Document 10703374

advertisement

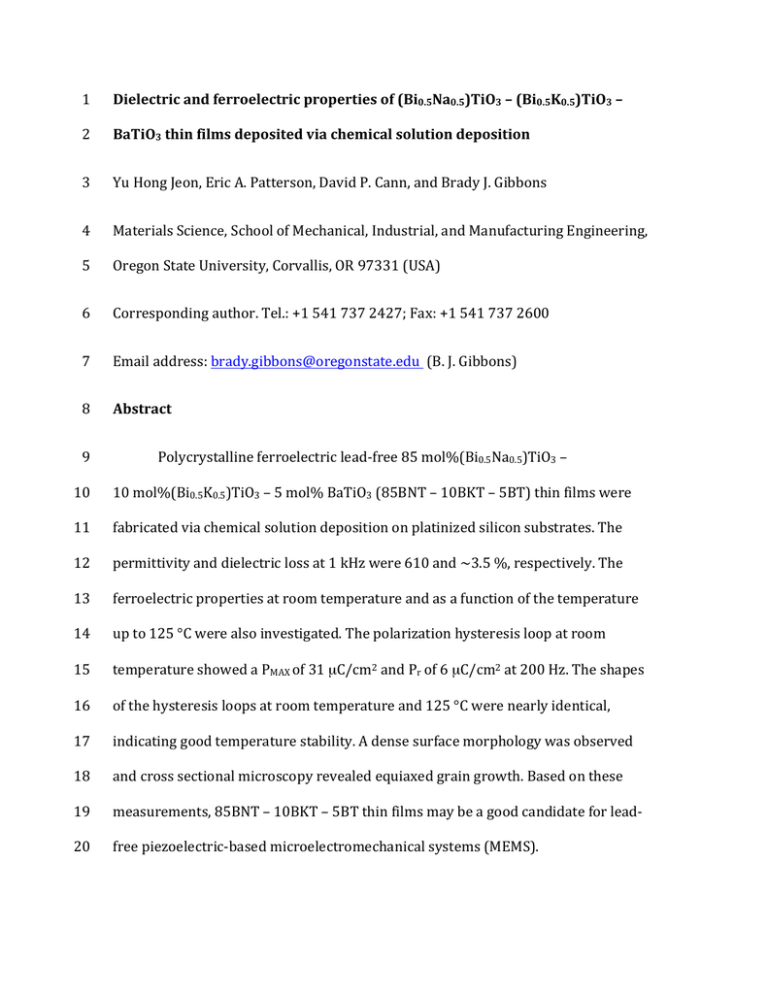

1 Dielectric and ferroelectric properties of (Bi0.5Na0.5)TiO3 – (Bi0.5K0.5)TiO3 – 2 BaTiO3 thin films deposited via chemical solution deposition 3 Yu Hong Jeon, Eric A. Patterson, David P. Cann, and Brady J. Gibbons 4 Materials Science, School of Mechanical, Industrial, and Manufacturing Engineering, 5 Oregon State University, Corvallis, OR 97331 (USA) 6 Corresponding author. Tel.: +1 541 737 2427; Fax: +1 541 737 2600 7 Email address: brady.gibbons@oregonstate.edu (B. J. Gibbons) 8 Abstract 9 Polycrystalline ferroelectric lead-­‐free 85 mol%(Bi0.5Na0.5)TiO3 – 10 10 mol%(Bi0.5K0.5)TiO3 – 5 mol% BaTiO3 (85BNT – 10BKT – 5BT) thin films were 11 fabricated via chemical solution deposition on platinized silicon substrates. The 12 permittivity and dielectric loss at 1 kHz were 610 and ~3.5 %, respectively. The 13 ferroelectric properties at room temperature and as a function of the temperature 14 up to 125 °C were also investigated. The polarization hysteresis loop at room 15 temperature showed a PMAX of 31 µC/cm2 and Pr of 6 µC/cm2 at 200 Hz. The shapes 16 of the hysteresis loops at room temperature and 125 °C were nearly identical, 17 indicating good temperature stability. A dense surface morphology was observed 18 and cross sectional microscopy revealed equiaxed grain growth. Based on these 19 measurements, 85BNT – 10BKT – 5BT thin films may be a good candidate for lead-­‐ 20 free piezoelectric-­‐based microelectromechanical systems (MEMS). 1 1. Introduction 2 3 Pb(Zr,Ti)O3 (PZT) and PZT-­‐based solid solutions have been widely used in many 4 electronic devices because they show the highest performing piezoelectric 5 properties.[1-­‐3] However, recent environmental legislation in the European Union, 6 such as Waste from Electrical and Electronic Equipment (WEEE), Restriction of 7 Hazardous Substances (RoHS), and End-­‐of Life Vehicles (ELV), have sought to limit 8 the usage of toxic elements.[4] The toxicity of lead oxide in PZT[5] and its high vapor 9 pressure during processing have led researchers to develop new, environmentally 10 benign piezoelectric materials as potential replacements for PZT-­‐based materials. 11 Bismuth sodium titanate, (Bi0.5Na0.5)TiO3 (BNT) was one of the earliest lead-­‐ In the past few decades lead-­‐based piezoelectric materials, represented by 12 free piezoelectric material candidates. In bulk form it exhibits good ferroelectric 13 properties, with Pr = 38 µC/cm2 and was long thought to have rhombohedral 14 symmetry.[6, 7] Recent reports have shown that the structure of BNT is more 15 complex; with Cc monoclinic symmetry and other structural features on different 16 length scales.[8] However, BNT ceramics do not readily exhibit very strong 17 piezoelectric properties because of the difficulty to pole the material due to the large 18 coercive field, Ec (=73 kV/cm).[9] To improve the piezoelectric properties, BNT-­‐ 19 based solid solutions formed with many other perovskite materials such as BaTiO3 20 (BT), (Bi0.5K0.5)TiO3 (BKT), NaNbO3 (NN), Bi(Zn0.5Ti0.5)O3 (BZT), and Bi(Mg0.5Ti0.5)O3 21 (BMT) have been developed.