Fulfillment of the Submitted in Partial I

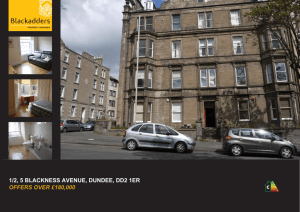

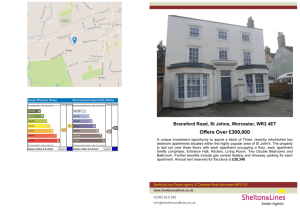

advertisement

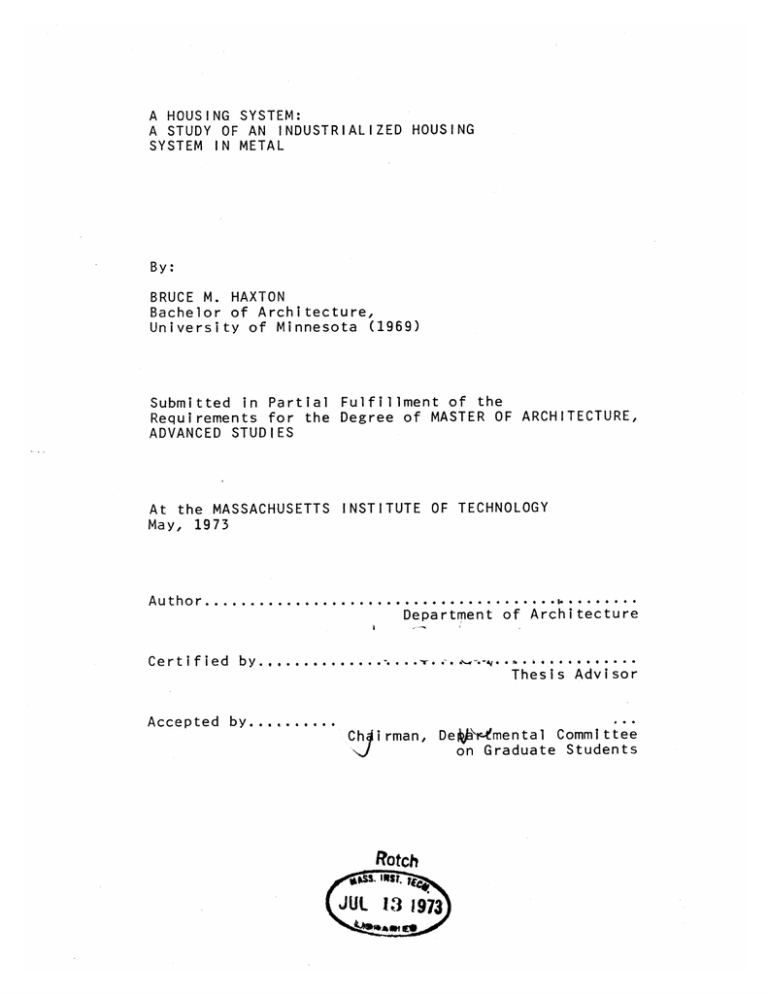

A HOUSING SYSTEM:

A STUDY OF AN INDUSTRIALIZED HOUSING

SYSTEM IN METAL

By:

BRUCE M. HAXTON

Bachelor of Architecture,

University of Minnesota (1969)

Submitted in Partial Fulfillment of the

Requirements for the Degree of MASTER OF ARCHITECTURE,

ADVANCED STUDIES

A t the MA SSACHUSETT S INST ITUTE OF TECHNOLOGY

May, 1973

Author..............

..

..

....

..

...

......

. -

...

Department of Arch itecture

Certified by.

..

..

..

..

.-

.

.

..-..

'

.

..

...

b.

.....

--

Thesis Advisor

Accepted by..........

Ch i rman,

-- Dew&icr.mental Committee

on Graduate Students

Rotch

JUL 13 1973

May 11,

1973

Dean William Porter

School of Architecture and Planning

Massachusetts Institute of Technology

Dear Dean Porter:

In partial

fulfillment of the requirements for the

degree of Master of Architecture, Advanced Studies, I

hereby submit this thesis entitled:

A HOUSING SYSTEM: A STUDY OF AN INDUSTRIALIZED HOUSING

SYSTEM IN METAL.

Respectfully,

Bruce M. Haxton

ACKNOWLEDGEMENTS

The author wishes to gratefully acknowledge the

following people, whose assistance and advice have

contributed significantly to the development of

this thesis.

Waclaw P. Zalewski

Professor of Architecture

Massachusetts Institute of Technology

Thesis Advisor

Eduardo Catalano

Professor of Architecture

Massachusetts Institute of Technology

Aurthor D. Bernhardt

Professor of Architecture

Massachusetts Institute of Technology

Ezra Ehrenkrantz

Visiting Professor

Massachusetts Institute of Technology

James Bock

Executive Vice President

Bock Industries Incorporated

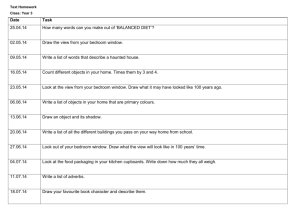

TABLE OF CONTENTS

Ti tle Page

Letter of Submittal

Acknowledgements

Table of Contents

Abstract

Introduct ion

Design Analysis

Design Constraints

Methodology

Design Considerations

Areas for Further Study

User Requirement Study

Market Study

Design Study

Design Categories

Design Components

Delivery Components

Unit Plans

Unit Cluster Plans

Details

Unit Model

Bibliography

ABSTRACT

A HOUSING- SYSTEM:

A STUDY OF AN INDUSTRIALIZED

HOUSING SYSTEM IN METAL

By BRUCE M. HAXTON

Submitted to the Department of Architecture on May 11,

1973 in partial fulfillment of the requirements for the

degree of Master of Architecture, Advanced Studies.

