Modelling a Global EPCM (Engineering, Procurement and Construction Management) Enterprise

advertisement

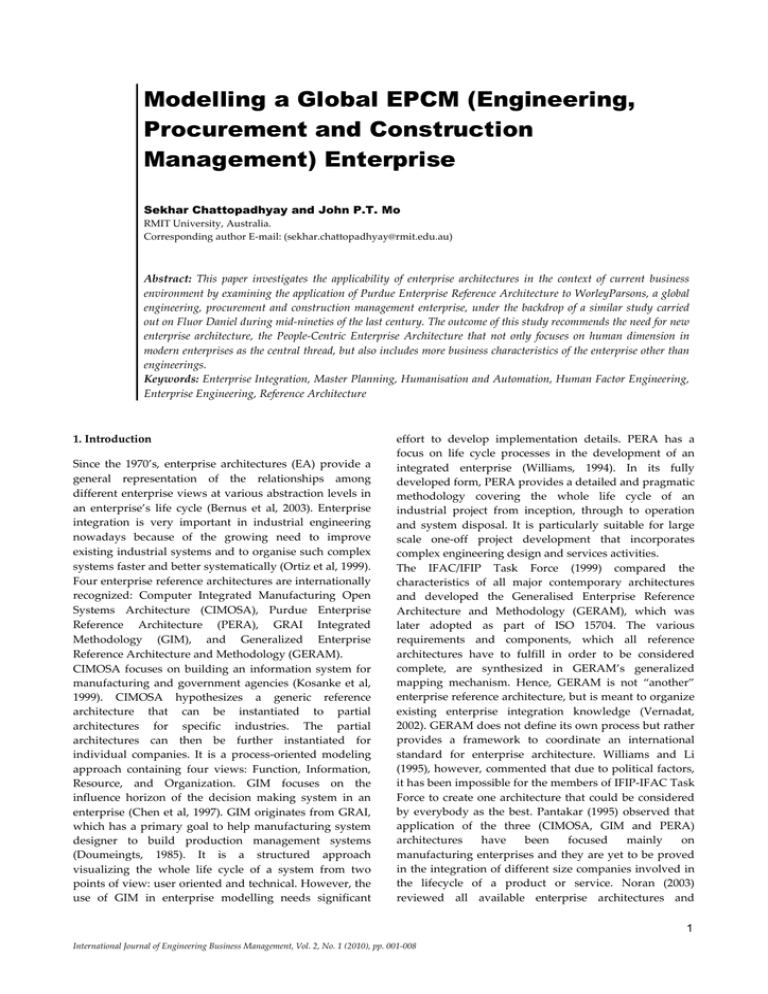

Modelling a Global EPCM (Engineering, Procurement and Construction Management) Enterprise Sekhar Chattopadhyay and John P.T. Mo RMIT University, Australia. Corresponding author E-mail: (sekhar.chattopadhyay@rmit.edu.au) Abstract: This paper investigates the applicability of enterprise architectures in the context of current business environment by examining the application of Purdue Enterprise Reference Architecture to WorleyParsons, a global engineering, procurement and construction management enterprise, under the backdrop of a similar study carried out on Fluor Daniel during mid-nineties of the last century. The outcome of this study recommends the need for new enterprise architecture, the People-Centric Enterprise Architecture that not only focuses on human dimension in modern enterprises as the central thread, but also includes more business characteristics of the enterprise other than engineerings. Keywords: Enterprise Integration, Master Planning, Humanisation and Automation, Human Factor Engineering, Enterprise Engineering, Reference Architecture 1. Introduction Since the 1970’s, enterprise architectures (EA) provide a general representation of the relationships among different enterprise views at various abstraction levels in an enterprise’s life cycle (Bernus et al, 2003). Enterprise integration is very important in industrial engineering nowadays because of the growing need to improve existing industrial systems and to organise such complex systems faster and better systematically (Ortiz et al, 1999). Four enterprise reference architectures are internationally recognized: Computer Integrated Manufacturing Open Systems Architecture (CIMOSA), Purdue Enterprise Reference Architecture (PERA), GRAI Integrated Methodology (GIM), and Generalized Enterprise Reference Architecture and Methodology (GERAM). CIMOSA focuses on building an information system for manufacturing and government agencies (Kosanke et al, 1999). CIMOSA hypothesizes a generic reference architecture that can be instantiated to partial architectures for specific industries. The partial architectures can then be further instantiated for individual companies. It is a process-oriented modeling approach containing four views: Function, Information, Resource, and Organization. GIM focuses on the influence horizon of the decision making system in an enterprise (Chen et al, 1997). GIM originates from GRAI, which has a primary goal to help manufacturing system designer to build production management systems (Doumeingts, 1985). It is a structured approach visualizing the whole life cycle of a system from two points of view: user oriented and technical. However, the use of GIM in enterprise modelling needs significant effort to develop implementation details. PERA has a focus on life cycle processes in the development of an integrated enterprise (Williams, 1994). In its fully developed form, PERA provides a detailed and pragmatic methodology covering the whole life cycle of an industrial project from inception, through to operation and system disposal. It is particularly suitable for large scale one-off project development that incorporates complex engineering design and services activities. The IFAC/IFIP Task Force (1999) compared the characteristics of all major contemporary architectures and developed the Generalised Enterprise Reference Architecture and Methodology (GERAM), which was later adopted as part of ISO 15704. The various requirements and components, which all reference architectures have to fulfill in order to be considered complete, are synthesized in GERAM’s generalized mapping mechanism. Hence, GERAM is not “another” enterprise reference architecture, but is meant to organize existing enterprise integration knowledge (Vernadat, 2002). GERAM does not define its own process but rather provides a framework to coordinate an international standard for enterprise architecture. Williams and Li (1995), however, commented that due to political factors, it has been impossible for the members of IFIP-IFAC Task Force to create one architecture that could be considered by everybody as the best. Pantakar (1995) observed that application of the three (CIMOSA, GIM and PERA) architectures have been focused mainly on manufacturing enterprises and they are yet to be proved in the integration of different size companies involved in the lifecycle of a product or service. Noran (2003) reviewed all available enterprise architectures and 1 International Journal of Engineering Business Management, Vol. 2, No. 1 (2010), pp. 001-008 International Journal of Engineering Business Management, Vol. 2, No. 1 (2010) concluded that their complexity made them difficult to be used by business users. The Zachman framework is probably the most popular approach to enterprise modelling in business environments. It provides a matrix that segments the enterprise into a variety of different views based on the different roles an actor can