Hydro Solo-E Lenntech DATA BOOKLET Complete pressure boosting systems

advertisement

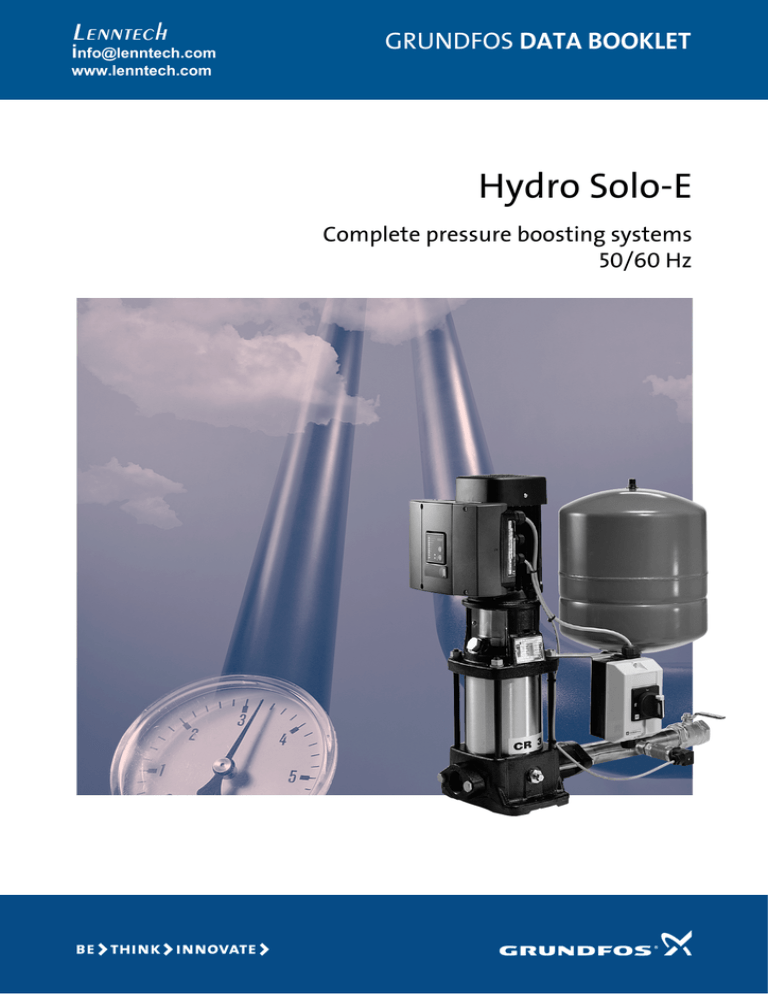

Lenntech info@lenntech.com GRUNDFOS DATA BOOKLET www.lenntech.com Hydro Solo-E Complete pressure boosting systems 50/60 Hz Contents Product data Performance range Hydro Solo-E Operating conditions Inlet pressure Type key Product range Construction Installation Mechanical installation Diaphragm tank Curve conditions Electrical connection 3 4 4 4 4 5 5 5 6 6 6 6 Control of CRE pumps Control options of CRE pumps Central management system Remote control Control panel Overview of functions 7 7 7 7 8 Electrical installation Additional protection Wiring diagram, single-phase Wiring diagram, three-phase 1.5 - 7.5 kW 9 9 9 Technical data Hydro Solo-E, CRE 1-xx Hydro Solo-E, CRE 3-xx Hydro Solo-E, CRE 5-xx Hydro solo-E, CRE 10-xx Hydro Solo-E, CRE 15-xx Hydro Solo-E, CRE 20-xx Hydro Solo-E, CRE 32-xx Hydro Solo-E, CRE 45-xx 10 11 12 13 14 15 16 17 Accessories R100 Dry-running protection 18 18 Further product documentation WinCAPS WebCAPS 2 19 20 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Product data Hydro Solo-E Performance range H [m] Hydro Solo-E 50 Hz 100 ISO 9906 Annex A 90 80 70 60 50 CRE 1 40 CRE 3 CRE 5 CRE 10 CRE 15 30 CRE 20 CRE 32 CRE 45 1 2 3 4 6 8 10 20 30 40 60 Q [m³/h] www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 TM02 7577 3803 20 3 Product data Hydro Solo-E Hydro Solo-E Maximum inlet pressure. Grundfos Hydro Solo-E booster set with one pump is a combined unit consisting of one E-pump (CRE) fitted with isolating valve, non-return valve, discharge pipe, pressure transmitter, pressure gauge and diaphragm tank. Upon delivery the booster set is ready for operation. CRE 1 1-7, 1-15, 1-19 10 [bar] CRE 3 3-7, 3-10 10 [bar] CRE 5 5-4, 5-8, 5-10, 5-16 10 [bar] CRE 10 10-3, 10-4, 10-6 10-9 8 [bar] 10 [bar] CRE 15 15-2, 15-3 15-5 8 [bar] 10 [bar] CRE 20 20-3 20-5 8 [bar] 10 [bar] CRE 32 32-3 4 [bar] CRE 45 45-2 4 [bar] Example of operating and inlet pressures PRESSURE PRESSURE TRANSMITTER TRANSMITTER Fig. 1 ISOLATING ISOLATING VALVE VALVE PRESSURE GAUGE PRESSURE GAUGE TM00 8427 2709 NON-RETURN NON-RETURN VALVE VALVE PUMP PUMP The values for operating and inlet pressures must not be considered individually but must always be compared, see the following example: Principal sketch of Hydro Solo-E Operating conditions Liquid temperature: 0°C to +70 °C Ambient temperature: 0 °C to +40 °C System pressure: The maximum system pressure is 10 bar. The total of inlet pressure and head must not exceed the maximum system pressure. Example: The following pump type has been selected: CRE 10-4 A-A-A Max. operating pressure: Max. inlet pressure: Desired pressure boosting: 10 bar 8 bar 2 bar This pump is allowed to start at an inlet pressure of 8 bar as the discharge pressure is only 2 bar which results in an operating pressure of 8.0 + 2 = 10 bar. Type key Single-phase: Example Hydro Solo-E CRE 5-8 1 