The aim of this thesis

is to study an industrialized

housing system based on metal

framed housing modules.

These housing modules would be produced using assembly

line techniques and delivered to the site for erection.

The thesis contains three primary elements:

1) The user

requirement study, 2) The market study, and 3) The

design study.

The user requirement and market studies

were used to establish parameters for the design study.

The design study demonstrates how basic living elements

can be used to generate building modules that are delivered to the site to form dwelling units.

Thesis Supervisor: Waclaw P. Zalewski

Title:

Professor of Structures

INTRODUCT ION

1.1

The Problem

A multitude of building systems are being marketed

today to meet the numerous housing demands of the

nation.

Examples satisfy variations in family

size and income level as well as providing a range

of housing types. Mobile homes, for example, largely

focus on rural,

low-cost, single family housing. Con-

versely, modular housing Is oriented toward larger

extended families at a higher income level.

Other

systems have been developed for the urban apartment

dweller using steel and concrete technology.

Upon

invest.igating a selected sample, the author has

discovered inadeqacies in the design of these

systems.

It has been observed that many of these

systems are based on preconceived or poorly analyzed design parameters.

Program inconsistencies ex-

ist which reflect a lack of a systematic investigation of three essential aspects; 1) Projected needs

of the user; 2) An accurate assesment of market

conditions; and 3) The effective and efficient application of utilizing existing factory production

and distribution technology.

1.2

Obiective of the Studv

This thesis is intended to provide the designers

and producers of industrialized housing systems

with a methodology and design example for integrating assembly-line production techniques, effective marketing, and user requirements.

1.3

Methodology

Three primary elements form the thesis: 1) A user

requirement study, 2) A market study, and 3) An

illustrative design example.

The user require-

ment study and market study were used to establish

design categories which are used as parameters for

the design study.

1.4

Scope

The design proposal is based on factory produced

metal

framed housing modules.

These housing modules

would be transported to the building site to form

dwelling units of the following types:

1) Single

family detached, 2) Single-family attached, and

3) Multi-family low-rise up to three stories in

height.

DESIGN ANALYSIS

2.1

Design Constraints

Unit Constraints

One to four bedroom Configurations

Units limited to one floor only

Units must accommodate variations in floor

area and utilities

Housing types will encompass single-family

detached, single family attached, and

multi-family low-rise up to three stories in

in height

Site Planning Constraints

Units must form cluster arrangements

The system must be suitable for single site

application as well as multiple unit sites

Manufacturing Constraints

The system must be adaptable to assembly line

production techniques

The system should use existing manufacturing

technology and products

Transportation Constraints

The maximum shipping width

14'-0"

The maximum shipping length

70'-0"

The maximum shipping height

13'-6"

The maximum shipping weight

30 tons

2.2

Methodologv

The procedure was to establish the ranges of

various housing elements such as, living/dining

square-footage, that could then be broken down

into categories and used as design parameters.

Minimum user requirements and housing examples

were used to establish these ranges.

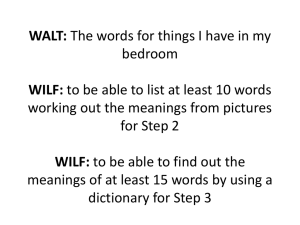

User Requirement Study

The User Requirement

Study is

divided into the

following categories: 1) Living room requirements,

2) Dining room requirements, 3) Bedroom requirements, 4) Kitchen requirements, and 5) Bathroom

requirements.

The primary source used for the study was the

Guide Criteria for the Design and Evaluation of

Operation Breakthrough: Volumell.- Multi-family

Low-rise.

performed by the Building Research

Division Team in 1970 and adopted by the U.S.

Department of Housing and Urban Development as

the criteria for Operation Breakthrough.

The study was used to generate and check room

sizes and shapes,

Market Study

The market study was accomplished by taking a

selected sample,

Dwelling unit groups of similar

bedroom counts formed subdivisions in the following categories: 1) Dwelling unit size, 2) LivIng and dining areas, 3) Kitchen counter length,

and 4)

Utilities.

Design Study

The user requirement and market studies were

used to form the range of various housing elements

to be used In the design study. The user requirements formed minimums while the market study

idenifled the the upper limits for each housing

element.

The ranges for each housing element

were then broken down into into categories within

each bedroom count.

Each category could be used

as a set of design parameters for a particular

unit design.

2.3

Design Considerations

Building Form

The cluster arrangement was used because it promotsocial

interaction and was conducive to providing

a hierarchy of spaces

The social

in planning arrangements.

basis for this type of housing is cover-

ed in Architectural

Enyironment and Our Mental

Health, by Clifford B. Moller.

Manufacturing Considerations

The use of existing materials would reduce the

-"tooling up"

aspect of production which could

otherwise be an inhibiting factor.

Box construction permits the highest degree of

industrialization possible and labor costs are

minimized.

The ample supply of metal

insures that material

costs will not seriously escalate in the future.

Metal

construction allows close tolerance levels

and rapid assembly.

Transportation Considerations

The use of the floor members as the chassis element for transportation allows a cost reduction.

The wheel and hitch assembly are returned to the

factory thus saving the cost of these items

over existing mobile home practices.

Marketing Considerations

The market network that has been established

by the mobile home industry could be used to

market this system.

Since the system encompasses both single family and multi-family structures a greater aggregation of the market is achieved.

Construction Considerations

The rigid frame structure promotes structural

continuity during the erection process.

The connections between units establishes a

structural continuity thus establishes

resistance to horizontal forces.

The use of steel promotes tolerance control.

The use of the metal frame allows easy erection

lifting with the metal column connections.