take e.g. owner, designer, builder (Zachman and Sowa, 1992). Since each view is modelled independently, each segment interface presents a discontinuity. Thus, the issue of the Zachman framework is that it divides the organisation into distinct segments which defeats its goal to integrate the organisation. While the framework provides an observation of some natural rules for segmenting an enterprise into understandable parts, there is little analysis of the laws and principles that govern these natural rules. As a result, the Zachman framework remains primarily a taxonomy with issues guiding the development of enterprise information systems. The vast number of architectures with diverse views in the last two decades posed difficulties for the enterprise designers and practitioners to develop effective and efficient enterprises. The fact is that one hardly finds industry applications, case studies or validation reports of the three main architectures (CIMOSA, GIM and PERA) in the literature. The authors noted through continuous dialogues with the industries and academics in Australia, Europe, India and China that today’s enterprises should be modelled through a consultative and cross-functional approach within an acceptable timeframe, at affordable cost and justifying the bottom line profit. Amongst various industries ranging from healthcare to banking, insurance to consulting, and from manufacturing to logistics/supply chain service providers there is a general lack of awareness of the benefits and applications of enterprise modeling and related fields. A survey report by Institute for Enterprise Architecture Developments (Schekkerman, 2005) showed that US topped the list of top 20 countries in the world in the global EA activities with 43.53% compared to Australia 4.09% and India 1.88%. The same survey also showed the reference enterprise architecture usage (Table 1). The survey clearly indicates that CIMOSA and PERA practically disappeared from industry since 2003, whereas Zachman had enormous growth as the US Federal Enterprise Architecture Framework. The low uptake of enterprise architecture in industry defeats the purpose of creating enterprise architectures for guiding enterprise design and implementation processes. Reasons for this low uptake include complexity, restricted applicability and use of proprietory enterprise architectures. Questions have been asked, particularly in the applicability of traditional enterprise architectures to new engineering oriented business environments of the 21st century. This paper discusses a research project that used PERA initially to model an engineering, procurement and construction management (EPCM) company but found that due to changes of 2 Reference Architecture CIMOSA PERA Zachman TOGAF Organization Own FEAF E2AF USA DoD; C4ISR 2003 2004 2005 6% 3% 20% 6% 32% 3% 0% 6% 13% 9% 35% 19% 3% 3% 25% 11% 22% 9% 9% 11% Trend in Usage Negligible Negligible Growth Growth Declining Declining Growth Growth Table 1. Enterprise Architecture Framework Usage (Schekkerman, 2005) business environment and new legal and cultural framework, there is severe deficiency in PERA that makes it impossible to provide complete enterprise architecture for current multi-national enterprises. We propose a new enterprise architecture framework that builds on prevailing enterprise architecture theory and extends to incorporate elements that are essential for describing contemporary enterprise activities. 2. Modelling WorleyParsons by PERA WorleyParsons (WP) is an Australian-based leading EPCM company providing technical, project and operational support services to customers in the hydrocarbons, minerals and metals, power and infrastructure sectors. With 118 offices in 38 countries and 31,000 employees worldwide, WP lists some of the world’s largest energy companies as clients. As resource projects continue to grow in size and complexity, WP is one of the few global companies with the resources, technical capabilities and systems to meet the demands of large-scale projects (http://www.worleyparsons.com). Headquartered in Australia, WP has grown revenue from A$ 0.5 billion to A$3.5 billion over the past five years. Half of WP’s business is related to contract alliances, typically in the form of long-term partnership with a global energy provider. It is important that WP has an enterprise system that enables its employees to work in joint ventures and distributed locations around the world. This research investigates whether there is any inherent reasons within the theory of enterprise engineering that prohibit application of enterprise architectures to industry. The seminal work on the use of PERA methodology to model the engineering company Fluor Daniel by Rathwell and Williams (1996) is a good example of how enterprise architecture can be applied in a process industrial environment. Since then, there is no further publication in this area exploring how the enterprise architecture can be used in companies of similar nature. Since the nature of business of WP is similar to that of Fluor Daniel, our intention