x 200-240 V Type range Inlet pressure Subgroup Minimum inlet pressure: Pump type The minimum inlet pressure H in metres head required to avoid cavitation in the pump is calculated as follows: Supply voltage H= pb x 10.2 – NPSH – Hf – Hv – Hs Three-phase: pb = Barometric pressure in bar. Barometric pressure can be set to 1, if required. Example NPSH = Net Positive Suction Head in metres head. NPSH can be read from the NPSH curve at the maximum capacity at which the pump will run. 4 Hf = Friction loss in suction pipe in metres head. Hv = Vapour pressure in metres head. Hs = Safety margin of min. 0.5 metres head. Hydro Solo-E CRE 10-4 1 x 200-240 V Type range Subgroup Pump type Supply voltage www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Product data Hydro Solo-E Product range Pressure Motor transmitter [kW] [bar] Product numbers 1 x 220 - 240 V 3 x 380 - 480 V CRE 1-7 0.37 0-10 96467828 - CRE 1-15 0.75 0-10 96467860 - CRE 1-19 1.1 0-10 96467861 - CRE 3-7 0.55 0-10 96467864 - CRE 3-10 0.75 0-10 96457865 - CRE 3-10 1.1 0-10 - 96468197 CRE 5-4 0.55 0-10 96467867 - CRE 5-8 1.1 0-10 96467868 96479543 CRE 5-10 1.5 0-10 - 96467871 CRE 5-16 2.2 0-10 - 96467872 CRE 10-3 1.1 0-10 96513873 - CRE 10-4 1.5 0-10 - 96513874 CRE 10-6 2.2 0-10 - 96513875 CRE 10-9 3.0 0-10 - 96513876 CRE 15-2 2.2 0-10 - 96513877 CRE 15-3 3.0 0-10 - 96513878 CRE 15-5 4.0 0-10 - 96513879 CRE 20-3 4.0 0-10 - 96513880 CRE 20-5 5.5 0-10 - 96513881 CRE 32-3 5.5 0-10 - 96468199 CRE 45-2 5.5 0-10 - 96468210 Designation 2 10 9 3 4 5 8 Fig. 2 7 6 Construction of Hydro Solo-E Installation Construction Pos. 1 TM02 7562 3803 Pump type Qty. 1 CRE pump 1 2 Diaphragm tank 1 3 Pressure gauge 1 4 Isolating valve for diaphragm tank and pressure gauge 1 5 Isolating valve 1 6 Discharge pipe (stainless steel) 1 7 Pressure transmitter 1 8 Non-return valve 1 9 On/off-switch 1 10 Nameplate 1 A Hydro Solo-E booster set must be installed in a well ventilated room to ensure sufficient cooling for the pump. Hydro Solo-E is not suitable for outdoor installation. The booster set should be placed with sufficient clearance around it. Enclosure class: Insulation class: IP 55 F. On the discharge side of the pump are fitted a nonreturn valve, a stainless steel discharge pipe (EN/DIN 1.4401 or EN/DIN 1.4571) and an isolating valve. On the discharge pipe are fitted a pressure transmitter and an isolating valve for the pressure gauge and the diaphragm tank. The pump is fitted with an on/off-switch for the supply voltage. www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 5 Product data Hydro Solo-E Mechanical installation Curve conditions The pipes connected to the booster set must be of adequate size. To avoid resonance, expansion joints should be fitted both in the discharge and suction pipes. The following curves are subject to the following guidelines: The pipes are to be connected to the discharge pipe and the pump suction port. • Performance measurement is made at a water