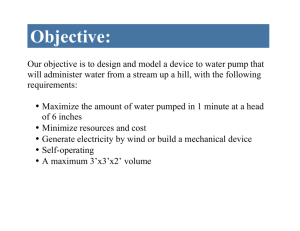

DESIGN AND IMPLEMENTATION OF A LOW COST GRID-CONNECTED 10 KW HYDRO

advertisement