Mechanical Behavior

advertisement

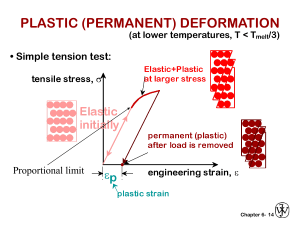

Mechanical Behavior Material Sciences and Engineering MatE271 Week9 1 Mechanical Behavior 1. Support load - Applied vs. dead weight - Static vs. dynamic 2. Controlled deformation -Small vs. large 3. Reliability • How microstructure affects mechanical properties • Tailored microstructure for mechanical properties Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Application Week 9 2 1 Goals for this unit (Ch. 6) Ø Detailed coverage of basic mechanical properties - Describe the concepts of stress and strain - Differentiate between elastic and plastic deformation - Quantify elastic properties of materials - Describe measures of hardness, ductility, toughness and strength - Understand fracture, fatigue and creep failures Material Sciences and Engineering MatE271 3 Week 9 6.1 Stress vs. Strain Engineering Stress - load/original cross sectional area Area (Ao) load Displacement (DL) Length (Lo) Stress s = P/ Ao (N/m2 ) Strain e = DL/ Lo For tensile or compressive stresses There are also shear and torsional stresses Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 4 2 Stress vs. Strain: units ØStress s = F/Ao (where Ao is the original cross-sectional area) psi (pounds force per square inch) MPa (Mega Pascals = 106 N/m2 ) ØStrain e = DL/Lo (where Lo is the original length) unitless-sometimes expressed as a percentage Material Sciences and Engineering MatE271 Week 9 5 Shear Stress vs. Shear Strain Dy a Lo z y Ps x t = Ps / As Material Sciences and Engineering Material Sciences and Engineering, MatE271 t g = tan a = Dy /Lo MatE271 Week 9 6 3 Application of Loads Tension Material Sciences and Engineering Compression MatE271 Week 9 7 Application of Loads Shear Torsional Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 8 4 Tensile testing Load cell • One of the most common stress-strain Grip tests performed is tensile testing Specimen Gage length • There are standards for the shape and size Grip Crosshead and finish of test specimens • Tensile testing equipment elongates a specimen at a constant rate and measures: – Load (load cell) – Elongation (extensometer) Material Sciences and Engineering MatE271 Tensile testing Week 9 Tensile strength Yield strength Load cell 9 Fracture Specimen Gage length Grip Stress Grip Crosshead Elastic Plastic Strain Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 10 5 Elastic Deformation ØDefinition • When stress and strain are proportional • Non-permanent • When stress is removed, strain disappears • i.e. the sample returns to it’s original shape ØWhat is happening? • small changes in inter-atomic spacing • bonds are stretching but not breaking Material Sciences and Engineering MatE271 Week 9 11 Modulus of elasticity depends on bond strength! Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 12 6 Modulus of Elasticity • Slope of stress-strain curve in elastic region s = (E)(e) (Hooke’s Law) E - modulus of elasticity (Young’s modulus) Material E (GPa) Steel 207 Aluminum 69 Al2O3 370 SiC 470 Material Sciences and Engineering Elastic modulus is the slope of the atom force vs distance curve at equilibrium spacing MatE271 Week 9 13 Elastic Stress - Strain Behavior ØShear stress and strain are also proportional to each other in the elastic region: t = Gg t = shear stress g = shear strain G = shear modulus Material Sciences and Engineering Material Sciences and Engineering, MatE271 Compare to s = Ee MatE271 Week 9 14 7 Example Problem ØA tensile force of 2000N is applied along the axis of an aluminum cylindrical specimen (E = 70 GPa, 1 m long, radius 0.01 m). Assuming the deformation is elastic, estimate the elongation. Material Sciences and Engineering MatE271 Week 9 15 Poisson’s Ratio ØQ. When a specimen is elongated in one direction - what happens in the other two directions? ØA. Usually, they contract. ØThe ratio of lateral to axial strains is called Poisson’s ratio ey e The - sign assures u u=- x =will be positive ez ez z Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 16 8 Poisson’s Ratio Material Sciences and Engineering MatE271 Week 9 17 Poisson’s Ratio Ø Q. What is Poisson’s ratio for an isotropic material? Ø A. If the properties are the same in all directions, then n = 0.25 Ø Most metals have a n = 0.25 to 0.35 Ø Admissible range -1 £ n £ 0.5 • for no volume change n = 0.5 Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 18 9 Poisson’s Ratio ØShear and elastic moduli are related: E = 2G(1+n) ØMost materials are elastically anisotropic • E varies with crystallographic direction • most polycrystalline materials may be considered to be isotropic ØMost engineering materials are polycrystalline Material Sciences and Engineering MatE271 Week 9 19 Tensile strength Plastic Deformation Fracture Stress Ø There is a limit to Yield strength how much a metal can be deformed before it will not return to its original shape when the stress Plastic is removed Elastic Ø After reaching elastic Strain limit, deformation is plastic (in metals dislocation movement). (in ceramics micro-cracking) Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 20 10 Plastic Deformation Stress Elastic Plastic sy Strain Material Sciences and Engineering Ø In metals: Plastic deformation corresponds to the breaking of bonds with atom neighbors and reforming bonds with new neighbors - (dislocation motion) Ø Beyond Yield point, stress is not proportional to strain (Hooke’s law is not valid) MatE271 Week 9 21 Slip produces plastic deformation • During plastic deformation, shear stresses cause dislocation movement resulting in slip. • This deformation is permanent (not recovered when stress is removed.) Check week 5 slides 20-33 Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 22 11 Yielding and Yield Strength Ø Most