Inexpensive, Energy-Efficient, Grid-Independent Storage and Cooling System for

ARCHIVES

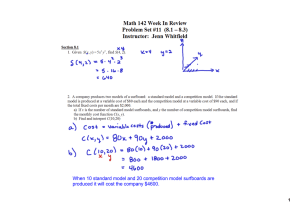

the Developing World

by

MASSACHUSETTS W7Tm TE

OF TECHNOLOLGY

Erik 0. Klatt

JUN 2 4 2015

LIBRARIES

Submitted to the

Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of

Bachelor of Science in Mechanical Engineering

at the

Massachusetts Institute of Technology

June 2015

C 2015 Massachusetts Institute of Technology. All rights reserved.

Signature of Author:

Signature redacted____

Department of Mechanical Engineering

May 18, 2014

Certified by:

Signature redacted

Leslie K. Norford

Professor of Building Technology, Department of Architecture

Thesis Supervisor

Accepted by:

Signature redacted

Anette Hosoi

Professor of Mechanical Engineering

Undergraduate Officer

Inexpensive, Energy-Efficient, Grid-Independent Storage and Cooling System for

the Developing World

by

Erik 0. Klatt

Submitted to the Department of Mechanical Engineering

on May 18, 2015 in Partial Fulfillment of the

Requirements for the Degree of

Bachelor of Science in Mechanical Engineering

ABSTRACT

Hunger and malnutrition can be significantly reduced in developing nations by improving the

farmer-to-consumer system. One important step in particular that can be improved is cold

storage at the local level. If small, rural farmers could have access to affordable and reliable

chilled storage, more produce would reach the consumer, and the farmer would see his income

increase.

A team of several people has been working to address this issue by developing a cold storage

system that is inexpensive, thermally efficient, and easy to assemble and maintain. Using

Polyurethane structure insulated panels, Cryogel ice balls, and a unique storage layout, the team

was able to design a prototype that met these criteria.

This thesis shows the author's research and design decisions, not the collective work of the entire

team.

Thesis Supervisor: Leslie K. Norford

Title: Professor of Building Technology, Department of Architecture

2

Table of Contents

Abstract

2

Table of Contents

3

List of Figures

4

List of Tables

6

1. Introduction

6

1.1. Food Grown in India

7

1.2. Electricity Grid Reliability

7

8

2. Research

2.1. Thermal Energy Storage

8

2.2. Insulation and Building Material

9

10

2.3. Existing Technology and Companies

11

3. Testing and Modelling

11

3.1. Door Test

12

4. Purchasing Decision

12

4.1. Criteria and Final Decision

5. Layout and Enhancements

14

5.1. Storage Bin Layout

14

5.2. Mylar Wrapping

16

6. Future Work

16

6.1. Assembly

16

6.2. Solar Power

16

17

7. Bibliography

3

List of Figures

Figure 1:

Cold storage capacity by state

6

Figure 2:

India's five power grid regions

8

Figure 3:

Door test

12

Figure 4:

Final, assembled product

14

Figure 5:

Insulated, locking panels

14

Figure 6:

Outside of cold room, inside storage bin set-up

15

Figure 7:

Solar radiation levels in India

16

4

List of Tables

TABLE 1:

Common fruits and vegetables, India's global rank and production size

7

TABLE 2:

India's projected power supply position

8

TABLE 3:

Thermal energy storage options

9

TABLE 4:

Various insulation material options

10

TABLE 5:

Potential companies

13

5

1

Introduction

About 805 million people, or 11.3 percent of the world's population, are undernourished [1].

This is not necessarily due to a lack of food, however. Oftentimes, good food spoils before

reaching the market, typically as a result of a lack in adequate cooled storage. In India

specifically, up to 18 percent of fruits and vegetables are wasted due to the absence of an

infrastructure that would otherwise support the farmer-consumer relationship [2]. Cold storage

is an important part of this infrastructure. See Figure 1 below for India's current cold storage

capacity. Note that this includes all cold storage, whether owned by retailers or individual

farmers.

