Characterization of AP-MALDI and ESI for a Differential Mobility Spectrometer

by

Priya Agrawal

Submitted to the Department of Electrical Engineering and Computer Science

in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Electrical Engineering and Computer Science

MASSACHUSETTS INS

OF TECHNOLOGY

at the Massachusetts Institute of Technology

May 19, 2005.

Copyright

rl

JUL 18 2005

2005 Priya Agrawal. All rights reserved.

I

LIBRARIES

The author hereby grants to M.I.T. permission to reproduce and

distribute publicly paper and electronic copies of this thesis

and to grant others the right to do so.

Author

r

PriyA Agrawal

Department of Electrical Engineering and Computer Science

May 19, 2005

Certified by

Dr. Cristina E. Davis

Charles Stark Draper Laboratory

Thesis Supervisor

Certified by

Professor Angela M. Belcher

Professo r--"ologicgl and Materials Science and Engineering

Thesis Advisor

Accepted by

Arthur C. Smith

Chairman, Department Committee on Graduate Theses

BARKER

E

[This Page Intentionally Left Blank]

2

Characterization of AP-MALDI and ESI for a Differential Mobility Spectrometer

by

Priya Agrawal

Submitted to the

Department of Electrical Engineering and Computer Science

May 19, 2005

In Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Electrical Engineering and Computer Science

ABSTRACT

The following thesis entails the construction, testing, modification, and analysis of two

systems that couple sample ion introduction methods with a Differential Mobility

Spectrometer (DMS).

The sample ionization methods used with a custom designed

interface for the DMS were Electrospray Ionization (ESI) and Atmospheric Pressure

Matrix Assisted Laser Desorption Ionization (AP-MALDI).

In addition to system

development, Fourier transform and decision tree analyses were explored as alternatives

to lead-cluster mapping and genetic algorithms for analyzing and classifying data

produced by the systems for large biomolecules. Findings from testing and experiments

using the prototype system have led to a second generation design of the interface.

Results from data analysis have also provided new insights into different methods for

classifying data whose form changes drastically for different sample introduction

methods.

Technical Supervisor: Dr. Cristina Davis

Title: Group Leader Bioengineering, Principal Member of the Technical Staff

Thesis Advisor: Professor Angela M. Belcher

Title: Assoc Professor, Biological Engineering and Materials Science and Engineering

3

[This Page Intentionally Left Blank]

4

14

ACKNOWLEDGEMENT

May 19, 2005

The following thesis is the last leg of a great journey in research and academics. My

experience at Draper and MIT has truly been a great one, and I have many people to

thank for making this possible.

First and foremost, I would like to thank my mother, my father, and my brother. They

have given me the confidence and ability to achieve my goals and to strive for excellence

in everything I do. I would never have been able to come this far without their constant

love, encouragement, and wisdom.

I am especially grateful to have had such an extraordinary group of colleagues to work

with at Draper Labs. Many thanks are due Dr. Cristina Davis for the opportunity to work

on such an interesting engineering problem, and for the guidance, optimism, and

motivation to tackle tough problems. I would especially like to thank Dr. Angela Zapata

and Ernie Kim for teaching me so much, for their technical expertise, and for their

patience in fielding all of my questions and ideas. I thank Melissa Krebs for her patience

in explaining analysis tools with me, and listening to me when I had exciting ideas. I

thank Sarah Cohen, Mariana Shnayderman, and Dr. Malinda Tupper for their advice

patience, and sense of humor. Thanks to Dr. George Schmidt, Joseph Sarcia, and Loretta

Mitrano in the Education Office for coordinating the Draper Fellow program, and making

my experience here possible.

At MIT, I would like to thank Professor Angela Belcher for advising me on my thesis,

and Professor Mildred Dresselhaus for supporting and advising my academic career.

Finally, I would like to extend a special thanks to my friends Ruth, Chaitra, Neha, Kiran,

Tara, and Shruti for all the great times we've had together during the few free moments

I've had from school these past 5 years.

This thesis was prepared at The Charles Stark Draper Laboratory, Inc. under Department

of the Army, Cooperative Agreement DAMD-17-02-2-0006.

Publication of this thesis does not constitute approval by Draper of the sponsoring agency

of the findings of conclusions contained therein. It is published for the exchange and

stimulation of ideas.

f0

5

Priya Agriwal

[This Page Intentionally Left Blank]

6

Table of Contents

I

12

In tro du ction ...............................................................................................................

14

B ack ground ...............................................................................................................

14

2.1

Differential Mobility Spectrometer................................................................

2.1.1

Operation Principle of Differential Mobility Spectrometry................... 14

Traditional Uses of Differential Mobility Spectrometry ....................... 18

2.1.2

18

2.2

Electrospray Ionization ..................................................................................

19

Operation principle of Electrospray Ionization......................................

2.2.1

20

Prior Uses of the ESI Technique...........................................................

2.2.2

21

2.3

A P -M A LD I....................................................................................................

21

Operation Principle of AP-MALDI......................................................

2.3.1

22

Prior Uses of the AP-MALDI technique ...............................................

2.3.2

Advantages and Potential of the ESI-DMS and AP-MALDI-DMS systems ... 23

2.4

23

D ata Analysis ...............................................................................................

2.5

24

Fourier Methods....................................................................................

2.5.1

26

2.5.2

Decision Trees ......................................................................................

27

Lead Cluster Mapping and Genetic Algorithms ....................................

2.5.3

28

Thesis Summary............................................................................................

2.6

29

ESI-DMS Instrumentation Development and Analysis.........................................

3

29

The ESI-DMS System..................................................................................

3.1

31

3.2

T he E SI U nit ..................................................................................................

31

1

Interface.......................................................................................

3.3

Prototype

34

Spray Pattern Characterization ......................................................................

3.4

34

Experimental Design..............................................................................

3.4.1

. . 35

R esults..................................................................................................

3.4 .2

36

3.5

Current Measurement Experiments ...............................................................

37

3.5.1

E xperim ent 1.........................................................................................

38

Experiment 2.........................................................................................

3.5.2

41

........................................................................

Probe

Experiments

Langmuir

3.6

42

3.6.1

Initial Testing with the Langmuir Probe................................................

43

Results of Initial Test Using Langmuir Probe ..............................

3.6.1.1

45

3.6.2

Air Pump and Breakup Gas effect on Current .......................................

49

Modified T-junction and Capillary Tube Interface.......................................

3.7

50

Design of the Capillary T-junction ......................................................

3.7.1

51

3.7.2

Experim ents ...........................................................................................

. . 52

3.7 .3

Results..................................................................................................

53

3.8

Prototype 1 Interface.....................................................................................

53

Design of the Interface...........................................................................

3.8.1

3.8.2

Experimental Method for Testing of the Prototype I Interface.............. 54

2

Resu lts.......................................................................................................

3 .8 .3

3.9

Modified Ion-Optics Interface ......................................................................

3.9.1

3.9.2

3.9.3

3.9.4

Hardware/Instrumentation Setup ...........................................................

Initial Test of the Modified Ion-Optics Interface..................................

Results of Initial Experiment with Modified Ion-Optics Interface........

