Formalizing the Four-Dimensional (4D) Topology as the Base for 4D... Construction Planning Xing SU

advertisement

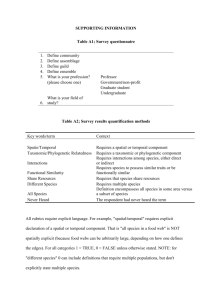

Construction Research Congress 2012 © ASCE 2012 Formalizing the Four-Dimensional (4D) Topology as the Base for 4D analysis in Construction Planning Xing SU1, Lei ZHANG2, Abdul Rahman ANDOH3, and Hubo CAI4 1 Xing Su, Ph.D. Candidate, Division of Construction Engineering and Management, School of Civil Engineering, Purdue University, 550 Stadium Mall Drive, West Lafayette, IN 47906; PH (765)-418-4331; email: XSU@PURDUE.EDU 2 Zhang, L., Institute of Geological Surveying and Mapping of Anhui Province, 18 JiuHuaShan Road, Hefei, Anhui, PRC 230022. 3 Abdul Rahman Andoh, M.S., Division of Construction Engineering and Management, School of Civil Engineering, Purdue University, 550 Stadium Mall Drive, West Lafayette, IN 47906 4 Hubo Cai, Ph.D., P.E., GISP, Assistant Professor, Division of Construction Engineering and Management, School of Civil Engineering, Purdue University, 550 Stadium Mall Drive, West Lafayette, IN 47906 ABSTRACT Construction site is a dynamic environment in which workspaces of construction activities continuously change in aspects of space and time throughout the entire lifecycle of a project. Without a comprehensive plan that considers spatial-temporal relationships between the site objects, conflicts or improper layout may frequently occur on construction site and influence the success of the project. Four dimensional (3D+time) modeling technique has been proven to be useful and promising in construction planning. However, it still lacks the ability to capture the site dynamic natures and analyze spatial-temporal relationships. The overall goal of this study is to develop a 4D topology system based on GIS concept for construction planning, which enables deriving 4D relationships between site objects in real-time and provides a comprehensive 4D topological analysis function, overcoming a major drawback in the current 4D practice. This paper presents the result of the development of the 4D topology framework in construction. The semantics of 4D topology are defined to describe corresponding dynamic construction site events. A 4D topological framework is formalized to capture the site dynamics which forms the base for 4D analysis. It could complement the CPM or 3D model in construction planning under both spatial and temporal constraints. The direction of future research in 4D topology-based analysis is also discussed. INTRODUCTION 4D Techniques and Construction Planning Construction site is a dynamic environment. Workspaces of construction activities, layout of temporary facilities, and material deployment continuously change on site in aspects of space and time throughout the entire lifecycle of a project. The dynamic objects on site interact with each other in a complex spatial-temporal manner. 397 Construction Research Congress 2012 © ASCE 2012 Without a comprehensive plan that considers spatial-temporal relationships between the site objects, conflicts and improper site layout may frequently occur on construction site. It has been identified that time-space conflict is one of the major causes of productivity loss in construction industry. The congested workspace and restricted access can cause efficiency losses of up to 65% and 58%, respectively (Sanders et al. 1989). Developing a construction plan is a critical task in the management of a construction project (Hendrickson, 2000). Construction planning and control are not only temporal but also spatial (Winch, 2001). Recently, research efforts are emerging in the provision of project planners and managers with computer-based advisory tools to visualize the construction plan in a 4D (3D+time) environment. 4D models, such as 4D CAD, were seen as a natural progression to 3D models, as it adds a further dimension (Phair, 2000). Positive attitudes were received from many researchers and practitioners towards the development and application of 4D technology in construction (Liston et al. 2001, and Fischer and Kunz, 2004). Knowledge Gaps in Current 4D Techniques Despite the benefit and demonstrated potential, to date, 4D technology is not accepted on a large scale in construction management (Webb et al. 2004). Some limitations of the current 4D technology are discussed such as the lack of a concept to prepare the 4D model within appropriate time and in parallel to the creation of the construction schedule (Tulke and Hanff, 2007), the visualization is not easily customizable (Issa and O’Brien, 2003), and that spatial relationships and topology are not well supported by most of the 4D models (Bansal, 2011). Akinci et al. (2002) indentified the dynamic