NUMBERS ON THE MAP INDICATE

PRESENT CAPACITY (IN MILLION MT)

STATES

WITH ADEQUATE COLD

STORAGE FACILITIES

4

STATES THAT HAVE SOME BUT NEED

MORE COLD STORAGE FACILITIES

STATES NEEDING MORE COLD

STORAGE FACILITIES

Source

Dtrectorate

of Marketn

and Inspecton MiisrM

Figure 1: Cold storage capacity by state as of 2010, in millions of metric tons

6

If Aqpic lurt Gcivernmenl of

India

If local farmers in India had a means of effectively holding their crop, they would increase their

profits by selling more units.

1.1 Food Grown in India

India produces much of the world's food, and is the world's second largest producer of fruits and

vegetables [2]. See Table 1 for common fruits and vegetables and India's global ranking in

production [3].

Fruit/Vegetable

Bananas

Mangoes

Oranges

Potatoes

Tomatoes

Global Rank Production (metric tons)

27,575,000

1t

18,002,000

1st

4___

2n

6,426,200

45,343,600

18,227,000

2 nd

Table 1: Common fruits and vegetables, India's rank and production size for each

One small example of the economic benefit that would accompany increased cold storage is the

banana industry. While India produces roughly 28% of the world's bananas, these bananas make

up only 0.3% all internationally-traded bananas. If the cold chain infrastructure were sufficiently

upgraded, the number of containers of exported bananas could rise from 3,000 to 190,000,

providing an additional 95,000 jobs and benefiting about 35,000 smallholder farmers [4].

1.2 Electricity Grid Reliability

The power grid in India is insufficient for its needs. Only 52.5% of rural households have access

to electricity [5]. During blackouts, around 400 million Indians lose access to electricity [6].

This lack of power makes it difficult for small farms to make effective use of cold storage. They

need cold storage that can last through the not infrequent blackouts that plague India. See Figure

2 [7] for a breakup of India into its five power grid regions and Table 2 [5] for power

requirements versus power availability by region.

7

Peculiarities of Regional Grids in India

REGIONAL

cmc

GRI

1

&mbd-"'"4d -ft^w1***

S Rn

H'V"w''aern~Mnlnd

1 MV6M we"Ma MMO

F&

ftio Mu*

Snmd

fthhyftpsl 61

High

ruaiwm

APithwadbwseiod

planl

Monow

wsm

ydro

Figure 2: The five power grid regions in India, along with some facts

Region

Northern

Western

Southern

Eastern

North-Eastern

India Total

Requirement

(MU)

328,944

288,062

298,180

118,663

14,823

1,048,672

Energy [8]

Availability

(MU)

318,837

289,029

260,366

114,677

12,248

995,157

Surplus/

Deficit

-3.1%

+0.3%

-12.7%

-3.4%

-17.4%

-5.1%

Peak Power [8]

Demand

Supply

(MW)

(MW)

47,570

46,899

52,652

45,980

32,423

41,677

17,608

17,782

2,215

2,543

147,788

144,788

Surplus/

Deficit

-1.4%

+14.5%

-22.2%

+1.0%

-12.9%

-2.0%

Table 2: India's Projected Power Supply Position for FY2014-15

2

Research

2.1 Thermal Energy Storage

Because the electric grid in India is unreliable for 24 hours per day, there needs to be some way

to maintain cold temperatures independent of consistent power. In order to reduce the need to

draw from solar panels-or eliminate the need to use them whatsoever-the research team

working on this project decided to use thermal energy storage (TES). TES refers to energy

storage based on a temperature differential. Energy is transferred from an energy source to a

storage unit, where the energy can later be accessed. A hot water heater is a good example of

TES; energy from the power grid or another source is stored in the water until it is ready for use

[9].

8

We considered several options when looking for the appropriate medium in which to store our

thermal energy. Table 3 shows those options.