Experimental Method for the Modified Ion-Optics Interface................

7

55

56

57

60

61

63

3.9.5

Results....................................................................................................

3.10 Data Analysis M ethods ..................................................................................

Fourier Transform s. ..............................................................................

3.10.1

3.10.2

Decision Tree Analysis.........................................................................

3.10.3

Correlogic Analysis ...............................................................................

Com parison of Analysis M ethods.........................................................

3.10.4

AP-MALDI-DMS Instrumentation Development and Analysis ...........................

4.1

Background ....................................................................................................

4.2

Hardw are Description - m aterials and methods.............................................

4.2.1

The AP-M ALDI-DM S system ..............................................................

4.2.2

The M ALDI unit ....................................................................................

4.2.3

The interface ...........................................................................................

Sam ple Preparation technique................................................................

4.2.4

Preliminary Testing.......................................................................................

4.3

4.3.1

Experimental Conditions ......................................................................

4.3.2

Results of Preliminary Testing..............................................................

:.................

4.4

Optim ization ...................................................................................

4.4.1

Sam ple Depletion Tim e ........................................................................

4.4.2

Effect of Break up Gas on Signal Quality .............................................

Effect of Pump Flow Rate on Signal Quality ........................................

4.4.3

Effect of Extraction Voltage on Signal Quality.....................................

4.4.4

4.5

Data Analysis for Finding Trends in the Data ...............................................

4.5.1

Scans from the AP-M ALDI-DM S System ...............................................

Determining that Signal is Present Using Fourier Methods ...................

4.5.2

Finding Trends from Optimization Experiments................

4.5.3

Peak Analysis..........................................................................................

4.5.4

5

Sum m ary and Conclusions .....................................................................................

ESI...................................................................................................................

5.1

4

5.2

AP-M ALDI.....................................................................................................

Data analysis ...................................................................................................

5.3

6

Future W ork ............................................................................................................

6.1

ESI...................................................................................................................

Shorter Ion Path Length ..........................................................................

6.1.1

Better insulation for electronics/HV .......................................................

6.1.2

Interaction between sam ple and carrier gas ............................................

6.1.3

6.2

AP-M ALD I.....................................................................................................

6.3

Data Analysis ..................................................................................................

6.3.1

Fourier Analyses .....................................................................................

Statistical analyses ..................................................................................

6.3.2

7

Appendix.................................................................................................................

8

References...............................................................................................................

8

65

65

66

72

80

81

83

83

84

84

84

85

86

87

87

88

90

91

92

94

96

98

99

100

102

103

105

105

107

109

109

110

110

110

111

111

112

112

112

113

114

List of Figures

Figure 1 Graph of ion mobility as a function of electric field for three hypothetical ion

sp ecie s.......................................................................................................................

15

Figure 2 Picture of the MEMS-based Differential Mobility Spectrometer. ................ 16

17

Figure 3 Schematic of ion trajectory through the DMS.................................................

Figure 4 (a) Varying electric field due to RF voltage waveform (b) Constant electric field

due to compensation voltage.................................................................................

17

19

Figure 5 Electrospray needle and plum e[18].................................................................

20

Figure 6 Depiction of ion dispersion from aerosol droplets. .........................................

24

Figure 7 Example of positive ion spectral data scan....................................................

30

Figure 8 Block diagram of ESI/AP-MALDI-DMS system ..........................................

Figure 9 AP-MALDI or ESI unit in open position on the left and closed position on the

32

right on the sample detector interface....................................................................

interface.

of

ESI/AP-MALDI-DMS

cross

section

through

Figure 10 Ion and gas flows

Figure courtesy of Ernest S. Kim, Draper Laboratory, Cambridge, MA.............. 33

Figure 11 SDI with Agilent ESI capillary interface components: 1. External capillary

34

shield 2. Glass capillary shield and inlet...............................................................

Figure 12 Plume diameter for various sample flow rates and nebulizing gas flow rates. 36

37

Figure 13 Schematic for current measurement experiment A. .....................................

Figure 14 Plot of current measured at plate versus sample flow rate ............................ 38

39

Figure 15 Current measurement setup with perpendicularly oriented ESI needle .....

40

Figure 16 Infusion rate versus current for perpendicular current measurements ......

Figure 17 Current measured versus extraction voltage for vertical needle geometry. ..... 41

42

Figure 18 Setup of Langmuir probe for initial test ........................................................

Figure 19 ESI current as a function of sample flow rate for different extraction voltage

43

lev els .........................................................................................................................

Figure 20 ESI current as a function of sample flow rate for two different concentrations

44

o f samp le ...................................................................................................................

45

Figure 21 ESI current as a function of Langmuir probe location. ................................

46

Figure 22 Langmuir probe setup in second set of experiments ....................................

47

Figure 23 Langmuir probe setup with ESI needle ........................................................

50

Figure 24 Cross-sectional view of capillary T-junction interface ................................

51

......................................

DMS

system

configuration

Modified

T-junction

-Figure 25

Figure 26 Inner component of prototype 1 interface where arcing was observed........ 54

56

Figure 27 Data replicate from prototype 1 Interface Data set .....................................

Figure 28 Schematic of the modified ESI-DMS interface with modified ion-optics....... 58

Figure 29 Schematic of voltage divider for ESI-DMS interface ...................................

59

Figure 30 (a) DMS positive ion spectra for the protein BSA with extraction voltage

turned off (b) DMS spectra with extraction voltage turned on and off in synch with

sample injection (c) DMS spectra with extraction voltages on for entire duration of

62

experim ent.................................................................................................................

Figure 31 Plot of single replicate from modified ion-optics interface data set.............. 65

Figure 32 Raw DMS spectra for data collected using modified T-junction capillary

67

in terface .....................................................................................................................

Figure 33 1-Dimensional Fourier transform magnitude (left) and phase (right).......... 68

9

Figure 34 Fourier transform magnitude (top) and phase (bottom) plots for data taken

69

using the prototype 1 interface...............................................................................

taken

using

plots

for

data

and

phase

(right)

magnitude

(left)

Figure 35 Fourier transform

70

the modified ion-optics interface. .........................................................................

Figure 36 Fourier transform magnitude and phase plots for data collected with the

71

modified T-junction interface ..............................................................................

Figure 37 Classification error for varying testing and training set sizes, for three different

74

datasets ......................................................................................................................

Figure 38 Error and minimum cost for optimally pruned tree for data collected using

76

m odified T-junction interface. ..............................................................................

Figure 39 Cost versus number of terminal nodes in tree built with 2400 data scans from

prototype 1 interface data set (top), and modified ion-optics interface data set

78

(b otto m).....................................................................................................................

Figure 40 Best pruned classification tree for modified ion-optics interface................. 79

Figure 41 Cutaway view of major substance flows in the prototype 1 interface.......... 85

Figure 42 (a) SDI with AP-MALDI capillary interface components: 1. Teflon high

voltage insulator, 2. break-up gas cylinder, 3. capillary extension. (b) SDI with ESI

capillary interface components: 1. break-up gas outlet, 2. glass capillary inlet (figure

86

courtesy of Ernest K im ) ........................................................................................

88

Figure 43 Timing diagram of sample introduction........................................................