structures are designed such that only elastic deformation occurs when a stress is applied Ø The point at which plastic deformation occurs must be known (what stress level will bend the metal permanently?) Ø Phenomenon is called yielding Ø For metals that experience a gradual transition, the point is called the proportional limit Material Sciences and Engineering MatE271 Week 9 23 Proportional Limit Elastic Plastic Stress sy P ØHow do you know where sy is? ØBy convention, a specified strain offset of 0.002 is used to identify the yield strength, sy. Strain 0.002 0.2% Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 24 12 Stress (MPa) Elastic recovery after plastic deformation Elastic Recovery Strain (mm/mm) Material Sciences and Engineering MatE271 25 Week 9 Work Hardening (Strain Hardening) Yield point multiplies the number of dislocations • As each increment of plastic Stress • Process of plastic deformation (slip) deformation occurs, dislocations find it harder and harder to move because of “entanglement” with ever increasing Strain number of dislocations • Result is that yield strength increases after plastic deformation (“strain hardening”) Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 26 13 Yield Point Phenomenon Stress Ø Some steels show a yield point which occurs abruptly Upper Yield Pt. sy Lower Yield Pt. Strain Material Sciences and Engineering Ø Yield point is taken as the average stress of the lower yield point Ø Yield points for steels vary from 5,000 to 200,000 psi! MatE271 27 Week 9 Tensile strength Tensile Strength Yield strength Fracture Stress Ø After yielding, stress increases to a maximum, then decreases, and eventually the material Elastic fractures Ø Tensile strength is the stress at the maximum of the engineering stress vs strain curve. Ø Deformation up to this point is uniform throughout the sample Ø After maximum stress, necking occurs Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 Plastic Strain 28 14 True vs. Engineering Stress and Strain • Does material actually get weaker after TS has been exceeded? • No, that is an “artifact” of using engineering stress instead of true stress in the plot. • X-sectional area is decreasing, and especially after necking starts. Material Sciences and Engineering MatE271 Week 9 29 True Stress and Strain True Stress = P/A True Strain = DL/L (A: is the current area) (L:current length) Vol= AL =Ao Lo P L strue= Ao Lo • When strength of a metal is cited, for design purposes, the yield strength is used. • The fracture strength is the stress at fracture Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 30 15 Definition - Ductility Ø Measure of degree of plastic deformation that has been sustained before fracture Ø If there is little plastic deformation before fracture --- called brittle Ø Ductility = percent elongation %EL = Material Sciences and Engineering (l f - lo ) lo x 100 MatE271 Week 9 31 MatE271 Week 9 32 Ductility Material Sciences and Engineering Material Sciences and Engineering, MatE271 16 Ductility Why is ductility important? Ø Specifies how much a structure will deform before fracture Ø Specifies how much deformation is allowable during fabrication Ø Ductility is strongly temperature dependent – i.e., ductile-to-brittle transitions Material Sciences and Engineering MatE271 Week 9 33 Toughness Ø Capacity to absorb energy when deformed, up to fracture Ø Given by area under curve Ø Describes the combination of strength and ductility tougher Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 34 17 Charpy Impact Test of Toughness Seldom have complete stess-strain curve, so an impact test is usually used to measure toughness Material Sciences and Engineering MatE271 Week 9 35 Comparison of Mechanical Characteristics Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 36 18 F Hardness Hardness: surface resistance to indentation d H= F/Aprojected Ap - Quantitative means use a small indenter forced into the surface - Indenter: round (ball) pointed (cone or pyramid) Material Sciences and Engineering MatE271 Week 9 37 Hardness Tests Ø There is a correlation between tensile strength and hardness Ø Hardness tests are simple and inexpensive Ø Hardness tests are nondestructive (you still have a usable sample when you are done) Ø Other properties can be estimated from hardness information. Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 38 19 Strength, MPa Tensile Strength often scales with Hardness Hardness, BHN Material Sciences and Engineering MatE271 Week 9 39 Hardness Tests Ø Although the scales are quantitative, the numbers are only relative (rather than absolute values) Ø Only compare hardness values obtained using the same method Ø Methods of testing • Rockwell Hardness • Brinell Hardness • Knoop and Vickers Microhardness Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 40 20 Rockwell Hardness Ø Most common method Ø Indenters are hardened steel balls of various diameters Ø The hardness is determined by the difference in depth of the indentation of two different loads Ø Modern instruments are automated Material Sciences and Engineering MatE271 Week 9 41 Brinell Hardness Ø Hard, spherical indenter is forced into the surface (like for Rockwell) Ø The indentor is steel or WC (tungsten carbide) Ø Standard loads are used Ø The load is maintained for a specified amount of time Ø The diameter of the indentation is measured with a microscope Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 42 21 Knoop and Vickers Ø Very small diamond indenter with a pyramid geometry is forced into the specimen. Ø The resulting impression is measured Ø Knoop is frequently used for ceramics Material Sciences and Engineering MatE271 Week 9 43 Summary of Standard Hardness Tests Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 9 44 22