process problem and considered most of the previous 4D model to be not informative enough as the spaces required by construction activities are not integrated. They developed a methodology to generate space-loaded 4D production models to create workspaces for each construction activity and detect space-time conflicts. This achievement makes 4D simulations more realistic and advances spatial conflict analysis. However, it still does not fully capture the dynamic geometry change of workspaces since every workspace in it is of the same prism shape through the project duration. In addition, it focuses only on space-time conflicts, and does not consider other relationships between site objects. Two issues are identified here as the critical primary research themes for advancing the development of 4D systems to automate construction project planning and control tasks. The first issue is the analytical capability. Current 4D technique focuses on visualizing 3Dgraphics over time and cannot support analytical programs (Halpin 2006). For instance, topological queries such as identifying columns within the 200ft crane radius cannot be answered. This is the main reason that 4D models are rarely used for construction phase decision making and administration (Martinez and Halpin 1999). The second issue is the dynamic capability. Visualizing 3D objects at discrete points throughout the duration of the associated task, i.e. displaying the entire product for the whole task duration, is not representative of the construction process 398 Construction Research Congress 2012 © ASCE 2012 399 (North and Winch 2002,). The shape, location, and properties of a construction object change throughout its life cycle. RESEARCH OBJECTIVES The overall goal of this research is to create a 4D system for construction planning to enable 4D topological analyses to address the second issue. The system contains a 4D topology framework that defines the semantics of the 4D topology in construction and their mathematical formulization, and a 4D construction model that integrates construction dynamics to be analyzed in the aspect of 4D topological relationships. The system structure is illustrated in Figure 1. 4D Topology System Method Temporal Interaction Research Entity Construction Construction Lifecycle Object Model Life cycle Geometry; Temporal area Location; Interaction Pattern Existing Site Dynamics in: Spatial 3D Interaction Topology Evolution style; 4D Topology 3D Model 1D Schedule knowledge 9-IM 4D Visualization Figure 1. 4D Topology System Architecture This paper proposes a conceptual 4D topology framework for the left part. The following sections introduce the existing 3D topology framework, identify the temporal interaction patterns, and integrate both to form the 4D topology framework. Specifically, the research objectives include: 1. Define the semantics of 4D topology in construction; 2. Identify site objects’ temporal interaction pattern; 3. Formalize the 4D topology in construction in a matrix format; 4D TOPOLOGY SEMANTICS IN CONSTRUCTION 4D Topology in construction describes relationships between site objects in temporal and spatial aspects. The site objects here has a generalized meaning, including building elements, temporal facilities, equipments and labors, their workspaces, and paths. During construction planning, not only building products and schedule need to Construction Research Congress 2012 © ASCE 2012 be considered, but also the work activities to create the building products as well as the interaction between those activities spatially and temporally. Some characteristics of 4D topology in construction are identified. First, the space and time attributes of each site object all have explicit boundaries. The information could be obtained from the 2D/3D drawing and the schedule. Second, every site object has an evolutionary geometry along periods. Nothing could appear on site without necessary activities which occupy certain spaces. A cast-in-place element needs concreting work; a prefabricated element needs installation, temporary facilities needs assembling and disassembling. Those activities for every object all need workspaces with different geometries at different construction stages. At last, the geometry evolution of each object all has predefined or expected evolutionary patterns. The patterns are determined by construction methods. The characteristics enable certain simplification of the 4D topology framework in construction, which is further discussed in the following sections. 