see the problem 6 Pillars DMAIC Stability Philosophy Continuous Improvement Continuous Flow Just-In-Time Assessment HOL-FY13 – Rev2 (LL) INTERNAL USE ONLY Background (FY 2011 - 2012) : The Plan & Execution • Classroom 1-2 hrs. by topic • Leads and above • One department at a time Topics and Lead Trainers • 5S – Paul Scheuer (Coach: Frank Limones) Content Development • Expand on existing lean templates Proof-of-Concept Training Delivery (Black Belt / MBB) • April – May, 2011 • Sacramento FDC • June 13-24, 2011 • 2 Sessions - Rx Outbound • Training materials: • Standard Work – Luis Loya & Craig Shockency (Coach: Tom Morgan) - Module Presentations - Town Hall decks - Hands-on Exercises • Takt – Luis Loya 7 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. • Field onsite black belts serve as primary training source • Bring in other regional black belts or MBBs as needed Sequential Rollout by Area • Each DC required to implement four areas in FY12 • Rx • OTC • Receiving • Other HELP Tracker • BB’s will update Tracker monthly • Operations Scorecard INTERNAL USE ONLY Background (FY 2013) : The Evolution - 8 New exercise = Letter’s Game New Audit & Results Report © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Time (seconds) • Updated 5S: 65 60 55 50 45 40 35 30 25 20 15 10 5 0 Letters Game 54.6 32.0 23.4 17.9 16.0 Goal 9.3 5.1 INTERNAL USE ONLY Background (FY 2013) : The Evolution • Updated SW: - New SOS format 9 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Background (FY 2014) : The Evolution • Updated Takt: - Added case studies to link Standard Work & Takt 10 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Class Size & Room Setting • 8 to 16 Participants • U-shape setting with a spacious conference room 11 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY The Agenda Time Day 1 Day 2 8-9 am 8:30 am Start 8:30 am Start Introductions Expectations 5S Module with Letters Game Exercise Boeing Video Review 5S & SW SOS Exercise create standard work Leader Standard Work draft personal LSW Lunch Lunch 9-10am 10-11am 11-12pm 12-1pm 1-2pm 2-3pm 3-4pm Standard Work Module Takt Module with Draw a House Exercise Takt Time Challenge Group Ex. Observation Group Ex. Stop Watch Takt Tools & Exercises Cycle Time Exercise bringing 5S, SW & Takt Time Observation Form together 4-5pm 4:30 pm End (estimated) 12 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. 4:30 pm End (estimated) INTERNAL USE ONLY 13 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 5S Module: with Exercise Game WIIFM Presentation Sort Set in Order Shine Standardize Sustain No 5S Exercise 1S 2S Exercise Exercise 3S Exercise Practice and Discussion 14 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. 4S Exercise 5S Exercise INTERNAL USE ONLY Sorting: Red Tag Syracuse: Forward Distribution Center 15 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Sorting: Red Tag Little Rock’s 1st SemiAnnual Red Tag Event • Do you have unnecessary items on, in or around your desk? • The next week is your opportunity to remove these unnecessary items - 16 What is a Red Tag Event? What could be considered? How should I determine? Where do I take these? © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 17 Pit Stops From 1950 & 2013: Video © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Shine: • Key component to Preventive Maintenance • Clean to Inspect • 5S Responsibility Board 18 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 19 RCPS: Closing the Loop © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 20 Boeing 5S: Video © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 21 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Standard Work “Where there is no standard, there can be no kaizen.” - Taiichi Ohno Businessman: father of Toyota Production System 22 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 23 The True Meaning