AREAS FOR FUTHER STUDY

Futher study is needed in the following areas:

Building Forms

Double loaded corridor configurations and two

story units should be investigated.

Criteria and options should be established for

intergrating more non-system elements into

the unit designs.

Structural and Code Requirements

Additional structural calculations and tes t i ng

should be made.

Fire testing and building code accepta nce should

be accomplished.

Market Studies

A more comprehensive market study should be made

taking a wider sampling.

A market anaylsis should be made of the specific

market area.

USER REQUIREMENT STUDY

COUCH

3'-0" X 6'-101

.......

...........

-----

----

-

. ... ......

.

... .. ... .. .. . ...............

.. .. ... . ... .. ... ..

.............

. ...............

..............

..............

..

..............

........... ..

.... .... ..... ....... ....

. .....

.................

..

..

I.......

.....

....

....

...

.....

...

.....

..

....

....

.......

..

......

. ..............

..

...I

....

..

...

....

.. ..............

....

..

...............

.............

...............

.................

..............

..

..............

..

...............

.............

...............

..............

...........................

..

.. ....

..........

..

.............

...............

....

..............

.................

......

I..........

..............

..

..............

....

.............

. ...............

....

..............

..

..............

.............

....

. ...............

.. ..............

1*'*"*""'*"""'*"""*"'*"'**

TWO EASY CHAIRS

2'-6" X 3'-0" each

DESK

1'-8" X 3'-6"

CHAIR

1'-6" X 1'-6"

n

- -

TELEVISION

1'-4" X 2'-8"

60"

24"1

36"

10'

3011

-.1

L

TABLE

1'-6" X 2'-6"

..................

............

..

................

.............

..

- ..

..

.........

..

..

. .............

.............

..

..

............

..

..

. .............

..

..

............

..

.............

..

. .............

............

..

..

.

..

............

..

..

.............

..

.

............

..

..

. .............

..

..

............

..........

..

..................

-- -----------..................

.................

..................

..................

..................

..................

..................

..................

..................

I

D

5'-0" to view

between facing seating

circulation between furniture

main circulation

diameter of conversation area

LIVING ROOM REQUIREMENTS

.....

......

F7LIZ..

I......

W ..

11'-0"

-- 4

4

4

12 '-8"

13'-O"

...

D...

LIVING ROOM ARRANGEMENT

TABLE FOR FOUR

3'-2" X 2'-6"

421

421

32"'

9'-4"

32"

L - .... - .... ..

8 -8

~-1

TABLE FOR SIX

3'-41"

X 41-0"

42"

10 '-2"

32"

4 21

321"

L ---

... ----------.

. - - -...

9 '-6"

TABLE FOR EIGHT

3'-4" X 6'-0"

42"

.....

]II

32

42"1

]II

..-... .

32" access .for seating

42' for serving

48" from table to base

cab Inets

12'-2"

32"

L--------------.-..-....-...........

--

--- -- --.--

_-_-_---

DINING ROOM REQUIREMENTS

..................

TWO TWIN BEDS

3'-3" X 6'-10"

.......................

........................

....................

.......................

.......................

........................

.......................

........................

.......................

........................

.................

.......................

........................

......................

........................

.......................

........................

.......................

........................

..........

..............

.......................

.......................

........................

...........

.........

.....................

...........

12

......

...

..

.

...

.

I----- ....

:12 .......................

...

....

.

.....

.............

..

..

.

.

...

.......................

.......................

................

......

.......................

..............

........

.......................

.................

I.....

.......................

.......................

.......................

.......................

.......................

..........

I............

..............

..........

........................

..............

.......................

.......................

.......................

........................

.......................

........................

.......................

1'

.......................

..........

...............

22"

4

L--- -----------------

10'-4

1

1

CR I B

2'-6" X 4'-6"

4'-4"

22"11

DRESSER

1 '-6"

X 4 '-4"

............................

....

... ...

... ... ..

. ....

.......

.. .

.

....

..

.. ... ...........................

... ..

... ..

... ...

.....

....

...

.......................

.

...............................

...............................

...............................

...............................

...............................

...............................

......................

...............................

...............................

...............................

3611

L ----------

41-611

J

TABLE

2'-6" X l'-8"

CHA I R

1'-6" X 1'-6"

....

L....-.........-..

I

L.. ... ..

DRESSING AREA

3'-6" X 3'-6"

PRIMARY BEDROOM

BEDROOM REQUIREMENTS

-4

12 ' -10"

11'-4"

14'-10"

r

.......................

....

.......

11'0ii

............

...............

.....

PRIMARY BEDROOM

-

BEDROOM ARRANGEMENT

..........I......

TWO TWIN BEDS

3'-3" X 6'-10" each

. .. ... .. .. .. .. ... .. ..

................

... .. .. .. .. ....

. .. ... ..

.......................

. .. .. .. .. ... .. ..

. ...

.. ...

..

.. ...

.. ..

.. ...

..

.. ..

.. ..

.. ..

. ..

. ...

..... .. .. .. .. ... . ... .. ..

.. ...... .. ..

777

. ..

.. ...

. ...

.. ...

.. ..

.. .. ...

. ...

.. ..

.. ..

.

... .. ..

.. .. ... .

.. .

. .. ... .. .. ... . ... ...........

. .. .. .. .. ... .. .. .. .. ...

.. . ... .. .. ... .. .. .. .. ..

...

. .. ..

.....

.. .. . ...

.. .. ...........

.. ..

. ...

.. ..

.. .

..

.. ..

.. ..

... ..

.. ..

.. .. .. .. ... .. ..

... .. .. ..

...............

........

2211 .. ................

1 2 11 8 - 8 11

112 .......................

......................

.......................

.......................

.......................

.......................

......................