3D TOPOLOGY FRAMEWORK IN GIS In most cases the architectural and/or structural function of a particular object or component is associated with its shape, position, and relationship to other components so that the geometric properties and 3D spatial relationships between building components accordingly play an important role in solving most of the design and engineering problems (Borrman and Rank, 2009). The first substantial progress towards a formalization of topological relationships was the development of the 4-Intersection Model (4-IM) by Egenhofer and Herring (1990). It was extended to 9-Intersection Model (9-IM) by incorporating the exteriors to solve topological relationships between elements including lines and regions. The 9-IM examines the intersections of each of the interior and boundary and exterior of object A with each of the interior and boundary and exterior of object B, resulting in the 3x3 matrix as follows: ⎡ Ao ∩ B o ⎢ I = ⎢ ∂A ∩ B o ⎢ A− ∩ B o ⎣ Ao ∩ B − ⎤ ⎥ ∂A ∩ B − ⎥ A− ∩ B − ⎥⎦ A○ denotes the interior, ∂A denotes the boundary, A⎯ denotes the exterior of A, and ∩ represents the intersection operator. Each element is the result from the intersecting operation, which can be TRUR or FALSE. This framework is updated to support 3D objects (Zlatanova, S., 2000). There are 8 basic possible relationships between 3D and 3D objects, which are illustrated in Figure 2. In construction context, most of the product and workspace could be presented by 3D geometries. The 4D topology framework developed in this study adopts this 9-IM to represent the spatial relationships. Ao ∩ ∂B ∂A ∩ ∂B A− ∩ ∂B 400 Construction Research Congress 2012 © ASCE 2012 401 Disjoints Meets Contains Covers Inside Covered by Equals Overlaps Figure 2. Configurations of topological relationships between 3D and 3D objects IDENTIFY TEMPORAL INTERACTION PATTERNS Site Object Life Cycle There are many types of construction site objects such as building element, temporary facility, equipment, and path. Those objects all interact with surrounding objects and environment and have different patterns of dynamics. For example, the concrete face of a rock-filling dam has its geometry changing through the concreting period; and a crane usually involves geometry change (arm swing and extending) and position change (translation and rotation). All the motions need time to perform and time is closely related to the evolution progress of these spatial properties. In traditional 1D scheduling method, every construction activity could be represented by a line segment on the time axis from “Start Time” (ST) to “Finish Time” (FT). It separates the time axis into three parts: 1, before ST, 2, from ST to FT, and 3, after FT (Figure 3). Activity 1 ST 2 FT 3 Time Figure 3. Representing an activity on the time axis From the geometry evolution perspective, every site object has different statues of geometry or spatial information during the three stages. Taking a concrete wall for example, it’s geometry does not exist at stage 1, which is represented by “empty” and indexed by “Emp”; at stage 2, the geometry becomes the concreted part plus its required activity workspace including formwork and labor working area, which can be called “activity geometry” and indexed by “Act”; at stage3, the wall has been finished and there is no activity workspace requirement, and its geometry is just the solid wall itself, which is called “solid geometry” and indexed by “Sol”. Therefore, along the time axis the concrete wall’s geometry has three distinguishable stages: empty, activity geometry, and solid geometry. Table 1 lists the geometry evolution in different stages Construction Research Congress 2012 © ASCE 2012 402 for six types of construction objects including building elements, excavated part, temporary facilities, equipments, storage, and paths. Akinci et al. (2000) actually has identified and classified space types into eight categories, which are product space and workspace, process space, equipment space, equipment path, storage space, path space, protected space, and support space. The space classification used in this study at this moment is more generalized to illustrate the geometry evolution process along time. Table 1. Site objects geometry evolution Stage Object Building Element (Ele) Excavated Part (Exc) Temporary Facility Assemble (TempA) Temporary Facility Dissemble (TempD) Equipment (Equ) Storage (Sto) Path (Path) 1 2 Empty Solid space Empty Solid space Solid space Solid space Empty Activity space Activity space Activity space Activity space Activity space Activity space Activity space 3 Solid space Empty Solid space Empty Solid space Solid space Empty The temporary facility itself has three types of statues: assembling, assembled, and disassembling. The table lists its assembling and dissembling statues as two different objects. During the assembled statues, the temporary facility could be