Document 10549344

advertisement

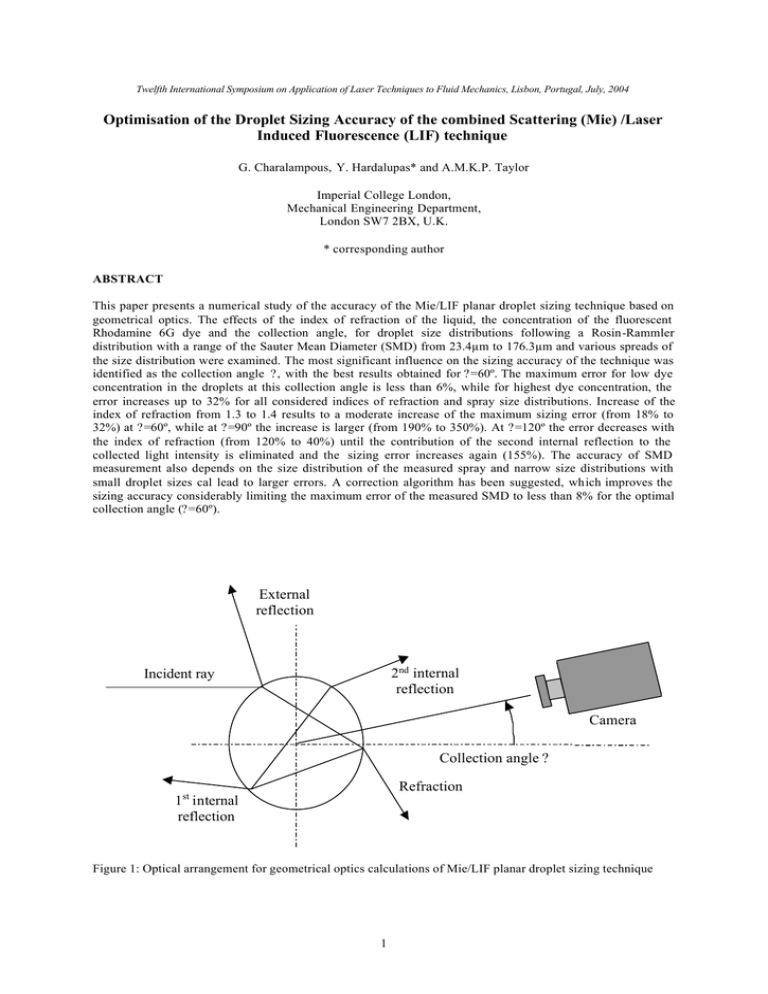

Twelfth International Symposium on Application of Laser Techniques to Fluid Mechanics, Lisbon, Portugal, July, 2004 Optimisation of the Droplet Sizing Accuracy of the combined Scattering (Mie) /Laser Induced Fluorescence (LIF) technique G. Charalampous, Y. Hardalupas* and A.M.K.P. Taylor Imperial College London, Mechanical Engineering Department, London SW7 2BX, U.K. * corresponding author ABSTRACT This paper presents a numerical study of the accuracy of the Mie/LIF planar droplet sizing technique based on geometrical optics. The effects of the index of refraction of the liquid, the concentration of the fluorescent Rhodamine 6G dye and the collection angle, for droplet size distributions following a Rosin-Rammler distribution with a range of the Sauter Mean Diameter (SMD) from 23.4µm to 176.3µm and various spreads of the size distribution were examined. The most significant influence on the sizing accuracy of the technique was identified as the collection angle ?, with the best results obtained for ?=60º. The maximum error for low dye concentration in the droplets at this collection angle is less than 6%, while for highest dye concentration, the error increases up to 32% for all considered indices of refraction and spray size distributions. Increase of the index of refraction from 1.3 to 1.4 results to a moderate increase of the maximum sizing error (from 18% to 32%) at ?=60º, while at ?=90º the increase is larger (from 190% to 350%). At ?=120º the error decreases with the index of refraction (from 120% to 40%) until the contribution of the second internal reflection to the collected light intensity is eliminated and the sizing error increases again (155%). The accuracy of SMD measurement also depends on the size distribution of the measured spray and narrow size distributions with small droplet sizes cal lead to larger errors. A correction algorithm has been suggested, which improves the sizing accuracy considerably limiting the maximum error of the measured SMD to less than 8% for the optimal collection angle (?=60º). External reflection 2nd internal reflection Incident ray Camera Collection angle ? Refraction 1st internal reflection Figure 1: Optical arrangement for geometrical optics calculations of Mie/LIF planar droplet sizing technique 1 1. INTRODUCTION A Planar Droplet Sizing (PDS) technique has been proposed (e.g. Yeh et al, 1993, Sankar et al, 1999, LeGal et al, 1999), which makes use of simultaneous imaging of intensities of scattered and fluorescence, due to a dye present in the liquid, light from droplets during illumination of a spray with a laser sheet. The PDS technique is based on the assumption that, when light passes through droplets containing a fluorescent dye, the intensity of the emitted fluorescent light is proportional to the volume of the spherical droplet (1) and the intensity of the scattered light is proportional to the surface area of the spherical droplet (2). ifluorescence = afD3 (1) = asD2 (2) iscattered Thus, the Sauter Mean Diameter (SMD) of all droplets present in a probe volume defined on the laser sheet is proportional to the ratio of the fluorescence to scattered light intensities: SMD = ∑ D ∑D 3 2 = 1 ∑i K ∑i fluorescen ce (3) scattered with K=a f/as . It should be noted that in equation (3), K is defined as constant and independent of the droplet diameter. This assumption has been used by previous studies (e.g. Stojkovic and Sick, 2001) This assumption was evaluated theoretically using a geometrical optics approximation, developed by Domann and Hardalupas (2001), which showed that deviations of the intensities from the assumed cubic and square droplet diameter dependencies could occur (Domann and Hardalupas, 2001). It was shown that deviations in the volume dependence of the fluorescence intensity were caused by the attenuation of the laser light within the droplet volume due to absorption by the dye. This effect becomes more profound for droplets of larger diameter and higher dye concentrations. In addition, the scattered light intensity was affected by the dye concentration, due to attenuation of contributions from refraction and internal reflections. The consequences of the change of the dependence of scattered and fluorescence intensities on droplet diameter on the assumption of a constant value of K was examined by Domann and Hardalupas (2003) and found that