is to apply PERA to model WP to see whether the methodology is sufficient to perform the modelling task today as compared to two decades ago. Sekhar Chattopadhyay and John P.T. Mo: Modelling a Global EPCM (Engineering, Procurement and Construction Management) Enterprise 2.1. Architecture Figure 1 depicts the application of PERA methodology to WP as it is and compared to the original PERA model as applied to Flour Daniel (FD). FD is an engineering, procurement and construction company which serves clients in all types of industries, including process and discrete manufacturing company. Moreover, the Fluor Daniel case study was applied to a manufacturing facility that required the construction of piping, instrumentation and control equipments, etc for a typical process control system development project during its construction and commissioning phases. FD also owns a number of manufacturing facilities around the world. The resulting model has a complete set of three column architecture (a) PERA model of Flour Daniel (b) PERA model of WP Fig. 1. Comparison of PERA models with defined life cycle processes of Information Systems, Human Organisation and Manufacturing Equipment functions. Contrary to FD, WP-PERA does not have the production equipment column. Their upstream and downstream projects in the oil and gas area (hydrocarbons) are carried out from inception to commissioning as per contracts from their clients. Being an EPCM company, WP provides essential management and technical services to the contractors during the construction phases of their projects. They do not have any manufacturing facility of their own, nor do they have any machinery and production equipment for construction activity of their projects. Constructions are done by sub-contractors who have their own engineering, technical and management supervision. 2.2. Life cycle concept PERA is based on division of phases in a project organisation. In the old days of limited email and Internet access, the engineering team had to overcome the issues of communication and work synchronization. A phase divided project provides certainty and risk detection. In today’s environment, software vendors are knocking doors with a variety of product portfolios like MYOB, MRP, ERP and SAP for enterprises of any size. With web 2.0 becoming the norm of business IT support in the 21st century, enterprise tasks are compressed in a much shorter timeframe. However, traditional manufacturing practices such as computer integrated manufacturing (CIM) are based on sequential processing. The step by step enterprise architectures managing CIM, process control and automation become out-of-sync when new information technologies force these sequential processes to occur simultaneously. The traditional concept of sequential phase divided life cycle can’t address complexity of today’s enterprises, i.e. they need a flatter organisation design. 2.3. Role of human Since WP does not have any manufacturing facility, the manufacturing equipment architecture becomes irrelevant. Compared to standard PERA model, the humanization and automation boundaries (in cell No.11 of Figure 2) should be purely human roles in the WP model. Human system design for WP should therefore start from the beginning of the enterprise life cycle but the PERA methodology does not allow this to occur until the implementation stage. Today’s enterprises are exposed to unpredictable and harsh global business environment. The factors contributing to the current situation are many and complex in nature including economy, globalization, and fluctuations in exchange rates and so on. Hence, enterprises are much more vulnerable to the harsh business climate as of today and this trend is likely to continue in the near future. ICT (Information & Communication Technology) is already playing an 3 International Journal of Engineering Business Management, Vol. 2, No. 1 (2010) (a) Standard PERA (b) PERA model of WP Fig. 2. Human role in WP-PERA indispensible role today to further facilitate human activities and this trend is likely to continue in near future since continuous revolution in ICT is driven by human for human. This creates the preamble of the classical (decades old) debate of humanization and automation. Automation would certainly creep into those tasks which are repetitive and have cost leverage but would never be able to erode the fundamental need of human. Although the fact is that manual tasks will be reduced in the years to come but none of the tasks would ever become 100% automated. Hence, 100% automation in each and every phase of the socio-economic lifecycle is impossible if not absurd. There always remains a hybrid mixture of varying degree depending on the need, application and economy of scale. 