of Kaizen: Video © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 24 Why Standard Work: The Wedge to Sustain © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 25 Why Standard Work: Promotes Teamwork © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Draw a Lean House: Exercise VOC Customer Requirements: Practice and Discussion Round 1 • Draw a house centered on the page. (front profile only) Round 2 • Create detailed SOS Standard Operating Sheet Step • The house must be large enough to touch all four inner edges of the graph area. Description Instructions 1 Foundation Draw a rectangle starting at point (A,0) then (A,1), to (K,1), to (K,0), back to (A,0) 2 Left Wall Draw a line from point (B,1) to (B,5) 3 Right Wall Draw a line from point (J,1) to (J,5) 4 Door Draw a line from point (E,1) to (E,3) to (G,3) then end at (G,1) Round 3 • Create SOS with visuals Standard Operating Sheet Finish 7 Step Desc. 1 Foundation Draw a rectangle starting at point (A,0) then (A,1), to (K,1), to (K,0), back to (A,0) Left Wall Draw a line from point (B,1) to (B,5) Instructions 5 Roof Draw a triangle starting at point (F,7) to (A,5) to (K,5) then end at (F,7) 2 6 Chimney Draw a line starting near (C,6) to (C,7), (D,7) then end near (D,6) 3 Right Wall Draw a line from point (J,1) to (J,5) 4 Door Draw a line from point (E,1) to (E,3) to (G,3) then end at (G,1) 5 Roof Draw a triangle starting at point (F,7) to (A,5) to (K,5) then end at (F,7) 6 Chimney Draw a line starting near (C,6) to (C,7), (D,7) then end near (D,6) Sta rt 6 5 4 3 2 1 0 5 6 2 4 A B C D E • The house must have a chimney. • The house must have a door centered. • Quality counts • Takt Time = 60 sec. No Standard Exercise 26 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. SOS Exercise 3 1 SOS Exercise F G H I J K INTERNAL USE ONLY The Power of Observation • • • • • One of our best tools = our eyes Gemba Genchi Genbutsu = go see the problem Gemba Walks Waste Walks * Where the action takes place 27 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Time Observation Form Time Observation Form Process Name: ______________________ Product Name: ______________________ Process WIP: ______________________ (Common Unit of Measure) Step No. Operator: ______________________ Observer: _____________________ Step Elements 1 2 3 4 Obervations 5 6 Total for 1 cycle: 28 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Shift/Time: _________________________ Average time 7 8 9 Average Number of times in 1 process cycle Total time for 1 for the designated process cycle Process WIP Notes 10 Total process time for 1 process cycle INTERNAL USE ONLY Time Observation Form • To Average or Not to Average? 1986 Geography Graduates from UNC Mean: $250,000 Median: $22,000 “The Michael Jordan Effect” 29 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY SOS: The Structure Heading: Approvals Document Control Legend • Cycle Time Data • Takt • WIP Visual / Diagram Repeatable Steps Area Equip/Tools Required Periodic Functions 30 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. QRA Change Approval INTERNAL USE ONLY SOS: Audit & Change Control Document Change Control Record section Audit Record section 31 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Change Details Observations Notes Comments INTERNAL USE ONLY Batch vs. 1 Piece Flow: Exercise Batch Process Customer needs 10 envelopes delivered. Process: Stuff 10, then Standard Operating Sheet Step • • Seal 10, then Stamp 10 Desc. Instructions 1 Fold Get paper & fold in thirds. 