Des Moines Register 08-04-06 Elbert: Ex-ISU profs market their search engine

advertisement

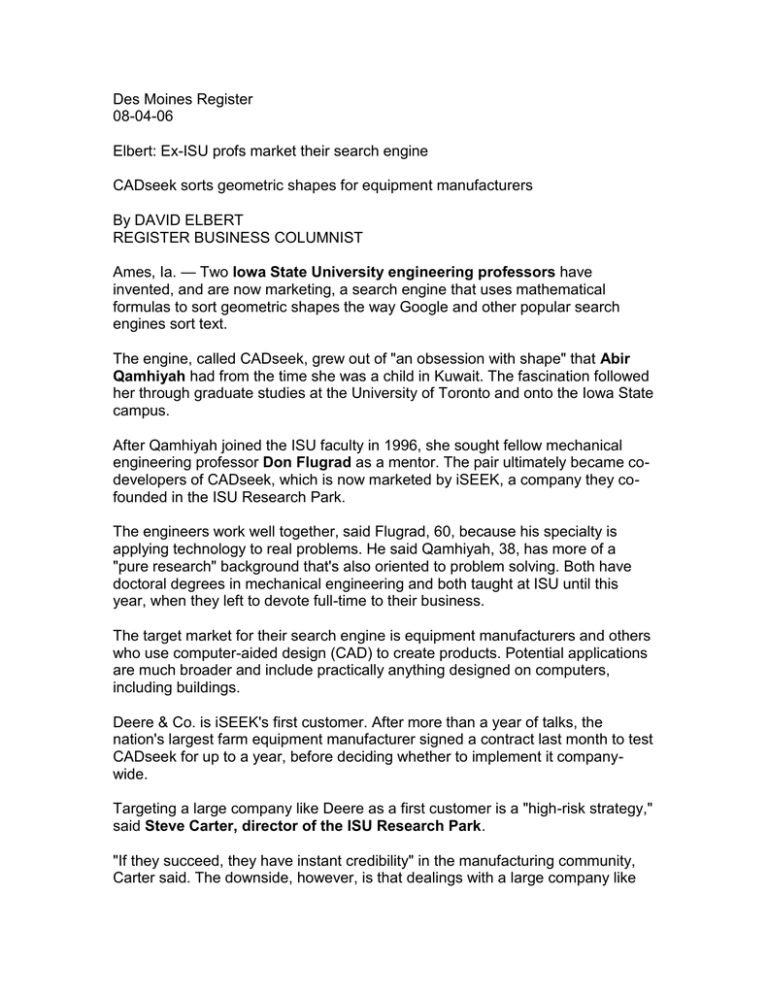

Des Moines Register 08-04-06 Elbert: Ex-ISU profs market their search engine CADseek sorts geometric shapes for equipment manufacturers By DAVID ELBERT REGISTER BUSINESS COLUMNIST Ames, Ia. — Two Iowa State University engineering professors have invented, and are now marketing, a search engine that uses mathematical formulas to sort geometric shapes the way Google and other popular search engines sort text. The engine, called CADseek, grew out of "an obsession with shape" that Abir Qamhiyah had from the time she was a child in Kuwait. The fascination followed her through graduate studies at the University of Toronto and onto the Iowa State campus. After Qamhiyah joined the ISU faculty in 1996, she sought fellow mechanical engineering professor Don Flugrad as a mentor. The pair ultimately became codevelopers of CADseek, which is now marketed by iSEEK, a company they cofounded in the ISU Research Park. The engineers work well together, said Flugrad, 60, because his specialty is applying technology to real problems. He said Qamhiyah, 38, has more of a "pure research" background that's also oriented to problem solving. Both have doctoral degrees in mechanical engineering and both taught at ISU until this year, when they left to devote full-time to their business. The target market for their search engine is equipment manufacturers and others who use computer-aided design (CAD) to create products. Potential applications are much broader and include practically anything designed on computers, including buildings. Deere & Co. is iSEEK's first customer. After more than a year of talks, the nation's largest farm equipment manufacturer signed a contract last month to test CADseek for up to a year, before deciding whether to implement it companywide. Targeting a large company like Deere as a first customer is a "high-risk strategy," said Steve Carter, director of the ISU Research Park. "If they succeed, they have instant credibility" in the manufacturing community, Carter said. The downside, however, is that dealings with a large company like Deere are fraught with delays. That's because there are so many bureaucratic steps to process at an international company that has annual sales of nearly $22 billion. In the meantime, there is no sales revenue to pay bills. Right now, Carter said, the lack of income doesn't appear to be a problem, because iSEEK has been able to raise start-up capital from a number of local venture capital groups. The selection of Deere as a target client makes sense, Carter added. The manufacturer understands the value of being able to do shape-based searches. In fact, Deere tried years ago to create its own searchable database for the hundreds of thousands of parts that go into products made by its four manufacturing divisions. Deere gave up on the effort because it took too long to write the computer code needed to identify each individual part. With CADseek, that process is automated and it takes an average of less than two seconds to create a unique code that gives a three-dimensional identification for each part. The unique code allows CADseek to identify similarly shaped parts, grouping washers, nozzles, gears and other parts into families based on shape and size. The new search engine creates a virtual parts library that designers can easily search when they begin inventing products. The library provides instant access