2.4. Flexibility and continuity Global enterprises are much more complex. An integrated enterprise architecture should be able to cope with the fast changing business environment with ever changing needs and relations with the customer and boundaries. There is a paradigm shift towards greater collaboration and sharing of resources. Substantial growth in micro-enterprises, SMEs, e-Enterprise, risk and security issues haunted by ever increasing competition 4 and volatile global economy are forcing businesses to become more flexible, adaptive and zero-latent. PERA focuses on the technicality of system development and process engineering. It does not cover the increased complexity of businesses in recent years, including risk, quality assurance, procurement economics, customer relations management, supply chain management and many other parallel business processes. In the WP modelling analysis, it is observed that a typical EPCM business in the 21st century requires significant degree of flexibility in the enterprise architecture to deal with a wide variety of customer expectations. The system also requires substantial certainty of continuity, both in the operations and inter-connection within its business environment. These characteristics must be built in the company’s operating system when it is designed from an enterprise architecture. 2.5. Integration with revenue and cost models Cost of skills, resources and time are absolutely critical for a service oriented enterprise that bills customers against man-hours (Sridharan and Berry, 1990). The bottom-line for sustainability and survival of any business is to have a cash flow through transaction of goods and services. Any job or project can be viewed as an outcome of a number of well coordinated and synchronized tasks that need to be accomplished against a given time-frame (schedule). Any task and the time available for its completion determine the levels and variety of skills (people) and resources (tangible and intangible) that are required. Skills, resources and time become the determinant factors for the assessment of cost for any task towards production of goods and services. Unit costs of production of goods and services have a direct bearing on the margin for given revenue for any enterprise. Therefore, revenue and cost models are an indispensable consideration for any enterprise architecture. Unfortunately, there is no such architectural construct in the WP-PERA model. 2.6. Requirements of a new enterprise architecture The PERA methodology with its root in CIM might have been suitable for Fluor Daniel but there are issues when it is applied to model WP. The deficiencies appear to be more vivid when considered under the context of new operating practices in the heavily ICT assisted engineering and services businesses. According to Khoury and Simoff (2004), an enterprise architecture needs a method that is effective in: • Developing a single and coherent model of an enterprise, and • Allowing us to guide the future development of an enterprise without the creation of arbitrary internal boundaries. An enterprise architecture methodology must be designed to produce specified, predictable results. It must specify not only “What to do” but most importantly, Sekhar Chattopadhyay and John P.T. Mo: Modelling a Global EPCM (Engineering, Procurement and Construction Management) Enterprise “How to do it” and “Why”. Moreover, it must be based on a set of concepts and principles that theoretically, logically and empirically establish a basis for producing an aligned, integrated, responsive, flexible enterprise architecture that in fact can be used to engineer, manufacture and implement an enterprise. A methodology which does not comply with these criteria is a waste of time and money. 3. People-Centric Enterprise Architecture This change in the fundamentals of business paradigm forces the enterprises of today to become more flexible, collaborative, directive, decentralized and geographically dispersed with shared resources in multi-country locations. Traditional responsibility related and vertically integrated organizations are fast disappearing since the hierarchical structures do not work any more. We propose the People-Centric Enterprise Architecture (PCEA) that addresses some of the problems we have in the WP enterprise model. The PCEA has four fundamental structures. 3.1. Hierarchical Global Decomposition Any project or service oriented enterprise views a task through a decomposed hierarchical structure optimizing its cost and speed of delivery to improve customer relationships. A consultative process at the global, regional or country level is initiated right from the bidding stage (Figure 3). Increased competition, push for lower cost for customer conceived quality and logistics/supply chain costs are closely looked into prior to execution. At the micro-level of operation any job or project is viewed as a number of well coordinated tasks through different views. The effect of global decomposition of tasks in this hierarchical structure is to allow the global organization to distribute work to the most appropriate engineering units with matching expertise. Such global decomposition is made possible with new ICT such as video conferencing, computer supported working environment and more significantly, with increased bandwidth and system mobility (e.g. wireless connectivity). This enterprise