considered as equipment. In practice, the objects should also be selectively considered depending on the expected detail level of the construction planning work. Temporal Relationships Configurations Since the temporal stage determines an object’s geometry pattern, it is necessary to examine the temporal attribute as a first step for 4D topology formalization. When there are two objects, more stages could happen. Figure 4 illustrates an example that two objects have five different interaction stages. Assume both objects are building elements, according to Table 1, the geometries of the two objects in the five stages are: P1: Emp(A) vs. Emp(B); P2: Act(A) vs. Emp(B); P3: Act(A) vs. Act(B); P4: Sol(A) vs. Act(B); and P5: Sol(A) vs. Sol(B). A A2 A1 A3 B2 B1 B P1 P2 P3 B3 P4 P5 Figure 4: Possible temporal relationships for building elements A 3x3 Temporal Interaction matrix TIAB examining the intersection of stages between A and B is utilized to identify the temporal relationships: Construction Research Congress 2012 © ASCE 2012 403 A ∩B A ∩B A ∩B TIAB = A ∩ B A ∩ B A ∩ B A ∩B A ∩B A ∩B The element of the matrix is either 0 (false) or 1 (true). There are 4 possible configurations for interaction without temporal overlaps and 9 possible configurations for interaction with temporal overlaps as shown in Table 2. Each configuration has a unique TIAB matrix so that Table 2 also serves as a lookup table for determination of temporal relationship configurations. The terminology describing the temporal relationships is similar to those in the 9-Intersection framework. The difference is that an “ahead” or an “after” is added as a prefix to describe the sequence of the two activities. Table 2 Two objects temporal relationship configurations No temporal overlaps: Config.4: Config.3: Config.2: Config.1: A after-Disjoint B A ahead-disjoint B A after-meet B A ahead-meets B 1 0 0 1 1 1 1 1 0 1 0 0 1 0 0 1 0 0 0 0 1 0 0 1 0 1 1 0 A0 1 0 0A 1 1 1 1 A A B Temopral overlaps: Config.1: A ahead-overlaps B 1 1 0 0 1 1 0 0 1A B B B Config.2: A ahead-coveredby B 1 0 0 0 1 1 0 0 1 A B Config.3: A equals B 1 0 0 0 1 0 0 0 1 Config.4: A ahead-covers B 1 0 0 0 1 0 0 1 A 1 Config.5: A contains B 1 1 0 0 1 0 0 1 1 A Config.6: A after-covers B 1 1 0 0 1 0 0 0 1A B Config.7: A after-overlaps B 1 0 0 1 1 0 0 1 1 A B Config.8: A after-coveredby B 1 0 0 1 1 0 0 0 1 A B B B B A B Config.9: A inside B 1 0 0 1 1 1 0 0 1 A B Construction Research Congress 2012 © ASCE 2012 FORMULATE 4D TOPOLOGICAL MATRIX A 4D ToPological (4DTP) matrix integrates 9-IM with the TI matrix. As for a TI matrix of object A and B, each element represents a certain period of temporal intersection or a simple result of “no intersection”. The geometries of A and B evolve and interact in the intersected periods. Assume A and B have fixed (non-time dependent) workspaces in A2 and B2 stages; each intersected period will have a unique 9-IM matrix representing the spatial interaction status of A and B. To simplify the matrix, two transform vectors are suggested to index the 9-IM matrices: 100 10 1 …… (4.1) 1 2 4 ………… (4.2) T1 and T2 are designed to convert a 3x3 matrix into an integer without ∙ , the Disjoints information lost. By using dot product operation ∙ 9 9-IM matrix could be indexed by a single integer as follows: 0 0 1 1 Disjoints: 100 10 1 ∙ 0 0 1 ∙ 2 447; 1 1 1 4 Similarly, other 9-IM matrices could all be indexed: Contains – 744; Inside – 117; Equals – 124; Meets – 467; Covers – 764; Covered by – 137; Overlaps – 777. The vector 4.2 contains the three smallest integers that the sum of any two of them is a different number, which guarantees that every transformed matrix is uniquely corresponding to the original one. Using the vector 4.1 and 4.2 together makes sure that no information is lost during the transform and the result is easy to present. Thus, a combination matrix could be formed containing all the spatial interaction information in all possible temporal interacting periods: 9 9 9 9 9 9 9 9 9 Each element of the above matrix is the index of the 9-IM matrix of A and B at the corresponding period. Considering the example shows in Figure 5, the spatial-temporal matrix of building element Wall (A) and building element Column (B) would be: 0 0 0 0 777 447 0 777 447 According to equations 4.3 and 4.10, “777” means “overlaps” and “447” means “disjoints”. The matrix tells that A’s workspace and B’s workspace overlap, A’s solid product and B’s workspace disjoint, A’s workspace and B’s solid product overlap, and A’s solid product and B’s solid product disjoint. 