Figure 44 Ion spectra from AP-MALDI-DMS system. (a) Shows data taken when laser is

off (b) Data recorded when laser fired on blank plate (c) Data collected when laser

89

fired on sample spot ...............................................................................................

90

Figure 45 AP-MALDI target plate sample spot layout..................................................

Figure 46 DMS signal intensity as a function of break up gas flow rate...................... 94

96

Figure 47 Trend from experiment to vary pump flow rate. ..............................................

98

Figure 48 Trends from experiment to vary extraction voltage ...................

99

Figure 49 Typical scan taken during blank region ablation...........................................

100

...................................

laser

ablation.

sample

Figure 50 Typical data scan taken during

Figure 51 Magnitude of Fourier transform of sample ablation spectra against magnitude

101

of Fourier transform of blank ablation spectra. ......................................................

10

List of Tables

Table 1 System components for ESI-DMS system...........................................................

31

Table 2 Conditions varied for electrospray plume pattern characterization.................. 35

Table 3 Experimental conditions for Langmuir probe test ...........................................

48

Table 4 Operating Conditions for Experiment using the prototype 1 interface............ 54

Table 5 Sampling sequence for modified ion-optics interface data collection.............. 55

Table 6 Voltage at outer capillary shield when voltage on inner capillary shield is -3200

V ................................................................................................................................

59

Table 7 Summary of experimental conditions for initial test with modified ion-optics

60

in terface .....................................................................................................................

Table 8 Summary of operating conditions for modified ion-optics interface data set...... 64

Table 9 Sampling sequence for modified ion-optics interface data collection............. 65

Table 10 Experimental conditions for initial experiments with AP-MALDI-DMS system.

87

...................................................................................................................................

Table 11 AP-MALDI-DMS experimental conditions for sample depletion time

91

ex perimen ts...............................................................................................................

92

for

Break

up

Gas......................

Table 12 AP-MALDI-DMS experimental conditions

Table 13 AP-MALDI-DMS experimental conditions for pump flow rate experiments... 95

Table 14 AP-MALDI-DMS experimental conditions for extraction voltage experiments.

97

...................................................................................................................................

11

1 Introduction

In an ideal world, one would be able to rapidly detect and classify any and all types of

chemical and biological substances in minute concentrations and volumes with small,

easy-to-use instruments. The number of applications for which such sensors are required

is numerous, from disease diagnosis to airborne toxin detection.

However, sensors

currently available have only some, but not all of these attributes. In particular, there are

few, if any, sensors that are small and easy to use for detecting and identifying large biomolecules.

Draper Laboratory has recently developed a Micro-Electro Mechanical

Sensor (MEMS)-based Differential Mobility Spectrometer (DMS) that is small, userfriendly, and has been demonstrated to quickly detect chemicals at low concentrations.

The aim of the research is to develop a small, easy-to-use system that employs this sensor

to identify large bio-molecules of high molecular weight at low concentrations.

The DMS does not require additional reagents to detect ions and it detects substances

very quickly using only small volumes of analyte. It operates by detecting the ions of an

analyte, and using the properties of those ions as identifiers for that particular

substance[1].

One of the major challenges in creating this detection and classification

system is to generate and keep intact ionized versions of these bio-molecules and to

transport these ions to the DMS. Most methods for ionizing substances tend to destroy

the intra-molecular bonds of large bio-molecules and preclude the detection of the

original bio-molecule[2, 3]. The system designed and tested in this project involves two

different sample ionization and introduction methods, known for their ability to ionize

substances while maintaining macro-molecular structure, coupled to the DMS through a

common interface. The resulting system will provide us with the ability to sense and

12

analyze large proteins and bio-molecules with a system that has several use and cost

advantages over current methods for such analyses.

The DMS generally works with gases, presenting another challenge in converting biomolecules to the gas phase.

In both ionization techniques, the sample of interest is

converted from the solid or liquid phases to the gas phase. The two methods of chemical

ionization investigated were Electrospray Ionization (ESI) and Atmospheric Pressure Matrix Assisted Laser Desorption Ionization (AP-MALDI).

Electrospray ionization

converts samples in solution to ions in the gas phase by creating a fine aerosol spray of

the sample ions.

Atmospheric pressure - matrix assisted laser desorption ionization

involves the laser ablation of a crystallized sample to ionize the sample and convert it to

the gas phase.

The motivation behind the interfacing of these sample ionization assemblies with a

differential mobility spectrometer is that these methods present several advantages over

traditional forms of biological analyses[4]. AP-MALDI and ESI both preserve molecular

properties that are destroyed by other forms of ionization[2, 5]. The ESI and AP-MALDI

methods are considered to be 'soft' ionization methods where the softness of an ion

transfer method can be defined as "the degree to which fragmentation of the ions is

avoided."[6] The properties that are preserved by these ionization processes are essential

in classifying large molecules.

This thesis describes the work done to initially construct, test, and optimize the ESI-DMS

and AP-MALDI-DMS systems and the first stages of work in arriving at a robust

detection and classification system. In the following sections, the fundamental principles

13

of this sensor and these sample introduction methods will first be described, followed by

descriptions of the experimentation and testing done to create the systems, and the

methods of data analysis used to determine system function and substance classification.

From the initial design stage, we have come to the point where we have been able to

successfully introduce substances into the DMS from both the AP-MALDI and the ESI

sample introduction methods, and preliminarily analyze data from the system. The two

different systems have been tested and optimized to the point where it is necessary to

implement a second generation system design to further improve ion sensing and

classification abilities.

2 Background

2.1 Differential MobilitySpectrometer

2.1.1 Operation Principle of Differential Mobility Spectrometry

The Differential

Mobility Spectrometer

(DMS)

detects and identifies chemical

compounds by measuring the differential mobility of their corresponding ions[l]. Ion

mobility is a property that relates to the ability of ions to be deflected and guided by

electric fields.

An ion's mobility in an electric field in a given gas environment is

dependent upon the charge, size, and mass of the ion[7]. As the strength of the electric

field increases, the mobility of ions changes non-linearly. Mason and McDaniel [7]

found that ion mobility is highly dependent on field strength, and changes non-linearly as

the field strength increases.

Figure 1 shows that the change in ion mobilities as a

function of the electric field applied for three hypothetical substances is non-linear. The

14

non-linearity of ion mobility and the greater separation between mobilities at higher

electric fields, are essential properties for classifying substances with the DMS.

..

I

**

Species A

I

*

Species B

K(E)

Species C

E= 2

E <1000

E

Figure 1 Graph of ion mobility as a function of electric field for three hypothetical ion species.

Draper Laboratories has recently developed a DMS (Figure 2) with detection limits in the

parts-per-billion and parts-per-trillion range that operates under atmospheric pressure and

temperature conditions [8].

DMS is loosely based on the principles of Ion Mobility Spectrometry (IMS). IMS works

by processing pulses of ions. Sample ions are pulsed into a constant DC voltage electric

field, which as show in Figure 1, causes the ions to have certain mobilities. These

mobilities are measured by the amount of time if takes for the ions from a particular pulse

In contrast to IMS, the DMS is a Radio

to travel through a drift tube region[8].