the value of K depends on droplet diameter. This work suggested a method to process the measured intensities in order to obtain quantitative SMD measurements in sprays, which was verified experimentally. The work of Domann and Hardalupas (2001) was limited to the behaviour of the constant K for one experimental arrangement, where the light was detected at angles normal to the laser sheet illumination of sprays (i.e. 90°), the dye concentration was fixed at a low concentration to ensure limited effect on the dependence of intensities on droplet diameter and the effect of the real part of the refractive index of the liquid was not examined. The purpose of the current work is to investigate numerically the effects of scattering angle, real part of the refractive index of the liquid and dye concentration on the dependence of the value of K on droplet diameter. In this way, data processing approaches, intending to minimise the error of the measurement of the SMD of spray droplets with the PDS technique, can be suggested depending on the properties of the liquid, droplet size range and available optical access during application of the technique. 2. THEORETICAL APPROACH The calculations were based on the geometrical optics approximation. This method, originally developed by (van de Hulst, 1957), is based on tracing the paths of a light from an incident laser beam through a spherical droplet. The intensity of the light scattered by a sphere located in a single laser beam was calculated with the geometrical optics approach with proper account of the phases between surface reflection, refraction, 1st and 2nd internal reflection. The scattering of a single incident ray is shown in figure 1. This approach was extended to droplets with fluorescing dye by taking into account the light absorption along these paths, calculated by the Beer-Lambert law (Domann and Hardalupas, 2001). The fluorescence intensity was estimated for each light path from the fluorescence efficiency of the dye and summation over all the light paths calculated the overall fluorescence intensity emitted by a droplet. This method also accounted for the integration of the light intensities over the pixels of a CCD camera and was in good agreement with Mie theory calculations (Domann et al, 2002). The overall scattered and fluorescence intensities were calculated from the geometrical optics approach from all the droplets present in various droplet size distributions with known Sauter Mean Diameters. The calculated intensities were then used to estimate the corresponding intensity ratios for each SMD. Equation (1) was then 2 applied to calculate the required value of the calibration constant K, so that the calculated intensity ratios could be converted to the value of the Sauter Mean Diameter of the assumed droplet size distribution. In this way, the dependence of the value of K on droplet diameter could be evaluated. Calculations were performed for many droplet size distributions, determined according to a Rosin-Rammler distribution function (Rosin and Rammler, 1933): 1-Q = exp(-(D/x) q) (4) where Q is the fraction of the total volume of the liquid carried by droplet diameters smaller than D and q and x are variables associated with the spread of the size distribution and the most probable diameter. The size distribution, estimated from eq. (4), is a cumulative volume distribution and is converted into a droplet number density size distribution. The function parameters q and x were selected in order to obtain wide variation of the spread of the droplet size distribution and the corresponding values of Sauter Mean Diameter. 5396 droplet distributions with a range of SMD from 23 µm to 167 µm and various widths were examined. For the results presented in this paper, four values of the refractive index of the liquid were considered, ranging from m=1.300 to m=1.400. This region covers most liquids of interest, including water (m≈1.333) and hydrocarbon fuels (m≈1.400). The dye characteristics were chosen to be that of Rhodamine 6G according to (Guilbault, 1973). Three cases of the dye concentration were examined, namely 0.001g/l, 0.010g/l and 0.100g/l corresponding to optical depths of 54.4mm, 5.44mm and 0.544 mm, which result in little, moderate and significant attenuation of the incoming light within the droplet. At each light collection angle ? (figure 1), the total intensity of the scattered light is comprised by the sum of