Medium

______

______

Initial Cost

Maintenance

(USD/ton)

__

_

_

Concrete

45 [10]

Low

Cryogel

Dirt

175 [12]

Essentially Free

Low

Low

Water

Essentially Free

Low

_

Energy Density

__

_

_

_

_

_

_

_

_

2122(J/kg*C) [11

3.35x106 (J/kg);

4190(J/kg*C) [11]

2100-2600 [11]

3.35x106 (J/kg);

4190(J/kg0 C) [11]

Table 3: Thermal energy storage options

The team decided to go with Cryogel ice balls. They are essentially four-inch diameter plastic

spheres filled with water which freezes and melts to store and release energy. Because of their

spherical shape, there is much more surface area exposed as compared to tubs of water, dirt, or

concrete, which drastically increases surface area. Compared to similar ice thermal storage

methods (e.g. tanks of ice, tubs of ice, etc.), Cryogel ice balls offer 1.5 to 3 times as much

surface area, resulting in over 24 ft2 of heat transfer surface area per ton-hour [13]. In

comparison, the surface area of ice-on-coil systems is only between 7.5 ft2 and 17 ft2 per tonhour [13]. This means that even though both water and Cryogel ice balls take advantage of their

phase change energy, the ice balls are more effective due to their greater surface area. Compared

to chilled-water systems (and by extension, chilled-dirt and chilled-concrete systems), use of

Cryogel ice balls can increase storage capacity by 4 to 5 times [12].

2.2 Insulation and Building Material

This system must be able to keep heat out so that it can preserve a stable, cool environment. It

must do so at a low cost and despite inconsistent power from local power grids. Along with

thermal storage, good insulation is key to maintaining appropriate temperatures. There were

many options to consider in selecting insulation. Cost, load-carrying capability, robustness,

portability, and ease of assembly were considered. Table 4 is a modified Pugh chart that the

team used to compare various insulation material options with respect to the aforementioned

aspects. Plywood was taken as the baseline because it was in the middle of many categories, it's

a simple material, and it's very common, therefore easy to visualize in comparison.

9

Material

Load

Robust

Portable

Ease

Plus Means

Handles

Larger

Load

More

Robust

More

Portable

Easier to

Assemble

Aluminum

[14]

Brick [14]

Concrete

[15]

S

Cost

$$

R-Value

(ft2-F-hr/Btu-in)

0.6

0.2

$$

0.08

$$0.9

Drywal

Plywood

[14]

Polyurethane

S

S

S

S

Rigid Panels

S

S

S

S

[14]

Steel [14]

Stone [16]

VacuumInsulated

Panels [171

$

1.25

6.25

$$$

0.6

$$

2.5-3.7

$$$$

30-50

Table 4: Various insulation material options

A lot of aluminum would have to be used to make the box strong enough, which would drive up

the price as well as decrease its portability and ease of assembly. While brick and concrete are

sturdy, moderately-priced materials, it would take considerable time to build the box, after which

it would be very difficult to transport. The R-values are not very high either. Drywall doesn't

have much going for it other than a moderate R-value. Plywood and polyurethane rigid panels

are similar except for the higher R-value of the latter, albeit at a higher cost. Steel is strong, but

too expensive, especially given the fact that insulation would need to be added. Stone has a

moderate R-value, but it may be the least portable option, as well as the most difficult to

assemble. While vacuum-insulated panels have the highest R-values by far, they are too

expensive for rural farmers.

While aluminum, plywood, or steel could have been used along with some sort of foam or

batting insulation, the team felt that using polyurethane rigid panels, combining insulation with

structural support, would increase ease of assembly and decrease short- and long-term

maintenance costs. Another benefit of using polyurethane rigid panels is that they can be

ordered for particularly-dimensioned rooms. They would come ready-to-assemble, and the

panels would interlock with each other. This is shown in more detail in section 4.1.

10

2.3 Existing Technology and Companies

There are similar products/companies in the market already. One such company, Natural

Vegetables & Fruits Storage Pvt. Ltd., offers food storage in large, warehouse-like facilities.