.....................

I

.

...

...

.......................

.................

........

.......................

.......................

.......................

.......................

.......................

...................................

........

.......

2211

L------------------------101-411

ONE DOUBLE BED

(ALTERNATE)

4 1'-6" X 6'-10"

......................

.................................

.................................

.................................

.................................

.................................

.................................

.................................

.................................

.................................

.................................

.................................

....................

.......................

:12

22"

.................................

.................................

...........

................................

.................................

................................

.................................

................................

.....................

.....................................

8' -8"

.................................

.........................

..

..................

................

2211

L------------------

7 -14"

TWO DRESSERS

1'-6" X 4'-41" each

36" to use

I

~

36'

Second dresser is

desirable but not

required.

..... I

. . . .I..

.

... ... ... ... .

I .. . . .. . . . . .. . . . .

I . . . . .. . . . . ...

I

. .

I.. .. . . . . . .. *I. . .

I.

... . ...-. . .. ..- ...... .. ... .. - .L -

DESK AND CHAIR

1'-8" X 3'-6"

30" to use

30'!

DRESSING AREA

31-6"

L----------a

X 3'-6"

SECONDARY

DOUBLE

OCCUPANCY

BEDROOM

BEDROOM REQUIREMENTS

--

I---

11'-4"

-- -

-

4

11'-4"'

10' -0"

r--

.....

.. .. .. .

.. .... ...

. . .. .

.. .

..

. ....

..

. . . . . .

.. .

L

........

. .... .

......

..

10'

-4"

...............I

.

.~

BEDOO

SECONDARY

OCCUPANCY

DOUBLE

BEDROOM

. .

~~.

.

. . ... ..

-

.. .

.

.

. . . . . .

...

..

...

ARRANGEMENT

ONE TWIN BED

..

3'-3"1 X 6'-10"1

I

. . . .. . . .. . . . . .

.. . .. . . .. . .

.. . .. . . ..I.

.I... .. ..

12

......

.I . .. . . .. .I..

.I . . .. . . .I..

. ..I.

.

.

. . .. . .. . .

22';....

8'-8"

22".........

...

. ..

. ....

..

LIII

.....

.....

..

..

..

I

L------------.

DRESSER

1'-6" X 3'-6"

I II.........

DESK

1'-8" X 3'-6'

CHA I R

1' -G" X 1'-6"

..I ...........

30..........

..............

..........

22

The desk and chair

are desirable but

not required.

DRESSING AREA

3'-6" X 3'-6"

r

i

L-----.

SECONDARY SINGLE

OCCUPANCY BEDROOM

BEDROOM REQUIREMENTS

-T--

...........

..........

..........

..........

...........

..........

..........

..........

. ..... .... ..... .... .

..........

. .-..

..I

I

-- I

-

-

J

4

81-511

.. . .. .

.. . . . . .

I.

11'-4"

SECONDARY SINGLE

OCCUPANCY BEDROOM

. .-.

.. ..

... .....

.... .... ...

. .. . .. . . .. .

..

... .... ..

.

. . ..

. .. ...

. ....

--4

BEDROOM ARRANGEMENT

SINK

18"

Counter and base

cabinets at each

...

...

......I...

..............

...

....

..............

............

..............

..............

.............

...... ... 20"

.

.............

..............

24"1

s ide

18"

24"1

..............

..............

.............

..............

.....

...

....

...

..

...

..

....

..

..

..

...

...

..

..

...

..

..

..

.

..

....

....

.....

.....

...

...............

..

..............

20"

RANGE

Counter and base

cabinet at one side

21"

24"

18"

20"

REFR.I.GERATOR

Counter at

30"

latch

15"

I

36"

15"

........

.......

.......

.

....

..

..

...

..

..

...

..

...

..

........

.......

MIXING AREA

Base and wall

cabinet

ONE BEDROOM /TWO

LuiJ

30"

.............

................

.. . .......

36"

BEDROOM

KITCHEN REQUIREMENTS

...............

..............

..............

..............

..............

..............

..............

SINK

Counter and base

cabinets at each

side

4

1

.............

..............

I.............

...............

..............

..............

1

30"

..............

..........

2 4"

36"

21"1

LI*.,-J.*

U i -.

..............

30"

..............

....

..........

...............

...............

..............

...............

RANGE

Counter and base

cabinet at one side

3 0'

2 4"

30"

..............

...............

..............

...............

...........

...............

..............

..............

..............

..............

30"

REFRI GERATOR

Counter at latch

s i de

36"

3 0"

1

5"

15"

.......

......

..

..............

....

.......

MIXING AREA

3 6"

Base and wall

cabinet

THREE BEDROOM

.......

.......

...... .......

..........

...............

/FOUR

BEDROOM

KITCHEN REQUIREMENTS

BATH TUB

2'-10" X 5'-0"

28"

28

for drying

5'-2"

WATER CLOSET

2'-5" deep

l'

21"

30"

to use

LAVATORY

2'-0" X 3'-0"

21" to use

3'-9"

-~

WASHER

2'-2" X 2'-7"

36"

to use

5 2"

DRYER

2'-2" X 2'-7"

5'-2

36"

5 '-2"

to use

36"

WASHER/DRYER

2'-2" X 2'-7"

36" to use

BATHROOM REQUIREMENTS

MARKET STUDY

I

1 BEDROOM

I

2 BEDROOM

I

I

3 BEDROOM

2400

I

4 BEDROOM

2300

2200

2100

2000

1111TIT-1--fT

1900

*FAN

I

THES IS

AU

1800

1700

eFAN T

HEE1

*FAN

THESIS

1600

*WAUSAU

*ECODESIGli

1500

:a

1400

1300

eRESTOD

*RESTON L.C.'