[9-­‐13] In particular, many researchers have 22 investigated a ternary solution based on BNT – BKT – BT in the vicinity of a 1 morphotropic phase boundary (MPB). This system revealed good piezoelectric 2 performance with a high d33 of 181 pC/N and kp of 0.56.[9, 14-­‐16] Achieving this 3 behavior in bulk materials is promising, however many of the ultimate applications 4 of these systems will be in thin film form (i.e., MEMS devices). Thus, it is important 5 to verify that this performance can also be achieved in thin film embodiments. 6 Due to the anisometric nature of thin films, and the difficulty in controlling 7 the stoichiometry because of the inherently volatile A-­‐site elements (Bi, Na, and K), 8 an increased electrical conductivity is often observed in these materials. As a result, 9 obtaining a large and reliable piezoelectric response is often challenging in thin 10 films.[17, 18] In previous work on BNT –BKT-­‐based thin films[19, 20], high quality 11 films on Pt/TiOx/SiO2/Si were fabricated by chemical solution deposition using an 12 appropriate amount of excess cations (overdoping). These films showed good 13 maximum polarization (PMAX) and remanent polarization (Pr) values at low 14 frequencies (200 Hz) with PMAX = 45 µC/cm2 and Pr = 16 µC/cm2 for BNT – BKT 15 films and PMAX = 52 µC/cm2 and Pr = 12 µC/cm2 for BNT – BKT – BMgT films, 16 respectively. For the closely related BNT-­‐BKT-­‐BT ternary system, Abazari et al. 17 reported on 88BNT – 8BKT – 4BT epitaxial thin films synthesized by pulsed laser 18 deposition on SrRuO3 coated SrTiO3 substrates. [21] These showed a saturated 19 polarization hysteresis loop with a large Pr = 30 µC/cm2. Polycrystalline thin films of 20 BNT – BKT – BT, however, have not yet been investigated. In this study, 85BNT – 21 10BKT – 5BT (near MPB composition) thin films were synthesized on 22 Pt/TiOx/SiO2/Si substrates via chemical solution deposition and their structural and 23 electrical properties were investigated. 1 2. Experimental Procedure 2 3 potassium acetate K(OOC2H3), barium acetate Ba(OOC2H3)2, and titanium 4 isopropoxide Ti[OCH(CH3)2]4 were used as precursors. Acetic acid and propionic 5 acid were chosen as solvents. First, titanium isopropoxide was chelated with 6 acetylacetone in a molar ratio of 1:2 in a dry atmosphere to prevent hydrolysis, as 7 shown in previous studies.[22, 23] Next, potassium acetate, sodium acetate 8 trihydrate, and barium acetate were dissolved in acetic acid at 70 °C. Bismuth 9 acetate was dissolved separately in propionic acid at room temperature. As Bismuth acetate Bi(OOC2H3)3, sodium acetate trihydrate Na(OOC2H3)•3H2O, 10 previously reported [20], to compensate for the volatility of the A-­‐site cations, 11 20 mol% excess potassium and sodium and 10 mol% excess bismuth were added to 12 their corresponding solutions. The final mixture was achieved by pipetting an 13 appropriate weight of the Bi, Na, K, and Ba solution into the Ti solution in order to 14 achieve a final concentration of approximately 0.3 molarity. 