Power generation

advertisement

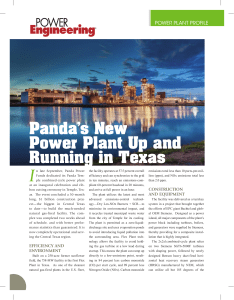

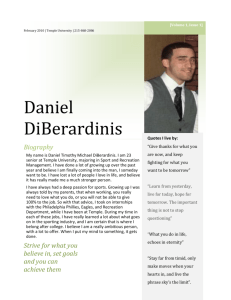

The 758 MW Panda Temple 1 Flex-Plant will provide electricity to the Texas Triangle, one of the fastest-growing areas in the U.S. Power generation Deep In The Heart Of Texas S Flexible combined-cycle power plant (CCPP) to balance strong Texas renewables; consortium synergy key to successful, safe construction iemens Energy Inc., in consortium with Bechtel and Panda Power Funds, has commissioned the Panda Temple Power 1 plant in Temple, Texas, U.S.A. The natural gas-fired, multishaft Panda Temple Flex-Plant is the first in commercial operation in Texas and has a gross installed electrical capacity of 758 MW, enough power to meet the needs of approximately 750 000 homes in the Central and North Texas regions. Flex-Plant CCPPs offer high efficiency and operational flexibility, the company said. Design features are incorporated to enable fast start and fast ramping up and down across a large operating window, from low plant turndown to high plant output, with carbon monoxide (CO) emissions less than 10 ppm and nitrogen oxide (NOx) emissions less than 2 ppm. “Siemens’ fast and efficient Flex-Plant technology is a perfect fit in balancing intermittent renewable resources and providing low cost electricity,” said Martin Tartibi, senior executive vice president, Siemens Energy Solutions Americas. “The Panda Temple plant is the third Flex-Plant in commercial operation in the U.S., and it will be considered one of the cleanest fossil-fueled plants in the nation.” The company said this was especially relevant in Texas, which has very strong renewable power generation. Texas exceeded its 2025 goal of 10 000 MW of renewable generation 16 years ahead of schedule, and by 2012 its total renewable installed capacity was more than 13 GW, according to Siemens. Diesel & Gas Turbine Worldwide April 2015 The Siemens scope of supply included the thermodynamic cycle design and power island engineering. The company also delivered two SGT6-5000F gas turbines, one SST6-5000 steam turbine, two SGen6-1000A generators, one SGen62000H generator, the SPPA-T3000 instrumentation and control system, two NEM USA Corp.-manufactured Benson heavy duct-fired heat recovery steam generators (HRSG) and other key cycle components. The gas turbines, steam turbines and generators were manufactured at the Siemens North American manufacturing hub in Charlotte, North Carolina, U.S.A. A long-term service agreement is also in place for the main generation components. “The successful completion of this plant demonstrates the strength of the Power generation Siemens’ scope of supply included the thermodynamic cycle design and power island engineering, two gas turbines, one steam turbine, three generators, the instrumentation and control system, two heat recovery steam generators and other key cycle components, while Bechtel provided project management, engineering, procurement, construction and startup services. Bechtel, Panda and Siemens consortium,” Tartibi said. “The team successfully delivered a plant that will quickly ramp up power to fuel the region’s growth and economic vitality.” The Temple 1 generating station is one of the fasteststarting power plants of its kind in the country, the company said. The combustion turbines can synchronize in 10 minutes and reach full load within 30 minutes — the entire plant can achieve full power production within 60 minutes. This startup flexibility avoids holding the gas turbine at low load to start, instead ramping up directly to a low emissions point that results in 84% less CO per start and 89% less NOx. The plant also features low cooling water usage, utilizing treated effluent (reclaimed) water. The 101 hectare site is designated as a “zero liquid discharge” site, meaning that no wastewater is discharged, but is instead evaporated in ponds under the hot Texas sun. In partnership with Siemens, Bechtel provided project management, engineering, procurement, construction and startup services. About 70% of the project’s subcontractors and 80% of Bechtel’s craft workers were from Texas, including several recently discharged Army veterans from the nearby Fort Hood military base. The company said it has successfully completed combined-cycle projects in the U.S., the U.K., Egypt, India, Turkey and Mexico, and operates through five global business units that specialize in civil infrastructure; power generation, communications and transmission; mining and metals; oil, gas and chemicals; and government services. Bechtel and Siemens are currently working to deliver the Panda Temple 2 generating station adjacent to Panda Temple 1, which will double the size and output The operational Panda Temple 1 plant is on the right, with the ongoing construction of the adjacent Panda Temple 2 shown on the left. When completed, the two facilities will provide 1615 MW of combined-cycle power to central and northern Texas. Diesel & Gas Turbine Worldwide April 2015 Power generation to 1615 MW. The Temple 2 project will share common facilities, laterals and operations with Temple 1, creating economic benefits for both plants. The facilities will be supplied with natural gas from Texas suppliers. The Temple 2 expansion is expected to come online during the summer of 2015. “Panda Temple 1 represents a tremendous team effort, including our consortium partner Siemens and Panda Power Funds, all of whom worked seamlessly to bring the plant online early,” said Mary McLaughlin, president of Bechtel’s thermal power business line. “As a result of a strong safety culture, the team worked the duration of the 30-month project without a losttime accident.” The companies are also working on the Panda Sherman Power Project in Sherman, Texas, U.S.A., and the Panda Stonewall Power Project in Leesburg, Virginia, U.S.A. The projects are similar in size to Panda Temple 1 and, when completed, will collectively generate enough electricity to power almost 3 million homes. The Temple site is strategically located to meet electricity demand in the Texas Triangle, a 155 399 km2 area bordered by Dallas, Austin, San Antonio and Houston — four of the fastestgrowing metropolitan areas in the U.S. — and home to 75% of the state’s population. “The early completion of this plant is critically important to the state and to the community of Temple, especially now when Texas is growing by more than 1000 people a day,” said Todd Carter, president and senior partner of Panda Power Funds. Founded in 2010, Panda Power Funds is a private equity firm headquartered in Dallas that has the ability to develop, acquire, construct, finance and operate utility scale, natural gas-fueled power generation facilities. The company has two CCPPs in operation in Texas and three CCPPs currently under construction in Texas and Pennsylvania U.S.A. Two power projects are currently in advanced development in northern Virginia, U.S.A., and southern Maryland, U.S.A., and the company said its 20 MW solar farm in New Jersey, U.S.A., is one of the largest solar facilities in the northeastern U.S. Panda said its 2012 financing of the Panda Temple plant was widely reported as a breakthrough for the U.S. project-finance market, representing the first time in six years that institutional investors had financed a capital-intensive construction project in the U.S. with a term loan. “Temple was our first project working with Siemens, and we made the right choice,” Carter said. “We are impressed with their state-of-the art technological power plant solutions and service.” Panda said that the Temple 1 CCPP, and Temple 2 when it is completed, would provide a reliable market for Texas natural gas supplies and a much-needed source of clean, economical power for a region that is growing at an impressive rate. According to an economic analysis conducted by Impact Data Source of Austin, Texas, the plant is expected to contribute up to US$1.6 billion to the central Texas economy during the now-completed construction phase and the plant’s first 10 years of operation. A REPRINTED FROM APRIL 2015 DIESEL & GAS TURBINE WORLDWIDE Copyright Diesel & Gas Turbine Publications Printed in U.S.A.