9FAN THESIS

1200

( j1

eWAu U

1100

1000

*WAUSAU

eWESTON

qeRESTON L.C.

*KELL THES IS

&WESTON

900

e.RESTON L. C

I.. ... ...

I

...

...

...

+w

.0 WAUSAU

800

THESL

700

!*MICH IGAN C.

0ETFAN

*R ES TO0N L. a C.s- .*WES TON

600

500

400

300

u

I

LIVING UNIT SQUARE FOOTAGE STUDY

I

1 BEDROOM

I

2 BEDROOM

3 BEDROOM

625

I

4 BEDROOM

600

575

550

525

500

475

450

OECODESIGN

425

400

*FAN

375

* FAN TI

THESIS

THES IS

*FAN

IITeW..TAUSAUL1

1 -1r IVFVVV

I5

.OWAUSAU

350

ORES TON L.C.

325

,FAN

WAUSAU

THESIS

ORESTON L.C.

300

275

* WESTON

I *RESTON L.C.

leRESTON L.C

oWESTON

t

250

225

*WESTON

200

175

150

125

100

LIVING/DINING ROOM SQUARE FOOTAGE STUDY

I

1 BEDROOM

I

2 BEDROOM

I

I

3 BEDROOM

14-6

14-0

4 BEDROOM

*WAUSAU

ii'

*FAN THESIS

114

4

13-6

*FAN THES I

OFAN THES IS

13-0

9WESTON

12-6

12-0

11-6

11-0

*ECODESIGN

e.

4

*FAN THESI

10-6

*FAN THESIS- I

10-0

9-6

9-0

;ORES

DA

I @RESTON I C~i

8-6

jeRESTON

L. C., *RESTON L.C

d eBR EAK THRO-UGH

8-0

p UN I MOD

7-6

Rnlit

B REAKi

*BREAKTHROUGH

I

7-0

6-6

I

EAf

I

6-0

5-6

5-0

*MICHIGAN

C

4-6

OFAN THESIS

4-0

ill H 14144 E fff

I..........

IWES TO N

KITCHEN COUNTER STUDY

I

2 1/2 B

w

D,

I

1 BEDROOM

I

2 BEDROOM

I

3 BEDROOM

*FAN

2B

L

w

D

2B

w

D

4 BEDROOM

THESIS

eFAN THESIS.f

*R ES TON L.

*WAUS AU

11/2 B

*

w

D

WAUAl

, h*

OFAN THESISi

1B

L

w

D

1B

w

D

,r

I.WAUSAU

*WAUS~AUl

1L-I 4

*FAN THES

[*FAN THES

I

*WAUSAU

1UNIMOD

*RESTON L.C.

1B

w

eFAN THESIS

1B

- AES IS: -" -'~

= 3

-I 1

ORESTON L.C. eRES TON L. C.

CFAN

- It

T

fECODESIGN

1SB

w

D

4 WESTONWESTON

1SB

w

[NiwE

TON

1SB

~SMICHI GAN C4

B

BATHROOM

SB SMALL BATHROOM

L

LXTORY

W

WASHER

D

DRYER

UTILITIES STUDY

DESIGN STUDY

1 BEDROOM

2 BEDROOM

3 BEDROOM

4 BEDROOM

LEVEL 1

688

770

1000

1200

LEVEL 2

752

971

1253

1450

LEVEL 3

816

1172

1506

1700

LEVEL 4

880

1375

1760

1950

1 BEDROOM

2 BEDROOM

3 BEDROOM

4 BEDROOM

LEVEL 1

235

235

280

337

LEVEL 2

272

286

324

374

LEVEL 3

310

337

368

411

LEVEL 4

350

390

412

450

LIVING UNIT

SQUARE FOOTAGE

LIVING / DINING

SQUARE FOOTAGE

DESIGN CATEGORIES

3 BEDROOM

2 BEDROOM

1 BEDROOM

4 BEDROOM

LEVEL 1

6'

8'

8'

9

LEVEL 2

81

91

10'

11'

LEVEL 3

10'

12'

13'

LEVEL 4

11'

12'

14'

15'

2 BEDROOM

3 BEDROOM

4 BEDROOM

KITCHEN

COUNTER

1 BEDROOM

LEVEL 1

LEVEL 2

___

LEVEL 3

_

REGULAR

BATHROOM

WASHER

REGULAR

BATHROOM

WASHER

REGULAR

BATHROOM

WASHER

REGULAR

BATHROOM

WASHER

__ __

___ ___

__

_

___

__

REGULAR

BATHROOM

WASHER

REGULAR

BATHROOM

-WASHER

_

.DRYER

REGULAR

BATHROOM

DRYER

11/2

BATHROOM

WASHER

DRYER

2 BATHROOMS

WASHER

DRE

DRYER

REGULAR

BATHROOM

WASHER

REGULAR

BATHROOM

WASHER

DRYER

11/2

BATHROOM

WASHER

DRYER

REGULAR

BATHROOM

LEVEL

WASHER

DRYER

REGULAR

BATHROOM

WASHER

DRYER

2 BATHROOMS 2 1/2

BATHROOMS

WASHER

WASHERE

WASHER

DRYERDRYER

UTILITIES

DESIGN CATEGORIES

El

E2

E3

E4

ENTRY CONFIGURATIONS

Li

L2

LIVING ROOM CONFIGURATIONS

L3

LIVING ROOM CONFIGURATIONS

B1

B2

B3

84

BEDROOM

CONFIGURATIONS

B5

B6

BEDROOM CONFIGURATIONS

till

111111

-4.1

B7

B8

B9

BEDROOM

CONFIGURATIONS

LI

ti

I

Lji

It

BEROIOFIUAIN

B2

1

B14

BEDROOM

CONFIGURATIONS

Dl

D2

D3

DECK CONFIGURATIONS

Li H

EH

H2

E]

--ELJ

0J

11

KITCHEN

COMPONENTS

L..