15 16 SiO2/Si substrates at 3000 rpm for 30 seconds. After each spin, the film was 17 pyrolyzed at 300 °C for 5 min on a hot plate and annealed in air at 700 °C in a 18 preheated furnace for varying times. The annealing and pyrolysis conditions were 19 adopted from previous work on BNT – BKT thin films[19], with the first layer 20 annealed for 30 min and subsequent layers annealed for 10 min each. The films 21 were comprised of 6 total spin cast layers. The phase purity of the films was 22 confirmed using X-­‐ray diffraction (XRD, Bruker, AXS D8 Discover). Film thickness The precursor solution was spin-­‐cast on 100 nm Pt/33 nm TiOx/500 nm 1 was obtained via variable angle spectroscopic ellipsometry (J. A. Woollam, V-­‐VASE). 2 Thermally evaporated silver electrodes (0.2mm diameter) were deposited through a 3 shadow mask for electrical measurements. An impedance analyzer (HP 4192A) was 4 used to obtain dielectric properties at a 50 mV oscillation level. Polarization 5 hysteresis loops up to 125 °C were recorded using a ferroelectric tester (aixACCT 6 Systems GmbH, TF Analyzer 2000HS system). The microstructure of the crystallized 7 films was observed via scanning electron microscopy (SEM, FEI Quanta 600F). 8 3. Results and discussion 9 A representative XRD pattern of an 85BNT – 10BKT – 5BT film is shown in 10 Figure 1. Perovskite phase with no second phase formation was observed, with the 11 pattern indexed according to a pseudo-­‐cubic perovskite structure. Similar to 12 previous work on BNT – BKT thin films[19], the (110) peak showed the strongest 13 intensity, with the films having an overall random orientation. The thickness of the 14 crystallized film was approximately 240 nm. 15 16 for a typical 85BNT – 10BKT – 5BT thin film at room temperature. As the frequency 17 increased from 100 Hz to 100 kHz, the permittivity decreased from 640 to 550, as is 18 very common for high permittivity materials. The dielectric loss remained relatively 19 stable over this frequency range, with only a slight increase at lower frequencies. 20 The permittivity and dielectric loss at 1 kHz were 610 and ~3.5%, respectively. 21 Compared to the work reported by Abazari, et al. the permittivity at 1 kHz is similar 22 but the dielectric loss here is lower.[21] However, it is difficult to compare directly Figure 2 shows the permittivity and dielectric loss as a function of frequency 1 with these previously reported BNT – BKT –BT films as those films were grown on 2 different substrates with very different crystallographic orientation (epitaxial vs. 3 polycrystalline). A lower dielectric loss (<6.5%) over the frequency range measured 4 here is a strong indication of a lower defect concentration in these films. 