Reel handling SCA Technical Support

advertisement

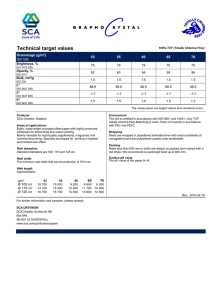

Reel handling SCA Technical Support Paper products Paper products SCA Publication Papers and Sustainable Packaging produce wood containing printing papers and packaging materials. The range includes LWC, Uncoated offset, Newsprint and light weight packaging papers. Lightweight coated paper (LWC) is essentially a thin paper made from ground spruce pulpwood, reinforced with a small proportion of kraft pulp to add strength. The resulting paper is then covered with coating in which the most important constituent is fine-grained clay. Uncoated offset paper and newsprint paper are made from fresh spruce pulp wood. Sustainable Packaging products are made from ground spruce pulpwood, reinforced in some products to a large extend of kraft pulp to add strength. The Splendo and Operio products have also an extrusion coating. Depending on the paper grade different clamping forces are recommended. If the clamping force is too high there is a risk that the reel may become oval shaped. Wrapping protects the paper The wrapping is a PE-paper laminate which provides a water vapour barrier and protects the reels against humidity and water. This means that the reels can handle light rain and dry snow. However the reel cannot stand in water or resist water under pressure. The wrapper also provides good protection against mechanical damage, dirt and airborne impurities, and is well suited for material recycling. Unloading On arrival Before unloading begins please check the reels for any damage. If any damage is found, a remark must be made on the way bill (carriers and receivers). Be cautious of protruding lashing points, do not push or drag the reels when unloading! The truck floor must be swept regularly. Even a very small stone or screw etc. can cause severe damage to the reel. Storage Use reel guards. Careless driving can cause severe damage to the reels. In the warehouse If possible divide the floor space in to bays and number them. Plan the bays so that different marks/lots are always accessible, avoiding unnecessary handling. Leave adequate space between the stacks. Ensure reels are correctly stacked within the bays. Storage Uneven stacking can cause edge damage and even serious accidents from falling reels. Always control the free height and distance when lifting and lowering in the stack. It is essential that the area is swept regularly; even a very small stone or screw can cause severe damage to the reel. The place of storage must be dry. Never place a reel in water. Clamping force Clamping force Clamping force is usually measured in kiloNewton (kN). 1 kN (1000 N) corresponds to a weight of approximately 100 kg on the reel. 30 kN corresponds to a weight of 3000 kg on the reel. Maximum clamping force according to reel weight Paper quality Pressure factor Uncoated offset and Newsprint 1.0-1.4 Sustainable Packaging – Puro LWC1.7-2.0 Sustainable Packaging – Splendo, Operio Example: Total paper weight 2000 kg × factor 1.3 = total pressure = 26 kN. Clamping force should be checked regularly, there are several different devices available for this purpose. Smart-Intelligent clamping systems These systems automatically regulate the clamp pressure to ensure that only the minimum required force is used at all times throughout the handling operation. This greatly reduces the risk for out-of-roundness and dropped reels. Why the correct clamping force is necessary Excessive force can cause: • Reel deformation • Reel out-of roundness (oval) • Reel core damage Insufficient force can cause: • Reel to drop • Reel to slide/telescope Please contact SCA Technical Support if you have any queries concerning the correct clamping force for SCA reels. Contact information is to be found at: www.publicationpapers.sca.com and sca.com/sp Clamping force Check list for the correct clamp: Check list for the correct lift truck: • Weight of reels to be handled • Max- and min diameter • Reel width • Clamping force required • Type of friction surface (clamp pad) • Storage and stowage pattern • Number of reels per handling • Rotation • Type of clamp • Lifting capacity • Height of stowage • Hydraulic functions pressure and flow • Tilting functions • Clamp mounting Handling Overloading/Incorrect handling To compensate for the extra weight of the free riding reels the clamping force can increase significantly above the recommended level, which can result in out of roundness. This practise is also dangerous for persons nearby as the free riding reels can easily fall and cause serious injury or even death. Risk for deformation and out of roundness. Always place the pad in the centre of the reel. Always control the distance to the floor before rotating. Never drive with a horizontal reel. Risk for edge damage and deformation. Always place the pads in the centre of the reels. Keep the mast vertical! Clamps Contact pads Contact pads are the most important part of the clamp. In most handling situations, the pads are the only part of the clamp in contact with the reels. Regular maintenance is essential. Control and clean the friction surface, and check the pad for damaged/sharp edges as these can cause severe damage. Worn pads can require up to 3-4 times more clamping force than a clamp in good condition. Re-surface or replace worn pads. SCA’s reel numbers Reel number identification The reel numbers look like this: YYABBCCCDDZZZZ YY =Year A = Paper machine number BB = Production week (54, 55 rewinded reels) CCC = Tambour number during the week DD = Set and position in the set ZZZZ = 1876 is the number for Ortviken paper mill We use 001-399 in even years and 501-899 in odd years. 01-15 for the reels from set 1. 16-30 for the reels from set 2. 31-45 for reels from set 3. Reels with numbers 1, 15, 16, 30, 31 and so on are the edge reels. The IFRA Code ABBCCCDD-EEEEFGZZ A = Paper machine number BB = Production week (54, 55 rewinded reels) CCC = Tambour number during the week DD = Set number and position in the set EEEE = Brutto weight in kilo F = Reels per pack, 1 or 2 G = Grammage code used for Newsprint ZZ = 76 is the number for Ortviken paper mill YYABBCCCDDZZZZ Claim routines Copy of the commercial invoice This document confirms the value of the goods. It also shows the delivery terms and who is on risk during the transport and consequently in the right of compensation under the transport (cargo) insurance. Copy of the way bill The way bill proofs that a transport has been carried out. It also shows the name of the carrier. Claim against the carrier Commercial invoice. • A remark in the way bill must be made to proof the con- dition of the goods at the time of delivery into the custody of the buyer/receiver. • If there is no remark in the way bill, it is considered that the goods is delivered in sound condition according transport law. • The remark has to be made for visible damage or dam- mage that should have been visible if a control had been carried out. Important: the remark has to be made in the carriers and receivers copy of the way bill. Why the documentation is important The way bill. In order to seek any compensation from the carriers a fully completed and correctly signed consignment note and copy of the commercial invoice needs to accompany any subsequent claim. To receive compensation from the transportation company or cargo insurance Should any goods be rejected at the point of delivery they will remain the property of the mill, who together with SCA claims department and cargo underwriters will decide what action to take for their disposal. Several options are available; • Negotiate a discounted rate for the goods • Mill looks to sell off the goods to an interested third party • Make arrangements for collection and transportation back to the terminal • Insurance company takes over ownership and control of the goods products Photo: Per-Anders Sjöquist. Illustrations: Originaldesign Sweden. Printer: Tryckeribolaget, February 2014. FSC nr SGS-COC-00332 Both the paper and the printer are FSC-certified. sca.com/publicationpapers sca.com/sp Because our products make life easier for you and for millions of people around the world. Because our resources and the way we work are natural parts of the global lifecycle. And because we care.