COMBINED CYCLE

advertisement

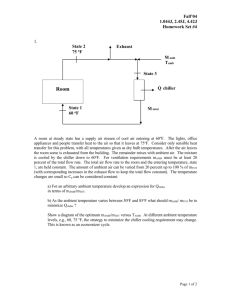

COMBINED CYCLE Pego experience confirms BENSON as proven HRSG technology Following improvements carried out in the wake of HP evaporator cracking problems encountered at Hamm-Uentrop and Herdecke some three years ago, a good body of reliable performance has now been amassed with BENSON HRSGs at combined cycle plants. Extensive recent monitoring and analysis at the Pego plant in Portugal, for example, reported here, confirms that the BENSON HRSGs are operating reliably, and are suitable for flexible operation, including fast starts. Figure 1. Pego plant and HRSG (HRSG photo: NEM) Jan Brückner and Gerhard Schlund, Siemens, Germany www.modernpowersystems.com The 17 BENSON HRSGs currently in commercial operation have amassed more than 175 000 operational hours. The Pego BENSON HRSGs The latest BENSON HRSGs to enter commercial service are the two at ElecGas’s Pego combined cycle power plant in Portugal (see Figure 1). These can be considered “state of the art”, having benefited from the operating experience of the BENSON fleet to date. They can be taken as representative of BENSON HRSG technology. Their evaporators have been extensively instrumented and their behaviour investigated in depth. The results are summarised here. Figure 2. Schematic diagram of BENSON HRSG evaporator, as installed at Pego Eva 2 outlet Eva 1 outlet Separator Evaporator 1 Exhaust flow direction Evaporator 2 I n Modern Power Systems, October 2008, pp 33-37, Siemens reported on measures taken to deal with cracks and leaks in the HP evaporators of the horizontal-exhaustflow BENSON HRSGs installed at the Hamm-Uentrop and Herdecke combined cycle plants. As described in that article, the cracking problem occurred in the inlet section of Evaporator 2 and the cause was greater than expected temperature fluctuations, in turn due to dynamic instabilities in Evaporator 1, which is connected in series to Evaporator 2 (Evaporator 1 and Evaporator 2 comprising the HP evaporator section of the HRSG). The corrective measures – installation of throttling orifices at the inlet of Evaporator 1, installation of T-pieces to improve water/steam distribution at the inlet to Evaporator 2 and addition of expansion loops in the Evaporator 2 tubes – were installed in June/July 2008 and subsequently the HRSGs have run without any new cracks or leaks. Since then several new BENSON HRSGs have been brought into commercial operation. Table 1 lists all commercially operating installations to date. The HRSGs at Cottam were fitted with expansion loops from the outset, while all units entering service after Herdecke and Hamm-Uentrop have been equipped with the same features that were installed on those units, ie orifices, T-pieces and expansion loops. None of them have experienced cracks or leaks. Downcomer Blow down Orifice Expansion loop T-piece Eva 2 inlet Eva 1 inlet Star distributor June 2011 Modern Power Systems 21 COMBINED CYCLE The Pego HRSGs are installed downstream of Siemens SGT5-4000F gas turbines in a single shaft arrangement. They were supplied by NEM under licence to Siemens (owner of the BENSON boiler technology), and received their PAC (provisional acceptance certificate) in March 2011. The HRSG of Pego unit 30 has been fitted with equipment to perform wall temperature measurements in the area of the HP evaporator. These measurements are being carried out in order to demonstrate that the evaporators are operating in a dynamically stable way and that the design values for the temperature spread in Evaporator 2 are not exceeded. Similar investigations have been done at Irsching 5 and Sloe Centrale. The basic components of the BENSON HP evaporator, as employed at Pego, are shown in Figure 2. The operating principle can be summarised in a few sentences. The feedwater enters the evaporator through the inlet lines of Evaporator 1 (Eva 1 inlet) and is distributed to the heating surface tubes of Evaporator 1. The distribution of the mass flow to the individual