Frequency (RF) filter and produces an added dispersive force which further enhances

mobility differences. The DMS is different from the IMS in that the mobility of ions are

measured according to the compensation voltage necessary to correct for the oscillatory

path of the ion caused by the RF field. One of the main advantages that DMS has over

IMS is that ions can be introduced into the sensor continuously whereas in IMS, ions are

15

introduced in pulses.

This allows for more continuous monitoring and sensing of

biologicals when time plays a critical factor in a particular application. The DMS is less

complex than the IMS, in part because it does not require the precise timing of ion travel.

Additionally, the simpler DMS instrument is also more conducive to miniaturization than

the IMS. The continuous sensing property also simplifies the sample injection process so

that samples can be injected in either a continuous or pulsed manner.

1cm

Figure 2 Picture of the MEMS-based Differential Mobility Spectrometer.

Just before injection into the DMS, analyte is combined with a carrier gas, passed through

an ionizing source (an ultraviolet light or a radioactive beta-particle source), then

introduced into the DMS. The inner ionization source ionizes the carrier gas, which then

transfers charge to the analyte. In some cases, if the ionization potential is higher than

that of the analyte, then the analyte may be ionized directly. In the DMS detector (Figure

3) ions are carried in a stream of nitrogen gas between two charged plates. The plates in

the DMS have a radio frequency electric field applied to them (Figure 4a). The changing

field causes ions to have different mobilities that in turn cause the ions to travel in an

oscillatory fashion, with a bias towards one of the plates[9].

16

The bias in travel is

--

--

dependent upon how the ion's mobility changes in that particular field and is caused by

the 30% duty cycle of the RF voltage waveform.

RF electric

Ionization

Source

Sample

in

Fow

Ion Trajectories

-~Detector

Compensation

electric field

Figure 3 Schematic of ion trajectory through the DMS.

In order to control which ions reach the detector and when, an additional DC voltage,

called the compensation voltage (V,), is applied to the plates. This DC voltage creates a

constant electric field that corrects for the bias in the ion's path, and is applied to reverse

the effect of the RF field. Some ions will be deflected more than others by the varying

RF field, so different ions can be guided through the region between the plates to the

detector by applying different compensation voltages to the metal plates.

EA(

ERF (o)

(b

(a)

Figure 4 (a) Varying electric field due to RF voltage waveform (b) Constant electric field due to

compensation voltage.

17

-~

2.1.2 Traditional Uses of Differential Mobility Spectrometry

In other applications, DMS is often used as a gas phase ion separation pre-filtering

technique for mass spectrometry [10]. Prior separation of ions increases the performance

of the mass spectrometer.

For instance, when a DMS is connected to a Gas

Chromatography-Mass sjpectrometer (GC-MS), the resulting analysis can often be more

accurate[ 11, 12]. The operation of gas chromatography is analogous to a race; substances

which travel faster in the gas phase reach the end of the GC column faster. If ions are

filtered prior to introduction into the column, then separation among substances is even

more pronounced. The analogy is that in the GC race, adding a DMS to the front/back

staggers the racers so that they are guaranteed to cross the finish-line - or reach the mass

spectrometer - individually.

The DMS has also been used with other sample introduction techniques. A pyrolysisDMS system has been shown to successfully detect trace quantities of Bacillus

spores[13]. Another system using pyrolysis-gas chromatography has also been used to

chemically characterize bacteria[14]

A system consisting of a headspace sampler and

gas chromatography column has been used with the DMS to detect bacterial headspace

[15].

2.2 ElectrosprayIonization

There are several characteristics of ESI which make it a desirable method of sample

introduction to the DMS sensor. One of these characteristics is the "softness" of the ESI

method which allows both the preservation of non-covalent interactions between

molecules in the gas phase that existed in solution and the study of three-dimensional

18

conformations[16].

The "softness" of the ESI method aids differentiation between

specific proteins of interest from other closely related interferent proteins or other organic

material because macromolecular structure is preserved, making ESI an attractive

technology to couple to the DMS sensor[2, 6].

2.2.1 Operation principle of Electrospray Ionization

Electrospray Ionization (ESI) is a method of ionized sample introduction for mass

spectrometry which facilitates the analysis of high molecular weight compounds such as

proteins and nucleotides by mass spectrometry[17]. ESI converts liquid samples to ions

in the gas phase by aerosolizing the sample in the presence of an electric field using a

nebulizing needle which creates a "nebula" of ions.

Figure 5 Electrospray needle and plume[18]

The ESI nebulizer needle assembly consists of two concentric needles. Sample solution

travels through the innermost needle, while a nitrogen (N2 ) nebulizing gas travels

between the outer and inner needles. When the sample solution comes out of the tip of

the inner needle it forms a dipolar layer at the meniscus of the solution. The presence of

the strong electric field, where the needle is the positive electrode, causes positive ions to

19

come to the outer surface of the meniscus during the redistribution of charge within the

solution at the capillary tip to create field-free conditions within the liquid[6].

The

repulsive forces between the positive ions at the surface overcome the surface tension of

the solution and cause the liquid to move further in the direction of the electric field,

forming a Taylor cone (Figure 5). A jet of positive ions extends out from the cone, and

then disperses into a plume of positive ion droplets. These droplets disperse further when

the solvent is evaporated by a heated drying gas, such as nitrogen.

As the solvent

evaporates, and ions come closer together, the repulsive force between the like charges

causes the ion droplets to further split apart into smaller clusters and the ions to disperse

(Figure 6).

Figure 6 Depiction of ion dispersion from aerosol droplets.

2.2.2 Prior Uses of the ESI Technique

The ESI method of converting samples to ions in the gas phase has been in existence for

many years and has been used for many different applications. The most widely used

application for ESI is in mass spectrometry. ESI-MS has been used to analyze peptides,

proteins[19], nucleic acids[16, 20], lipids, carbohydrates [21], and inorganic and

organometallic complexes[22].

Outside the context of Mass Spectrometry, ESI is an

20

important method for the creation of aerosols, and for the electrostatic dispersion of

liquids[6].

2.3 AP-MALDI

2.3.1 Operation Principle of AP-MALDI

AP-MALDI is a technique that is most often used to generate ionized gases from solid

and dried liquid samples of non-volatile materials[23, 24]. When a sample is ionized

using AP-MALDI, the sample is dispersed into a matrix that absorbs and transfers energy

to the sample when the mixture is ablated with an ultraviolet laser source. The matrix is a

compound mixture chosen for certain properties which allow for successful ionization of

the experimental sample. These properties include the ability to dissolve the analyte and

recrystallize with it, and the ability to absorb energy from the laser. The matrix must also

not react with the analyte, but should still be able to transfer some positive charge to it.

The wavelength of the laser is selected to excite the matrix without altering the

experimental sample; the experimental sample is only ionized. The abrupt transfer of

energy from matrix to sample causes the sample to desorb and form an ionized gas[2].

These ions are then transported into the analytical sensor of choice via a carrier gas.

One of the unique characteristics of the AP-MALDI ionization process is that it is gentle

enough to desorb and ionize large molecules while keeping the entire molecule intact[5].

