GustoMSC Variable-speed drive solution for Rack & Pinion jacking systems Combined strengths

advertisement

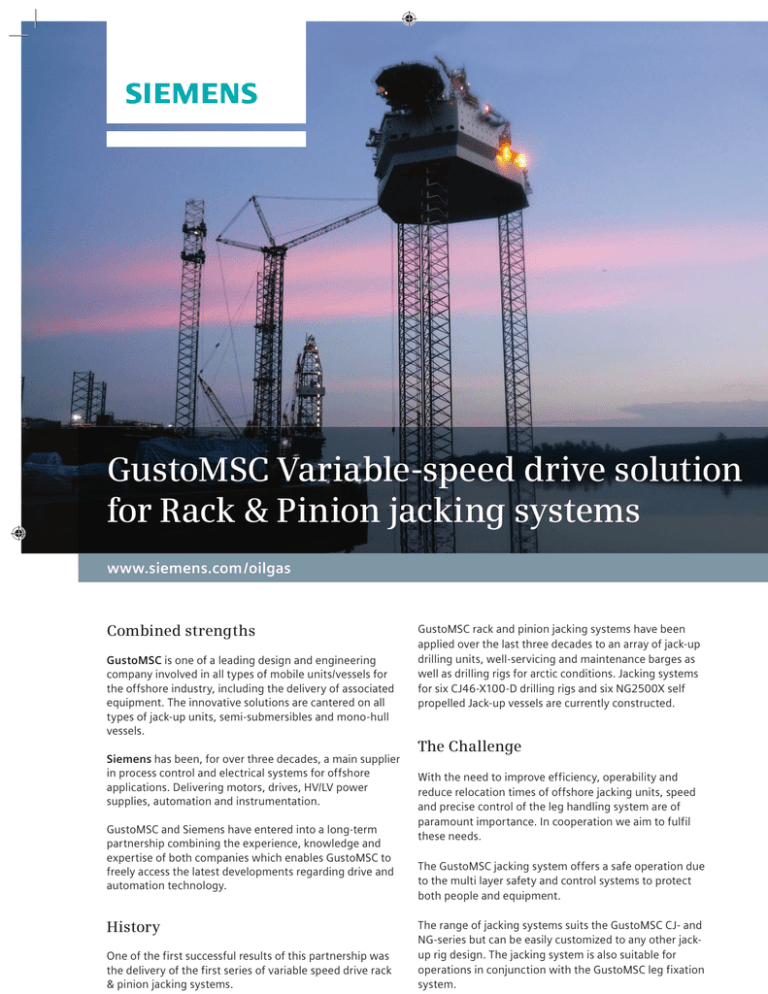

GustoMSC Variable-speed drive solution for Rack & Pinion jacking systems www.siemens.com /oilgas Combined strengths GustoMSC is one of a leading design and engineering company involved in all types of mobile units/vessels for the offshore industry, including the delivery of associated equipment. The innovative solutions are cantered on all types of jack-up units, semi-submersibles and mono-hull vessels. Siemens has been, for over three decades, a main supplier in process control and electrical systems for offshore applications. Delivering motors, drives, HV/LV power supplies, automation and instrumentation. GustoMSC and Siemens have entered into a long-term partnership combining the experience, knowledge and expertise of both companies which enables GustoMSC to freely access the latest developments regarding drive and automation technology. History One of the first successful results of this partnership was the delivery of the first series of variable speed drive rack & pinion jacking systems. GustoMSC rack and pinion jacking systems have been applied over the last three decades to an array of jack-up drilling units, well-servicing and maintenance barges as well as drilling rigs for arctic conditions. Jacking systems for six CJ46-X100-D drilling rigs and six NG2500X self propelled Jack-up vessels are currently constructed. The Challenge With the need to improve efficiency, operability and reduce relocation times of offshore jacking units, speed and precise control of the leg handling system are of paramount importance. In cooperation we aim to fulfil these needs. The GustoMSC jacking system offers a safe operation due to the multi layer safety and control systems to protect both people and equipment. The range of jacking systems suits the GustoMSC CJ- and NG-series but can be easily customized to any other jackup rig design. The jacking system is also suitable for operations in conjunction with the GustoMSC leg fixation system. Jacking System Features Step-less speed control The electric motors of the rack and pinion systems are driven by Siemens’ individual variable speed drives (VSD’s). This arrangement allows for step less speed control between zero and maximum speed and very accurate control of the motor torque and therefore pinions torque. By ensuring the torque is equally shared by all motors and pinions the operation is smoother with less stress and wear. Rack phase difference (RPD) One potential challenge is if the spudcan, at the bottom of the leg, encounters an uneven sea-bed it can deflect the leg, this deflection causes RPD. The GustoMSC jacking system uses Siemens’ encoders on the motors to monitor the position of each chord on a leg to detect RPD before damage occurs. Torque control Pre-torque to each pinion can be applied without manual intervention. By means of the Siemens PCS7 automation platform, providing central torque control functions the GustoMSC jacking system can limit sudden leg movements, for instance when a leg is extracted from the sea-bed or prior deployment of the fixation system, using the invertors at very low speed. The electric VSD driven rack and pinion systems offer the following operational characteristics: • Variable and slow / zero speed control • Optimized load sharing over the pinions • Use of standard, offshore type electric motors, without special high-slip requirements • Easy retorqing through the VSD drives • Automatic platform leveling during lifting and lowering • Leg position indication and rack phase difference (RPD) • Redundant PLC system • Load measuring through the VSD drives and optionally through load measuring devices in the upper shock pads for floating units • Increased leg handling speed Certification The jacking systems can be delivered with certificates from recognized Classification Societies such as ABS, DnV, Lloyds. After Sales Service Through its worldwide network the GustoMSC/Siemens partnership provides 24/7 after sales service. ! Technical Characteristics Each jacking unit consists of a special design, 7 teeth pinion, driven by an electric motor through an input- and planetary gearbox. In general, the jacking units, assembled in a floating jacking frame, engage with a rack of the jack-up legs. The floating jacking frame is equipped with rubber pads on upper and lower end, allowing the units to follow the rack. In the rubber pads, load measuring devices can be incorporated. Alternatively, the jacking units are mounted in a fixed jacking structure, depending on the overall jackup design. ! "#$%&'#(! )*+&(,+! ! -../0#+,! "#$%&'#(! "1,2'*$'/&! Gusto MSC, Netherlands P.O. Box 11, 3100 AA Schiedam Tel. +31 (0)10 232 0000 Email: Marketing@GustoMSC.com Siemens Nederland N.V. Prinses Beatrixlaan 800 2595 BN Den Haag Tel: +31 (0)70 333 3333 Email: oilgas.nl@siemens.com