GT2004-53112 CFD Simulation of the Flow Within and Downstream of a... Swirl Lean Premixed Gas Turbine Combustor

advertisement

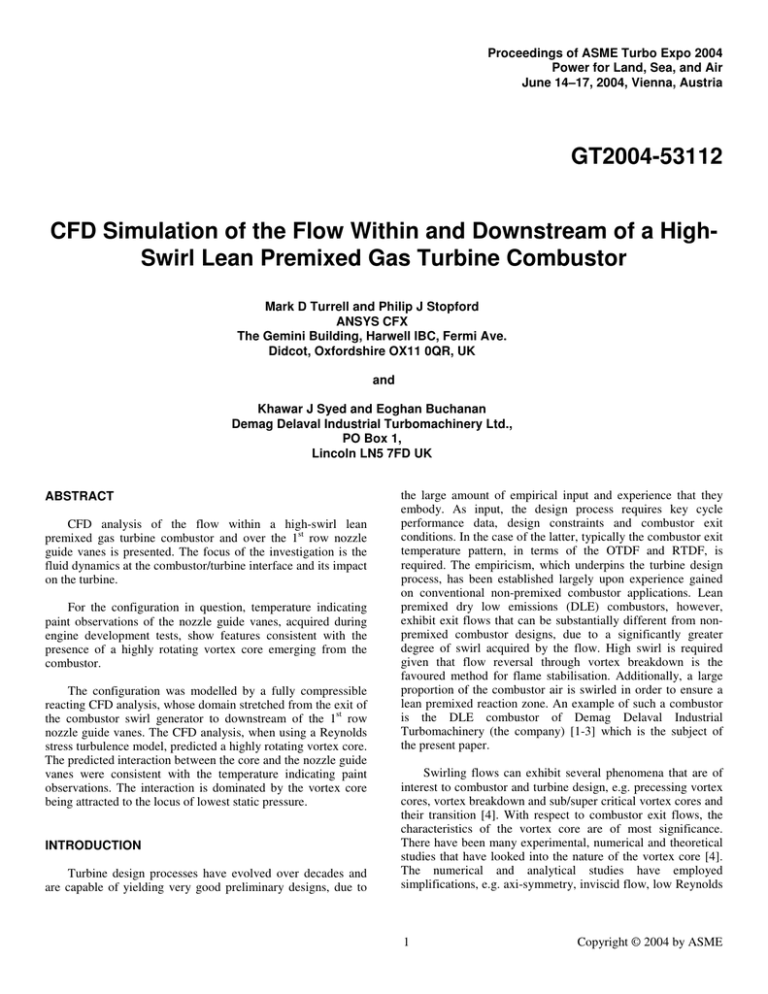

Proceedings of ASME Turbo Expo 2004 Power for Land, Sea, and Air June 14–17, 2004, Vienna, Austria GT2004-53112 CFD Simulation of the Flow Within and Downstream of a HighSwirl Lean Premixed Gas Turbine Combustor Mark D Turrell and Philip J Stopford ANSYS CFX The Gemini Building, Harwell IBC, Fermi Ave. Didcot, Oxfordshire OX11 0QR, UK and Khawar J Syed and Eoghan Buchanan Demag Delaval Industrial Turbomachinery Ltd., PO Box 1, Lincoln LN5 7FD UK ABSTRACT CFD analysis of the flow within a high-swirl lean premixed gas turbine combustor and over the 1st row nozzle guide vanes is presented. The focus of the investigation is the fluid dynamics at the combustor/turbine interface and its impact on the turbine. For the configuration in question, temperature indicating paint observations of the nozzle guide vanes, acquired during engine development tests, show features consistent with the presence of a highly rotating vortex core emerging from the combustor. The configuration was modelled by a fully compressible reacting CFD analysis, whose domain stretched from the exit of the combustor swirl generator to downstream of the 1st row nozzle guide vanes. The CFD analysis, when using a Reynolds stress turbulence model, predicted a highly rotating vortex core. The predicted interaction between the core and the nozzle guide vanes were consistent with the temperature indicating paint observations. The interaction is dominated by the vortex core being attracted to the locus of lowest static pressure. INTRODUCTION Turbine design processes have evolved over decades and are capable of yielding very good preliminary designs, due to the large amount of empirical input and experience that they embody. As input, the design process requires key cycle performance data, design constraints and combustor exit conditions. In the case of the latter, typically the combustor exit temperature pattern, in terms of the OTDF and RTDF, is required. The empiricism, which underpins the turbine design process, has been established largely upon experience gained on conventional non-premixed combustor applications. Lean premixed dry low emissions (DLE) combustors, however, exhibit exit flows that can be substantially different from nonpremixed combustor designs, due to a significantly greater degree of swirl acquired by the flow. High swirl is required given that flow reversal through vortex breakdown is the favoured method for flame stabilisation. Additionally, a large proportion of the combustor air is swirled in order to ensure a lean premixed reaction zone. An example of such a combustor is the DLE combustor of Demag Delaval Industrial Turbomachinery (the company) [1-3] which is the subject of the present paper. Swirling flows can exhibit several phenomena that are of interest to combustor and turbine design, e.g. precessing vortex cores, vortex breakdown and sub/super critical vortex cores and their transition [4]. With respect to combustor exit flows, the characteristics of the vortex core are of most significance. There have been many experimental, numerical and theoretical studies that have looked into the nature of the vortex core [4]. The numerical and analytical studies have employed simplifications, e.g. axi-symmetry, inviscid flow, low Reynolds 1 Copyright © 2004 by ASME number and constant density. Though some studies have been extended to include phenomena such as compressibility [5], they still fall short of addressing all the complexities of practical combustor flows. Practical systems exhibit flows of high Reynolds number and therefore, for practical reasons, require some modelling of the turbulence as well as the heat release process. Issues which affect the vortex core state are the inlet velocity and pressure distribution, turbulence, the heat release process and the resultant density field. CFD offers a way of predicting the vortex core state, however, processes requiring modelling can have a substantial impact on the results, as does the accuracy of the numerical solution. THE DLE COMBUSTOR The company’s