architectural construct provides a framework for the global enterprise to define an optimal set of human roles across the organization. Fig. 3. Hierarchical Global Decomposition 3.2. Hierarchical Task Decomposition An EPCM company with multi-country operation takes a holistic view for any new project or prospect since their core skills and resources are dispersed globally. Depending on the location of the customer, they can mobilize all their global resources for execution of the mega-projects. Being a service oriented enterprise they offer all sorts of expertise and skills in relation to engineering, procurement and construction management but does not own or have any manufacturing facility. Hence, having defined human roles in the global management context, the task view needs to be further decomposed for detailed implementation and operation. Current management practices emphasize the need for a cross-functional team approach to optimize resource utilization and increased productivity. A job or project is thus further evaluated by both top-down and bottom-up views as in Figure 4. The task view is the technical view of the work to be done. It depends on the work breakdown structure. The hierarchical task decomposition view is created by the chief engineer in charge of the project, and devolves to different work packages that individual engineering units are required to perform. This view forms the foundation of work allocation, outcome monitoring, performance indicators, tracking and reporting. 3.3. Kaleidoscopic View The kaleidoscopic view represents the holistic approach to project governance. Project control and monitoring are embedded within the ‘gates’ of various stages. The kaleidoscopic view looks at resources and human skills that are available at the Strategic Business Unit (SBU) level. The kaleidoscopic view includes modern complexities of both internal and external business environments such as risks, quality, procurement, construction, logistics and supply chain management (SCM), customer relationships management (CRM) and so on. These are the functions that are not considered in traditional enterprise architectures. The customer’s view is analyzed by various cross-functional teams and overseen by both the SBU and customer for monitoring progress and control purposes Figure 5. Fig. 4. Hierarchical Task Decomposition 5 International Journal of Engineering Business Management, Vol. 2, No. 1 (2010) Fig. 5. Kaleidoscopic View A customer’s view at the regional, centre or strategic business unit (SBU) level is managed by CRM practices. The project requirements are viewed by all stakeholders at every phase of its lifecycle. Diverse views are aligned through regular consultative process and feedback at all times with the spirit of collaboration and sharing. This enables the global enterprise to achieve its objective and meet their goal with utmost efficiency. The engineering view is composed of various engineering departmental views according to specialization or discipline such as structural engineering, process engineering, electrical engineering and instrumentation and so on. Similarly, the task view is analyzed from the project management perspective. At the micro-level, any task is accomplished through maximized utilization of available skills and resources (tangible and intangible) at any given point of time. This also determines the intraand inter-engineering department task flow. It is also obvious that the time factor is very critical throughout and has a direct bearing on the cost of delivery and determines the efficiency of the taskforce. 3.4. Resources View Traditionally, resources in enterprise architectures refer to physical resources. However, an enterprise is perceived as living because of its people. It is driven by people and exists for the purpose defined by people. Information flow and communication acts as a glue to hold people together with a common goal. Humans are unique by nature and the costliest resource amongst all others in its category. Therefore, an enterprise architecture should structure itself for all stakeholders including the crucial one, the customer and form the central focal point of all enterprise architecture. The resources view in the PCEA puts people (and their skills) as the binding strand for two other resources: time and physical resources (i.e. equipment). Without the existence of people, there is no concept of time and equipment. People play the pivotal role in any organization and their presence pervades through all layers of the organization from shop floor to the board room as shown in the resource view in Figure 6. 