This trait of AP-MALDI makes it a particularly useful technique for analyzing proteins,

peptides, and other biological macromolecules for mass spectrometry analysis [3, 25, 26].

Additionally, AP-MALDI allows for the analysis of analytes in a large range of

molecular weights at small concentrations[23]. The ionization technique has several

21

advantages in chemical analysis over other methods of chemical ionization[23].

AP-

MALDI preserves chemical structure and intramolecular interactions that are often

destroyed by other methods[3].

The ability to preserve structure is important for the

detection and sensing of molecules with high molecular weights, such as proteins. Other

forms of ionization tend to destroy or fragment these kinds of larger molecules. For solid

and liquid samples for example, pyrolysis is a highly destructive process, and can fracture

and damage the samples, resulting in detection of pieces and fragments of the compound

or molecule of interest [27].

2.3.2 Prior Uses of the AP-MALDI technique

Initially, the AP-MALDI was coupled with a time-of-flight mass spectrometer (TOFMS), which has a large mass range and high sensitivity [2]. In 1995, the AP-MALDI

sample introduction technique was used with a quadrupole mass spectrometer to

demonstrate the direct sequencing of proteins and peptides of unknown structure[2]. The

AP-MALDI technique was then subsequently demonstrated to work successfully with

Fourier Transform Mass Spectrometry (FTMS), allowing for the high resolution analysis

of complex peptide mixtures.

High kinetic energy and extensive meta-stable decay

characteristic were thought to be obstacles that prohibited, or made insensitive, the use of

AP-MALDI with FTMS, but were overcome by decoupling the AP-MALDI source from

the superconducting magnet [28].

The unique ionization characteristics of the AP-

MALDI process makes it extremely attractive to interface with novel analytical sensors,

especially those that also operate at atmospheric pressure.

22

2.4 Advantages and Potential of the ESI-DMS and AP-MALDIDMS systems

As discussed above, the ESI and AP-MALDI techniques are soft ionization techniques

that require few reagents to ionize analytes of interest. Hence, ESI and AP-MALDI are

good techniques for ionizing large bio-molecules such as proteins because they will not

fragment the ions, and will allow for detection based on properties of the entire ionized

molecule. These ionization methods coupled to the DMS have the potential to be an

extremely powerful new system to detect and classify biological substances with the use

of sophisticated classification algorithms.

The DMS is small and portable, and also requires no extra reagents other than carrier

gasses to detect ions. ESI-DMS and AP-MALDI-DMS systems would provide the ability

to detect and analyze large bio-molecules at low concentrations in small volumes quickly,

and efficiently, at very low cost. Additionally, instruments that can analyze ions at

atmospheric pressure can be coupled to both ESI and AP-MALDI sources with only

minor changes[24].

The applications for such systems are numerous, providing great

motivation behind the research described in the following thesis.

2.5 Data Analysis

The data collected by the DMS varies in three dimensions: time, ion abundance, and

compensation voltage. A typical positive background scan showing reactive ion peaks at

-17.9 V, -14 V, and -7.5 V (Figure 7). Each scan represents a slice in time for which ion

abundances versus compensation voltages are recorded.

23

Cuso 1961I-.15--

\-

Figure 7 Example of positive ion spectral data scan

Data collected using the ESI-DMS and AP-MALDI-DMS systems are different from

previous types of DMS data collected because the sample introduction methods are

different. Current methods for analyzing DMS data are computationally expensive, and

can not be used for every set of data generated. It is therefore necessary to develop other

methods for analyzing data which can provide valuable information without resorting to

lead-cluster mapping and genetic algorithms.

2.5.1 Fourier Methods

The Fourier transform is a mathematical transformation of signals that forms the basis for

modem signal processing, and is used in the context of this research to help extract

information from signals for which methods of analysis are not yet well formed.

The Fourier transform breaks signals up into a sum of periodic waveforms, and

transforms them from time varying signals to frequency varying signals. Inspection of

signals in the frequency domain is often the first step in developing methods for further

processing and extracting information from unknown signals.

discrete Fourier transform is:

24

The equation for the

X(k)=

x(j)Nijl)(kl-)

for k =0,1,2,...,(N -1)

and

WN =ej(2,T/N)

j=1

Where X(k) is the transformed signal, x(j) is the original data signal, and N is the

number of points in the original signal. Each point in X(k)is computed by multiplying

every point in x(j) by a power of

which is called the "frequency", and then

(~),

summing those all together. The transformed signal has the same number of points as the

original signal does. For all otherk, the transform X(k) is equal to 0.

Each point in the transform X(k) is the sum of all the points in the original signal, where

each point has been multiplied by a different root of 1.

The transformed signal is a

complex signal, because it involves multiplications by roots of 1 - complex numbers.

The transform, because it is complex, can then be broken up into a magnitude and phase.

From the magnitude and phase of the Fourier transform, one can fully and uniquely

reconstruct the original signal using the following equation:

x(j) = -

X(kojl(l

Nk=1

for k=O0,1,2,...,(-)adONe(t)

Each scan of DMS data has compensation voltage V, on the horizontal axis, and

abundance V, on the vertical axis, so the integer index j, is analogous to the index of V'.

When we make the transformation from x(j) to X(k), the only thing left in common

between k and jis that they both range from 0 to (N - 1). By convention, k is usually

deemed frequency because most signals vary over time. In the case of DMS data, k

refers to the voltage analog of frequency, 1

AV,

25

The Fourier transform is helpful in extracting information about periodicities in the data

which may not be obvious in the raw data. For a further explanation of the Fourier

transform and its properties, see Oppenheim and Willsky [29].

As shown in the

following chapters, the Fourier transform can be used to detect differences in data taken

under different conditions. The results of these analyses show differences in data much

more clearly than the raw data does itself.

2.5.2 Decision Trees

Decision trees are non-parametric classification models that can be used to classify and

recognize non-linear patterns in data. Decision trees have simple tree structures where

each node of the tree is associated with some classification test, and each leaf of the tree

is associated with a specific classification outcome. The input, also called the predictor,

is tested at each node by the classification test. Whether or not the predictor satisfies the

classification test will determine what the next test or classification applied to the

predictor is. The classification tests can be expressed as if-then statements. The decision

trees are constructed by partitioning data in increasingly homogeneous subsets according

to algorithms described by Breiman, et al[30].

Decision trees have previously been used to classify proteins that were analyzed by mass

spectrometry to distinguish between diseased and non-diseased specimens [31-33].

In

both cases, proteins from humans with and without cancer were successfully

differentiated using decision tree analysis on MS data of those proteins. Decision trees

have also been used in the context of medical diagnosis and chemical analysis [34].

26

2.5.3 Lead Cluster Mapping and Genetic Algorithms

The use of genetic algorithms, developed by Correlogic Systems, Inc. (Bethesda, MD), in

analyzing DMS data is currently being explored. These algorithms have been used to

detect prostate cancer [35] and ovarian cancer [36] using proteomic patterns in serum.

This section will provide a brief overview of the algorithms used by Correlogic in their

software, ProteomeQuest@, to find biomarkers in DMS data collected at Draper

Laboratory. At this time, we are exploring their use for several types of DMS data.