404 Construction Research Congress 2012 © ASCE 2012 405 Wall (A) A Column B Column Wall (A) Figure 5: An example of using 4D topology in construction planning The 4D topology matrix is finally generated by the following operation: 1000 Since all the elements in the Spatial-Temporal matrix are three-digit integers, the factor 1000 put the temporal interaction information on the thousandth digit. Referring to the example in Figure 5: 1 1 0 0 0 0 1000 1000 0000 4 1000 0 1 1 0 777 447 0000 1777 1447 0 0 1 0 777 447 0000 0777 1447 The matrix contains all the 4D topological information regarding to the interaction between Wall (A) and Column (B) based on the assumption that A and B all have fixed (non-time dependent) geometries during construction. In real construction projects, there are some types of construction activities actually have their geometry varies along time, such as trenching (geometry grows) and backfilling (geometry shrinks). In this case some elements in the 4DTP matrix may have two or more values. Multiple values are used in one matrix location to solve this problem by listing all the interacting situations in time sequence. 4 CONCLUSION AND DISCUSSION As part of an overall research, this paper presents the theoretical foundation of a 4D topology system for construction planning. A set of 4D topological matrices is developed to describe the interacting manner of site objects in 4D context. The geometry evolution of the site objects is considered and formatted by the matrices. The resulting framework of the 4D topology forms the base for 4D analyses and complements the CPM or 3D model in construction planning under both spatial and temporal constraints. The main work of the remaining part of this research is the development of the 4D dynamic model. Currently, this part of is in progress. The model is designed to serve as an entity to conduct 4D topological analyses. It could be generated from CAD models by incorporating the site dynamic information such as construction methods and the schedule. A construction method library will be developed based on field observation to store default parameters of different construction methods for site space requirements. A topology operation libraries based on GIS concept will be integrated as the technical tools to enable 4D topological analysis. The resulting system of the 4D Construction Research Congress 2012 © ASCE 2012 topology will enable 4D analysis and visualization considering workspaces. It could also serve as an effective explanative communication tool in construction project management. REFERENCE Akinci, B., Fischer, M., Levitt, R. and Carlson, R. (2002). “Automated generation of work spaces required by construction activities,” Journal of Construction Engineering and Management, 128(4), ASCE, 306-315. Bansal V. K. (2011) “Use of GIS and Topology in the Identification and Resolution of Space Conflicts.” J. Comput. Civ. Eng., 22(4), 233-242. Borrmann, A. and Rank, E. (2009). “Topological Analysis of 3D Building Models Using a Spatial Query Language,” Advanced Engineering Informatics, 23, Elsevier Ltd. 370-385. Egenhofer, M., and Herring, J. (1990) “A mathematical framework for the definition of topological relationships”, Proc. of the 4th Int. Symp. on Spatial Data Handling. Halpin, D. W. (2006). Construction Management, Chapter 7, Project Scheduling, John Wiley & Sons, Inc. 101-125. Hendrickson, C. (2000) “Project Management for Construction – Fundamental Concepts for Owners.” Engineers, Architects and Builders, 2nd edition. Issa, R. R. A., Flood, I., and O’Brien, W. J., eds. (2003). “Closure.” 4D CAD and visualization in construction: Developments and applications, A.A. Balkema, Tokyo, 281–284. Martinez, L. H., and Halpin, D. W. (1999). “Real world applications of construction process simulation,” Proc., 1999 Winter Simulation Conf., P. A. Farrington, H. B. Nembhard, D. T. Sturrock, and G. W. Evans, eds., WSC Foundation, Phoenix, 956–962. North, S. and Winch, G.M. (2002). “VIRCON: a proposal for critical space analysis in construction planning,” ECPPM, Slovenia, 9–11 September, Balkema, Rotterdam. Phair, M. (2000). “Software model builders add an extra dimension to 3D CAD.” ENR, 6 March. Sanders, S.R., Thomas, H.R. and Smith, G.R. (1989). “An Analysis of Factors Affecting Labor Productivity in Masonry Construction.” PTI # 9003, Pennsylvania State University, University Park, PA. Tulke J., Hanff J. (2007) “4D construction sequence Planning -- new process and data model.” CIB 24th W78 Conference. Maribor, Slovenia, 79-84. Webb, R. M., Smartwood, J., and Haupt, T. C. (2004). “The potential of 4D CAD as a tool for construction management.” J. Constr. Res., 5(1), 43-60. Winch, G.M. (2002). “Managing construction projects: an information processing approach.” Blackwell Sicence, Oxford. Zlatanova, S. (2000) “3D GIS for Urban Development”, ITC Dissertation Series No.69. 406