dual fuel DLE can-type combustion technology is applied across its range of small industrial gas turbines from the Typhoon at ca. 5MW to the Cyclone at 13.4MW [1-3]. In order to cover this power range, rather than having a single combustor design and applying different numbers of combustors to each engine type, the combustors have been scaled. The Typhoon, Tempest and Cyclone have 6 combustors per engine and the Tornado has 8. The company’s dual fuel DLE combustor is a device that benefits from a high degree of swirl in terms of robust low emissions combustion. In fact, the factors which limit the degree of swirl are turbine rather than combustor characteristics. For high levels of swirl, complex flow patterns can exist at turbine entry rendering the established turbine design process deficient. Engine development tests on the 13.4MW Cyclone engine [6], suggested the possible existence of a highly rotating vortex core, generated within the combustor, which interacts with the 1st row NGVs. Whether or not such a vortex core exists, and the understanding of the implications that arise from it, are therefore of interest. CFD analysis has an important role to play in both understanding the full ramifications of combustor exit flow on the turbine and in establishing combustor designs that are acceptable to the turbine. This however can only be realised if the CFD analysis is capable of predicting sufficiently accurately the key fluid dynamic features. The focus of the present paper is the validation of CFD analysis applied to the combustor/turbine interface in the case of a high-swirl lean premixed DLE combustor. The flow within the combustor and over the 1st row NGVs of the Cyclone machine is computed and the results are evaluated in terms of their consistency with temperature indicating paint observations obtained during the engine development tests. Main Burner Pilot Burner PreChamber Radial Swirler Figure 1 : The Dry Low Emission combustor construction. The combustor consists of three main sections (figure 1): [i] the pilot body, which houses the pilot fuel galleries and injectors for both gaseous and liquid fuel, [ii] the main burner, which houses the main air swirler and main gas and liquid fuel systems and [iii] the combustor, which includes a narrow inlet duct, called the prechamber. The combustor is of a double skin construction and is cooled through impingement cooling. The cooling air is then either exhausted into the combustor through dilution holes downstream of the main reaction zone, or enters the combustor uniformly over the inner liner through effusion cooling holes. The combustor considered in the present work is the effusion-cooled variant. A transition duct, located downstream of the combustor, conditions the flow from the circular combustor exit to a sector of the turbine entry annulus. In the next section, the company’s DLE system is described. The temperature indicating paint results acquired during engine development tests are then presented. Subsequently the CFD model and procedure is described. Finally the CFD results are presented and evaluated. NOMENCLATURE CFD DLE NGV OTDF RTDF SSG Computational fluid dynamics Dry low emissions Nozzle guide vane Overall temperature distribution factor Radial temperature distribution factor Differential Reynolds stress model of Speziale, Sarkar and Gatski Double Skin Impingement Cooled Combustor Combustion air Main fuel Reaction supported by internal and external recirculation zones Pilot fuel Combustion air Figure 2 : Schematic of the dry low emissions combustor concept. 2 Copyright © 2004 by ASME Figure 2 shows a schematic of the combustion concept. The main combustion air enters through a single radial swirler at the head of the combustor. The flow then turns through a right angle into the prechamber followed by a sudden expansion into the combustion chamber. The swirl number is sufficiently high to induce a vortex breakdown reverse flow zone along the axis. This is termed the internal reverse flow zone. In the concept, this reverse flow zone remains attached to the back surface of the combustor, thereby establishing a firm aerodynamic base for flame stabilisation. In the wake of the sudden expansion, an