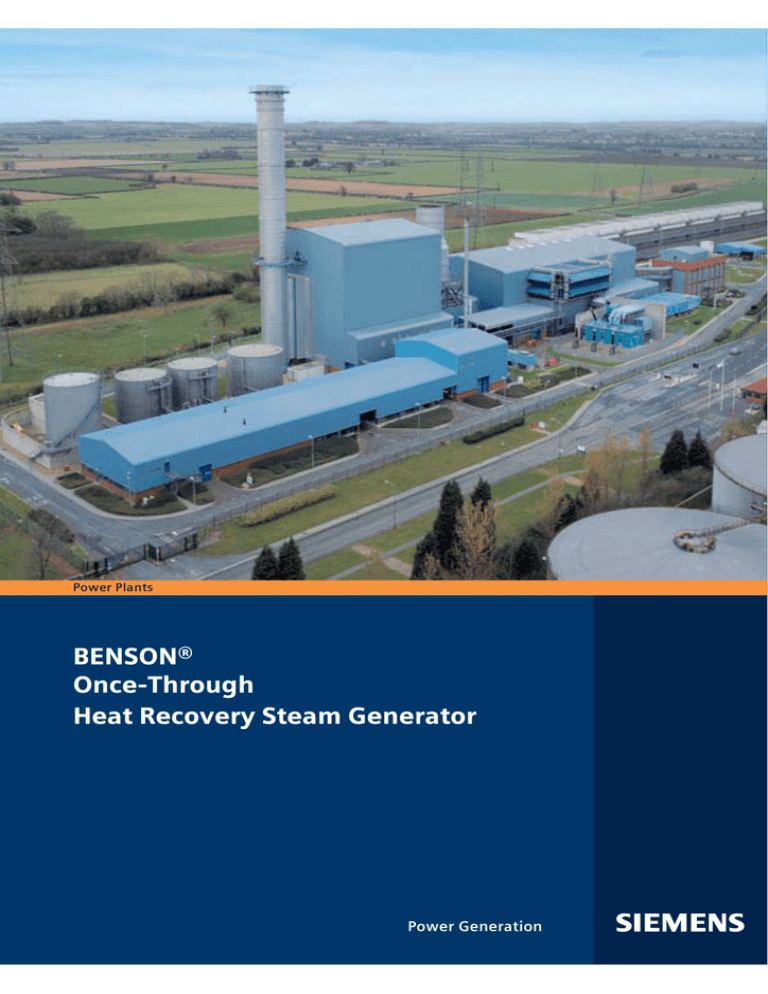

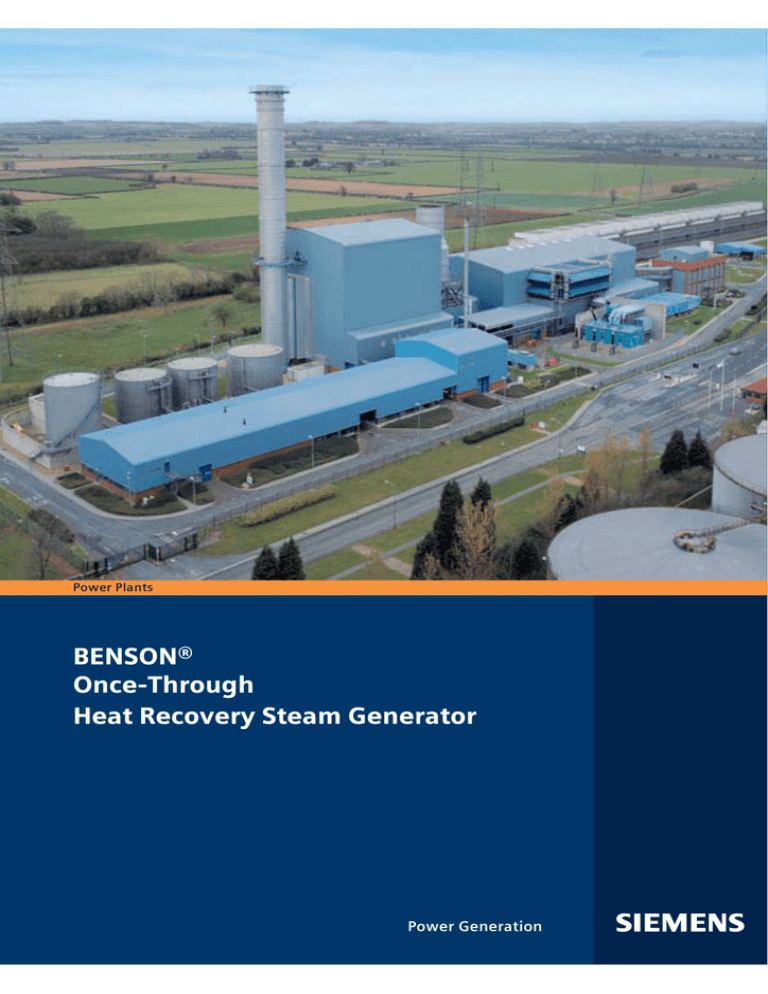

Power Plants

BENSON®

Once-Through

Heat Recovery Steam Generator

Power Generation

BENSON® Once-Through technology for Heat Recovery Steam Generators

New application of proven

technology

Siemens’ development of the OnceThrough (OT) technology started in 1924

with the acquisition of the patent rights

from Marc Benson.