to the universe of parts that already exist, so engineers will not duplicate those parts. That happens frequently with large manufacturers like Deere. The savings in time and elimination of redundancy should be considerable for Deere engineers, Qamhiyah said. CADseek will also help engineers identify and retain the best designs, plus standardize superior parts, resulting in more savings for large manufacturers, she said. Deere officials said the company has been actively looking for a search engine like CADseek for more than two years. The manufacturer looked at five companies before settling on Ames-based iSEEK. The search engine invented by the ISU professors was more advanced than anything the Deere engineers tested, a spokesman said. None had 3-D recognition like CADseek, which allows designers to rotate parts 360 degrees using a computer mouse. Without 3-D recognition, any search of a parts' universe, or other geometric shapes, is incomplete, Qamhiyah said. Her own preoccupation with shapes is lifelong. "I've always liked looking at things from different angles, trying to extract the three-dimensional shape," said Qamhiyah, whose father was also a mechanical engineer. Her love of shapes drew her to painting when she was a child, a hobby she continues today. The artist in her is apparent in the way CADseek organizes databases. Similarly shaped parts are clustered into families, which appear as bubbles on a computer screen. The bigger the bubble, the more parts there are in the family. The bubbles are color-coded by manufacturing division, and rolling a cursor across a bubble pulls up images of the parts. The result is a bubble landscape with spheres of varying sizes and colors. "Combining mechanical engineering, art and coding of shapes became a mission for me," Qamhiyah said. iSEEK Corp. BUSINESS: Design and market CADseek, a search engine for geometric shapes, such as manufactured parts. FOUNDERS: Former Iowa State University professors of mechanical engineering Abir Qamhiyah and Don Flugrad. OFFICERS: Qamhiyah is president and chief executive; Flugrad is senior vice president and chief operating officer. PATENTS: Iowa State Research Foundation holds two patents based on research of Qamhiyah and Flugrad; iSEEK has an exclusive license to use the technology, with a portion of all sales going to the foundation. EMPLOYEES: Seven LOCATION: Iowa State Research Park: 2501 North Loop Drive, Suite 1850, Ames; (515) 296-7043 The Bubbles CADseek, the search engine for shapes, uses bubbles to create an index of machine parts for Deere & Co. Similarly shaped parts are clustered in families; the larger the family the larger the bubble. Color coding is also used to distinguish different manufacturing units. Abir Qamhiyah BORN: Kuwait, where her father, like herself, was a mechanical engineer. Her father helped develop a desalination system for removing salt from sea water, a critical need for the small oil-rich, desert nation at the northern end of the Persian Gulf. Qamhiyah recalled in a biography on an Iowa State University Web site how proud she was of the acclaim her father got for the desalination effort. At age 13, she set a goal to pursue similar contributions . “She had nearly completed her master’s degree in fluid mechanics and thermal systems when Iraq invaded Kuwait, causing her family to flee,” the ISU biography states. They resettled in Jordan. “We started from nothing,” she said. In 1996, Qamhiyah was hired by the mechanical engineering department at Iowa State.