external reverse flow zone is established. The flame is stabilised in the shear layers around the internal and external reverse flow zones. seems plausible that it would be drawn towards the suction side of the central NGV, given the low static pressure in this region. Further, given that the combustor has a clockwise swirl (looking downstream) the deflection of the leading edge and hub platform cooling flows are consistent with this assumption. Example of central nozzle guide vane The fuel, both gas and liquid, is introduced in two stages: the main, which results in a high degree of premixedness and hence low NOx emissions, and the pilot, which is steadily increased as the load demand decreases in order to ensure flame stability. The pilot is arranged, such that as the pilot fuel split increases, the fuel is biased towards the axis of the combustor. Coolant tracks do not remain attached to suction side surface Unlike concepts that involve a free-standing vortex breakdown, such as the EV burner of ALSTOM Power [7], the present combustion concept can benefit from very high swirl numbers, which allows very firm aerodynamics for flame stabilisation and is thus more robust against combustor dynamics. The maximum swirl number that can be allowed is governed by the characteristics of the vortex core. If a highly rotating, axially-accelerating vortex core is produced, such as identified in the experiments of Escudier and Keller [8], part load emissions and turbine performance problems can arise. High temperature Sweeping down of coolant tracks Example of non-central nozzle guide vane OBSERVATIONS OF THE NOZZLE GUIDE VANES During the Cyclone development programme, temperature indicating paint tests were performed to verify the temperatures of the hot components. Observations of the 1st row NGVs indicated high temperatures on the six vanes having their leading edge closest to the axis of each of the six combustors. Figure 3 shows an example of one of these vanes (termed a central NGV) and, for comparison, an example of a non-central NGV. The figure shows high temperatures on the suction side of the central vane and at the hub platform immediately downstream of this. A degree of flow visualisation is offered by the leading edge film cooling, whose tracks can clearly be seen on the temperature indicating paint. The tracks on the suction side of the central vane can be seen to be deflected downwards and seem to be rapidly detached from the surface of the vane. Figure 4 shows the tracks of film cooling at the hub platform in the region of the suction surface of the central vane and its neighbours. The coolant associated with the neighbours can be seen to follow the direction of the nozzle guide vanes, whilst the coolant downstream of the suction side of the central vane moves in a trajectory away from the suction surface. The observations seem to be consistent with the presence of a highly rotating vortex core, i.e. a Rankine vortex, such as that observed in the experiments of Escudier and Keller [8], for a sub-critical vortex core. If such a flow feature is present, it Figure 3 : Temperature indicating paint results for the 1st Stage NGVs. View of leading edge of central and non-central NGVs. In view of these observations, the present CFD analysis was commissioned to determine whether fluid dynamics consistent with the NGV observations could be predicted. The CFD analysis could then be applied to aid either the control of the combustor fluid dynamics or to aid the better design of the turbine to accept the combustor exit flow. The present paper is concerned with the first issue of determining whether CFD 3 Copyright © 2004 by ASME analysis is capable of predicting features consistent with the temperature indicating paint results. for the reactions: CH4 + 3/2O2 → CO + 2H2O and CO + 1/2O2 → CO2. Central differencing has been applied to the diffusion terms of all transport equations. Second order upwind differencing has been applied to the convection terms. In the case of bounded variables, however, first order upwinding has been applied, when physical bounds would otherwise be violated. Transient calculations were performed for the combustor, for which the second