The BENSON® Once-Through technology

using the principles introduced by Siemens

has been successfully demonstrated in

more than 1000 conventional steam

plant applications with ratings up to

1000 MW and steam conditions up to

300 bar/610 °C (4350 psi/1120 °F). The

design principles were successfully applied

for an Once-Through Heat Recovery Steam

Generator (HRSG) at the Cottam 390 MW

combined cycle power plant in Great Britain

in 1999 (as shown on the cover page).

Today, after further development and

more than five years of operational

experience at Cottam – with more than

50,000 operating hours – the BENSON®

Once-Through HRSG technology has

become the most promising one for future

advanced combined cycle power plants.

Simply stated, it retains all the virtues of

the proven natural circulation principle of

drum-type boilers (i.e. flow stability and

uniform temperature distribution), yet at

the same time replaces the high-pressure

drum with thin-walled components to

improve operating flexibility.

As the result of the excellent operating

experience at the Cottam plant, Siemens

is providing the BENSON® HRSG for several

additional utility projects in Central Europe.

Small changes lead to big improvements

Main features of BENSON®

Once-Through HRSG

Drum-type HRSG

The BENSON® Once-Through evaporator

is implemented in the high pressure (HP)

section. This provides the following

attributes:

Drum

• Thick-walled

HP drum limits

operating

flexibility due

to high thermal

stresses

Maintains vertical tube module

arrangement in horizontal gas path

as proven in drum-type boilers.

Replaces HP drum with thin-walled

components (separator), which

improves operational flexibility.

Maintains natural circulation flow

characteristics and therefore assures

flow stability and even heat distribution.

BENSON® Once-Through

Exhaust gas flow

• Natural

circulation

principle

Separator

Exhaust gas flow

• Eliminates HP

drum, thereby

enhancing

operating

flexibility

• Maintains

natural

circulation flow

characteristics

Evaporator

Superheater

Superheater

Evaporator

Requires no changes in HP economizer

and HP superheater.

Retains proven low pressure and

intermediate pressure drums.

The BENSON® system – Elimination of thick-walled components

BENSON® HRSG technology maintains proven features of drum-type boiler and improves operational characteristics

BENSON® Once-Through technology and its licensees

The proven choice for advanced

combined cycle power plants

The BENSON® technology represents the

Once-Through principle for evaporation

at the highest level.

High operating reliability has been

achieved by applying sound design

fundamentals and extensive empirical

analyses:

Intensive research and development

especially in the field of heat transfer

and pressure drop of two-phase flow

at the Siemens BENSON® test rig.

Continuous exchange of design and

testing information between Siemens,

our BENSON® licensees and power

plant owners.

The BENSON® Once-Through technology

is the best choice for advanced combined

cycle power plants. This is evidenced by

the fact that a growing number of customers are adapting it for their power plants.

There are more than ten boiler and HRSG

suppliers worldwide as Siemens BENSON®

licensees and the list continues to grow:

As of the end of 2005, this list includes

five major suppliers in Europe, three in

North America, two in Japan and one

in Korea.

For further information, please refer to

the BENSON® homepage:

www.siemens.com/bensonboiler

The cornerstone for operational flexibility

The BENSON® Once-Through HRSG technology provides the following:

pe

Dr

um

ty

ON

Improved efficiency at high ambient

temperatures due to adjustable evaporating point.

Increase of efficiency during start-up

by minimizing gas turbine operation

in part loads.

Capability for higher steam parameters (pressure and temperature),

because there are no limitations

through natural circulation.

Reduction of gaseous and liquid

emissions through shorter start-up

process and elimination of drum

blow down.

Same

efficiency

Higher efficiency

with BENSON® HRSG

Dr

um

Design

point

N®

BE

NS

Reduced consumption of chemicals

through advanced feedwater treatment.

O

NS

Short

operation in

unfavorable

load

Significant shortening of plant startup time by allowing unrestricted gas

turbine start-up.

BE

Power

®

Since it is difficult for power plant

owners and operators to predict future

operating requirements, the application

of the BENSON® Once-Through HRSG,

along with additional system integration

provided by the Siemens plant designers,

gives the plant the flexibility to meet

cycling and fast start requirements.

And this is done while maintaining high

efficiency levels and environmental

friendliness required for advanced

combined cycle plants.

Efficiency decrease

Integration into Siemens

power plants

Reduced

start-up time

Below design point

Time

Exemplary combined cycle plant start-up curve

Above design point

Ambient temperature

Improved efficiency at high ambient temperatures

With the optimized integration of BENSON® HRSG, Siemens advanced combined cycle power plants provide unsurpassed

operating flexibility.

Power Plants

Published by and copyright © 2006:

Siemens AG

Power Generation

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Power Generation, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

www.siemens.com/powergeneration

Order No. A96001-S90-A496-X-4A00

Printed in Germany

1355 107643M WS 02062.

All rights reserved.

Subject to change without prior notice.

Printed on paper treated with chlorine-free bleach.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or their

respective owners.

The information in this document contains general

descriptions of the technical options available, which

may not apply in all cases. The required technical

options should therefore be specified in the contract.