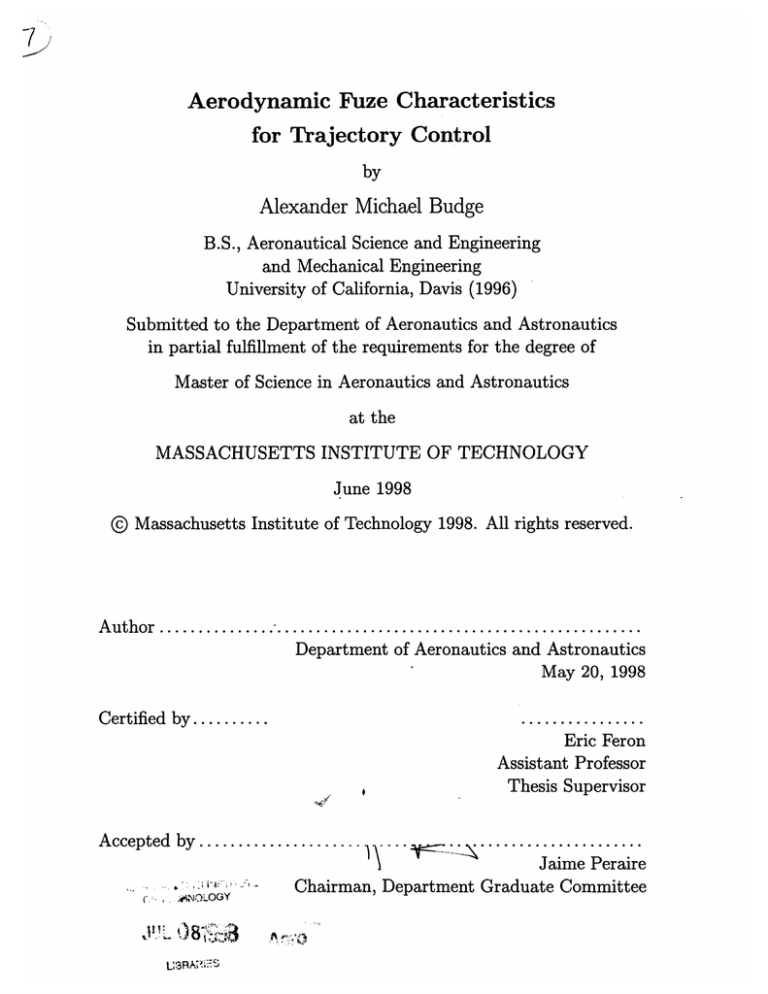

Aerodynamic Fuze Characteristics for Trajectory Control

advertisement