5 6 different measuring conditions. First, in Figure 3(a), PE loops at room temperature 7 were measured at 200 Hz. The shape of the loop indicates good ferroelectric 8 behavior, with maximum and remanent polarizations at 360 kV/cm of 31 µC/cm2 9 and 6 µC/cm2 respectively. Considering that the Pr of bulk BNT – BKT – BT is 10 typically over 30 µC/cm2, here the Pr is only 20% of that of the bulk ceramic 11 value.[24, 25] This could be attributed to being slightly off the morphotropic phase 12 boundary composition or to the very different morphology and stress states in thin 13 films compared to bulk.[26, 27] Polarization hysteresis loops taken at +/-­‐370 kV/cm 14 and 500 Hz as a function of temperature up to 125 °C are displayed in Figure 3(b). 15 The polarization values for these 85BNT – 10BKT – 5BT thin films were very stable 16 as a function of temperature, and the shape of the loops changed very little. Both 17 PMAX and Pr at room temperature and 125 °C were nearly identical; approximately 18 32 µC/cm2 and 6 µC/cm2, respectively. Hysteresis loops above this temperature 19 range (> 125°C) became highly rounded in shape, which is indicative of conduction 20 and defect migration beginning to occur. For loops measured at lower frequencies 21 (i.e., 200 Hz, not shown) this electrically lossy behavior was apparent at lower 22 temperature, indicating some optimization of process conditions is still necessary. Figure 3 shows polarization-­‐electric field hysteresis loops (PE loops) at 1 Nevertheless, good polarization hysteresis loops at 200 Hz and room temperature 2 were observed with temperature stability demonstrated at 500 Hz. 3 4 a 85BNT – 10BKT – 5BT thin film by SEM. There are many “clusters” present on the 5 film surface, which consist of small grains. Outside of these clusters, the grain size is 6 approximately 80 -­‐ 100 nm. Pores or voids, which could result from solvent 7 evaporation or carbon oxidation during heat treatment of the film, were not 8 observed. Previous work on 80BNT – 20BKT showed some degree of columnar 9 growth in cross-­‐sectional SEM images, however this was not observed in these Figure 4(a and b) shows the surface morphology and cross-­‐sectional image of 10 85BNT – 10BKT – 5BT thin films (Fig. 4b). Instead, a significant degree of equiaxed 11 growth was observed. Columnar grain growth can be achieved when a 12 heterogeneous nucleation event at the substrate is favored over a homogenous 13 nucleation events within the amorphous gel.[28] To be favored over a homogenous 14 nucleation event, increased crystallization temperatures could lower the driving 15 force for crystallization on the substrate surface. Using higher annealing 16 temperatures to do this could cause two potential issues. First, increasing the 17 crystallization temperature would likely have an adverse effect of the film 18 stoichiometry due to increased volatilization of A-­‐site cations (Bi, Na, and K). 