temperature of +20°C. • Test liquid: Pure water. The booster set should be tightened up prior to start-up. • The curves describe the pump mean values. It is always advisable to fit pipe hangers both on the suction and discharge side. • The curves should not be used as guarantee curves. The system should be positioned on an even and solid surface, e.g. a concrete floor or foundation. If the booster set is not fitted with vibration dampers, it must be bolted to the floor or foundation. • Curve tolerance: ISO 9906, Annex A. • The conversion between head H(m) and pressure p (kPa) has been made for water with a density of ρ = 1000 kg/m3. • The curves apply to a kinematic viscosity of 1 mm2/s (1 cSt). Electrical connection 2 Fig. 3 1 1 2 TM01 0227 0797 2 The electrical connection and protection should be carried out in accordance with local regulations. Mechanical installation 1. Expansion joints 2. Pipe hangers Expansion joints and pipe hangers shown are not included in a standard booster set. • The pump must be connected to an external mains switch. • The E-pump must always be correctly earthed. Note: The 4.0 - 7.5 kW motors must be connected to especially reliable/sturdy earth connections due to an earth leakage current above 3.5 mA. • The pump requires no external motor protection. The motor incorporates thermal protection against slow overloading and blocking (IEC 34-11: TP 211). • When the pump is switched on via the mains, the pump will start after approx. 5 secs. Diaphragm tank Note: The number of starts and stops via the mains voltage must not exceed 4 times per hour. The diaphragm tank is pre-charged to correct pressure. If the setpoint is altered, a new pre-charge pressure should be calculated to obtain optimal duty: The pump mains connection must be made as shown in the diagrams below. Calculation of pre-charge pressure: • Pre-charge pressure = 0.7 x setpoint The diaphragm tank’s pre-charge pressure must be measured in a pressureless system. It is recommended to refil the tank with nitrogen. 6 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Control of CRE pumps Hydro Solo-E Control options of CRE pumps Remote control Communication with CRE pumps is possible by means of The R100 remote control produced by Grundfos is available as an accessory. • a central management system, The operator communicates with the CRE pump by pointing the IR-signal transmitter at the control panel of the E-pump terminal box. • remote control (Grundfos R100) or • a control panel. TM00 4498 2802 The purpose of controlling an E-pump is to monitor and control the pressure, temperature, flow and liquid level of the system. Central management system Communication with the CRE pump is possible even though the operator is not present near the CRE pump. Communication is enabled by having connected the CRE pump to a central management system allowing the operator to monitor and change control modes and setpoint settings of the CRE pump. Fig. 5 R100 