Forest Service Aviation TECH BULLETIN

advertisement

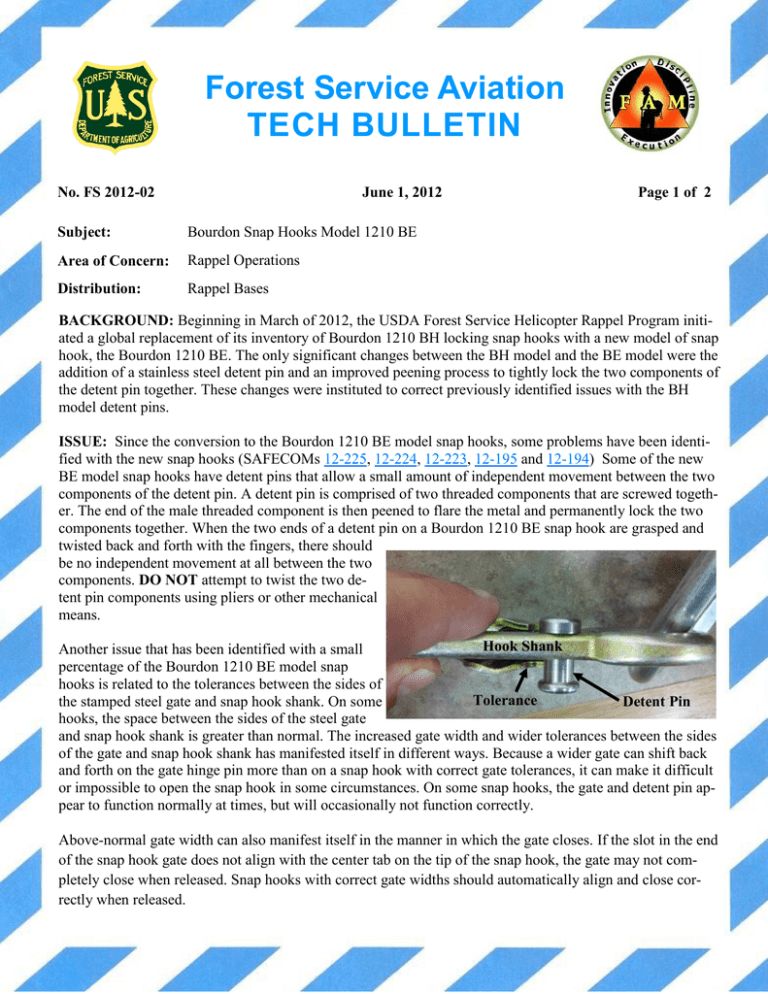

Forest Service Aviation TECH BULLETIN No. FS 2012-02 June 1, 2012 Subject: Bourdon Snap Hooks Model 1210 BE Area of Concern: Rappel Operations Distribution: Rappel Bases Page 1 of 2 BACKGROUND: Beginning in March of 2012, the USDA Forest Service Helicopter Rappel Program initiated a global replacement of its inventory of Bourdon 1210 BH locking snap hooks with a new model of snap hook, the Bourdon 1210 BE. The only significant changes between the BH model and the BE model were the addition of a stainless steel detent pin and an improved peening process to tightly lock the two components of the detent pin together. These changes were instituted to correct previously identified issues with the BH model detent pins. ISSUE: Since the conversion to the Bourdon 1210 BE model snap hooks, some problems have been identified with the new snap hooks (SAFECOMs 12-225, 12-224, 12-223, 12-195 and 12-194) Some of the new BE model snap hooks have detent pins that allow a small amount of independent movement between the two components of the detent pin. A detent pin is comprised of two threaded components that are screwed together. The end of the male threaded component is then peened to flare the metal and permanently lock the two components together. When the two ends of a detent pin on a Bourdon 1210 BE snap hook are grasped and twisted back and forth with the fingers, there should be no independent movement at all between the two components. DO NOT attempt to twist the two detent pin components using pliers or other mechanical means. Hook Shank Another issue that has been identified with a small percentage of the Bourdon 1210 BE model snap hooks is related to the tolerances between the sides of Tolerance the stamped steel gate and snap hook shank. On some Detent Pin hooks, the space between the sides of the steel gate and snap hook shank is greater than normal. The increased gate width and wider tolerances between the sides of the gate and snap hook shank has manifested itself in different ways. Because a wider gate can shift back and forth on the gate hinge pin more than on a snap hook with correct gate tolerances, it can make it difficult or impossible to open the snap hook in some circumstances. On some snap hooks, the gate and detent pin appear to function normally at times, but will occasionally not function correctly. Above-normal gate width can also manifest itself in the manner in which the gate closes. If the slot in the end of the snap hook gate does not align with the center tab on the tip of the snap hook, the gate may not completely close when released. Snap hooks with correct gate widths should automatically align and close correctly when released. No. FS 2012-02 May 25, 2012 Page 2 of 2 RECOMMENDATIONS: To test gate width and alignment, shift the gate on the hinge pin to one side and then open and release the gate multiple times. Then shift the gate on the hinge pin to the opposite side and open and release the gate multiple times. If the gate does not open and close correctly every time, remove the hook from service. The manufacturer has been informed of these issues and is taking steps to correct these deficiencies. Any 1210 Bourdon BE snap hook that permits independent movement between the two detent pin components, or exhibits the above described issues with opening or closing of the snap hook gate, should be removed from service and sent to Tim Lynch at the Missoula Technology and Development Center. Any questions about these issues or other problems with Bourdon 1210 BE model snap hooks should be directed to Tim Lynch (tlynch@fs.fed.us; 406-329-3958. /s/ Ron Hanks Chief, Aviation Safety Management Systems U.S. Forest Service