19 Second, delamination and hillock formation from diffusion of the TiOx adhesion 20 layer due to thermophysical instabilities of the platinized silicon are known to be 21 issues at higher temperatures (>700 °C)[29] Additionally, this type of equiaxed 22 microstructure has been observed in CSD BaTiO3 thin films[22, 28], indicating even 23 5% BaTiO3 can alter the nucleation and growth mechanism in the films shown here. 1 It has also been reported that BaTiO3 thin films can show microstructures varying 2 from columnar to fine-­‐grained depending on the thickness of the individually 3 crystallized layers.[30] In this study the dependence of the film microstructure on 4 changing solution molarity (and hence thickness of each spin-­‐cast layer) was not 5 explored, but could potentially alter the film morphology from an equiaxed nature 6 to a columnar nature. 7 4. Conclusions 8 9 Thin films of the composition 85BNT – 10BKT – 5BT were synthesized via chemical solution deposition. By adopting the processing conditions from previous 10 work on the BNT-­‐BKT-­‐Bi(Mg1/2Ti1/2)O3 system, phase pure perovskite films were 11 achieved as confirmed by XRD. Excellent dielectric properties were obtained over 12 the frequency range 100 Hz to 100 kHz. The observed permittivity and dielectric 13 loss at 1 kHz were 610 and 3.5%, respectively. Polarization hysteresis loops were 14 obtained at 350 kV/cm and 200 Hz with Pr = 6 µC/cm2 and PMAX = 31 µC/cm2. 15 Analysis of the film microstructure using SEM revealed fine-­‐grained homogenous 16 film growth. Future investigations of this system should include using seed or buffer 17 layers and the effects of varying solution molarity for different microstructure or 18 nucleation mechanisms. The results of this current work suggest that BNT – BKT – 19 BT thin films are promising candidates for thin film piezoelectric applications. 20 21 22 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 References [1] G.L. Brennecka, J.F. Ihlefeld, J.P. Maria, B.A. Tuttle, P.G. Clem, J Am Ceram Soc. 2010;93:3935-­‐54. [2] C.T. Shelton, B.J. Gibbons, J Am Ceram Soc. 2011;94:3223-­‐6. [3] S. Trolier-­‐McKinstry, P. Muralt, J Electroceram. 2004;12:7-­‐17. [4] A. Safari, M. Abazari, Ieee T Ultrason Ferr. 2010;57:2165-­‐76. [5] W.J. Foster, J.K. Meen, D.A. Fox, Cutan Ocul Toxicol. 2013;32:18-­‐22. [6] V.A.I. G. A. Smolenskii, A. I. Agranovskaya, and N. N. Krainik, Sov Phys Solid State. 1961;2:2651. [7] Y. Hiruma, H. Nagata, T. Takenaka, J Appl Phys. 2009;105:084112. [8] I. Levin, I.M. Reaney, Advanced Functional Materials. 2012;22:3445-­‐52. [9] H. Nagata, M. Yoshida, Y. Makiuchi, T. Takenaka, Jpn J Appl Phys Part 1 -­‐ Regul Pap Short Notes Rev Pap. 2003;42:7401-­‐3. [10] P. Jarupoom, E. Patterson, B. Gibbons, G. Rujijanagul, R. Yimnirun, D. Cann, Appl Phys Lett. 2011;99:152901. [11] A. Sasaki, T. Chiba, Y. Mamiya, E. Otsuki, Jpn J Appl Phys Part 1 -­‐ Regul Pap Short Notes Rev Pap. 1999;38:5564-­‐7. [12] T. Takenaka, K. Maruyama, K. Sakata, Jpn J Appl Phys Part 1 -­‐ Regul Pap Short Notes Rev Pap. 1991;30:2236-­‐9. [13] T. Takenaka, T. Okuda, K. Takegahara, Ferroelectrics. 