6 Fig. 6. Resource view People use their skills, knowledge (tacit and explicit) and resources as available to them (tangible and intangible) to produce individual outputs. In units of time, these outputs are products and services or parts thereof. This is true for all people in the enterprise irrespective of their position in the hierarchy. At the macro-level, the units of outputs are therefore the product of skills, resources and time. The model has a number of layers which are, for a typical EPCM company, which has engineering, procurement, construction, quality, risk. Except the ‘feedback’ (both formal and informal) layer, all other layers and their numbers would be different according to the function, organization structure, its size and type (manufacturing or service), workflow and so on. Any enterprise has to have its own organization structure, strategy and customer. In fact a customer focused strategy drives the structure and restructuring of any organization today. 3.5. Summary of the People-Centric Enterprise Architecture A global EPCM company with large skills and resource base of their own is able to enhance their capacity by operating through a pool of experts, consultants and suppliers from various engineering and management disciplines. The hierarchical global decomposition model in Figure 3 indicates how a job or project is initially assessed in regard to its feasibility. The bottom most layer of this decomposition boils down to a set of well coordinated tasks. Tasks are further analyzed through simultaneous ‘top-down’ and ‘bottom-up’ views by their own engineering and management hierarchy as in Figure 4. The kaleidoscopic view in Figure 5 indicates a multidimensional exploded view as seen by all stakeholders of the project or job with customer at the focal point. A customer-oriented organization involves customer from ‘end to end’ of the project life cycle. This justifies the need to include all functions, disciplines, resources and above all its people and their skills in the architecture. Information flow is vital to hold various elements in cohesion and acts as the glue to the structure of the Sekhar Chattopadhyay and John P.T. Mo: Modelling a Global EPCM (Engineering, Procurement and Construction Management) Enterprise organization. Therefore, the kaleidoscopic view conforms to the view dimension of the GERAM modeling framework (Bernus and Nemes, 1997). Global Decomposition View 4. The PCEA applied to WP Fig. 7. Modelling flow for WP WP has a people-centric organization culture. Trust and responsibility with authority empowers a project owner at WP. Hall (2008) described the primary business objective for WP is to design, oversee and manage immense complex and risky projects to foster strong relationships between the company, its stakeholders and the clients. WP has a strong global presence in its specialized field and is well supported by its own Global Business System that integrates its operation. A salient feature of the Global Project Delivery Systems and Tools is WorleyParsons Project Management Process (WPPMP) that is based on a phased and gated project development process with clearly documented project value objectives and value improving practices. Decision support package requirements are fundamental to what is planned for and delivered in each phase. The WPPMP is scalable for small and large projects. WP manages its projects by the well-defined Work Breakdown Structure (WBS). This provides the framework from which the project management and project control systems will be set-up to facilitate the tracking and reporting of the project status and costs. It facilitates all aspects of engineering, procurement and construction for the execution of all projects undertaken by WP. The WBS is normally agreed by the project team, including representatives of the Customer. As the Customer will normally use this same structure during the Operations phase of the facility, the Customer may have a pre-configured WBS that will have to be complied with. For any new project (green or brown oilfields), WP takes a global view which is then decomposed into country, centre, SBU (i.e. hierarchical global decomposition) and ultimately to task level. A task is further decomposed to the macro-level in the hierarchy of every discipline involving cross-functional teams (i.e. hierarchical task decomposition). Stipulated standards and procedures are strictly followed, monitored and controlled for each project lifecycle. Continuous improvement is embedded throughout right from kick-off stage to operate stage of the project in direct consultation with the customer to ensure on-time delivery and minimize project overruns. WP has meticulous customer relationships management (CRM), supply chain management (SCM), budget and cost control policy and procedure in place. The kaleidoscopic view developed at different levels depicts the holistic view of the project as seen by all stakeholders (both internal and external). These levels represent various functional departments as layers with scope for further expansion and flexibility as shown by a pair of extended dotted lines. All these layers are held together by people with the support of resources where Task Decomposition View Kaleidoscopic View People-Centric Model time is a critical parameter. The number of variables thus get reduced to only three (People, Resource and Time) thereby simplifying the effort on enterprise engineering and integration. Figure 7 shows the modeling flow for WP. 5. Conclusion Traditional enterprise