b g σ π

advertisement

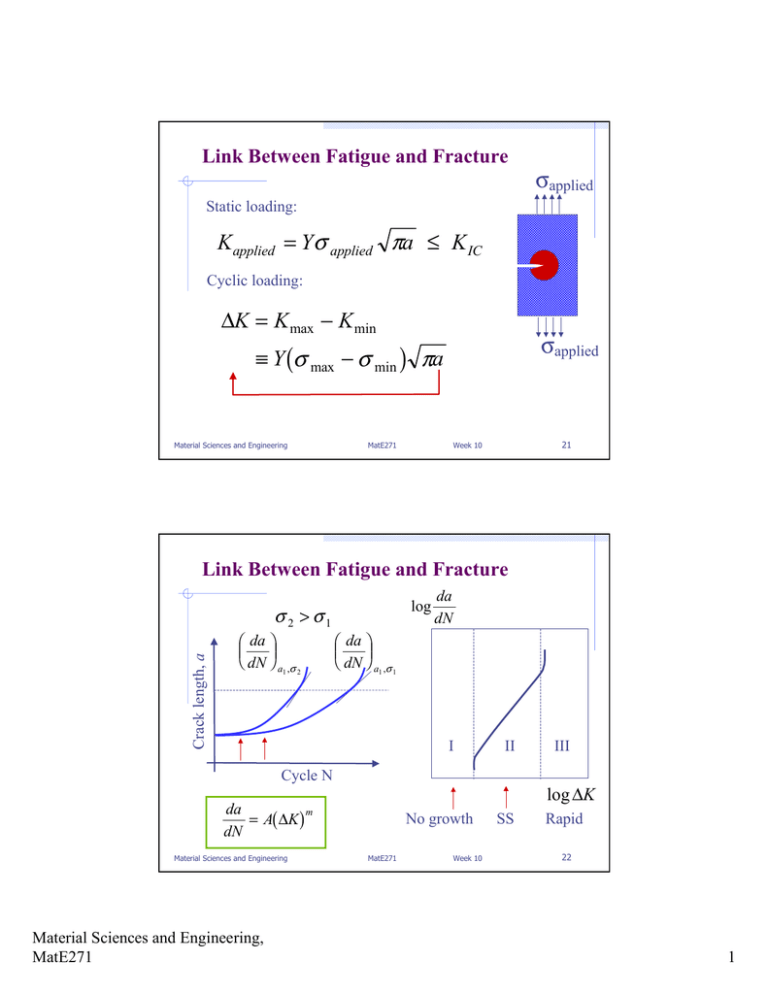

Link Between Fatigue and Fracture σapplied Static loading: Kapplied = Yσ applied πa ≤ K IC Cyclic loading: ∆K = K max − Kmin b ≡ Y σ max − σ min Material Sciences and Engineering g σapplied πa MatE271 21 Week 10 Link Between Fatigue and Fracture Crack length, a σ2 >σ1 FG da IJ H dN K a1 ,σ 2 log FG da IJ H dN K da dN a1 ,σ 1 I II Cycle N b g da = A ∆K dN Material Sciences and Engineering Material Sciences and Engineering, MatE271 III log ∆K m No growth MatE271 Week 10 SS Rapid 22 1 Q? How does material fail by fatigue? Metals: (sequence of events) 1. 2. Ceramics: 1. 2. Material Sciences and Engineering MatE271 23 Week 10 Example: Fatigue Strength, F.S. (MPa) For an alloy with T.S.= 800MPa, Estimate σapplied Maximum Use safety factor = 2. Fig. 8-16 F.S.= 1/2 T.S. F.S.= 1/4 T.S. Tensile strength T.S. (MPa) Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 10 24 2 6.5 Creep and Stress Relaxation ØIncreased Strain with time under constant stress • Continuous plastic deformation of materials subjected to a constant stress at T > 0.4Tm – Occurs at stresses well below room temperature yield strength • Both temperature and applied stress influence creep behavior • Alloys resistant to creep have - high E - high melting T Material Sciences and Engineering MatE271 Week 10 25 MatE271 Week 10 26 Stages of Creep Load cell Grip Specimen Grip Dead weight Material Sciences and Engineering Material Sciences and Engineering, MatE271 3 Creep depends on σ and T ε Increasing σ Creep rate affected by changes in applied stress time ε Increasing T Creep rate affected by changes in temperature time Material Sciences and Engineering MatE271 Week 10 27 Creep Mechanisms Ø. • vacancy diffusion • grain boundary diffusion • dislocation motion • grain boundary sliding - Different for different materials - Creep Strain rate follow the Arrhenius expression ε& = Ce − Q RT For the needed activation energy to move any of these defects Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 10 28 4 High Temperature Alloys o Improve creep resistance • higher Tm (less diffusional creep) • greater E (harder) • larger grain size (reduce grain boundary sliding) o Metals include • stainless steel • refractory metals • superalloys (e.g. Co-Ni superalloys) o Processes include • addition of insoluble dispersed phase • directional solidification Material Sciences and Engineering MatE271 Week 10 29 Stress Relaxation: ØDecrease Stress with time under constant strain Creep Stress Stress Relaxation Strain Material Sciences and Engineering Material Sciences and Engineering, MatE271 Strain MatE271 Week 10 30 5 Summary of Mechanical Properties of Metals • Describe the concepts of Stress and Strain • Differentiate between Elastic and Plastic Deformation • Quantify Elastic Properties of Materials • Describe measures of hardness • Describe different modes of failure • Explain fatigue and creep ØRead Class Notes and Relevant portions of Shackelford 2001 Ch. 6:186-200, 210-230, Ch. 8:270-288 Material Sciences and Engineering Material Sciences and Engineering, MatE271 MatE271 Week 10 31 6