KI

I-

El

-Lt=:

ONE

BEDROOM UNIT

BASIC PLANS

i

K2

KITCHEN CONFIGURATIONS

TWO

BEDROOM UNIT

BASIC PLAN

K3

THREE

BEDROOM UNIT

BASIC PLAN

K4

KITCHEN CONFIGURATIONS

FOUR

BEDROOM UNIT

BASIC PLAN

KITHEN CONFIGURATIONS

0

-0

-1

K7

-E

I

ONE

BEDROOM UNIT

BASIC PLANS

KITCHEN CONFIGURATIONS

-- -

I

.~

Dl

I

ha

I

I~II

uu-j

rEfl

__

s....mL~L

0

C

I

E

K9

TWO

BEDROOM UNIT

BASIC PLANS K10

KITCHEN CONFIGURATIONS

I

0

L.~.

THREE

BEDROOM UNIT

BASIC PLANS

K121

I__

_

I

I

KITCHE N CONFIGURATIONS

I---7

K13

FOUR

BEDROOM UNIT

BASIC PLANS

KITCHEN

CONFIGURATIONS

ONE

BEDROOM UNIT

BASIC PLAN

TWO

BEDROOM UNIT

BASIC PLAN

KITCHEN CONFIGURATIONS

I--

THREE

BEDROOM UNIT

BASIC PLAN

-

K17

KITCHEN CONFIGURATIONS

L~I~ 71

L-1

W

IwI

1]