They mainly deal in long-term storage up to two years. They offer temperature and humidity

control as well as the ability to manage the concentration of gases. Their unique method of

blending gases enables them to control the ripening cycle of stored products. They offer to build

these large facilities for its clients, who are likely retailers or very wealthy farmers [18].

Another similar company is International Coil Ltd. They feature warehouses with separate

rooms for various foods that require different temperatures and humidities. Their typical

installation is 4,000 metric tons, although they offer as small as 500 metric tons and as large as

40,000 metric tons [19].

These are just two of many companies that deal in large, cold storage technology; however, they

do not target the consumer group made up of poor, small farmers. The team hopes to help fill

this gap in the industry.

3

Testing and Modelling

3.1 Door Test

A very rough door test was conducted during a senior mechanical engineering class at MIT,

2.009: Product Engineering Processes. While the test was very simple and limited, it did point

the team in the right direction for door selection. The general idea was rudimentary but

effective: set cups of ice inside different boxes, and after a period of time take out the cups and

compare the amounts of water that melted. The set-up was simple: five 36"x36"x36" cardboard

boxes, sealed with tape, with different-styled doors cut into one side. One box was the control,

with no door. One box's door opened from the top. Another box had a sideways-swinging door

on the side. Another had an upwards-swinging door on the side. A fourth had a sliding side

door. The final and most complicated box had a swinging door with plastic strips on the inside

so that when the door was opened, there was still a layer of plastic. Figure 3 shows the box setup.

A team of four people opened and closed the four doors simultaneously, once every minute for

30 minutes. At the end of the half hour, the cups were taken out of the boxes and the water was

measured visually. The control box hardly had any water at all, meaning that almost no ice had

melted. The plastic-strip box had the second lowest amount of water. The other three boxes had

almost half of the ice melt during the test.

While this test may be very simple, we were able to conclude that for a prototype, it would make

sense to have plastic strips hanging on the inside of the door.

11

Figure 3: Five boxes set up for testing

4

Purchasing Decision

4.1 Criteria and Final Decision

As this product intends to work on a smaller scale than a warehouse, smaller options were

preferred. After extensive research into companies that sold either already-assembled storage

systems or insulation panels that could easily be assembled into a storage system, the field was

narrowed down to several companies based on the following criteria: first, established shipping

lanes with India; second, low minimum order requirements; and third, price. See Table 5 for

details.

12

Company

China Construction Ltd.

Lareitin

T Minimnnm Order of Panels

I

Cost (USD/m2)

Dinghao

Shanghai Soovee

Trading Co., Ltd.

Shanghai Xinlong

Fireproofing Materials

Co., Ltd.

Hebei Guanhong

Trading Co., Ltd.

Zhejiang Terasum Air

Duct Co., Ltd.

Guangzhou Koller

Refrigeration

Equipment Co., Ltd.

Table 5: Potential companies from which to buy polyurethane structural insulated panels

The final set of companies happened to all be from China, which worked well because China and

India have good shipping lanes connecting them. Based on the minimum order, only two

companies offered a lucrative deal: China Construction Ltd. and Guangzhou Koller Refrigeration

Equipment Co., Ltd. Note that one piece is larger than one square meter. One set is defined as

the number of panels needed to build one storage room, which is exactly what was needed. It

was then decided to go with Koller, as they offered a lower price. The reason some prices are so

low per square meter is that the minimum order is very high. The prototype being built is

estimated to have a surface area of less than 60 square meters, so buying a bulk order would not

be cost-effective.

The set bought from Koller consists of 59m 2 of 0.110 m-thick polyurethane structural insulated

panels. It comes with a hinged door, 1.800 m tall, 0.800 m wide, and 0.110 m thick. The

dimensions of the room are 4 m long, 3 m wide, and 2.5 m high. This gives an internal storage

capacity of 30m2 . See Figures 4 and 5.