order backward Euler scheme was used with a time step of 0.4 msec. The number of mesh nodes in the combustor model was 458,000 nodes (1,973,000 elements). The analysis was run for 26.0msec, with a time step of 0.4 msec and took a total of 330 hours CPU (130 hours wall clock time) on three Pentium IV 1.7 GHz processors with 3.6 Gb of RAM. cen tra l van e Figure 4 : Temperature indicating paint results for the 1st Stage NGVs. View of trailing edge hub platform cooling. FLUID DYNAMICS AND NUMERICAL MODELLING The numerical model was based on the commercial Computational Fluid Dynamics (CFD) software, CFX-5 [9]. Given that the domain of interest spanned both the combustor and the NGVs, a reacting, fully compressible formulation was adopted. Grotjans et al. [10] have compared the predictions of various turbulence models with laser Doppler anemometry measurements for the tangential velocity profile in an industrial hydrocyclone. The results show that the flow in the cyclone is a strong Rankine-type vortex with a potential vortex at large radius and solid body rotation near the axis. Only the Reynolds stress model of Speziale, Sarkar and Gatski (SSG) [11] reproduced this characteristic behaviour. In particular, the k-ε model, even with curvature correction, failed to predict the potential vortex and gives solid body rotation at all radii. While demonstrating the importance of using a Reynolds stress model for a highly swirled vortex flow, it is also apparent that the SSG model is better able to capture the strong shear gradients near the centre of the vortex. The SSG model has therefore been adopted for the present work. Mixing and reaction of the oxidant and fuel (assumed to be methane) are simulated by the eddy dissipation model of Magnussen and Hjertager [12]. In this model, it is assumed that the rate of turbulent combustion is the minimum of the turbulent mixing rate of the reactants and products and the chemical kinetic rate. The CH4 oxidation reaction is represented by a two-step global mechanism of Westbrook and Dryer [13] GEOMETRY AND BOUNDARY CONDITIONS Figure 5 shows the combustor/NGV arrangement. At the head of the combustor is the radial swirler, through which the main combustion air enters. The flow within each of the swirler channels is complex, exhibiting secondary flows which influences the development of the swirl, as well as the fuel/air mixing. In order to resolve the flow details, a very fine computational grid is required for each of the swirler channels, making a single domain calculation, extending from upstream of the combustor to downstream of the NGVs unfeasible. The domain was therefore represented by two computational domains. The first extended from upstream of the swirler and considered only a single swirler channel, utilising suitably defined periodic boundaries. The domain included a sector of the combustor with an axi-symmetric contraction at its exit. This computation was used to determine the flow properties at the exit of the swirler channel. These were then used as upstream boundary conditions for the full combustor calculation, which extends from the swirler exit to downstream of the NGVs. The inlet boundary condition was mapped round to represent the exit flow from each of the swirler channels. Swirler Combustor Transition duct Nozzle guide vanes Figure 5 : Geometry of the computational domain. 4 Copyright © 2004 by ASME The effusion cooling holes were not represented in the computational grid, but account was taken of the effusion air by introducing a uniform mass flux over the combustor surface. Figure 6 shows the surface mesh for the combustor/NGV domain, with a close-up view of the mesh in the region of the NGVs. Figure 8 shows the temperature at a plane through the centre of the combustor and an iso-surface of relatively high vorticity. The latter is high in boundary layers and shear layers, but can also be high in the central part of a Rankine-type vortex which exhibits a solid body rotation. Moving away from the centre of the vortex, the vorticity drops, given that the outer potential vortex is irrotational. A highly rotating vortex core is indicated along the axis of the combustor. Temperature contours Figure 6 : Surface mesh for CFD analysis. RESULTS Figure 7 shows a vector plot of the combustor front end extracted at an arbitrary time step. The velocity vectors are coloured with the component of velocity in the direction of the combustor axis. The transient nature of the flow is clearly seen. The most significant transient feature apparent within the computations is a precessing vortex core. Highly rotating vortex core indicated by high vorticity magnitude Figure 8 : Temperature contours at a diametral plane through the combustor and an iso-surface of relatively high vorticity. The above vortex core characteristic is predicted using the SSG Reynolds stress model, but is not present within a kepsilon model solution. This is illustrated in figure 9 where the tangential velocity magnitude is shown. The SSG model results in significantly greater values, especially immediately upstream of the NGVs. Normalised velocity 1 k-ε model 0.8 0.6 0.4 Reynolds stress model 0.2 0 Figure 7 : Vector plot at a diametral plane at the head of the combustor. Vectors are coloured with the velocity component in the direction of the combustor axis. Figure 9 : Normalised tangential velocities at a diametral plane through the combustor. Comparison between k-ε and Reynolds stress turbulence models. 5 Copyright © 2004 by ASME Figure 10 shows the secondary flow velocity vectors just upstream of the turbine. The vortex core can clearly be identified. The vectors also show the impact of the global swirl and the flaring out effect induced by the transition duct profile. Figure 10 : Velocity vectors at the transition duct exit. Vectors are coloured with the vorticity component in the direction of the engine axis. The progress of the vortex core through the NGVs is shown in figures 11 and 12, where the vortex core is visualised by a surface of relatively high vorticity. Figure 12 shows that the vortex core is directed towards the leading edge of the central NGV. However, as expected, it is attracted by the low pressure over the suction side of this vane. A second rotation is set up near the hub over the pressure surface, due to a large variation in incidence angle with span induced by the vortex core. The vortex core passes the leading edge of the vanes at approximately 40% span, but, as seen in figure 13, migrates towards the hub through the NGV passage. This migration appears to be due to the core being attracted by the locus of lowest static pressure and an interaction between the vortex core and the secondary flows set up within the NGV passage. tral Cen N GV Figure 12 : View of the vortex core over suction surface of the central NGV. The vortex core is visualised by an iso-surface of relatively high vorticity magnitude. Peak gas temperature Central NGV C en tra NGV l Figure 13 : Upper picture: CFD results of the wall shear stress on the suction surface of the central NGV and its neighbours. The vortex core is visualised by an iso-surface of relatively high gas temperature. Lower picture: Temperature indicating paint observation of the suction surface of the central NGV. Figure 11 : View of the vortex core approaching the leading edge of the central NGV. The vortex core is visualised by an iso-surface of relatively high vorticity magnitude. Figure 13 shows a surface of high gas temperature in the region of the NGVs. Given the nature of the temperature distribution within the combustor, the highest temperatures are located in the vortex core. The figure also shows the wall shear stress over the NGVs. The wall shear stress, and therefore the wall heat transfer coefficient, over the suction surface of the central NGV is significantly greater than that over its neighbours. The central NGV would therefore experience a higher heat loading over the suction surface, because of higher temperatures associated with the vortex core and enhanced heat transfer coefficient induced by the core. The above CFD results are consistent with the temperature indicating paint observations depicted in figures 3, 4 and 13. 