remote control On the R100 display it is possible to monitor and change control modes and settings of the CRE pump. Control panel The control panel of the CRE pump terminal box makes it possible to change the setpoint settings manually. Light fields LON-bus connection G10-LON Interface Indicator lights Fig. 6 TM00 7600 0404 Buttons Control panel on CRE pump CRE pump Fig. 4 TM06592 1103 GENIbus connection Structure of a central management system www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 7 Control of CRE pumps Hydro Solo-E Overview of functions E-pumps/functions Hydro Solo-E TM00 7600 0404 Setting via control panel: Setpoint z Start/stop z Max. curve z Min. curve z Reading via control panel: Setpoint z Operating indication z Fault indication z TM00 4498 2802 Setting via R100: 8 Setpoint z Start/stop z Max. curve z Min. curve z Controlled/uncontrolled z PI-controller z Signal relay z Operating range z Stop function z Reading via R100: Setpoint z Operating indication z Pump status z www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Electrical installation Hydro Solo-E Additional protection If the pump is connected to an electric installation where an earth leakage circuit breaker (ELCB) is used as an additional protection the earth leakage circuit breakers must be marked with the following symbols. • Single-phase: The earth leakage circuit breakers must trip out when earth fault currents with DC content (pulsating DC) occur. • Three-phase: The earth leakage circuit breakers must trip out when earth fault currents with DC content (pulsating DC) and smooth DC earth fault currents occur. Wiring diagram, single-phase 1 x 200-240 V, +/–10% External switch N N ELCB PE Max. 10 A L L TM02 0792 0101 PE Wiring diagram, three-phase 1.5 - 7.5 kW 3 x 380-480 V, +/–10% External switch Max. 10 A L1 ELCB L3 PE www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 L2 L3 TM00 9270 4696 L2 L1 9 Technical data p [kPa] H [m] 130 1200 120 Hydro Solo-E CRE 1 CRE 1-19 ISO 9906 Annex A 110 100 CRE 1-15 90 800 80 600 60 H 1000 Hydro Solo-E with CRE 1 50 200 40 4 30 3 20 2 10 0 600 420 1 NPSH 0 0 0.0 0.4 0.0 P2 [kW] 0.8 1.2 0.2 1.6 0.4 2.0 Q [m³/h] 0.6 Q [l/s] TM02 2317 3803Hydro Solo-E, CRE 1-xx 400 NPSH [m] CRE 1-7 TM01 0458 3903 70 1.0 -19 0.8 -15 0.6 0.4 -7 0.2 0.0 0.0 0.4 0.8 1.2 1.6 2.0 Q [m³/h] Electrical data, dimensions and weights Pump type 10 Motor [kW] Full load current 1/1 [A] Supply voltage 1 x 220-240 V, PE 3 x 380-480 V, PE Diaphragm tank [litres] Connection inlet outlet Weights [kg] H [mm] Net Gross Packing [m3] CRE 1-7 0.37 3.0-2.5 z - 8 Rp 1¼ Rp 1¼ 537 39.0 42.0 0.6 CRE 1-15 0.75 5.10-4.70 z - 8 Rp 1¼ Rp 1¼ 707 44.7 47.7 0.6 CRE 1-19 1.1 7.40-6.80 z - 8 Rp 1¼ Rp 1¼ 779 47.2 50.2 0.6 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Technical data p [kPa] H [m] 70 600 60 500 50 Hydro Solo-E CRE 3-10 65 Hydro Solo-E with CRE 3 CRE 3 ISO 9906 Annex A H 55 CRE 3-7 45 400 40 300 30 NPSH [m] 25 100 20 4 15 3 10 2 