Wing Spars -Aer E 423 Final Project- By: Joe Rees

advertisement

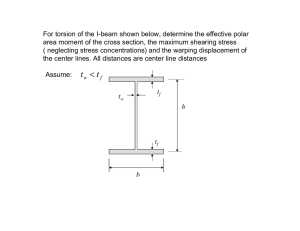

Wing Spars -Aer E 423 Final Project- By: Joe Rees Outline Background Theoretical Calculations Predictions Fabrication/Construction Testing Data Analysis Failure Modes Results/Conclusion Background Competing in the SAE-Advance Class R/C plane competition in the spring. Need to develop a strong, lightweight wing spar Background Actual R/C Plane: NACA 4414 airfoil Chord of 18 inches 12 foot span Max gross weight 55lbs Test Sections: 18 inch long beams 2.5 inches tall Beam Types Rectangular C-Channel I-Beam Sinusoidal Theoretical Data From E-Glass Carpet Plots: 12 plies: 0.005”/ply x 12 plies = 0.06” total thickness [03/903]s Volume Fraction: 0.5 matrix and 0.5 fibers Elastic Modulus (Ex) Poisson's Ratio (νxy) Shear Modulus (Gxy) 1st Ply Failure Tensile Strength Tensile Strength at Fiber Failure Compressive Strength at Fiber Failure 25 GPa 0.14 3.3 GPa 95 MPa 460 MPa 195 MPa Theoretical Data Moment of Inertia: bd h ( b t ) 3 I I beam I C C hannel I rectangle 3 12 bh 3 12 Maximum Displacement: 3 1 PL y 48 E I Beam I-beam C-Channel Rectangular Sinusoidal Moment of Inertia (in4) 0.157 0.157 0.0781 0.0781 Force (lbs) 100 100 100 100 Max Displacement (in) 0.0260 0.0260 0.0495 0.0495 Predictions I-Beam and C-Channel will deflect half as much as rectangular and sinusoidal beams No flanges = loss of strength Failure Modes: Rectangular – foam/composite interface C-Channel – crushing or foam/composite interface I-Beam – crushing Sinusoidal – foam/composite interface Fabrication/Construction Used hot wire to cut foam molds/cores Cut fiber glass composite strips Cured rectangular and sinusoidal beam under room conditions with weights Cured I-beam and C-channel with vacuum bag Foam Core Fibers Testing MTS Machine Point load beam bending Recorded displacement vs. load Data Analysis Graphed theoretical data for various loads, P vs. experimental data from MTS machine 3 1 PL y 48 E I P Best fit line to experimental data: Calculated and compared effective bending stiffness: L P E I eff 3 48 y slope y Data Analysis - Rectangular Beam Effective Bending Stiffness, (EI)eff : Theoretical: 2.81x105 lb·in2 Experimental: 3.31x105 lb·in2 Error: 18% Displacement (in) -0.25 -0.2 -0.15 -0.1 -0.05 0 0 -50 -100 Experimental Data -150 therotical -200 -250 -300 y = 2726.3x + 26.931 -350 -400 -450 -500 Data Analysis - C-Channel - Effective Bending Stiffness, (EI)eff : Theoretical: 5.64x105 lb·in2 Experimental: 1.66x105 lb·in2 Error: 71% Displacement (in) -0.2 -0.18 -0.16 -0.14 -0.12 -0.1 -0.08 -0.06 -0.04 -0.02 0 0 -50 y = 1364.3x - 0.8696 Experimental Data -100 Theoretical Data -150 -200 -250 Force (lbs) Data Analysis - I-beam - Effective Bending Stiffness, (EI)eff: Theoretical: 5.64x105 lb·in2 Experimental: 2.28x105 lb·in2 Error: 60% Displacement (in) -0.55 -0.45 -0.35 -0.25 -0.15 -0.05 0 -100 -200 Experimental Data Theoretical Data -300 -400 -500 y = 1879.8x + 93.431 -600 -700 -800 -900 Force (lbs) Data Analysis - Sinusoidal - Effective Bending Stiffness, (EI)eff: Theoretical: 2.81x105 lb·in2 Experimental: 1.13x105 lb·in2 Error: 60% Displacement (in) -0.25 -0.2 -0.15 -0.1 -0.05 0 -5 Experimental Data -15 Theoretical Data -25 y = 195.7x - 3.9594 -35 -45 -55 Force (lbs) Failure Modes Foam/composite interface sheared Sinusoidal Rectangular Failure Modes Matrix/fibers crushed I-Beam C-Channel Results/Conclusion I-beam Theoretical EI (lb·in2) 5.64x105 Experimental EI (lb·in2) 2.28x105 C-Channel 5.64x105 Rectangular Sinusoidal Beam Max Force (lb) Max Displacement (in) 890 0.54 1.66x105 250 0.19 2.81x105 3.31x105 465 0.2 2.81x105 1.13x105 50 0.25 Observations: I-Beam held most weight Max force held by sinusoidal was less then expected C-Channel twisted out of MTS More test samples needed More experience using MTS Questions? Special Thanks To: Dr. Dayal Chunbai Wang Peter Hodgell