6 Copyright © 2004 by ASME The high temperatures over the suction surface of the central NGV are due to the presence of a highly rotating vortex core. High temperatures on the hub platform in the neighbourhood of the trailing edge are due to the migration of the vortex core towards the hub. The CFD results presented in figures 7 to 13 are taken from a single time step of the transient solution. However, with respect to the interaction between the vortex core and the NGVs, there is little variation in time as shown in figure 14. The figure shows vorticity at a plane just downstream of the leading edge of the NGVs. Results are presented at different time steps, which represent the most extreme motion of the vortex core. Though there is variation in the magnitude of the vorticity and in its location, the vortex core is seen to be confined to a region close to the suction surface of the central NGV. 5.6 msec 7.6 msec CONCLUSIONS Development testing of the 13.4MW Cyclone gas turbine, revealed high temperatures over the suction surface of the six NGVs which have their leading edge closest to the axis of each of the six combustors. High temperatures were also evident on the hub platform immediately downstream of these vanes. Observations of the trajectories of cool air emerging from leading edge and hub platform film holes show the cooling air to be deflected from the normal gas path. The observations indicate the possible presence of a highly rotating vortex core emerging from each of the combustors. CFD analysis of the flow within the combustor and over the NGVs, utilising the SSG Reynolds stress model, does indeed predict a highly rotating vortex core. The core is seen to be drawn over the suction surface, being attracted by the low static pressure in this region. The core is at approximately 40% span at the leading edge of the NGV, but migrates towards the hub through the NGV passage. This is due to it following the locus of lowest static pressure and due to the interaction between the core and the secondary flows within the NGV passage. The computed vortex core characteristics are in agreement with the high metal temperatures and coolant paths observed during the engine development tests. REFERENCES [1] Kowkabie, M., Noden, R., De Pietro, S., 1997, “The Development of a Dry Low NOx Combustion System for the EGT Typhoon”, ASME paper 97-GT-60. 11.6 msec 14.4 msec [2] Cramb, D.J., McMillan, R., 2001, “Tempest Dual Fuel DLE Development and Commercial Operating Experience and Ultra Low Nox Gas Operation”, ASME paper 2001-GT-76. [3] Alkabie, H., McMillan, R., Noden, R., Morris, C., 2000, “Dual Fuel Dry Low Emission (DLE) Combustion System for the ABB ALSTOM Power 13.4MW Cyclone Gas Turbine”, ASME paper 2000-GT-0111. [4] Lucca-Negro, O. and O’Doherty, T., 2001, “Vortex Breakdown : A Review”, Prog. in Energy and Comb. Sci., Vol. 27, pp. 341-481. [5] Keller, J.J., 1994, “On the practical application of vortex breakdown theory to axially symmetrical and three-dimensional compressible flows”, Physics of Fluids Vol. 6(4) pp. 15151523. [6] Igoe, B.M. and McGurry, M., 2002, “Design, Development and Operational Experience of ALSTOM’s 13.4MW Cyclone Gas Turbine”, ASME paper 2002-30254. Figure 14 : Vorticity at a plane just downstream of the leading edge of the nozzle guide vanes. The middle of the three vanes is the central NGV. [7] Aigner M., Engelbrecht E.G., Eroglu A., Hellat, J. and Syed K.J., 1999, “Development of an oil injection system optimised to the ABB double cone burner”, ASME paper 99-GT-218. 7 Copyright © 2004 by ASME [8] Escudier, M.P. and Keller, J.J., 1985, “Recirculation in Swirling Flows : a Manifestation of Vortex Breakdown”, AIAA Journal, Vol. 23, No. 1. [9] ANSYS CFX, 2003, “CFX-5 Solver Manual, Release 5.6”. [10] Grotjans, H., Menter, F.R., Burr, R.C. and Gluck, M., 1999, “Higher Order Turbulence Modelling in Industrial Applications”, 4th Int. Symp. on Engineering Turbulence Modeling and Measurement. [11] Speziale, C.G., Sarkar, S. and Gatski, T.B., 1991, “Modelling the Pressure-Strain Correlation of Turbulence”, J. Fluid Mech., 227, pp.245-272. [12] Magnussen, B. and Hjertager, B., 1976, 16th. Comb. (Int.) Symposium, pp 719-729, The Combustion Institute. [13] Westbrook, C. and Dryer, H., 1981, “Simplified Reaction Mechanisms for the Oxidation of Hydrocarbon Fuels in Flames”, Combust. Sci. and Technol., 2, pp.31-47. 8 Copyright © 2004 by ASME