ProteomeQuest@ employs lead cluster mapping and genetic algorithms to construct

models for classifying biological substances. The data sets are divided into three portions

which are used separately in the three stages of the algorithm - training, testing, and

validation.

Lead cluster mapping first randomly selects a user-defined number of

features, usually between 5 and 12, on which to build the cluster maps. Each feature

corresponds to one pixel from a DMS data file which contains 250 scans in the V,

dimension and 200 scans in the time dimension, for 50,000 total pixels. Each data file is

then mapped to the feature space using the intensities of the selected features. After the

first data file is mapped on the feature coordinate system, a user defined radius specifying

the degree to which the model will fit the data, is drawn around that point to define a

cluster. If after the next file is mapped to the feature coordinate system it falls within that

first radius, the centroid of the cluster is redefined around the two data files. If not, a new

cluster is formed around the second data file. After all the data files have been mapped,

each cluster is labeled according to what types of data files define that particular cluster,

thereby creating cluster map. The testing set of data is used to determine how accurately

the cluster map classifies data it was not constructed with. If the accuracy is low, then

27

another cluster map is constructed using a different random set of features. This process

of training and testing is repeated until a user defined number of maps, called the

population, is achieved.

Once the cluster map population has been built, the genetic algorithms come into play.

Each map has associated with it an accuracy value calculated by the performance of the

map on the testing data.

Using the maps that achieved higher accuracies, new maps are

made using some combination of the features from the higher achieving maps. If a high

accuracy is achieved, then this new map replaces a lower performing map in the

population. This process of attempting combinations of features from maps made while

creating the map population is continued for a user-specified number of generations, at

which point the best map available will be selected, or until a map is able to achieve a

high target accuracy. Once this final map is determined, it is used to classify the data in

the independent, blinded validation data set to come up with a final accuracy for that

cluster map model.

The following thesis presents work done to develop alternative methods for classifying

data, and compares the results of those analyses

with those obtained

using

ProteomeQuest@ lead cluster mapping and genetic algorithm tools.

2.6 Thesis Summary

Chapter 2 will describe the experiments and hardware optimization tasks completed in

order to optimize the ESI-DMS system and to determine how to classify different

substances. Chapter 3 will provide a description of the AP-MALDI-DMS system and the

work done to characterize and optimize that system. Both chapters contain discussions of

28

the data analysis methods used for the different forms of data extracted from each system.

These chapters will be followed by a summary of conclusions from each system, plus

another chapter detailing ideas for future work to continue the optimization and

improvement in functionality of both systems.

3 ESI-DMS Instrumentation Development and Analysis

This chapter describes the function, design, and optimization of the Sample-to-Detector

Interface (SDI) which couples the ESI and AP-MALDI units to the DMS sensor. This

chapter is divided into characterization of the interface, experimental testing of three

different versions of the interface and system setup, and data analysis techniques for

DMS signal output. The results and conclusions of the testing and optimization described

in this chapter are currently being used to design the second generation of the interface

and system. Additionally, data analysis tools investigated here will be further developed

to determine whether more robust methods for identifying and quantifying biological

substances can be created.

3.1

The ESI-DMS System

A block diagram of the entire ESI/AP-MALDI-DMS system is shown in Figure 8, and

corresponding components are listed in Table 1.

The ESI or AP-MALDI sample

introduction unit is connected to the SDI, which is in turn connected to the DMS unit. A

small pressure drop of approximately 0.013 atm is applied to the outlet of the DMS to

facilitate the transport of ions through the sensor. The DMS unit is connected to a

standard notebook PC which controls the sensor and collects data.

29

mass flow

conlrollers

gas heaters

control / data acquisition

co mput er

nit roge n

gas

rer gas

breakup gas

to

u, E

+

-- sample

-------

Pump

exast

exus

sample

flow

carne r gas

flow

Figure 8 Block diagram of ESI/AP-MALDI-DMS system

A list of parts used in the system is summarized in Table 1. Nitrogen (UHP grade 5,

Middlesex Gases and Technologies, Everett, MA) flows through the mass flow

controllers, is heated by the low flow heaters, and then fed into the inlet of the carrier gas

and breakup gas lines. Gas flows in the system are controlled by mass flow controllers

(M100B, MKS Instruments, Wilmington, MA), and are heated by low flow gas process

heaters. The temperature of the heaters is regulated by variable AC voltage waveform

generators that control the amplitude of the AC voltage waveform applied to the metal

heater block, subsequently heating the block to a corresponding temperature. A high

voltage power supply, (Stanford Research Systems) provides the voltages necessary to

produce the high electric fields for extracting ions from the AP-MALDI sample plume.

30

Table 1 System components for ESI-DMS system.

Model and Manufacturer

G1607A, Agilent Technologies, Palo

Alto, CA

G1972A, Agilent Technologies, Palo

Alto, CA

MDP-1, Sionex Corporation, Waltham,

Part

ESI Unit

AP-MALDI Unit

Differential Mobility Spectrometer

Custom Made, Draper Laboratory,

Cambridge, MA.

Air Cadet 5730-40, Cole-Parmer,

Vernon Hills, IL

M100B, MKS Instruments,

Wilmington, MA

PS350/5000V-25W, Stanford

research Systems, Sunnyvale, CA

AHPF-062, Omega Engineering

Prototype I Interface

Air pump

Mass flow controllers

High voltage power supply

Low flow gas process heaters

3.2 The ESI Unit

The ESI unit consists of a nebulizing needle and an ionization chamber. Analyte solution

is drawn into a syringe and then delivered to the nebulizing needle through 1/16 inch

outer diameter Teflon PTFE tubing. The output flow rate of the syringe is controlled by a

syringe pump (HA2000P, Harvard Apparatus, Holliston, MA). Nitrogen gas is supplied

to the nebulizing needle via 1/8 inch outer diameter Teflon PTFE tubing. The unit is

connected electrically to earth ground by a spring-loaded pin that makes contact with

grounded portions of the interface when the interface is in the closed position; these

features are described in further detail below.

3.3 Prototype 1 Interface

A custom designed interface was used to couple the ESI and AP-MALDI units to the

DMS sensor. The interface is designed such that commercially available ESI and APMALDI units available from Agilent Technologies can be easily swapped on and off the

interface. The mating mechanism is a simple hinge and latch assembly that also allows

31

the user to swing the ESI or AP-MALDI units from open position to closed position to

allow adjustment of parts in the ionization chamber without dismantling the interface.

Figure 9 shows a drawing of the interface with the AP-MALDI unit attached.

The

drawing on the left shows the unit in the open position. The drawing on the right shows

the unit in the closed position with the latch engaged.

Figure 9 AP-MALDI or ESI unit in open position on the left and closed position on the right on the

sample detector interface

A cross-section of the SDI is shown in Figure 10 with labeled gas and ion flows. Analyte

ions are attracted to the inlet of the interface by an electric field and slight suction exerted

by a pump applied to the outlet of the DMS. The break up gas is directed against the

flow of analyte ions, breaking up any ion clusters and drying any remaining liquid to

prevent liquid from entering and damaging the DMS.