NPSH 5 0 420 1 0 0 0.0 0.8 0.0 P2 [kW] 1.6 2.4 0.4 3.2 0.8 4.0 Q [m³/h] 1.2 Q [l/s] TM02 2318 3803Hydro Solo-E, CRE 3-xx 200 600 TM01 0457 3903 35 0.8 -10 0.6 -7 0.4 0.2 0.0 0.0 0.8 1.6 2.4 3.2 4.0 Q [m³/h] Electrical data, dimensions and weights Pump type Motor [kW] Full load current 1/1 [A] Supply voltage 1 x 220-240 V, PE 3 x 380-480 V, PE Diaphragm tank [litres] Connection inlet outlet Weights [kg] H [mm] Net Gross Packing [m3] CRE 3-7 0.55 4.30 - 3.60 z - 8 Rp 1¼ Rp 1¼ 519 39.6 42.9 0.6 CRE 3-10 0.75 5.10-4.70 z - 8 Rp 1¼ Rp 1¼ 617 42.9 45.9 0.6 CRE 3-10 1.1 2.60-2.30 - z 8 Rp 1¼ Rp 1¼ 617 42.9 45.9 0.6 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 11 Technical data H [m] 120 Hydro Solo-E 1000 CRE 5 CRE 5-16 110 ISO 9906 Annex A 100 H 90 80 CRE 5-10 70 600 60 CRE 5-8 NPSH [m] 50 400 40 30 200 420 3 CRE 5-4 20 2 NPSH 10 0 600 4 1 0 0 0 1 0.0 P2 [kW] 2.5 2 3 0.5 4 1.0 5 6 7Q [m³/h] 1.5 2.0 Q [l/s] TM02 2319 3803Hydro Solo-E, CRE 5-xx 800 TM01 0457 3903 p [kPa] Hydro Solo-E with CRE 5 -16 2.0 1.5 -10 -8 1.0 -4 0.5 0.0 0 1 2 3 4 5 6 7Q [m³/h] Electrical data, dimensions and weights Pump type 12 Motor [kW] Full load current 1/1 [A] Supply voltage 1 x 220-240 V, PE 3 x 380-480 V, PE Diaphragm tank [litres] Connection inlet outlet Weights [kg] H [mm] Net Gross Packing [m3] CRE 5-4 0.55 4.3-3.6 z - 18 Rp 1¼ Rp 1¼ 501 40.8 43.8 0.6 CRE 5-8 1.1 7.40-6.80 z - 18 Rp 1¼ Rp 1¼ 653 47.0 50.0 0.6 CRE 5-8 1.1 2.60-2.30 - z 18 Rp 1¼ Rp 1¼ 653 47.0 50.0 0.6 CRE 5-10 1.5 3.30-2.70 - z 18 Rp 1¼ Rp 1¼ 773 56.6 59.6 0.6 CRE 5-16 2.2 4.60-3.80 - z 18 Rp 1¼ Rp 1¼ 773 61.8 64.8 0.6 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Technical data H [m] 120 Hydro Solo-E CRE 10 110 1000 ISO 9906 Annex A 100 CRE 10-9 80 70 600 CRE 10-6 60 NPSH [m] 50 400 CRE 10-4 40 CRE 10-3 30 200 425 3 20 2 NPSH 10 0 650 4 1 0 0 0 2 4 0.0 0.5 P2 [kW] 3.0 1.0 6 1.5 8 2.0 10 Q [m³/h] 2.5 3.0 Q [l/s] TM02 7534 3803Hydro solo-E, CRE 10-xx 800 H 90 TM02 7563 3803 p [kPa] Hydro Solo-E with CRE 10 -9 2.5 2.0 -6 1.5 -4 -3 1.0 0.5 0.0 0 2 4 6 8 10 Q [m³/h] Electrical data, dimensions and weights Motor [kW] Full load current 1/1 [A] CRE 10-3 1.1 7.40-6.80 z CRE 10-4 1.5 3.30-2.70 - CRE 10-6 2.2 4.60-3.80 - CRE 10-9 3.0 6.40-5.20 - Pump type Supply voltage Diaphragm tank [litres] inlet - 33 z 33 z z 1 x 220-240 V, PE 3 x 380-480 V, PE www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Connection Weights [kg] Packing [m3] outlet H [mm] Net Gross Rp 1½ Rp 1½ 608 62.0 65.0 0.6 Rp 1½ Rp 1½ 704 71.0 74.0 0.6 33 Rp 1½ Rp 1½ 804 80.0 83.0 0.6 33 Rp 1½ Rp 1½ 913 87.0 90.0 0.6 13 Technical data p [kPa] H [m] 800 80 Hydro Solo-E CRE 15 ISO 9906 Annex A CRE 15-5 H 70 600 Hydro Solo-E with CRE 15 60 50 CRE 15-3 40 CRE 15-2 30 200 20 425 4 10 0 700 6 TM02 7564 3803 NPSH [m] 2 NPSH 0 0 0 4 0 8 12 2 16 4 20 Q [m³/h] 6 Q [l/s] P2 [kW] 4 -5 3 -3 2 -2 1 0 0 4 8 12 16 20 Q [m³/h] TM02 7535 3803Hydro Solo-E, CRE 15-xx 400 Electrical data, dimensions and weights 14 Connection