reference architectures such as PERA focused on manufacturing with their root in CIM are too rigid to adapt to new enterprise modelling needs. Global business texture has drastically changed in the mean time due to various factors including recession, increased competition, mass customization and other factors such as socio-economic, political and climate change. Today’s enterprises are more complex involving globally dispersed supply chain, increased collaborative and resource sharing partnership and volatile economic climate. This paper illustrates a step by step methodology for developing a generalized enterprise model that is simple and easy to understand and is executable possibly at an affordable cost. The new model has four different views: global, task decomposition, kaleidoscopic and resources, which are typical for a service type enterprise with engineering, procurement and construction management characteristics. People play the pivotal role in any organization. Their presence pervades all layers of the organization from shop floor to the board room. Tomorrow’s information technology will bring radical changes to economy, society and the way businesses are run today but would never be able to replace people. So the enterprise modelling concepts People-Centric EA with people at the helm of everything in business. 6. Acknowledgement The authors are thankful to Mr. John Sorrentino, Director Business Development and Mr. David Bailey, General Manager, Hydrocarbons, WorleyParsons for their kind support and advice during the field study. Thanks are also due to all staff of WorleyParsons, Melbourne for their encouragement and continued support. The opinion, theme and views expressed in this paper are purely of the authors and not necessarily of WorleyParsons. 7. References Bernus, P., Nemes, L. (1997). Requirements of the Generic Enterprise Reference Architecture and Methodology, Annual Reviews in Control, 21:125-136 Bernus, P., Nemes, L., Schmidt, G., (2003). Handbook on Enterprise Architecture. ISBN: 978-3-540-00343-4.2003. 2003. Chapter 1 pp.1-17. 7 International Journal of Engineering Business Management, Vol. 2, No. 1 (2010) Chen, D., Vallespir, B., Doumeingts, G. (1997). GRAI integrated methodology and its mapping onto generic Enterprise reference architecture and methodology. Computers in Industry, 33(2-3):387-394. Doumeingts, G. (1985). How to decentralize decisions through GRAI model in production management. Computers in Industry, 6(6):501-514 Hall, J., (2008). Foremost a people company and one ahead of its peers. The Australian Financial Review, Supplement, dated 7th February, p.7 Schekkerman, J. (2005). Trends in Enterprise Architecture 2005: How are Organizations Progressing? Report of the Third Measurement, December, pub. Institute For Enterprise Architecture Developments, available from http://www.enterprise-architecture.info, 33 pages IFIP–IFAC Task Force (1999). GERAM: Generalised Enterprise Reference Architecture and Methodology, Version 1.6.3, Annex to ISO 15704, Requirements for enterprise-reference architectures and methodologies, Mar, 31 pages Khoury, G. R., Simoff, S. J. (2004). Enterprise architecture modelling using elastic metaphors. In Proceedings of the First Asian-Pacific Conference on Conceptual Modelling - Volume 31 Kosanke, K., Vernadat, F., Zelm, M. (1999). CIMOSA: enterprise engineering and integration. Computers in Industry, 40:83-97 Noran, O., (2003). A Mapping of Individual Architecture Frameworks (GRAI, PERA, C4ISR,CIMOSA, ZACHNAN, ARIS) onto GERAM. Handbook on Enterprise Architecture. Bernus, Peter; Nemes, Laszlo; 8 Schmidt, Günter. ISBN: 978-3-540-00343-4. Chapter 3 pp.65-204. Ortiz,A., Lario,F., Ros, L. (1999). Enterprise Integration – Business Processes Integrated Management: a proposal for a methodology to develop Enterprise Integration Programs. Computers in Industry, 40:155– 171 Pantakar, K. (1995). Enterprise Integration Modeling: a review of theory and practice. International Journal of Computer Integrated Manufacturing, 8(1): 21-34 Rathwell, G.A., Williams, T.J. (1996). Use of the Purdue Enterprise Reference Architecture and methodology in industry (the Fluor Daniel example), Modelling and Methodologies for Enterprise Integration, pub. Chapman and Hall, London, pp.12–44. Sridharan, V., Berry, W.L. (1990) Master production scheduling make-to-stock products: a framework for analysis. International Journal of Production Research. 28(3):541-559 Vernadat, F.B. (2002). Enterprise Modelling and Integration (EMI): Current Status and Research Perspectives, Annual Reviews in Control, 26:15-25 Williams, T.J. (1994). The Purdue Enterprise Reference Architecture. Computers in Industry, 24:141-158 Williams, T.J., Li, H., (1995). A specification statement of requirements for GERAM with all requirements illustrated by examples from PERA. Report number 159, Purdue Laboratory for Applied Industrial Control, September. Version 1.1 Pages 652 Zachman, J. A. and J. Sowa (1992). Extending and formalizing the framework for information systems architecture. IBM Systems Journal, 31(3):590-616.