Heated carrier gas enters the

interface and flows in the same direction as the analyte ion path. The carrier gas is

ionized when it passes through the radiation source within the DMS, subsequently

transferring charge to analyte molecules through collisions.

32

Heated

Heated

Break-up gas carrier gas

gas

DMS

Analyte

ions

2.4 i n

Figure 10 Ion and gas flows through cross section of ESI/AP-MALDI-DMS interface. Figure

courtesy of Ernest S. Kim, Draper Laboratory, Cambridge, MA.

The ESI and AP-MALDI units each have easily interchangeable components that must be

attached to the interface (Figure 11). The ESI components include a capillary shield and

inlet to which the high extraction voltage is applied (Figure 11, item 2). An external

shield which focuses the break up gas flow, and also includes an additional break up gas

outlet, is placed over the capillary inlet, (Figure 11, item 1). This shield both focuses the

break up gas flow against the flow of ions from the ESI needle, and also focuses the

electric field by reducing the surface area of the high voltage inlet which is exposed to the

ESI needle. Components for the AP-MALDI unit are discussed further in Chapter 3.

33

Figure 11 SDI with Agilent ESI capillary interface components: 1. External capillary shield 2. Glass

capillary shield and inlet.

Several experiments were designed to evaluate the performance of the ESI-DMS

interface. These experiments investigated the following: properties of ions generated by

the ESI method, characteristics of sample introduction, shape and form of the sample

aerosol plume emitted form the ESI needle, and ways of manipulating the plume.

Conclusions from these experiments then provided the impetus for further investigation

to determine system function, leading eventually to design changes in the ESI/APMALDI-DMS interface.

3.4 Spray Pattern Characterization

The goal of the first set of experiments was to characterize the shape and quality of the

aerosol created by the ESI needle. The results would provide information that would

guide further experiments to vary the position of the ESI needle relative to the SDI.

3.4.1

Experimental Design

Measurements of electrospray plumes were collected for several different parameters to

characterize the spray pattern of the electrospray needle. Nebulizing gas was flowed into

the nebulizing needle, and a colored aqueous solution was injected into the electrospray

needle. The resulting spray pattern was collected on filter paper some distance away

34

from the needle tip. The nebulizing gas flow rate, the distance between needle and filter

paper, and the sample injection rate were all varied to examine their effect on the

electrospray plume. Table 2 summarizes the different conditions for which a plume

pattern was collected. Plumes for all combinations of conditions were collected.

Table 2 Conditions varied for electrospray plume pattern characterization

Condition set points

3.4.2

Sample Flow Rate

(pl/min)

5

100

Nebulizing Gas

Flow Rate (L/min)

400

800

1.0

1.2

1.6

2.0

Distance to Filter

paper (cm)

2

3.5

5

Results

Each pattern was analyzed qualitatively to gain a general sense of what variations in

parameters would cause changes in the spray, and what types of changes would occur.

As shown in Figure 12, as the distance between the needle and the filter paper was

increased, the diameter of the plume became larger and less dense, as expected for a low

sample flow rate of 5 pl/min. The trend is not as clear for the 100 pl/min sample flow

rate measurements.

These measurements were taken for a spray accumulation lasting

only 5 seconds. The edges of the collected pattern were difficult to determine, leading to

variability in the measurement of the pattern diameter.

Across the different

measurements, as the nebulizing gas flow rate increases, the plume diameter decreases,

indicating that the high gas flow rate causes the jet to be more spatially focused. For all

subsequent experiments, the flow rate for the nebulizer gas was set to 1 L/min to provide

an ionized aerosol that was not too narrow.

35

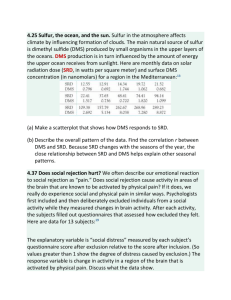

14

12

Sample Flow Rates

-+-5 ul/min, 2 cm

-u-5 ul/min, 3.5 cm

10

E

E

cc

is5

6

-

-r-

8

K-

-&-5 ul/min, 5 cm

ul/min, 2 cm

x-100

-1

*-100 ul/min, 3.5 cm

-.-

4

100 ul/min, 5 cm

2

0

0

0.5

1

2

1.5

2 .5

Nebulizing Gas Flow Rate (L/min)

Figure 12 Plume diameter for various sample flow rates and nebulizing gas flow rates.

3.5 Current Measurement Experiments

Several different experiments were conducted to confirm the operating principle of the

ESI method, and to confirm that the ions created by the needle were traveling properly

along the pathway to the DMS. One goal for these tests was to maximize the number of

ions generated by the ESI method by varying operating conditions while measuring the

current between the ESI needle and a detection point some distance away from the

needle. An increase in measured current is caused by an increase in the number of ions

produced, translating to a stronger ion signal in the DMS, and resulting in increased

sensitivity for the entire system.

Observations from these experiments led to design

changes in the configuration of ion-optics in the interface, and changes to the path

traveled by ions from the ESI needle into the DMS.

36

Several different geometries of the ESI needle were tested to determine the effect on the

current generated at different distances away from the needle.

Additionally, several

different methods of measuring current generated by the ESI spray were tested in

attempts to improve upon the accuracy of the current readings. One of the challenges in

conducting these experiments was that the current being measured was extremely small

and that it was to be measured across a large distance which would cause further

attenuation of the measured ion signal. Current data collected at non-vacuum conditions

would also be highly susceptible to noise and other disturbances.

3.5.1

Experiment 1

In the first experiment, current was measured as a function of the sample injection rate.

The ESI needle was aligned on the axis of desired ion path travel (Figure 13). The spray

was manipulated by an electric field between the electrospray needle which was

connected to earth ground, and the capillary orifice which was connected to an extraction

voltage of -3000 V.

ESI Needle

-3000V

Ion Collection

Plate

Capillary

-

-

orifice

Figure 13 Schematic for current measurement experiment A.

In the configuration shown in Figure 13, the ions would be sprayed from the needle,

attracted into the orifice by the electric field between the needle and the orifice, and

37

directed towards a metal plate which is connected to an ammeter. The distance from the

needle to the capillary orifice entrance was 6.5 mm, and the distance from the capillary

orifice fitting was 15 mm. The flow rate of the nebulizing gas was 1 L/min. The sample

flow rate was varied across the values 0, 100, 250, 500, 750, and 1000 ptl/min.

Measurements were taken when the current reading had stabilized.

0.05

0.04

<0.03

0.02

0.01

0

-0.01

0

200

400

600

800

1000

1200

Sample Injection Rate (pl/m in)

Figure 14 Plot of current measured at plate versus sample flow rate

As shown in Figure 14, as the sample flow rate increased, the current measured also

increased.

This result confirms the intuitive hypothesis that as more sample is

aerosolized per unit time, more ions will travel to the detector plate per unit time, and

measured current - charge per time - will therefore increase.

3.5.2

Experiment 2

The previous experiment confirmed the operation principle behind the electrospray

ionization method.

However, it did not confirm that the electric field between the

capillary orifice and the needle was the driving force in attracting ions through the orifice

opening to the collector plate because the needle was spraying aerosolized ions directly at

the detector plate.

