COOLING C ONTROL OPTIMIZATION Optimize Performance of Your Cooling System with

advertisement

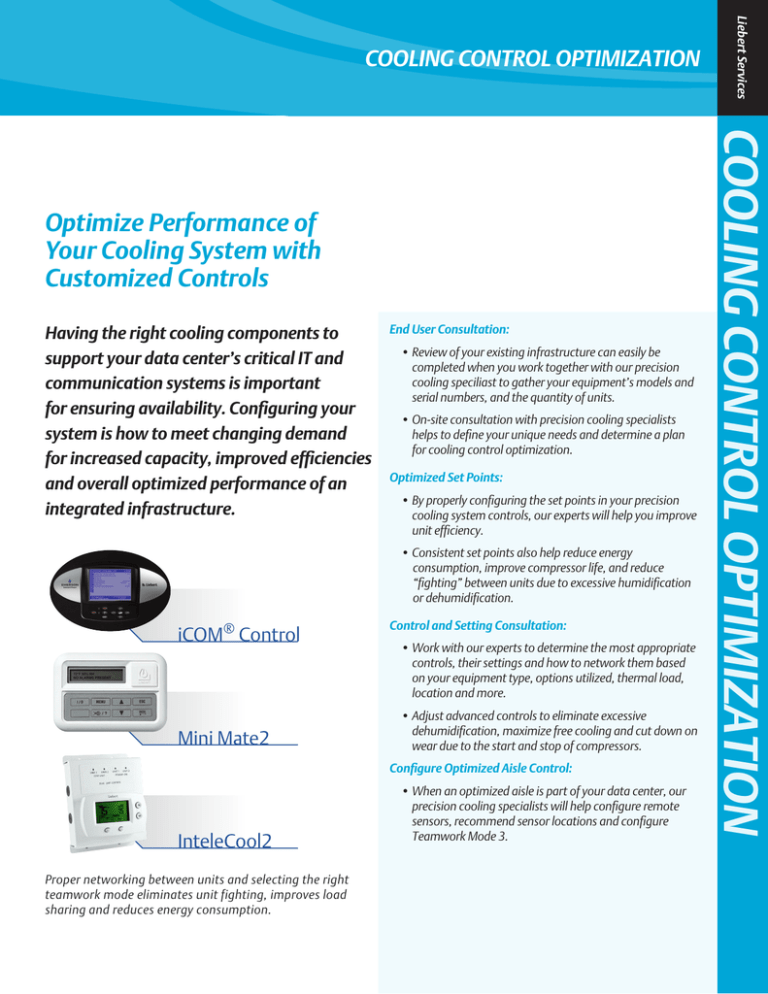

Having the right cooling components to Mini Mate2 support your data center’s critical IT and communication systems is important for ensuring availability. Configuring your system is how to meet changing demand InteleCool2 for increased capacity, improved efficiencies and overall optimized performance of an integrated infrastructure. End User Consultation: • Review of your existing infrastructure can easily be completed when you work together with our precision cooling speciliast to gather your equipment’s models and serial numbers, and the quantity of units. • On-site consultation with precision cooling specialists helps to define your unique needs and determine a plan for cooling control optimization. Optimized Set Points: • By properly configuring the set points in your precision cooling system controls, our experts will help you improve unit efficiency. • Consistent set points also help reduce energy consumption, improve compressor life, and reduce “fighting” between units due to excessive humidification or dehumidification. iCOM® Control Mini Mate2 Control and Setting Consultation: • Work with our experts to determine the most appropriate controls, their settings and how to network them based on your equipment type, options utilized, thermal load, location and more. • Adjust advanced controls to eliminate excessive dehumidification, maximize free cooling and cut down on wear due to the start and stop of compressors. Configure Optimized Aisle Control: InteleCool2 Proper networking between units and selecting the right teamwork mode eliminates unit fighting, improves load sharing and reduces energy consumption. • When an optimized aisle is part of your data center, our precision cooling specialists will help configure remote sensors, recommend sensor locations and configure Teamwork Mode 3. COOLING CONTROL OPTIMIZATION Optimize Performance of Your Cooling System with iCOM® Control Customized Controls Liebert Services COOLING CONTROL OPTIMIZATION Work with the Precision Cooling Industry Leader to Customize System Features Using the factory-trained specialists from Emerson Network Power to customize your data center’s precision cooling system allows you to easily optimize performance for your application. As the original equipment manufacturer, we have unmatched technical knowledge and resources that help you quickly realize the benefits of enhanced cooling control. • Industry Leadership — With more than four decades of experience in precision cooling, Liebert Services understands every aspect involved in keeping your data center up and running. • Expertise — Our regionally based factory-trained technicians are required to attend and pass annual technical training and safety classes. We are experts in the ability to apply the latest technology and configure it properly. As the original equipment manufacturer, we have direct access to the engineering group who built the equipment including access to technical documentation. • Parts Availability — Through our network of service partners, we offer national coverage of all factory parts with local stocking, inventory and distribution. Control disables heaters in “cold zone.” System-level control reduces conflict between room air conditioning units operating in different zones in the data center. EmersonNetworkPower.com 800 LIEBERT (543 2378) CS-00193 (05/13) Emerson Network Power, Liebert Services and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co. All other trademarks are the property of their respective owners. ©2013 Emerson Electric Co. Liebert Services COOLING CONTROL OPTIMIZATION