13

Figure 4: The final, assembled product

Figure 5: On the left are the structure insulated panels. On the right is an example of the locking mechanism that

securely connects the panels.

5

Layout and Enhancements

5.1 Storage Bin Layout

It is important to have an estimate of the volume available for food storage. To do so first

requires a blueprint for food storage bins. See Figure 6 for a visualization of this setup.

14

0

Figure 6: On the left is an artist's rendition of the outside of the cooled storage room. On the right is an artist's rendition

of the interior storage bin set-up. This layout makes efficient use of the room, maximizing storage space and minimizing

empty space, %hile still allowing full access to each storage bin. The gray panels are interior insulation panels, and the

yellow panels are hanging plastic strips.

This layout of storage bins is an optimization of maximum storage volume, reduced air

circulation, and ease of human movement. By splitting the room into two sections with insulated

panels, air leakage through the open door is reduced. One side can be accessed, while the other

side is left relatively untouched. Plastic strips hanging at the entrances of these two sections

further limit air flow. Lining the outer walls and inner panels with bins maximizes storage

volume, while providing the user with two walkways with access to all of the bins.

Using five (only three are shown in the illustration for good visualization) layers of small storage

bins has several purposes. It is economical, because when fruits and vegetables are stored in

very large (in excess of one cubic meter) bins, the produce on the bottom gets crushed by the

weight of the produce on top, leading to bruising and rotting, unsellable crops, and lower profits

for the farmer. It is ergonomical, as workers are dealing with relatively light loads to carry. It is

space-effective, for if larger bins were used, farmers would not be able to lift them up to a high

shelf, and the top third (approximately) of the room would be wasted space that would still need

to be cooled. Finally, it accommodates the bin size that is already in common use on rural farms

in India. In case of a shortage of bins, milk crates or other reusable containers will suffice.

After establishing the storage bin blueprint, the total storage volume can be estimated. 100

storage bins with dimensions of 0.5 m long, 0.4 m wide, and 0.3 m tall gives a total bin storage

area of 4.3 m3 . The produce geometry is estimated as spherical. The volume of randomlypacked spheres has a density limit of 63.4%, which gives a total volume of 2.73 m 3 taken up by

produce [20]. This equates to 9.1% of the total volume of the room. Given that the volume that

would be taken up if the entire room were randomly packed with spherical produce has an upper

bound of 63.4% of the total volume, or 19.02 m3 , this storage bin layout occupies 14.4% of the

usable space.

15

5.2 Mylar Wrapping

One way to increase the thermal insulation of the storage container is to wrap the outside in

aluminized Mylar. Mylar is extremely reflective, with an emissivity of 0.03. Mylar is also

relatively cheap-around $90.00 to wrap the container in 2 mm-thick sheets. Reflecting the rays

of the hot Indian sun will improve the efficiency of the system by approximately 50% based on

very rough calculations. Since it is so cheap, the team plans on buying the Mylar to test its effect

on the efficiency of our cooling system. Even if it turns out to be far less than an improvement

of 50%, an improvement will make a positive difference.

6

Future Work

6.1 Assembly

The next step in this project is to assemble the prototype. A working space has been rented; it is

large enough to comfortably assemble the cold-storage system, and it has adequate power for any

tests that need to be run.

6.2 Solar Power

Although it is currently beyond the scope of this project, the possibility of using solar panels to

provide additional power was discussed at length. This is something that will be looked into in

greater detail and in the near future as the prototype is tested. India receives a lot of sunlight, so

solar panels would be effective if it is decided that they are necessary. See Figure 7 for a map of

India and its solar resources [21]. The system would need about 6 m 2 of solar panels, based on

rough calculations [22]. Placed on the roof, these panels would provide power to the cooling

system. Battery storage has not yet been thoroughly researched, as the team wants to rely on the

Cryogel ice balls as much as possible. Batteries would be a last resort, and the team will make a

final decision on them after testing the prototype.