nIII

uIli

Ii

ii

IiII

LI

BATHROOM COMPONENTS

=__

__

Cl

FORCED AIR HEATING

C2 I

I

III

BATHROOM CORE CONFIGURATIONS

F

00,

u

0

:31

FEH 110

C3

FORCED AIR HEATING

C4

BATHROOM CORE CONFIGURATIONS

II

C5

I

FORCED AIR HEATING WATER HEATER IN

KITCHEN MODULE

C6

BATHROOM CORE CONFIGURATIONS

C7

FORCED AIR HEATING

WATER HEATER IN

KITCHEN MODULE

C8

BATHROOM CORE CONFIGURATIONS

C9

FORCED AIR HEATING -

WATER HEATER IN

KITCHEN MODULE

Cio

BATHROOM CORE CONFIGURATIONS

C1l

HEAT PUMP

AND WATER HEATER

IN A COMMON SPACE

C 12

BATHROOM CORE CONFIGURATIONS

C13

HEAT PUMP

AND WATER HEATER

IN A COMMON SPACE

C14

BATHROOM CORE CONFIGURATIONS

C15

HEAT PUMP

AND WATER HEATER

IN A COMMON SPACE

C16

BATHROOM CORE CONFIGURATIONS

C17

SECONDARY

BATHROOMS

C18

BATHROOM CORE CONFIGURATIONS

D1

D1

L2

DI

Li

El

DC1

L1

E3

DC2

E3

DC3

L-A

DI

L3

E3

DC4

DELIVERY COMPONENTS

_

=

-

=

=

E4

=

___

L2

E4

DC5

88

DC6

________________

E4

L2

DI

B8

II

-

L2

D1

D1

E2

Li

01

=

w

B9

DELIVERY

DC7

B14

B8

DC8

COMPONENTS

DI

E4

L3

K3

D1

88

B6

C2

DC9

DC10

D1

ol

K5

C2

DC11

K7

Cs

DC12

DELIVERY COMPONENTS

D1

a

____

I

I

I

I----

I

I

I

II

---

t: =

Dl

-

-

F

I

n xi

-

-

-

-

LI

i I[FT IH

::-==t===

K11

C1O

________

fl

-

Ii

L//,

0

__

DC15

B10

C7

K7

D1

DC14

B10

Ca

K3

Dl

DC13

Cd

K14

*fl-

paB13

M

ttt

II

1

I

t

I

H

t

t

1

U

1

II

I

I

-

B10

DC16

DELIVERY COMPONENTS

84

B1o

B7

B13

B13

B10

82

DC17

B3

DC18

DC19

-

B5

B6

DC20

DELIVERY COMPONENTS

B13

B1

812

B10

L

B10

B12

B1

B7

DC21

B1O

B1

DC22

DC23

B10

~U__L_

B13

B1

B3

DC24

DELIVERY COMPONENTS

-1~

0

~J D

III

I

0

__

B10

B13

C17

B7

DC25

Blo

C16

B3

B1

B13

B10

DC26

DC27

DELIVERY COMPONENTS

1 BEDROOM

LEVEL 2

760 SO

I

0

C7 DI{iI

_--D

UNIT 1.1

UNIT PLAN

1 BEDROOM

LEVEL 2

805 SO

UNIT 1.2

UNIT PLAN

1 BEDROOM

LEVEL 3

849 SO

UNIT 1.3

UNIT PLAN

1 BEDROOM

LEVEL 4

893 SO

UNIT 1.4

UNIT PLAN

2 BEDROOM

LEVEL 1

937 SQ

UNIT 2.1

UNIT PLAN

2 BEDROOM

LEVEL 1

IDC19

937 SO

UNIT 2.2

UNIT PLAN

2 BEDROOM

LEVEL 1

893 SQ

UNIT

2.3

UNIT PLAN

2 BEDROOM

LEVEL 2

981 SQ

UNIT 2A

UNIT PLAN

2 BEDROOM

LEVEL 2

981 So

UNIT 2.5

UNIT PLAN

2 BEDROOM

LEVEL 2

981 SQ

UNIT 2.6

UNIT PLAN

2 BEDROOM

LEVEL 3

1203 SQ

2.7-

-

_

-

___I

_

00

UNIT 2.7

UNIT PLAN

2 BEDROOM

LEVEL 3

1158 SQ

UNIT 2.8

UNIT PLAN

2 BEDROOM

LEVEL 3

1158 So

UNIT 2.9

UNIT PLAN

2 BEDROOM

LEVEL 4

1424 SO

I

UNIT 2.10

UNIT PLAN

3 BEDROOM

LEVEL 1

I

Lik4

o

1070 SQ

UNIT 3.2

UNIT PLAN

3 BEDROOM

LEVEL 2

1379 SO

UNIT 3.3

UNIT PLAN

3 BEDROOM

LEVEL 2

D3 12

DS 7

23

EDC

1335 SO

UNIT 3.4

UNIT PLAN

3 BEDROOM

LEVEL 3

1680 SO

UNIT 3.5

UNIT PLAN

4 BEDROOM

LEVEL 1

1291 SO

UNIT 4.1

UNIT PLAN

4 BEDROOM

LEVEL 1

Li

IDC 23

1335 SO

UNIT 4.2

UNIT PLAN

4 BEDROOM

LEVEL 2

1601 SQ

UNIT 4.3

UNIT PLAN

4 BEDROOM

LEVEL 2

DC 13

DC 18

1468 SO

UNIT 4.4

UNIT PLAN

4 9EDROOM

LEVEL3

1680 SO

UNIT 4.5

UNIT PLAN

A

LEVEL 1

A

LEVEL 2

CLUSTER PLANS

A

LEVEL 3

CLUSTER PLANS

B

LEVEL 1

B

LEVEL 2

CLUSTER PLANS

B

LEVEL 3

CLUSTER PLANS

C

LEVEL 1

C

LEVEL 2

CLUSTER PLANS

|2.5

L.--.--..J-

'--------

--

-

-

-

-

-

~ ~

C

LEVELS 3

CLUSTER PLANS

GRID LINES 13'-4" 0.C.

CHASE AREA

4,

=1.

I-Il

1=

_______________________________________________________________

3"x10"E

.

OPEN WEB FLOOR JOIST 20"QC.

FLOOR FRAMING

PLAN

-4-

GRID LINES 13'-4"O.C.

CHASE AREA

N

N

3"x10"c

4"C CEILING JOIST 16" O.C.

-n

CEILING FRAMING PLAN

STEEL TUBE

21/2"x3" COLUMN

COLUMN BASE PLATE

END COLUMN

STEEL TU

2 1/2"x5"

IN

INTERIOR COLUMN

METAL SHIM AND

CONNECTOR PLATE

0

GRID LINES 13'-4"O.C.

+o

0

0

TWO DELIVERY COMPONENT

CONNECTION

COLUMN

DETAILS

3"xlO"E

THREE DELIVERY COMPONENT

CONNECTION

METAL SHIM AND

CONNECTOR PLATE

THREE DELIVERY COMPONENT

CONNECTION

CORNER BRACKET

END COLUMN

THREE DELIVERY COMPONENT

CONNECTION

COLUMN

DETAILS

CORNER BRACKET RIVET

TWO DELIVERY COMPONENT

CONNECTION

POSITION FOR BOLTING

TWO DELIVERY COMPONENT

CONNECTION

CONNECTOR PLATE

METAL SHIM AND

COLUMN BASE PLATE

THREE DELIVERY COMPONENT

CONNECTION

COLUMN DETAILS

METAL SHIM AND

CONNECTIOR PLATE

THREE DELIVERY COMPONENT

CONNECTIO

3"x10" E

FOUR DELIVERY COMPONENT

CONNECTION

STEEL CORNER BRACE

CANTILEVER CONDITION

COLUMN

DETAILS

CONTINUOUS METAL

FLASHING

SECTION AT ROOF

EXTERIOR WALL

COLUMN BASE PLATES

BOLTED TO METAL CONNECTOR

3 E 6 RIVET CONNECTION

SECTION AT CEILING

FLOOR CONNECTION

EXTERIOR WALL

GYPSUM SCREW

ATTACHED TO METAL STUDS

INSULATION

WOODROCK SIDING

OVER SHEATHING

3 E 10

OPEN WEB

FLOOR JOIST

STEEL CONNECTOR

BOLTED TO FOOTING

SECTION AT FLOOR

EXTERIOR WALL

r

WALL DETAILS

CONTINUOUS METAL

FLASHING

GYPSUM ATTACHED TO

RESILIENT CHANNELS

3 E 6 METAL CHANNEL

4" METAL CEIUNG JOIST

RIVET ATTACHED TO CHANNEL

SECTION AT CEILING/

FLOOR CONNECTION

INTERIOR WALL

METAL STUDS

ATTACHED TO 3 E 10

STEEL CONNECTOR

BOLTED TO FOOTING

SECTION AT FLOOR

INTERIOR WALL

WALL DETAILS

METAL CONNECTOR BOLTED

TO COLUMN BASE PLATES

OPEN WEB ROOF JOIST

GYPSUM ATTACHED

TO RESILIENT PANELS

n

MINERAL FIBER

4" METAL CEILING JOIST

RIVETED TO CHANNEL

SECTION AT CEILING /

FLOOR CONNECTION

FIRE WALL

GYPSUM SCREW ATTACHED

TO METAL STUDS

2 1/2"x5" STEEL TUBE COL.

~~~~~~1

.. i

1" CONSTRUCTION CLEARANE

3 C10

w

OPEN WEB

FLOOR JOIST

mww

STEEL CONNECTOR

BOLTED TO FOOTING

ii

SECTION AT FLOOR

FIRE WALL

I'

Ii

II

I I

Ii

ii

II

WALL DETAILS

STEEL CONNECTOR BOLTED

TO COLUMN BASE PLATE

SECTION AT ROOF

INTERIOR WALL

PLYWOOD SUBFLOOR

