Superconducting Transformer Design and Construction I. E. Chew

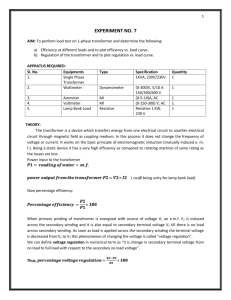

advertisement