Weights [kg] Motor [kW] Full load current 1/1 [A] Supply voltage 3 x 380-480 V, PE Diaphragm tank [litres] CRE 15-2 2.2 4.60-3.80 z 33 DN 50 Rp 2 736 CRE 15-3 3.0 6.40-5.20 z 33 DN 50 Rp 2 800 CRE 15-5 4.0 8.10-6.60 z 33 DN 50 Rp 2 927 115.0 Pump type Suction side Discharge side H [mm] Gross Packing [m3] 91.0 94.0 0.6 96.0 99.0 0.6 188.0 0.6 Net www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Technical data p [kPa] H [m] Hydro Solo-E 90 800 Hydro Solo-E with CRE 20 CRE 20 ISO 9906 Annex A 80 CRE 20-5 60 50 200 CRE 20-3 NPSH [m] 40 30 6 20 4 10 0 700 TM02 7564 3803 400 425 2 NPSH 0 0 0 4 0 8 12 2 16 20 4 24 Q [m³/h] 6 Q [l/s] P2 [kW] 5 -5 4 -3 3 2 1 0 0 4 8 12 16 20 24 Q [m³/h] TM02 7536 3803Hydro Solo-E, CRE 20-xx 600 H 70 Electrical data, dimensions and weights Connection Weights [kg] Motor [kW] Full load current 1/1 [A] Supply voltage 3 x 380-480 V, PE Diaphragm tank [litres] CRE 20-3 4.0 8.10-6.60 z 33 DN 50 Rp 2 837 112.0 115.0 0.6 CRE 20-5 5.5 11.0-8.80 z 33 DN 50 Rp 2 978 136.0 133.0 0.6 Pump type www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Suction side Discharge side H [mm] Net Gross Packing [m3] 15 Technical data p [kPa] H [m] 70 Hydro Solo-E with CRE 32 Hydro Solo-E CRE 32 65 ISO 9906 Annex A 600 60 500 50 400 40 300 30 6 25 5 20 4 15 3 CRE 32-3 H 55 45 35 100 10 431 2 NPSH 5 0 669 1 0 0 0 5 0 10 2 15 20 25 30 4 6 8 Q [m³/h] 10 Q [l/s] P2 [kW] 6 -3 5 4 3 2 1 0 0 5 10 15 20 25 30 Q [m³/h] TM02 2320 3803Hydro Solo-E, CRE 32-xx 200 TM02 7565 3803 NPSH [m] 7 Electrical data, dimensions and weights Pump type CRE 32-3 16 Connection Motor [kW] Full load current 1/1 [A] Supply voltage 3 x 380-480 V, PE Diaphragm tank [litres] Suction side Discharge side 5.5 11.0-8.80 z 33 DN 65 DN 65 Weights [kg] H [mm] Net Gross Packing [m3] 1036 138.0 143.0 0.6 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Technical data p [kPa] H [m] 60 Hydro Solo-E CRE 45 55 500 Hydro Solo-E with CRE 45 ISO 9906 Annex A CRE 45-2 50 H 45 400 40 35 100 25 5 20 4 15 3 10 431 2 NPSH 5 0 714 TM02 7566 3803 200 NPSH [m] 30 1 0 0 0 10 0 20 30 5 40 10 50 Q [m³/h] 15 Q [l/s] P2 [kW] 8 -2 6 4 2 0 0 10 20 30 40 50 Q [m³/h] TM02 2321 3803Hydro Solo-E, CRE 45-xx 300 Electrical data, dimensions and weights Pump type CRE 45-2 Motor [kW] Max. I N [A] 5.5 11.0-8.80 Supply voltage Connection 3 x 380-480 V, PE Diaphragm tank [litres] Suction side Discharge side z 33 DN 80 DN 80 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Weights [kg] H [mm] Net Gross Packing [m3] 1029 146.0 149.0 0.6 17 Accessories Hydro Solo-E R100 R100 is used for wireless communication. The communication takes place by means of infrared light. Product Product number R100 625333 Dry-running protection Type Pressure [bar] 0.11 - 2 96421253 Hydro Solo-E 0.22 - 4 96421254 0.5 - 8 96421255 Product number To protect the booster set against dry running, dryrunning protection is obligatory. The dry-running protection unit is to be mounted on the site. Automatic reset after water