the components of the scattered light, which contribute at that angle (there is also double contribution in angle regions of the 1st and 2nd internal reflections due to the existence of the 1st and 2nd rainbow angles). The region of angles at which each component of scattered light contributes depends on the index of refraction of the droplet as can be seen in figure 2 (for clarity only the cases of m=1.333 and m=1.400 have been plotted). Based on this plot three collection angles of scattered and fluorescence light were considered to evaluate the influence of the different component contributions to the scattered light. The cases considered were at scattering angle ?=60°, where the refraction and the external reflection are significant, at ?=90°, where the external reflection is dominant, and at ?=120°, where the external reflection and the second internal reflection are important. The calculations were performed with droplet size resolution of 1 µm. 1.0E+07 External reflection 1.0E+06 1.0E+05 82.8 88.8 m=1.333 137.9 1st internal reflection iscatter(D) Refraction 165.6 m=1.400 1 st rainbow angle 146.8 111.6 2nd internal reflection 2 0 30 60 113.0 90 120 nd 60° 90° 120° 1.0E+03 177.7 129.1 93.5 1.0E+04 1.0E+02 rainbow angle 1.0E+01 150 1.0E+00 180 Scattering angle ? 1 10 100 1000 D (µm) Figure 2: Contributions of the scattered light components with collection angle ?. (Values for m=1.333 and m=1.444 are positioned above and below each line respectively) Figure 3: Variation of scattered light intensity with droplet diameter (for water droplets with m=1.333 and dye concentration 0.001g/l) 3. RESULTS & DISCUSSION The effect of the collection angle, where the CCD camera used to record the scattered light intensity is positioned, on the scattered light intensity is shown in figure 3 as a function of the droplet diameter, for the low dye concentration (0.001g/l). The strong dependence of the amplitude of the scattered light intensity on the collection angle is apparent. In order to investigate if the assumption of the D2 dependence of the scattered light intensity is valid, the scattered light intensities were fitted to a power function: iscattered=ksDEs (5) The values of the exponent Es for the same dye concentration where the attenuation of light within the droplet volume is small are shown in Figure 4. The value of 2 is the desired value, because it indicates proportionality 3 2.00 2.00 1.98 1.95 1.96 1.90 Scatter Exponent Es Scatter exponent Es with the droplet surface area. The angle at which the value of Es is closer to the ideal value of 2 is 60º, where refraction of the laser light is the dominant scattering contribution. This comes in contradiction to the most common choice of collection angle of 90º for recording images of the scattered light intensity on CCD cameras, where external reflection is the primary scattering mechanism. It is also noticeable that at 60º, there is minimal variation in the value of the Es exponent with the index of refraction of the liquid, while at 90º higher values of the index of refraction result in exponent values closer to 2. At ?=120º, the variation of the scattering exponent with the index of refraction is large ranging from 1.81 up to 1.95, which is non monotonic. This behaviour can be attributed to the changing influence of the second internal reflection. As the index of refraction increases the second rainbow angle progressively approaches 120º. At m=1.400 the second rainbow angle occurs at 113º eliminating its contribution (figure 2) to light collected at 120º. 1.94 1.92 m=1.300 m=1.333 m=1.366 m=1.400 1.90 1.88 1.86 1.85 1.80 1.70 1.65 1.84 1.60 1.82 1.55 1.80 60 90 60º 90º 120º 1.75 1.50 0.001 120 Collection angle ? 0.01 0.1 Dye concenctration (g/l) Figure 4: Variation of scattered light exponent Es with collection angle ? (for water droplets with dye concentration 0.001g/l) Figure 5: Variation of scattered light exponent Es with dye concentration (for droplets with m=1.333) The values of the fluorescence exponent are similarly derived by a fit of the fluorescence intensity data to a power function: ifluorescence =kfDEf (6) At low dye concentration, for all refractive indices, the value of the exponent is about Ef≈2.995 (table 1). This value is very close to the desired value of 3 making the fluorescence intensity proportional to the droplet volume and also shows that at small dye concentrations the attenuation of light within the droplet