harps or tube rows is determined by the tube parameters, the level of heating and the extent of throttling due to orifices at the Evaporator 1 inlet. The mixture of water and steam enters the downcomer through the outlet lines from Evaporator 1 (Eva 1 outlet) and is distributed uniformly to the inlet headers of Evaporator 2 through the star distributors and T-pieces which are installed at the end of the connecting lines from the star distributors to increase the number of inlets to the Evaporator 2 inlet headers. Depending on the load and operating mode, superheated steam or wet steam exits Table 1. BENSON HRSGs in commercial operation PAC Project/ Country CCPP supplier HRSG supplier 1999 Cottam UK Siemens 2007 Herdecke Germany Siemens Ansaldo 2007 Hamm-Uentrop Germany Siemens 2010 Langage UK 2010 Deutsche Babcock SGT5-4000F 1 SGT5-4000F multi shaft 1:1 ~ 400 MW 1 Ansaldo SGT5-4000F single shaft ~ 800 MW 2 Alstom Alstom GT26 multi shaft 2:1 ~ 885 MW 2 Lingen Germany Alstom Alstom GT26 multi shaft 2:1 ~ 850 MW 2 2010 Irsching 5 Germany Siemens STF SGT5-4000F multi shaft 2:1 ~ 820 MW 2 2009 Sloe Centrale Netherlands Siemens CMI SGT5-4000F single shaft ~ 870 MW 2 2010 Severn Power UK Siemens CMI SGT5-4000F single shaft ~ 870 MW 2 2011 Malzenice Slovakia Siemens STF SGT5-4000F single shaft ~ 400 MW 1 2011 Pego Portugal Siemens NEM SGT5-4000F single shaft ~ 870 MW 2 downstream of Evaporator 2 (Eva 2 outlet), is routed to a common manifold and then flows to the separator. It is well established, and confirmed by a wide range of measurements, that, in the BENSON HRSG, the water–steam mixture is not distributed uniformly to the single tubes inside the inlet headers of Evaporator 2. This leads to different steam qualities at the inlet of the individual tubes, resulting in different wall Average wall temperature (ºC) Outlet wall temperature (ºC) (fluid temp.) Tube mass flow (kg/s) 0.20 0.30 0.40 0.50 0.60 0.70 Steam content at tube inlet (kg/kg) 0.80 0.90 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 1.00 Resulting mass flow per tube (kg/s) Tube wall temperature (ºC) Overall average wall temperature over the tube height of all tubes of one header: 366°C +60/-21K 0.10 Configuration/ No of power HRSGs single shaft ~ 390 MW Figure 3. Calculated temperature profile diagram for Pego showing tube wall temperatures (average and outlet) plotted against steam quality (steam content) at the tube inlet of Evaporator 2e (hottest row of Evaporator 2). 100% gas turbine load, BENSON mode 500 480 460 440 420 400 380 360 340 320 300 280 260 0.00 Gas turbine temperatures. See Figure 3, which shows an example from Pego. Accordingly, as already noted, expansion loops are installed at the inlet of each individual tube of Evaporator 2 to compensate for different tube expansions resulting from the temperature spread caused by different average wall temperatures among the single tubes of one harp. The expansion loops are designed to accommodate a temperature spread of ±50 K, being the maximum difference between the average wall temperature (averaged over tube height) of a single tube and all tubes of one header. The Pego evaporators were designed based on the following assumptions: • The temperature spread of the average wall temperatures will not exceed ±50 K. • The evaporator will be dynamically stable at each load point. • Evaporator 1 will not be superheated at the outlet. • The Evaporator 2 risers of each row will exhibit balanced temperatures. Thermocouples were installed at the upper end of the Pego Evaporator 2 heating surface tubes, as shown in Figure 4 in order to confirm these assumptions. Figure 5. Location of thermocouples at Pego for wall temperature measurements on Evaporator 1 and 2 risers 22 Modern Power Systems June 2011 126 Tube number 84 85 42 43 1 Flue gas 20 18 17 16 Rows Figure 4. Location of thermocouples at Pego for outlet wall temperature measurements on Evaporator 2 www.modernpowersystems.com COMBINED CYCLE Figure 6. Overview of the relation between the calculated, measured