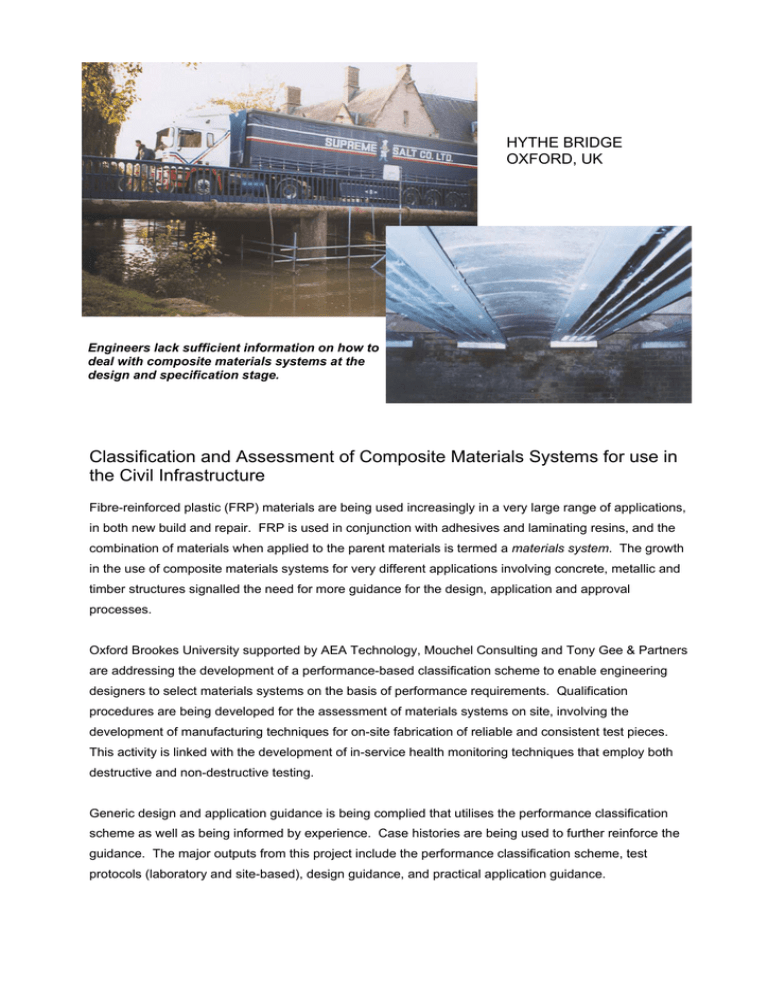

HYTHE BRIDGE OXFORD, UK

advertisement

HYTHE BRIDGE OXFORD, UK Engineers lack sufficient information on how to deal with composite materials systems at the design and specification stage. Classification and Assessment of Composite Materials Systems for use in the Civil Infrastructure Fibre-reinforced plastic (FRP) materials are being used increasingly in a very large range of applications, in both new build and repair. FRP is used in conjunction with adhesives and laminating resins, and the combination of materials when applied to the parent materials is termed a materials system. The growth in the use of composite materials systems for very different applications involving concrete, metallic and timber structures signalled the need for more guidance for the design, application and approval processes. Oxford Brookes University supported by AEA Technology, Mouchel Consulting and Tony Gee & Partners are addressing the development of a performance-based classification scheme to enable engineering designers to select materials systems on the basis of performance requirements. Qualification procedures are being developed for the assessment of materials systems on site, involving the development of manufacturing techniques for on-site fabrication of reliable and consistent test pieces. This activity is linked with the development of in-service health monitoring techniques that employ both destructive and non-destructive testing. Generic design and application guidance is being complied that utilises the performance classification scheme as well as being informed by experience. Case histories are being used to further reinforce the guidance. The major outputs from this project include the performance classification scheme, test protocols (laboratory and site-based), design guidance, and practical application guidance. INDUSTRIAL ADVISORY GROUP PROJECT SUMMARY A project industrial advisory group (IAG) comprises materials suppliers, civil engineering Title contractors, engineering designers, specifiers and specifying authorities. The group Classification and Assessment of meets twice a year, receives regular updates on the outcomes of the separate Composite Materials for use in the Civil Infrastructure Objectives To develop a performance-based classification scheme for the workpackages and enjoys access to a closed website. The IAG influence the direction of the work, members provide direct and indirect inputs to the project, and they have direct access to the projects’ outputs. REVIEW OF APPLICATIONS, PROPERTY REQUIREMENTS, AND DESIGN AND CODE REQUIREMENTS The range of principal applications for composite materials systems associated primarily with repair work is reviewed early in the project. This forms the basis for assessing the selection of composite materials material and structural requirements, and appropriate forms and types of materials systems systems for use. Current design approaches, design parameters, safety factors, To identify, adapt and develop acceptance procedures and test protocols are appraised and analysed. qualification and quality control PERFORMANCE CLASSIFICATION SCHEME procedures associated with on-site applications of composite materials The property requirements of entire materials systems are used to develop a systems comprehensive performance-based classification scheme that combines component To compile generic design and materials separately into a materials system. The scheme includes design life / durability application guidance, reinforced with case history material requirements, and it identifies test protocols and qualification limits on materials parameters for use in specification. QUALITY CONTROL PROCEDURES, LONG-TERM PERFORMANCE AND HEALTH MONITORING Keywords Adhesives; classification; composite materials; design; health monitoring; structures; test methods; validation Mechanical test procedures and protocols are validated and documented, including techniques for the fabrication and testing of specimens appropriate to both laboratory and on-site evaluation. Destructive and non-destructive test methods are identified for longterm assessments of changes in materials systems/bonded joint systems. These methods include laboratory-based predictive techniques and on-structure site-based Exploitation Checking authorities; clients; designers; materials suppliers; specifiers methods. GENERIC DESIGN AND APPLICATION GUIDES A generic design guide covering the principal applications of composite materials systems will be developed as the project progresses. This will illustrate the performance classification scheme approach to satisfy the design requirements. Generic specification Contact and practical application guidance will also be developed. The latter is essential for Professor Allan Hutchinson ensuring an acceptable outcome in reality because workmanship and on-site materials Oxford Brookes University conformance issues dictate overall quality. Tel: 01865 483504 Fax: CASE HISTORIES AND VALIDATION EXERCISES A range of case history applications, together with the associated quality control 01865 484179 procedures and health monitoring protocols, is used to highlight different design E-mail: considerations and materials performance requirements. Full validation exercises of the arhutchinson@brookes.ac.uk performance-based design, specification and approval process for commercial contracts demonstrate the benefits of the new procedure.