shortage Pressure switch Level switch CRE pump CRE pump PS CRE pump CRE pump PS 2 Start/stop 2 Start/stop 3 GND (frame) TM02 2560 4003 1 Digital input 3 GND (frame) TM02 2589 4003 LS 1 Digital input Manual reset after water shortage Pressure switch Level switch CRE pump CRE pump PS CRE pump CRE pump PS LS 18 TM02 2561 4003 3 GND (frame) 3 GND (frame) TM02 2590 4003 1 Digital input 1 Digital input www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 Further product documentation In addition to the printed data booklet, Grundfos offers the following sources of product documentation. • WinCAPS • WebCAPS. WinCAPS WinCAPS is a Windows-based Computer-Aided Product Selection program containing information on more than 90,000 Grundfos products. cd-wincaps Available on CD-ROM in more than 15 languages, WinCAPS offers • detailed technical information • selection of the optimum pump solution Fig. 7 • dimensional drawings of each pump WinCAPS CD-ROM • detailed service documentation • installation and operating instructions • wiring diagrams of each pump. Click on Sizing and select the most suitable pump for your application. WinCAPS Click on Catalogue and select a product from the extensive product catalogue. Fig. 8 WinCAPS www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 19 Further product documentation WebCAPS WebCAPS is a Web-based Computer Aided-Product Selection program and a web-version of WinCAPS. Available on Grundfos’ homepage, www.grundfos.com, WebCAPS offers • detailed technical information • dimensional drawings of each pump • wiring diagrams of each pump. Click Replacement and select the right replacement pump based on the current installation. Click Catalogue and select a product from the extensive product catalogue. Click Literature to Click Product select and download search and select Grundfos documentation a product from the by browsing the product extensive product ranges or performing catalogue. a specific search. The Click CAD drawings literature includes: to select and download CAD darwings in: - Data booklets - .stp - Installation and operating instructions - .dxf - .dwg - Service instructions. Click Service to to find information on service kits and spare parts. If you are a registered user click Log in to: - save your settings - define and save your own units - save personalised information. Click Units and select your preferred units of measurement: - Default units - SI units - US units. Click Language and select your preferred language. WebCAPS Click the dropdown list to select the frequency Fig. 9 20 WebCAPS www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 21 22 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 www.lenntech.com - +31(0)152-610-900 info@lenntech.nl - +31(0)152-616-289 23 Being responsible is our foundation Thinking ahead makes it possible Innovation is the essence V7140010 0305 Repl. V7140010 0604 GB Subject to alterations. Lenntech info@lenntech.com www.lenntech.com