Electrical Testing at Elevated Frequency

of Stator Cores and Exciter Circuits

Generators are subjected to high electrical,

thermal and mechanical stresses over

the course of their service life. Continuous

heavy thermo-mechanical stresses and

thermal cycles can have a particularly

­severe impact on the stator core. Over

time, this can lead to deficiencies in the

core insulation and it is therefore recommended to regularly check its condition.

Stator cores with paper insulation in particular are hygroscopic and can exhibit

­fatigue effects over the course of time.

Our Service

Our portfolio includes the following:

500-Hz flux test with thermal

imaging of

■■ stator core

■■ laminated armature of exciter rotor

■■ pilot exciter stator core.

Siemens has developed a series of electrical tests to determine the current technical

condition of the core insulation and to

­indicate thermo-mechanical fatigue and

aging phenomena as well as mechanical

damage due to foreign objects. The purpose of these core tests is to help prevent

unscheduled outages and thus to increase

availability and reliability. Most of them

are flux tests and pole voltage comparison

tests which are performed at a frequency

of 500 Hz.

These tests are especially intended for

early detection of insulation damage to

the core. These are standstill diagnostics

which can be performed during an inspection where a removal of the rotor o

­ ccurs.

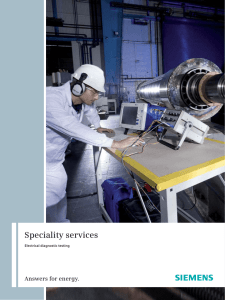

The equipment is easy to handle and can

be installed quickly and simply in the

power plant.

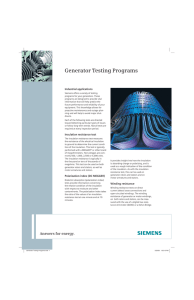

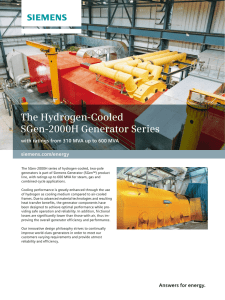

Thermal imaging of a stator

Close-up of hot spots

Performance Maintenance – Generator

Answers for energy.

500-Hz pole voltage comparison

test of

■■ generator rotor

■■ main exciter stator.

Features

500-Hz flux test with thermal imaging

The 500-Hz flux test with thermal imaging

patented by Siemens already has a proven

track record in the field of generator stator

core testing. It has now also been further

developed for exciters.

This examination method is used for

­evaluating generator stator cores as well

as for pilot exciters and the laminated

­armature of exciter rotors. The flux test

is used to measure the condition of the

stator core insulation and thus to detect

possible local insulation damage. Insulation failure can result in local hot spots

between several sheets of the core during

magnetization. These hot spots can be

detected and localized with thermal

­imaging.

The measurement is performed at a frequency of 500 Hz, as significantly lower

power is required at high frequency than

at grid frequency (50 or 60 Hz) to generate equivalent magnetization losses in

the stator core. However, since the stress

on the insulation between the laminations

is comparable, the integrity of the core

can be evaluated just as effectively. The

requisite instrumentation is also considerably smaller and lighter in comparison

with that needed for 50 Hz testing. This

helps shorten test duration and assembly

of the test setup. The system is more

transportable and simpler to implement

worldwide.

500-Hz pole voltage comparison test

This measurement is performed on the

generator rotor winding as well as on

the stator winding of the main exciter.

By comparing the measured voltages

across each pole it is possible to detect

interturn faults in DC windings. This is

done by applying a sinusoidal voltage to

the winding and measuring the resulting

voltage drops with a voltage meter. If the

voltage drops are essentially equivalent,

there is no interturn fault. If the test results

Published by and copyright © 2011:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

www.siemens.com/energy

are outside the specified tolerance limits,

this indicates an interturn fault. The sensitivity and the localization accuracy of

the 500-Hz pole voltage comparison test

are especially high for low-resistance or

metallic interturn faults.

Your Benefits

The measurements to establish the integrity of the stator core or exciter system

can be performed during an outage with

rotor removal. Our specialists analyze

the localized indications and recommend

measures for future operation. This can

help improve operating reliability and

availability and reduce the risk of developing hot spots in the generator. In extreme

cases, these hidden operating risks can

result in sudden loss of individual parts,

components or even the entire generator.

If deficiencies are detected, measures

can be implemented during the ongoing

inspection, such as replacing or repairing

the affected components. These measurements have been included in Siemens’

standard measures in new generator

manufacture as well as in Field Service

since 2004. 500-Hz flux test as well as

the 500-Hz pole voltage comparison

test of generator components has been

recommended by industry groups.

In addition to the 500-Hz measurements,

the following measurements can also be

performed on the generator:

■■ Recurrent Surge Oscillography (RSO)

of the rotor to detect interturn faults

■■ Insulation resistance measurement

(RISO) of all windings to determine the

degree of cleanliness of the insulation

system

The following examinations can

be p

­ erformed on the exciter:

■■ Insulation resistance measurement

(RISO) of all windings to detect i­nterturn

faults

■■ Blocking characteristics of diodes

(overall blocking characteristic)

to ­determine operability of diodes

in the blocking direction

■■ Measurement of fuse resistances

to determine fuse operability

Please contact your Siemens Sales branch

office for further information on this topic.

Thermal imaging of a stator with hot spots

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Energy Service Division

Order No. E50001-G520-A392-X-4A00

Printed in Germany

Dispo 34805, c4bs No. 7816, 7823

TH 258-111031 BR 460862 DB 11111.5

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should therefore

be specified in the contract.