10X 2 Stuff Get envelop & stuff folded paper 10X 3 Seal Simulate sealing envelope 10X 4 Stamp Get stamp & place on envelope 10X 5 Finish Place envelope 10X Start Paper 1 2 3 Stamps 4 5 Mail • Finished Fold 10, then Envelopes • Finish 32 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Batch vs. 1 Piece Flow: Video & Exercise Batch Process Customer needs 10 envelopes delivered. Observations: 33 • Waiting • Inventory (WIP) • Defect potential • Large batching = Chaos • 5S • Cycle Time: 4:25 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Batch vs. 1 Piece Flow: Video & Exercise 1 Piece Flow Process Customer needs 10 envelopes delivered. Observations: 34 • Waiting • Inventory (WIP) • Defect potential • Large batching = Chaos • 5S • Cycle Time: 3:29 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Full Cycle Time Cycle Time Start Start Finish Walking Waiting Setting Up 35 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY The Stopwatch: Exercise (practice) Time Observation Form Process Name: Stuffing Envelopes Product Name Process WIP: Step Operator: Observer: Avg Time time Obervations Step Elements No. Shift/Time: 1 6 Number Total time of times for 1 in 1 process process cycle cycle 2 3 4 5 7 8 9 1 Fold: 10.1 8.6 8.7 9.0 8.9 10.7 9.0 9.7 8.8 9.7 9.3 10 93.2 2 Stuff: 10.5 6.2 6.6 7.6 6.8 6.9 9.0 8.5 7.1 7.7 7.7 10 76.9 3 Seal: 5.3 4.4 3.8 3.2 3.5 3.5 3.4 3.4 3.4 3.4 3.7 10 37.3 4 Stamp: 8.5 5.4 5.2 4.9 6.2 4.2 5.0 4.5 4.9 4.7 5.4 10 5 Finish: Place envelope aside 10 53.5 #DIV/0! #DIV/0! 6 #DIV/0! #DIV/0! 7 #DIV/0! #DIV/0! 8 #DIV/0! #DIV/0! 9 #DIV/0! #DIV/0! 10 #DIV/0! #DIV/0! 11 #DIV/0! #DIV/0! 12 #DIV/0! #DIV/0! Total for 1 cycle: Notes 260.9 34.4 24.6 24.3 24.7 25.4 25.3 26.4 26.1 24.2 25.5 Total process time for 1 process cycle Total for 1 cycle: 36.0 34.0 32.0 30.0 28.0 26.0 24.0 22.0 20.0 1 36 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. 2 3 4 5 6 7 8 9 10 INTERNAL USE ONLY The Stopwatch: Exercise (Pack-out Station) 100 90 80 70 60 50 40 30 20 10 0 1 37 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 INTERNAL USE ONLY Leader Standard Work Role Director of Operations Leads 10% 25% 50% 80% Employee 95% Managers Supervisors 38 % time spent daily on Standard Work Focus Time on the production floor to verify the chain of standard work is upheld and the production process is stable and improving. Monitor and support supervisors in their ability to carry out their standard work. Monitor and support leads in their ability to carry out their standard work. Maintain production and ensure standard work is followed by employees. Perform production activities described in standard work. © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Leader Standard Work Leader Standard Work Pos i ti on: Year: Month: 2014 If compl eted, pl ace a n "X" or "√" i n the box bel ow the da y # Frequency Ta s k 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 1 2 Dai l y 3 4 Daily 5 Ta s k Frequency Weeks If compl eted, pl ace a n "X" or "√" i n the box bel ow the week # 1 2 3 4 5 Notes 1 2 Weekl y 3 4 Weekly 5 Frequency Ta s k Wk If completed, pl a ce an "X" or "√" i n the box bel ow the week # 1 2 Notes Semi-Weekly 1 Semi -Weel y 2 3 If compl eted, pl a ce an "X" or "√" i n the box Ta s k Frequency Notes 1 2 Monthl y 3 4 Monthly 5 Frequency Ta s k Qua rter If compl eted, pl a ce a n "X" or "√" i n the box bel ow the qua rter # 1 2 3 4 Notes 1 2 Qua rterl y 3 4 Quarterly 5 If completed, pl a ce a "X" or "√" in the box Frequency Ta s k 1 Annua l 2 3 Notes Annual Lea der Sta nda rd Work Revi ews & Si gna tures Date Ma na ger Manager Reviews 39 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Notes , Comments , Observa tions INTERNAL USE ONLY 40 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Pre-Readings 1. Plan vs. Actual – The Swiss Army Knife of Charts 2. Takt Time vs. Cycle Time 3. Does Your Cycle Time Have A Weight Problem? 4. Ban the Stop Watch! 