is small. The minimal dependence on the value of the refractive index asserts that the proportionality of the fluorescence intensity to the droplet volume remains unaffected by the course of the ray paths within a droplet of low dye concentration in the liquid. Table 1: Dependence of fluorescent light intensity exponent on index of refraction Fluorescence exponent Ef Index of refraction Dye concentration 0.001g/l Dye concentration 0.010g/l Dye concentration 0.100g/l 1.300 2.9955 2.9566 2.6687 1.333 2.9954 2.9553 2.6638 1.366 2.9952 2.9537 2.6578 1.400 2.9949 2.9513 2.6494 Increasing the dye concentration leads to higher absorption of light within the droplets. For the scattered light, this results to the reduction of the intensity of the components that come from refraction and internal reflections while the reflection part remains unaffected and, as a consequence, the total signal intensity is reduced. 4 Consequently, the relation of the scattered light intensity to the surface of the sphere is affected, as can be seen by the values of the scattered light exponent Es (figure 5). At ?=60º, where the refracted component represents a significant proportion of the total intensity, the deviation of the exponent is proportional to the concentration of the dye, as absorption within the droplets scales accordingly. At ?=90º, it can be seen that the Ef remains practically unaffected by the dye concentration, as expected, due to external reflection being the primary scattering mechanism. At ?=120º, there is considerable decrease of the exponent with the increase of dye concentration, but, since the 2nd internal reflection is affected (which is a minority contribution to the scattered light at this angle), the magnitude of the effect is smaller than that at 60º. For the other indices of refraction the increase of the dye concentration results in similar effects. The only exception to this rule is at ?=120º with m=1.400, where the scattering exponent Es is independent of dye concentration and has a fixed value of Es ≈1.88. As presented in figure 2 for this case there is no contribution of the 2nd internal reflection, therefore the scattered light exponent Es does not scale with dye concentration. 3.00 1.2E-02 1.0E-02 2.90 2.85 Constant K Fluorescence exponent Ef 2.95 m=1.300 m=1.333 m=1.366 m=1.400 2.80 2.75 Kfit 8.0E-03 6.0E-03 4.0E-03 2.70 2.0E-03 2.65 2.60 0.001 0.0E+00 0.01 0.1 0 Dye concenctration (g/l) 20 40 60 80 100 120 140 160 180 200 SMD (µm) Figure 6: Variation of fluorescence light exponent Ef with dye concentration Figure 7: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 90º collection angle (m=1.333, dye concentration 0.001g/l). Dashed line is K fit of eq. (7) The increase of dye concentration improves the signal levels of fluorescence as more light is absorbed to be reemitted. The increased concentration also leads to attenuation of light for distances comparable to the diameter of the droplets studied. As a result, the fluorescence contribution of the region close to the surface becomes more significant than that of the rest of the volume. Consequently fluorescence becomes progressively a surface phenomenon (Zaller, 1999) and deviation from the assumed cubic dependence of the fluorescence intensity to the droplet diameter occurs. A moderate absorption within the droplet results in a fluorescence exponent of Ef≈2.95 (fro m Ef≈2.99 in the low absorption case) and high absorption in an exponent of Ef≈2.65 (Table 1). It is evident that the assumption of a cubic dependence of the fluorescence intensities becomes invalid, especially in the last case. Differences in the index of refraction do not affect the value of the exponent significantly (figure 6). Only in the case of the high concentration there is some noticeable deviation of the exponents between the different indices of refraction, which can be attributed to the increasing importance of the refraction path length that occurs when absorption within the droplet is considerable. In order to determine the sizing accuracy of the PDS technique, a constant calibration value was estimated as: K fit=a f/as (7) where the values of as and af are obtained by force-fitting the scattered light and fluorescence intensities to the expected cubic (eq. 1) and square (eq. 2) dependencies. This value of Kfit was accepted as a constant value, which would be obtained from a calibration with large droplet diameters during an experiment. The