16

India

kwh I sq.m

4.4 - 5

5.2 - 6

6.2 - 6.6

TmINK-6OAX-OWER C OM

2

Figure 7: Levels of solar radiation across India, with purple being the highest and approaching 7 kWh/m and blue being the

2

lowest and approaching 4 kWh/m

17

7

Bibliography

[1]

"2015 World Hunger and Poverty Facts and Statistics," 2015. [Online]. [Accessed 04 05 2015].

[2] S. Narayanswami, "The Food Wastage & Cold Storage Infrastructure Relationship in India," Emerson

Climate Technologies.

[3]

FAO, "faostat3.fao.org," 2013. [Online]. [Accessed 05 2013].

[4] T. U. o. Nottingham, "Cold Chain Opportunity Assessments," United Technologies, [Online].

Available: http://naturalleader.com/programs/future-of-food/.

[5] "The Electricity Access Database," [Online]. Available: iea.org.

[6] A. C. Revkin, "Money for India's 'Ultra Mega' Coal Plants Approved," The New York Times, 2008.

[7] "Plug In India: Off-grid Solar Market in India Set to Take Off," 2014. [Online]. Available:

http://www.pluginindia.com/off-grid-solar-set-to-take-off.html.

[8] C. E. Authority, "Load Generation Balance Report 2014-15," 2014. [Online]. Available:

http://www.cea.nic.in/reports/yearly/lgbr-report.pdf.

[9] W. G. Bartley, "Thermal Ice Storage: Application & Design Guide," EVAPCO, INC., Taneytown,

Maryland, 2007.

[10] "Concrete Price Considerations- Cost of Concrete," [Online]. Available:

http://www.concretenetwork.com/concrete-prices.html.

[11] "Heat Storage in Materials," [Online]. Available: http://www.engineeringtoolbox.com/sensibleheat-storage-d_1217.html.

[12] "Cryogel Ice Ball - Thermal Energy Storage (TES)," Cryogel, 2011. [Online]. Available:

www.cryogel.com.

[13] "Cryogel: Ice Ball Thermal Storage," [Online]. Available: www.cryogel.com.

[14] "R-Value Table," Residential Shipping Container Primer, [Online]. Available:

http://www.residentialshippingcontainerprimer.com/R%20Value%2OTable. [Accessed 09 May

2015].

[15] R. A. Ristinen and J. J. Kraushaar, Energy and the Environment 2nd Edition, Hoboken, NJ: John Wiley

& Sons, Inc., 2006.

18

[16] "Buildings Energy Data Book," [Online]. Available: buildingsdatabook.eren.gov. [Accessed 09 May

2015].

[17] A. Binz and A. Moosmann, "Vacuum Insulation in the Building Sector: Systems and Applications,"

The IEA Energy in Buildings and Communities (EBC) Programme, 2005.

[18] Y. Dahiya, "Welcome to Natural Vegetables & Fruits Storage Pvt. Ltd.," Natural Vegetables & Fruits

Storage Pvt. Ltd., [Online]. Available: http://nvfl.in/.

[19] "Cold Storage, Freezer - Ice Plants," International Coil Ltd., 2013-2014. [Online]. Available: http://icltech.com/index.php?option=comcontent&view=article&id=7&ltemid=138.

[20] C. Song, P. Wang and H. A. Makse, "A Phase Diagram for Jammed Matter," Nature, Volume 453,

Issue 7195, pp 629-632, 2008.

[21] "Solar Power in India," [Online]. Available: http://www.think-solar-power.com/Solar-Power-nIndia.html.

[22] D. McKenzie, "Lights on Solar," 16 November 2013. [Online]. Available:

http://www.lightsonsolar.com/solar-basics-kw-and-kwh/.

[23] J. Milnes, "Ice Balls Save Data Centre Energy Costs," Regrigeration and Air Conditioning Magazine,

27 October 2010. [Online]. Available: http://www.racplus.com/news/-ice-balls-save-data-centreenergy-costs/8607432.article. [Accessed 10 May 2015].

19