and “averaged over height” wall temperatures and how the “average over height” is calculated Calculated wall temperatures over the entire tube length/height Outlet wall temperature Tcalc n Tcalc 1 + Tcalc 2 + Tcalc + Tcalc n n Measured wall temp. at tube outlet Calculated wall temp. Profile over height Average calculated wall remp. Over the height Tcalc ... ø Twall calc Tube length/height The thermocouples measuring the wall surface temperature were insulated in order to eliminate the influence of the gas side temperature. Figure 5 shows thermocouples installed on all risers connected to the outlet harps of Evaporator 1 and Evaporator 2. The measurement system has been operating since the commissioning of Pego. Saturated conditions must exist in Evaporator 1 at all loads and this is confirmed by the measurements taken in Evaporator 1. To confirm that the limit of a maximum +50/-50 K temperature spread between the average wall temperature of single tubes and the average wall temperatures of the entire harp is not exceeded the average wall temperature over the height of each tube during operation needs to be known. The tube wall temperature can only be measured at the upper end of the tubes just below the upper cavity. These measured outlet wall temperatures therefore need to be converted into an average wall temperature, as shown in Figure 6. This was done using thermodynamic calculations based on the boundary conditions valid for the load cases under investigation (see Figure 3 and Table 2). Tcalc 1 Flue gas Tcalc 0 Temperature The results Fast start tests During commissioning of the Pego combined cycle power plant, intensive investigations www.modernpowersystems.com 375 350 0 325 300 0 275 250 0 225 200 0 175 150 0 125 100 0 75 50 0 25 0 0 600 1200 1800 2400 3000 3600 4200 Time (sec) 4800 5400 6000 TURBINE SPEED (Hz) CALC GT LOAD (MW) GT EXH GAS MASS FLOW (kg/s) HP DS/HTR2 OUT PRES (bar) HP STM FLOW (kg/s) CALCULATED ST LOAD (MW) HPS D/STR S/HTR3 2OF3 T (ºC) EG temp at flue gas stack 9ºC) EG temp at HRSG inlet (ºC) 7 750 7 700 6 650 6 600 5 550 5 500 4 450 4 400 3 350 3 300 2 250 2 200 1 150 1 100 5 50 0 7200 6600 All temperatures/ EG mass flow Others Figure 7. DCS data from Pego for 100% GT load EG = exhaust gas Figure 8. Spread of tube outlet wall temperatures, row 16, harp 22, 100% GT load Harp 26 Harp 27 Harp 22 Harp 23 Harp 24 20 18 17 16 500 50 450 40 400 30 350 20 300 10 250 0 200 -10 150 -20 100 -30 50 -40 0 0 600 1200 Row16 Harp22 Average temperature 1800 2200 3000 Row16 Harp22 Minimum temperature 3600 4200 Time (sec) 4800 Row16 Harp22 Maximum temperature 5400 6000 Row16 Harp22 Max. minus deviation 6600 -50 7200 Max. deviation from average temperature (K) Rows Harp 25 Flue gas Wall temperature (ºC) An overview of the measurement data from Pego is given below, along with the results of analysis performed for representative load points. Analysis has been performed at the load points listed below to confirm that the evaporator is operating correctly. The choice of points is designed to encompass the full range of normal evaporator operation: • 34% GT load (inlet guide vane); • 60% GT part load; • 100% GT full load; • 48% GT part load; • Cold start; • Advanced FACY (Fast Cycling) warm start; and • Shut down. The first step of the measurement analysis is to display the measured outlet wall temperatures together with selected DCS (distributed control system) data describing the load point and the status of the evaporator. By way of example, the DCS data for the 100% GT load case are shown in Figure 7. Two plots are created for each harp to display the outlet wall temperatures. The first one shows average temperatures and the existing temperature spread. The second one shows all temperature measurements taken on the harp over a certain time period. Figure 8 and 9 show, respectively, these two plots for Eva 2e left harp (row 16/harp 22), at 100% GT load. It can be seen from this example that at 100% load the evaporator is dynamically stable and that the temperature