real value of Kreal for each droplet size distribution was calculated from eq. (3) as: ∑ D ∑i = ∑ D ∑i 2 Kreal ( D) scattered(D) fluorescence 3 (8) In Figure 7, the actual values of Kreal for a number of droplet size distributions with different spreads and Sauter mean diameters are compared to the constant calibration value Kfit (dashed line) for a collection angle of 90º (which is commonly used in practice) at low dye concentration. The results show that, while there is a systematic deviation between the constant (calibration) value Kfit and the real value Kreal, the two values tend to become the same for large droplet diameters. However, Kreal also deviates from the observed systematic 5 behaviour with droplet diameter, indicated by the continuous grey line of figure 7, with the deviation becoming larger for smaller values of SMD. At ?=60º (figure 8) the agreement between the calibration value Kfit and the values of Kreal is very good for all SMD and size distributions. There is minimal fluctuation of the Kreal value and the conformance to a single calibration value is valid so the sizing accuracy is expected to be good. It is worth mentioning, that at this angle the value of the scattered light exponent Es was closest to the desired value of 2. At ?=120º (figure 9), the main trend is similar in shape to that of ?=90º, showing greater systematic deviation as the SMD decreases. While there are large deviations for the Kreal value for each SMD, the pattern is much different from that at 90º as the scattering for these two angles is affected by different components of scattered light, which exhibit different characteristics. The random error for Kreal for each angle is associated with the fluctuation of the scattered light intensity with the diameter. Therefore, as for each SMD value various spreads of the size distribution were considered, the intensity of the scattered light varies affecting Kreal . At ?=60º where the fluctuations of the intensity are minimal with diameter, the value of Kreal are almost constant. At 90º and 120º, where the fluctuations are considerable and for each SMD many spreads of the size distribution have been considered, the total scattered light intensity for each spread is different, causing the deviations from the main trend and increasing the uncertainty of the measurement. The effect of the index of refraction for low dye concentration is generally small and the main trends as well as the deviations from the main trends are not significantly affected. Exception to this is the case of ?=120º, where the deviations become uniformly oriented around the main trend as the index of refraction increases (figure 10). 7.0E-04 7.0E-03 Kfit 6.0E-04 6.0E-03 5.0E-04 5.0E-03 Constant K Constant K Kfit 4.0E-04 3.0E-04 4.0E-03 3.0E-03 2.0E-04 2.0E-03 1.0E-04 1.0E-03 0.0E+00 0.0E+00 0 20 40 60 80 100 120 140 160 180 200 0 20 40 60 80 SMD (µm) 100 120 140 160 180 200 SMD (µm) Figure 8: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 60º collection angle (m=1.333, dye concentration 0.001g/l). Dashed line is K fit of eq. (7) Figure 9: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 120º collection angle (m=1.333, dye concentration 0.001g/l). Dashed line is K fit of eq. (7) As the dye concentration increases and conformance to square and cubic dependencies for the scattered and fluorescent light respectively become invalid, the difference between the Kfit value and main trend of the Kreal values increases (figures 11 and 12). This will cause an increase to the overall error in the estimation of the SMD. This difference is higher for the high dye concentration. At ?=60º, the deviation from the main trend is not as large as the deviation at 90º and 120º. It is also observed that at high dye concentration the fluctuation of the Kreal values is higher. Nevertheless the fluctuation of Kreal at ?=60º is lower than at ?=90º and ?=120º. Similar observations are present for all considered values of refractive index. It is thus expected that the sizing error will increase as the dye concentration increases but not equally for all collection angles. 