5. Takt Time in Service Operations 41 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Takt Time Challenge: Example Assumptions: • • • • • Produce 1 Product Run 1 Shift Work 5 Days / Week Work 9 Hours / Day 75 min of Non-Productive Time 30 min Lunch 30 min Break 15 min Planned Down Time What’s The Takt Time? 42 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY The Formulas Exit Rate = Work-in-Process Process Lead Time Net Available Time Takt Time = Customer Demand Takt Rate = Customer Demand Net Available Time Labor = 43 = Little’s Law Takt Rate x Cycle Time © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY The Basics Process Takt Rate = 10 units/Hr Takt Rate = 0.167 units/min SOS A 4 min SOS B 5 min SOS C 3 min Labor = 8 Minutes units/min Takt Time = 6 min 6 5 3 Kaizen 5min 4min 3min 2 1 Labor (A) = Labor (B) = Labor (C) = Labor (D) = 0.167 0.167 0.167 0.167 min/cycle x x x x 4 5 3 8 Total Labor = A 44 Takt Rate x Cycle Time 8min 7 4 SOS D 8 min B C D © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. = = = = 0.667 0.833 0.500 1.333 3.3 Operators INTERNAL USE ONLY Takt Time vs. Cycle Time: Example (Resource Requirement) Customer Demand 40 8 160 20 45 Takt Times 0.2 hr 12 min 1 hr 60 min 0.05 hr 3 min 0.4 hr 24 min 8 hrs. Independent Processes Cycle Labor # Time A Available Working Time 480 min 30 min 2.5 Dependent Processes 30 min B 0.5 15 min C 5 0.04 hr 2.11 min E 2.5 min 228 1.2 90 min D 3.8 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. Theoretical Actual 12.94 14 INTERNAL USE ONLY 46 Standard Work & Takt: Case Study © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 47 Q&A © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY Reference Material 48 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. INTERNAL USE ONLY 8:30 8:45 9:00 9:15 9:30 9:45 10:00 10:15 10:30 10:45 11:00 11:15 11:30 11:45 12:00 12:15 12:30 12:45 13:00 13:15 13:30 13:45 14:00 14:15 14:30 14:45 15:00 15:15 15:30 15:45 16:00 16:15 16:30 49 H.E.L.P. Workshop Detailed Agenda H.E.L.P. Overview (Purpose & Objective) Roundtable Introductions. (What do you expect to gain from workshop?) 5S Module (with Letter's Group Exercise) BREAK Review 5S Audit & Tracking toolkit. (allow for discussion) View Boeing 5S video (25min) LUNCH Lean Standard Work Module (with Lean House Exercise) SOS, Time Observation Form, Audit Floor Tour (focus on 5S, Standard Work, Takt, Visual Mgmt at the Gemba) BREAK Batch vs One Piece Flow video Stop Watch use Cycle Time Exercise (with Stop Watch) Create Batch process SOS Review Day 2 objectives © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved. 8:30 8:45 9:00 9:15 9:30 9:45 10:00 10:15 10:30 10:45 11:00 11:15 11:30 11:45 12:00 12:15 12:30 12:45 13:00 13:15 13:30 13:45 14:00 14:15 14:30 14:45 15:00 15:15 15:30 15:45 16:00 16:15 16:30 Brain Teasers / The True Meaning of Kai Zen (video clip) Review any 5S or Standard Work Q&A SOS Exercise (Cycle Time at the Gemba, Time Observation Form) Create / Document the SOS BREAK Review SOS results Leader Standard Work Create personal LSW LUNCH Takt Module / "I Love Lucy" - Chocolate Factory (video clip) Takt Time Challenge Review individual results BREAK Takt Time Case Study Excercises H.E.L.P. Worshop Q&A (SharePoint site) Wrap-up INTERNAL USE ONLY TOPIC SUMMARY Topic: Hands-on Execution of Lean Principles (H.E.L.P.) Presenter: Luis Loya, Master Black Belt, Cardinal Health Level: Beginner Many corporate Lean Six Sigma training programs do an excellent job with teaching six sigma methodologies and tools but sometimes fall short of providing an in-depth fundamental understanding of practical lean concepts and principles. At Cardinal Health, a supplemental workshop style training has been developed for the purpose of closing this gap and to expand lean skills in 5S, Standard Work and Takt in a hands-on environment. This session will examine the strategy, content, tools and the exercises from this two day workshop style training. Attendees will also have an opportunity to participate and experience an abbreviated version of the interactive hands-on exercise for 5S. 50 © Copyright 2010, Cardinal Health, Inc. or one of its subsidiaries. All rights reserved.