38

To test the efficacy of the electric field in attracting ions into the capillary orifice, another

experiment was conducted with the same configuration for the capillary interface and the

detector plate, but with the ESI needle now oriented perpendicularly to the direction of

the desired final ion path. The horizontal distance from the needle tip to the orifice, a,

was set to lcm, the vertical distance from the needle tip to the center of the capillary, b,

orifice was 7.1 mm, and the distance from the capillary orifice to the metal detector plate

was 13.5 mm.

4-

ESI Needle

Ion Collection

-3000V

b

a

t

Plate

c

Capillary

orifice

A

Figure 15 Current measurement setup with perpendicularly oriented ESI needle

The flow rate of the nebulizing gas was set to 1 L/min based on spray characterization

tests described earlier, and two experiments to determine the effect of separately varying

the sample flow rate and extraction voltage were conducted.

The goal of these

experiments was to determine that amount of ions that could be generated and how that

amount could be varied using an ESI needle geometry configuration more similar to that

39

of the commercially available ESI unit. The sample flow was varied across the values 0,

50, 100, 175, 250, 500, and 750 p.l/min. The extraction voltage was set to -3000 V.

0.005

0.004

0.003

0.002

0.001

-1

-0.001 0

2

400

600

800

-0.002

-0.003

-0.004

Infusion Rate (pl/m in)

Figure 16 Infusion rate versus current for perpendicular current measurements

As the sample infusion rate increased, the measured current increased as shown in Figure

16. This indicates that ions were attracted into the capillary orifice and to the metal

detection plate. Current measurements for flow rates less than about 200 pl/min were

negative, which means ions might have been traveling in a direction opposite to the

electric field. However, the negative measurements are likely to be due to noise which

caused the picoammeter to fluctuate from positive to negative readings. This experiment

confirmed the expectation that current would increase for higher sample flow rates, even

when the ESI needle was positioned vertically.

In the next experiment which would further prove the principle of the ESI method, for a

sample infusion rate of 500 pl/min, the extraction voltage was varied across the values 0,

-1.0, -1.5, -2.0, -2.5, -3.0, -3.5, -4, and -4.5 kV. Single measurements were taken because

the current reading stabilized over time. As the potential difference between the ESI

needle and the capillary orifice increased in Figure 17, the measured ion current also

increased. This result confirms the idea that as the electric field increases in strength,

40

proportional to the increase in the potential difference between the needle and orifice, the

number of ions directed to the detector plate will increase.

0.005

0.004

=L

0.003

0.0021

0.001

0

-0.001

---

-

-4

-3

-2

,

0

-0.002

-0.003

Extraction Voltage (kV)

Figure 17 Current measured versus extraction voltage for vertical needle geometry.

3.6 Langmuir Probe Experiments

Langmuir probes are typically used to measure currents due to ion travel in plasmas[37].

The ESI needle can be treated as an ion source, so a Langmuir probe would improve the

method for measuring ion currents and lend greater accuracy to the measurements.

Additionally, the Langmuir probe would allow for current measurement experiments in a

setup that was far more similar to the actual ESI-DMS interface so conclusions from

these tests could more easily be applied to the actual ESI-DMS system. The goal of these

experiments was to determine the conditions at which ion generation and transport

occurred most optimally.

The following section describes the different experiments

conducted using the Langmuir probe in a setup similar to the modified capillary Tjunction interface.

The outcomes of these experiments contributed to the decision to

modify the ion-optics setup in the prototype 1 interface, and led to a deeper

understanding of the effect of the ion-optics on ion travel.

41

3.6.1

Initial Testing with the Langmuir Probe

The first Langmuir probe configuration is shown below in Figure 18.

A T-junction

fitting with a copper electrode, and a fused silica capillary tube were attached to the

carrier gas heater outlet. The nebulizing needle was positioned at an angle to the Tjunction with 0 = 75', x = 0.5 cm, y = 1.5 cm, where 6 is the angle from the horizontal,

and x and y are the horizontal distance and vertical distance, respectively, of the needle

from the center of the glass capillary. The probe, a thin wire threaded through a GC

column until slightly protruding from the other end of the column, was positioned in

between the charged T-junction and the nebulizing needle. As shown in the figure below,

the probe is placed directly in the stream of ions.

Liquid

Carrier

sample

,

Nebulizergas

-3500 V

Glass capillary

Nebulizer

needle

Capillary entrance

Nebulized

analyte and

solvent

Langmuir probe

amreter

-5 V

Figure 18 Setup of Langmuir probe for initial test

Current measurements were taken for various sample flow rates with QPUMP = 500

ml/min, and

QNEB =

1 L/min. The probe was biased relative to the ammeter to allow for a

more accurate reading of current. Measurements were taken at 1 minute intervals, as the

42

sample flow rate was varied. The experiments were repeated with different extraction

voltages and a sample solution of 1mM acetic acid in water, and with different sample

concentrations at an extraction voltage of -3.5 kV. As the extraction voltage was turned

on, and as the sample concentration increased, the measured current was expected to

increase, as the increase in these two parameters should increase the total number of ions

that reach the detector. Another experiment was conducted to determine the effects that

different positions of the probe within the path of the ion spray would have on the total

ion current measured. The results of these tests are shown below.

3.6.1.1 Results of Initial Test Using Langmuir Probe

-+-HV=OV --

HV=-3500V

34

33

32

____

______

-

31

-

30

29

28

27

-

26

25

24

----

0

10

20

40

30

50

60

70

Sample Row Rate(pl/min)

Figure 19 ESI current as a function of sample flow rate for different extraction voltage levels

As shown in Figure 19, when the extraction voltage was set at -3.5 kV, the measured

current increased as the sample flow rate increased, in a somewhat linear fashion. When

the extraction voltage source was turned off, current decreased as the sample flow rate

increased. As the sample flow rate changes, the absolute value of the change in both

lines is nearly the same. One way to interpret this graph is that when the power supply is

turned off, the polarity of the current changes, so the sign of the trends are opposites.

43

36 ................................................................................ .........

.

!...............................

35

34

-

-

33

E 32

31

30

-

--

29

1 mM acetic acid

-

28

.5 mM acetic acid-

27

0

20

80

60

40

Sample Flow Rate [pl/min]

100

120

Figure 20 ESI current as a function of sample flow rate for two different concentrations of sample

In another test using the Langmuir probe setup of Figure 18, the sample flow rate was

varied and current measured for two different sample concentrations.

Contrary to

expectation, the lower concentration sample of acetic acid in Figure 20 produced a larger

current than the higher concentration sample did.

The plot of Figure 21 shows the change in current as the x-position of the probe was

varied for two different y-positions.

As the distance from the probe to the orifice

increased, current also decreased, for both y-positions. We suspect the trend is nonlinear

because the probe may have been positions of higher ion density in some positions than

others. Because ions were traveling in the direction of the electric field, and because the

field is non-uniformly distributed given the geometry of charged components, then the

plot below yields information about where the field might be strongest as evidence by

higher current which means that more ions were traveling in that location.

44

38

- 0.5 mm

-ay=2mm

37

36

a,

C.)

35 -I

___________

34

33

32