1997;196:495-­‐8. [14] Y. Hiruma, H. Nagata, T. Takenaka, Jpn J Appl Phys Part 1 -­‐ Regul Pap Brief Commun Rev Pap. 2006;45:7409-­‐12. [15] Y.M. Li, W. Chen, Q. Xu, J. Zhou, X.Y. Gu, Mater Lett. 2005;59:1361-­‐4. [16] S.J. Zhang, T.R. Shrout, H. Nagata, Y. Hiruma, T. Takenaka, Ieee T Ultrason Ferr. 2007;54:910-­‐7. [17] Y.P. Guo, D. Akai, K. Sawada, M. Ishida, Solid State Sci. 2008;10:928-­‐33. [18] L. Lu, D.Q. Mao, D.M. Lin, Y.B. Zhang, J.G. Zhu, Physica B. 2009;404:325-­‐8. [19] Y.H. Jeon, Ph.D Thesis. Corvallis: Oregon State University; 2012. [20] Y.H. Jeon, E.A. Patterson, D.P. Cann, P. Mardilovich, W. Stickel, B.J. Gibbons, J Am Ceram Soc. 2013 (Accepted). [21] M. Abazari, A. Safari, S.S.N. Bharadwaja, S. Trolier-­‐McKinstry, Appl Phys Lett. 2010;96:082903. [22] J.F. Ihlefeld, A.M. Vodnick, S.P. Baker, W.J. Borland, J.P. Maria, J Appl Phys. 2008;103:074112. [23] R.W. Schwartz, P.G. Clem, J.A. Voigt, E.R. Byhoff, M. Van Stry, T.J. Headley, et al., J Am Ceram Soc. 1999;82:2359-­‐67. [24] T. Takenaka, H. Nagata, Y. Hiruma, Ieee T Ultrason Ferr. 2009;56:1595-­‐612. [25] X.X. Wang, X.G. Tang, H.L.W. Chan, Appl Phys Lett. 2004;85:91-­‐3. [26] Y.I. Yuzyuk, P. Simon, I.N. Zakharchenko, V.A. Alyoshin, E.V. Sviridov, Phys Rev B. 2002;66. [27] C.H. Yang, W.B. Wu, F. Yang, H.T. Wu, X.Y. Zhang, Mater Lett. 2012;66:86-­‐8. [28] R.W. Schwartz, Chem Mater. 1997;9:2325-­‐40. [29] C.T. Shelton, P.G. Kotula, G.L. Brennecka, P.G. Lam, K.E. Meyer, J.P. Maria, et al., Advanced Functional Materials. 2012;22:2295-­‐302. 1 2 3 [30] U.H. S. Hoffmann, R. Waser, C. L. Jia, and K. Urban, Materials Research Society Proceeding. 1997;474:9-­‐14. 1 2 Figure Captions 3 Figure. 1. XRD pattern for a 85BNT – 10BKT – 5BT thin film synthesized with excess 4 cations (+10% Bi, +20% Na, and +20% K). 5 Figure 2. Permittivity and dielectric loss of a 85BNT – 10BKT – 5BT thin film as a 6 function of frequency. 7 Figure 3. P-­‐E loops of 85BNT – 10BKT – 5BT thin films (a) at room temperature and 8 200 Hz and (b) as a function of temperature up to 125 °C at 500 Hz. 9 Figure 4. Plan view (a) and cross-­‐section (b) SEM images of a 85BNT – 10BKT – 5BT 10 thin film. 11 10 6 10 4 Si (200) 5 Si (110) 10 (100) 10 20 30 40 50 2θ (°) 1 (211) 100 (311) 1000 (210) Log (Intensity, A.U) Pt 60 70 80 2 3 4 Figure. 1. XRD θ-­‐2θ pattern for 85BNT – 10BKT – 5BT thin film synthesized with excess cation concentration in solution (+10% Bi, +20% Na, and +20% K). The Si peak at 33° is from λ/2 of the Si (400) 5 700 1 650 550 500 0.1 450 Tangent δ Permittivity 600 400 350 300 0.1 1 10 Frequency (kHz) 1 0.01 100 2 Figure 2. Permittivity and dielectric loss of a 85BNT – 10BKT – 5BT thin film as a 3 function of frequency. 4 5 2 Polarization(µC/cm ) 40 30 (a) 20 200 Hz 10 0 -10 -20 -30 -40 -400 -300 -200 -100 0 100 200 300 400 Electric Field(kV/cm) 2 Polarization(µC/cm ) 40 30 (b) 20 500 Hz 10 0 -10 125 °C 100 °C 75 °C 50 °C 25 °C -20 -30 -40 -400 -300 -200 -100 0 100 200 Electric Field(kV/cm) 1 300 400 2 Figure 3. PE loops of 85BNT – 10BKT – 5BT thin films (a) at room temperature 3 and 200 Hz (b) as a function of temperature up to 125 °C at 500 Hz 4 (a) (b) 1 2 Figure 4. Plan view (a) and cross-­‐section (b) SEM images of 3 a 85BNT – 10BKT – 5BT thin film 4