enter

advertisement

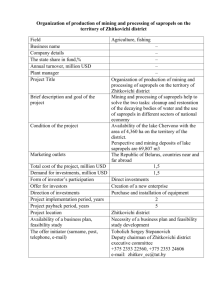

enter Energy Intelligent Solutions Established in 1992, providing energy efficiency, carbon management and carbon process improvement solutions for Energy and management solutions industrial and commercial organisations Energy audits, utilities strategy, carbon management, process integration, exergyData analysis, data mining, mining specialists optimisation, implementation, business intelligence, EMIS .. BP, Rohm & Haas, Lafarge, Syngenta, Carlsberg, Dairy Crest, Cleveland Potash, Blue Sainsbury’s, chip client Marston’s, Centrica Power, Agfa, Artenius, ... oil, petrochemicals, chemicals minerals, mining, metals power, paper, Wide food and beverage base food retail, Experience hospitality, offices Some Recent Clients • • • • • • • • • • • • BP (oil) KBC (refineries) Honeywell (controls) Schneider Electric (controls) Endress & Hauser (instrumentation) Rohm and Haas (petrochemicals) Cleveland Potash (minerals) Buxton Lime (lime) Lafarge (cement) Artenius (plastics) Marks and Spencer (food retail) Sainsbury’s (food retail) • • • • • • • • • • • • Marston’s (breweries, pubs) Mitchells and Butler (pubs) Carlsberg (brewing) Heineken (brewing) Dairy Crest (dairies) Pfizer (pharmaceuticals) Syngenta (agrichemicals) Centrica (power generation) SSE Power (CHP) M real Paper (paper) British Sugar (sugar) British Airways (data centre) Some Recent Projects Chemicals Sector - Development of a strategy for energy and utilities at a major chemicals complex to reduce energy and maintenance costs and improve profitability Petrochemicals - Development of a new utilities strategy including the use of renewable energy source and bio-fuels to reduce operating costs and improve profitability Minerals - Feasibility of a large combined heat and power plant and conversion of the site from gas to oil. Development of an energy strategy Dairy - Development of a strategy for fuels taking account of prices, capital investment, carbon emissions, operability, reliability and maintenance Drinks - Identification and development of energy cost reduction initiatives, involving process heat recovery, boilers and steam systems, CHP, compressed air and refrigeration. Aluminium Processing - Development of heat recovery solutions to reduce energy costs associated with the production of aluminium plates for digital printing Military Base - Development of a solution to recover heat from engines to provide chilled water for cooling. Foods Manufacture - Development of a strategy and implementation plan for the efficient design and operation of refrigeration systems More Recent Projects Dairy - Development of a strategy and implementation plan to reduce energy costs in dairies, and provision of support to achieve improved performance Pubs – Development of carbon and energy management strategy and implementation plan, followed by support for the implementation of improvements Minerals – Energy studies at minerals processing plants to identify and develop opportunities to improve energy and process performance Power Generation – Detailed analysis of power plant performance to identify opportunities to increase energy efficiency Oil and Gas – Detailed analysis of process and production data to identify measures to improve the operations of oil fields, drilling, gas processing, oil stabilisation and oil refining Brewing – Identification of opportunities to reduce energy costs and development of business cases Commercial Buildings – Identification and development of strategies to reduce energy costs and carbon emissions. Identification and development of specific opportunities Paper Manufacture – Detailed analysis of process performance using data mining techniques to identify quick hit solutions to lowering energy use and costs. Implementation of a real time energy management information system Global Energy Consumption Where will the new energy come from - Oil? Gas Global Energy Trading Issues in the UK Volatile energy prices Concerns over security of supply Demand restrictions Uncertainty over regulations Planning requirements Stakeholder interest Incentives for energy efficiency and low carbon New technologies A typical industrial process Energy Flows The drivers for energy management in industry Need to reduce operating costs to improve profitability and increase competitiveness Regulatory compliance Increasing demands for low carbon products and services from customers Further emphasis on environmental performance by key stakeholders Risks Concerns about the security of energy supplies Competitor actions Restrictions on energy demands The solutions Short term Make the best of existing assets – improved performance monitoring and management, process control, optimisation, lower cost investments in efficient equipment Minimise impact of changes with flexible (optimum) plant operation Longer term Alternative energy sources Renewable energy Combined heat and power Process modifications and significant investments in energy efficiency New products Energy dashboards to raise interest and awareness • http://84.22.181.22:2031/Viewer.aspx?Dd_ContentId=7abc6dd8-7b01-45d1-a9c0-7af911528ff5&Dd_ContentType=Dashboard&Dd_ViewerFeatures=IsLogoVisible=false;IsToolbarVisible=false;IsNavigationVisible=false Optimisation Using data mining models and optimisation to manage production and reduce electricity demand 18,000 16,000 14,000 Demand kW 12,000 10,000 With production management 8,000 Without production management 6,000 4,000 2,000 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Hour The solutions Short term Make the best of existing assets – improved performance monitoring and management, process control, optimisation, lower cost investments in efficient equipment Minimise impact of changes with flexible (optimum) plant operation Longer term Alternative energy sources Renewable energy Combined heat and power Process modifications and significant investments in energy efficiency New products More CHP Renewable Energy Developing an energy strategy What are the future scenarios? How likely are they? How will alternative options perform in the different scenarios? Which options are best? What is the payback? Firstly we need to model performance Use data mining … … to predict future energy demands and costs Define the uncertain inputs Understand the possible energy costs And find the main drivers But we need solutions, not just insight Use risk optimisation to evaluate benefits But we also need to consider flexible operation One solution is not best for all circumstances Minimum daily energy costs (carbon, demand,..) In Summary Energy and carbon is uncertain and represents a significant risk Analysis of the scenarios shows the likelihood of significant impacts on the business Identifies the main issues Risk optimisation Finds the best options for plant investments Taking account of flexible operations Allows for handling of constraints One of a range of tools to understand and improve energy and carbon performance What is the value of risk analysis Forces a methodology Raises interest and awareness Creates the business case Improves understanding (Finds optimum solutions) (Finds the best strategy)