9.0E-02 9.0E-03 K fit 7.0E-03 7.0E-02 6.0E-03 6.0E-02 5.0E-03 4.0E-03 5.0E-02 4.0E-02 3.0E-03 3.0E-02 2.0E-03 2.0E-02 1.0E-03 1.0E-02 0.0E+00 0.0E+00 0 20 Kfit 8.0E-02 Constant K Constant K 8.0E-03 40 60 80 100 120 140 160 180 0 200 20 40 60 80 100 120 140 160 180 200 SMD (µm) SMD (µm) Figure 10: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 120º collection angle (m=1.400, dye concentration 0.001g/l). Dashed line is K fit of eq. (7) Figure 11: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 60º collection angle (m=1.333, dye concentration 0.100g/l). Dashed line is K fit of eq. (7) 6 The sizing error of the PDS technique based on a constant value of Kfit, is quantified relative to the known value of the SMD of the considered size distribution according to the value of: error = SMD fit − SMD real SMD real (9) where SMDfit is the SMD obtained from the ratio of the calculated intensities assuming a constant value Kfit. This sizing error is shown as contour plots for various values of the parameters X and q of the Rosin-Rammler size distribution (figures 14-19). It should be noted that lower values of X indicate lower SMD and higher values of q narrower size distribution. In order to compensate for the systematic change of the value of K with SMD, the iterative correction procedure that was proposed by Domann and Hardalupas (2003) was applied here. This correction procedure is as follows. From the calibration value Kfit (eq. 7) a first estimate of the SMD was calculated from the fluorescence and scattered light intensities (eq 3) corresponding to the experimental conditions. This value was used to obtain a new value for K from the main trend of the Kreal values for the experimental conditions considered (e.g. the continuous line of figure 7). This is repeated till the SMD converged (figure 13). 1.0E+00 Kfit 9.0E-01 8.0E-01 Constant K 7.0E-01 Kcorr Kreal 6.0E-01 5.0E-01 4.0E-01 Kfit 3.0E-01 2.0E-01 1.0E-01 0.0E+00 0 20 40 60 80 100 120 140 160 180 200 SMDreal SMD (µm) Figure 12: Dependence of value Kreal (dots), estimated according to eq. (8), with SMD for various droplet size distributions at 120º collection angle (m=1.333, dye concentration 0.100g/l). Dashed line is K fit of eq. (7) SMD corr SMD fit Figure 13: Example of the correction procedure of the estimated SMD value by compensating for the difference between the calibration Kfit and the true value Kreal of the spray using the calculated trend of the Kreal values. At low dye concentrations the maximum sizing error is smaller for 60º. For all SMD and spreads considered at m=1.333 its maximum value does not exceed 5% (figure 14, left) while the average error (calculated as the mean value of the sizing error of each size distribution considered at that angle, dye concentration and refractive index) is less than 1.5% making possible the use of the sizing data without any correction. This occurs due to the good agreement of the Es and Ef exponents to the ideal values of 2 and 3 respectively that leads to close proximity between the Kfit value obtained from calibration with large size droplets to the Kreal values (figure 8). Furthermore, at this angle, the application of the correction improves further the sizing accuracy by reducing the maximum sizing error to less than 3% (figure 14, right). The sizing error before correction at 90º (figure 15, left) is widespread over many droplet size distributions with an average value of about 7% (maxima go as high as 26%). A large part of the error is due to the non-compliance of Es to the value of 2. The fluctuations of the Kreal value for the various size distributions, manifested themselves as alternating areas of large and small error. The reduction of the sizing error after the application of the correction procedure for the case was significant (figure 15, right). After the correction, the error was restricted in the region of small SMD and low spread of the size distribution and its average value did not exceed 2% (maxima go as high as 22%). The error at ?=120º is similar in magnitude (29% maximum, 10% average) to that of 90º (26% maximum, 7% average), but its distribution is different as it appears to be concentrated in particular areas (figure 16, left), which can be traced to figure 9 as the areas where the difference between Kreal and Kfit is maximum. Applying the correction procedure at this angle lowers the maximum error to about 12% and the average error to 4%. For the other considered values for refractive index the results are qualitatively similar although the absolute values show a small variation. It should be also noted that in the case of 120º and m=1.400, where the contribution of the second internal reflection terminates, a small reduction of the maximum error that was