~~~~1

FIRE RETARDANT PLYWOOD

SLIP ON PIN CONNECTION

METAL CONNECTOR BOLTED

TO COLUMN BASE PLATES

3 E6

4"METAL CEILING JOIST

RIVET ATTACHED TO CHANNEL

SECTION AT CEILING /

FLOOR CONNECTION

INTERIOR WALL /

EXTERIOR

-0

IN

COLUMN

GYPSUM SCREW

ATTACHED TO METAL Sl

MINERAL FIBER BOARD

W/ METAL COVER

2 1/2"x 5"

METAL COLUMN

SECTION AT FLOOR

EXTERIOR WALL /

EXTERIOR COLUMN

WALL DETAILS

LATERAL SUPPLY

AND RETURN

VERTICAL SUPPLY

AND RETURN

7Z-7

WASTE LINE

COLD WATER SUPPLY

HOT WATER SUPPLY

KITCHEN EXHAUST

BATH AND DRYER EXHAUST

a

J-~---__

LII

'II

UNIT EXHAUST

HEATING DUCT

ELECTRICAL AND COMMUNICATION

WATER ALTERNATE

GAS SUPPLY

FAN COIL SUPPLY

FAN COIL VENTILATION

o000

0

0

000

I- -

CHASE DETAILS

AIR DIFFUSER

HEATING DUCT

FLEXIBLE CONNECTOR

E

PLUMBING BRANCH

w

It-

-

mmgm

%

j~~:zz:

HEATING SOURCE ABOVE

.. IN

N

~1Iiz1

lILlY

j

M

KI

6%.'

MN

MECHANICAL PLAN

I

114

ACCESS PANEL

ACCESS PANE

HEATING DUCT

FLEXIBLE CONNECTOR

METAL REINFORCING PLATE

LA

I

TRANSVERSE SECTION /

HEAT DUCT CONNECTION

OPEN WEB FLOOR JOIST

HEATING DUCT

-2

LONGITUDINAL SECTION /

HEAT DUCT AND FLOOR JOISTS

HOT AND COLD WATER SUPPLY

I )ONI

WASTE LINE

HEATING~ DUCT

14FATING ntICT

TRANSVERSE SECTION

MID SPAN

/

MECHANICAL

DETAILS

EXTERIOR WALL OPTIONS

EXTERIOR WALL OPTIONS

-

-.N

N

N

-

N

N

I

N

N

N

-

-

1 1,

EXTERIOR WALL OPTIONS

IZ~

I.~i1

II,~IU

*i,~ii

I~1

II/\II

II/\IE

II/\II

I~I

Lii

EXTERIOR WALL OPTIONS

EXTERIOR WALL OPTIONS

IL

EXTERIOR WALL OPTIONS

B I BL I OGRAPHY

Books and Reports

1. The Building Research Division Team, Guide Criteria

for the Design and Evaluation of: Operation Breakthrough, Department of Housing and Urban Development,

United States Government Printing Office, Washington,

D.C.,

1970

2. Building Systems Development Incorporated, University

Residential Building System, Contract Documents and

Proformance Specifications, Educational Facilities

Laboratories,

New York, New York,

June 1967

3. Building Officials and Code Administrators International

1970

Incorporated, The BOCA Basic Building Code

-

Fifth Edition, Interstate Printers and Publish-

ers, Danville, Illinois, 1970

4. Bulbulian, Francis A. and Goodman, Joel H.,

"A Multi-

Story Industrialized Housing System," Massachusetts

Institute of Technology, April 1968

5. Cornell University, "The New Building Block,"

Press,

Ithaca,

New York,

1969

Cornell

6. The Design Team 1971, "Housing Systems,"

University

of California, Berkeley, 1971

7. Dietz, Albert G. H. and Cutler,

Lawrence S.,

trial ized Building Systems For Housing,

Indus-

Massachusetts

Institute of Technology Press, Cambridge, Massachusetts, 1970

8. Fan, Samuel S. L.,

In Wood,"

"An

Industrialized Housing System

Massachusetts Institute of Technology,

June 1972

9. Horayangkura, Vimolsiddhi;

Intha, Chalermpol; and

Surintraboon, Chumpon, An Industrialized Housing

System," Massachusetts

Institute of Technology,

June, 1970

10. Kell,

Duane A. and Rafferty, Craig E.,

"A Housing

System: A Study Based on the Production Capabilities

of the Mobile Home Industry," Massachusetts

of Technology,

Institute

June 1972

11. Litle, William A. and Herrey, Antony, "Industrialized Housing Feasibility Study," Massachusetts

tute of Technology, 1970

Insti-

12. Massachusetts

Institue of Technology, Department

of Architecture, "Housing Systems:

Seven Studies

for Factory Produced Concrete and Steel Modular

Units,"

Limited published master's thesis,

Massachusetts Institute of Technology, 1971

13. Moller, Clifford B.,

and Our Mental

Architectural Environment

Health, Horizon Press, New York,

New York, 1968

14.

Quon, Norman, "A Cost Design System For Residential Building Systems," Massachusetts

Institute

of Technology

15.

Rowland, Norman, Low Income Housing Demonstration

Program, Clearinghouse for Federal Scientific and

Technical

April

1969

Information, Springfield, Virginia,

Manufacturers Printed Material

1. Bock Industries Incorporated

Elkhart, Indiania

2. Wausau Homes Incorporated

Wausau, Wisconsin

3. Weston Homes Incorporated

Rothschild, Wisconsin

4. Westinghouse Home Systems Division

Pittsburg, Pennsylvania