spread is within the allowable limits, ±50 K. The same analysis has been done for all the load cases listed above. In every one of these cases it has been shown that no instabilities occur and that the temperature imbalances do not exceed the ±50 K limit. Results of the analysis for each of the load points listed are summarised in Table 2. Row16 Harp22 Max. plus deviation June 2011 Modern Power Systems 23 COMBINED CYCLE were done on the fastest achievable start-up times. The monitoring at Pego has shown that the BENSON design allows maximum gas turbine ramp rates to be achieved, without any limit arising from components of the HRSG. Start-up times of close to 30 minutes from gas turbine ignition to full load were demonstrated (see Figure 10) without sacrificing component life time. Figure 9. Tube outlet wall temperatures, row 16, harp 22, 100% GT load Harp 26 Harp 27 Harp 22 Harp 23 Harp 24 20 18 17 16 Rows Harp 25 Flue gas 500 450 Wall temperature (ºC) 400 Proven technology Analysis of the data from the Pego combined cycle plant is giving clear confirmation that the evaporators are behaving within design assumptions: • The maximum existing temperature spread of the average wall temperature is approximately 50 K (+42/-8). 100 K (+50/50) was assumed for the design. • The measurements have shown that the HP evaporator is operating at dynamically stable conditions during each phase of start up and shut down as well as at each steady state load. • In addition to that, the front harps of Evaporator 1 have always exhibited saturated temperature at the outlets. In combination with the dynamically stable operation this indicates that the orifices installed at the Evaporator 1 inlet are working as expected and are designed correctly. • Measured values for variables such as pressure drop across the evaporator, outlet steam temperatures, and average wall temperatures, have been successfully reproduced by calculation. In addition, it has been shown that combined cycle plants equipped with BENSON HRSGs are extremely flexible in terms of start-up times and the HRSG components do not limit the ramp rates of the gas turbine. Siemens has now gained a good body of operational experience with the BENSON HRSG and it has firmly established itself as a MPS proven technology. 350 300 250 200 150 100 50 0 0 600 1200 1800 2200 3000 3600 4200 Time (sec) 4800 5400 6000 6600 7200 375 350 0 325 300 0 275 250 0 225 200 0 175 150 0 125 0 100 75 0 50 25 0 0 600 1200 1800 2400 3000 3600 4200 Time (sec) 4800 5400 6000 6600 7 750 7 700 6 650 6 600 5 550 5 500 4 450 4 400 3 350 3 300 2 250 2 200 1 150 1 100 5 50 0 7200 All temperatures/ EG mass flow Others Figure 10. Fast start test at Pego GAS TURBINE SPEED (Hz) CALC GT LOAD (MW) STEAM TURBINE SPEED (Hz) CALCULATED ST LOAD (MW) HP DS/HTR2 OUT PRES (bar) HP STM FLOW (kg/s) HP RED STN CTRL-V POSN (%) EG temp at HRSG inlet (ºC) HPS D/STR S/HTR3 2OF3 T (ºC) EG temp at flue gas stack (ºC) GT EXH GAS MASS FLOW (kg/s) EG = exhaust gas Table 2. Summary of measured data and results of analysis Measurements and DCS data during commissioning Date (all 2010) 06/10 04:00-06:00 Plant load 100% GT GT power m-flow HP Evap (kg/s) HP evap mode (MW) Pressure HP evap (separator) (bar) 277 131 77 BENSON Maximal temperature spreads ∆TS/x Attemp. in operation HP Eva, row/harp Measured outlet wall temp. (K) Calculated average wall temp (K) No 2a middle, 20/26 65 (+40/-25) 61 (+40/-21) 2c middle, 18/26 55 (+34/-21) 26 (+18/-9) (K) 11.5 - ditto01/10 00:00-02:00 60% GT 160 97 53 BENSON 15 No 2a right, 20/27 70 (+55/-15) 50 (+42/-8) 26/10 19:30-21:30 34% GT (IGV) 95 76 45 Level 0.91 No 2d left, 17/22 60 (+45/-15) 26 (+23/-3) 19/11 04:30-06:30 48% GT 132 87 50 BENSON 11 Yes 2c middle, 18/26 65 (+55/-10) 47 (+42/-5) 13/09 07:40-11:40 Cold start 2d left, r17/h20 80 (+45/-35) 30 (+23/-5) 08/10 12:00-14:00 Warm start/ Advanced FACY 2a right, 20/27 75 (+55/-20) 30 (+24/-6) 13/09 20:00-24:00 Shut down 2e left, 16/22 90 (+50/-10) - 24 Modern Power Systems June 2011 www.modernpowersystems.com