observed with the increase of the index of refraction is reversed. Increasing the dye concentration results in a significant increase in the magnitude of the error for all cases (figures 17 left, 18 left and 19 left). The largest part of the error comes from the difference between the value of 7 K fit and the systematic change of the Kreal values with droplet diameter (figures 11 and 12). It is apparent that calibration with large droplets produces a large offset between the Kfit value and the Kreal values. The reason for this is that at larger diameters attenuation of light within the droplet takes place in a smaller fraction of the droplet diameter, making fluorescence more of a surface phenomenon and resulting in a fluorescence exponent Ef lower than the value, which corresponds to small diameter droplets (figure 6). The magnitude of the error is again mostly dependant on the collection angle (Table 2). For the maximum dye concentration, the error at 60º is by far the smallest, reaching a maximum value of 32%. In this case of 90º (an angle frequently used), it is interesting to notice that the error maxima reach about 350%. It should be mentioned that at this angle (with external reflection being the primary scattering mechanism) the ratio between the Ef and Es has fallen down to about 1.4 instead of the ideal value of 3/2=1.5. The result is a great overestimation of the value of the SMD due to the very low value of Kfit. The error is lower at 120º with a maximum not exceeding 155%. It is also important to notice the effect of the increase of the index of refraction at this angle (table 2) as the average error reduces significantly when the rainbow angle approaches 120º until at m=1.400 the contribution of the second internal reflection is eliminated and the error increases significantly. Application of the correction algorithm for these cases reduced the error considerably (figures 17-19, right) with the best results for ?=60º, where the maximum error is limited to 8% and the average error is consistently 1% (table 3). Good results are also obtained for all other cases with average errors less than 5% but there are error maxima of up to 68% remaining that would give erroneous results for some size distributions. Table 2: Error at high dye concentration (before correction) Collection angle Index of refraction 60º 90º 120º Max error Average error Max error Average error Max error Average error 1.300 18% 12% 191% 137% 117% 107% 1.333 25% 19% 206% 143% 79% 59% 1.366 29% 24% 277% 148% 39% 17% 1.400 32% 27% 347% 155% 155% 145% Table 3: Error at high dye concentration (after correction) Collection angle Index of refraction 60º 90º 120º Max error Average error Max error Average error Max error Average error 1.300 8% 1% 19% 3% 23% 3% 1.333 8% 1% 20% 3% 11% 3% 1.366 8% 1% 45% 3% 15% 1% 1.400 8% 1% 68% 5% 19% 3% 4. CONCLUSIONS The accuracy of the Mie/LIF planer droplet sizing technique has been investigated numerically on the effects of the index of refraction of the liquid, of the concentration of the fluorescent Rhodamine 6G dye and of the collection angle, for droplet distributions following a Rosin-Rammler distribution with a range of the Sauter 8 Mean Diameters and spreads. The results showed the importance of the properties of the liquid, the droplet size distribution and the optical arrangement of the experiment. 1. The most significant parameter influencing the accuracy of the technique was identified as the collection angle ?. The best sizing accuracy is obtained at ?=60º. The maximum error for the low dye concentration (0.001g/l) is less than 6%, while for the highest dye concentration (0.1g/l) it does not exceed 32% for all indices of refraction and spray size distributions. 2. The sizing accuracy error is negatively affected by high dye concentration as a result of deviation from the assumed D3 dependence of the fluorescent light and the D2 of the scattered light. At the highest dye concentration considered a maximum sizing error of 350% was calculated. 3. The increase of the index of refraction results in a moderate increase of the maximum sizing error (from 18% to 32%) at ?=60º, while at ?=90º the increase is larger (from 190% to 350%). At ?=120º the maximum sizing error decreases with the index of refraction (from 120% to 40%) until the contribution of the second internal reflection is eliminated and the maximum sizing error increases again (155%). 4. The accuracy of SMD measurement depends on the size distribution of the measured spray and the error increases for narrow distributions of small droplet sizes. 5. A correction algorithm was suggested, which improves the sizing accuracy considerably limiting, the maximum sizing error of the estimated SMD to less than 8% for the optimal collection angle (?=60º). REFERENCES Domann R., Hardalupas Y. and Jones A.R. ‘A study of the influence of absorption on the spatial distribution of fluorescence intensity within large droplets using Mie theory, geometrical optics and imaging experiments’. Meas. Sci. and Technol., 13, 280-291 (2002). Domann R., Hardalupas Y., ‘A study of parameters that influence the accuracy of the Planar Droplet Sizing technique’, Part. Part. Syst. Char., 18, 3-11 (2001) Domann R., Hardalupas Y., ‘Quantitative Measurements of planar Droplet Sauter Mean Diameter in Sprays using Planar Droplet Sizing’ Part. Part. Syst. Charact., 20, 209 - 218 (2003) Domann R., Hardalupas Y., ‘Spatial distribution of fluorescence intensity within large droplets and its dependence on dye concentration’, Appl. Opt., 40, 3586-3597 (2001) Guilbault, G.G., Practical Fluorescence - Theory, Methods and Techniques, Marcel Dekker, (1973). LeGal P., Farrugia N., Greenhalgh D. A., ‘Laser sheet dropsizing of dense sprays’, Optics and Laser Techn. 31, 75-83 (1999). Rosin P. and Rammler E., ‘Laws governing the fineness of powdered coal’, J. Inst. Fuel, 7, 29 - 36, (1933) Sankar S.V., Mahler K.E., Robart D.M., ‘Rapid characterization of fuel atomizers using an optical patternator’, J. Eng. Gas Turb. Power, 121, 409 - 414 (1999) Stojkovic B.D. and Sick V. ‘Evolution and impingement of an automotive fuel spray investigated with simultaneous Mie/LIF techniques’. Appl. Phys. B, 73, 75-83 (2001). van de Hulst, H.C., Light Scattering by Small Particles, Dover Publications, 1957. Yeh C.N., Kosaka H., Kamimoto T., ‘A fluorescence / scattering imaging technique for instantaneous 2-D measurements of particle size distribution in a transient spray’, Proc. 3rd Congr. on Opt. Part. Sizing, Yokohama, Japan, 355 -361 (1993) Zaller M., Locke R.J., Anderson R.C., ‘Imaging techniques for liquid and gaseous fuel characterization in a subscale gas turbine combustor’, ILASS Americas 12th annual conference on liquid and spray systems, Indianapolis IN, 85-89, (1999) 9 SM D error wi th corrected K 23 May2004 0.05 0.04 0.04 0.03 0.03 0.02 0.02 0.01 0.01 0.00 X 150 100 50 0.05 0.04 0.04 0.03 0.03 0.02 0.02 0.01 0.01 0.00 150 X SMD error with constant K 23 May2004 100 50 50 100 150 50 q 100 150 q Figure 14: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.001g/l) for collection angle 60º. SMD error with constant K 23 May 2004 S MD error with correced K 23 May2004 150 X 100 100 50 50 50 100 0.25 0.20 0.15 0.10 0.05 0.00 150 X 0 .25 0 .20 0 .15 0 .10 0 .05 0 .00 150 50 q 100 150 q Figure 15: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.001g/l) for collection angle 90º. S MD error with corrected K 23 M ay 2004 0 .25 0 .22 0 .19 0 .17 0 .14 0 .11 0 .08 0 .06 0 .03 0 .00 X 150 100 50 0.25 0.22 0.19 0.17 0.14 0.11 0.08 0.06 0.03 0.00 150 X SMD error with constant K 23 May 2004 100 50 50 100 150 50 q 100 150 q Figure 16: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.001g/l) for collection angle 120º. 10 S MD error with correced K 23 May2004 0 .25 0 .22 0 .19 0 .17 0 .14 0 .11 0 .08 0 .06 0 .03 0 .00 X 150 100 50 0.25 0.22 0.19 0.17 0.14 0.11 0.08 0.06 0.03 0.00 150 X SMD error with constant K 23 May 2004 100 50 50 100 150 50 q 100 150 q Figure 17: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.100g/l) for collection angle 60º. S MD error with corrected K 23 M ay 2004 2 .00 1 .78 1 .56 1 .33 1 .11 0 .89 0 .67 0 .44 0 .22 0 .00 X 150 100 50 2.00 1.78 1.56 1.33 1.11 0.89 0.67 0.44 0.22 0.00 150 X SMD error with constant K 23 May 2004 100 50 50 100 150 50 q 100 150 q Figure 18: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.010g/l) for collection angle 90º. S MD error with corrected K 23 M ay 2004 1 .00 0 .89 0 .78 0 .67 0 .56 0 .44 0 .33 0 .22 0 .11 0 .00 X 150 100 50 1.00 0.89 0.78 0.67 0.56 0.44 0.33 0.22 0.11 0.00 150 X SMD error with constant K 23 May 2004 100 50 50 100 150 50 q 100 150 q Figure 19: Sizing error (%) of SMD before (left) and after (right) the application of a correction procedure, based on a variable value of K with droplet diameter (m=1.333 with dye concentration of 0.100g/l) for collection angle 120º. 11