Improving the Technical Quality of a Universal Motor

advertisement

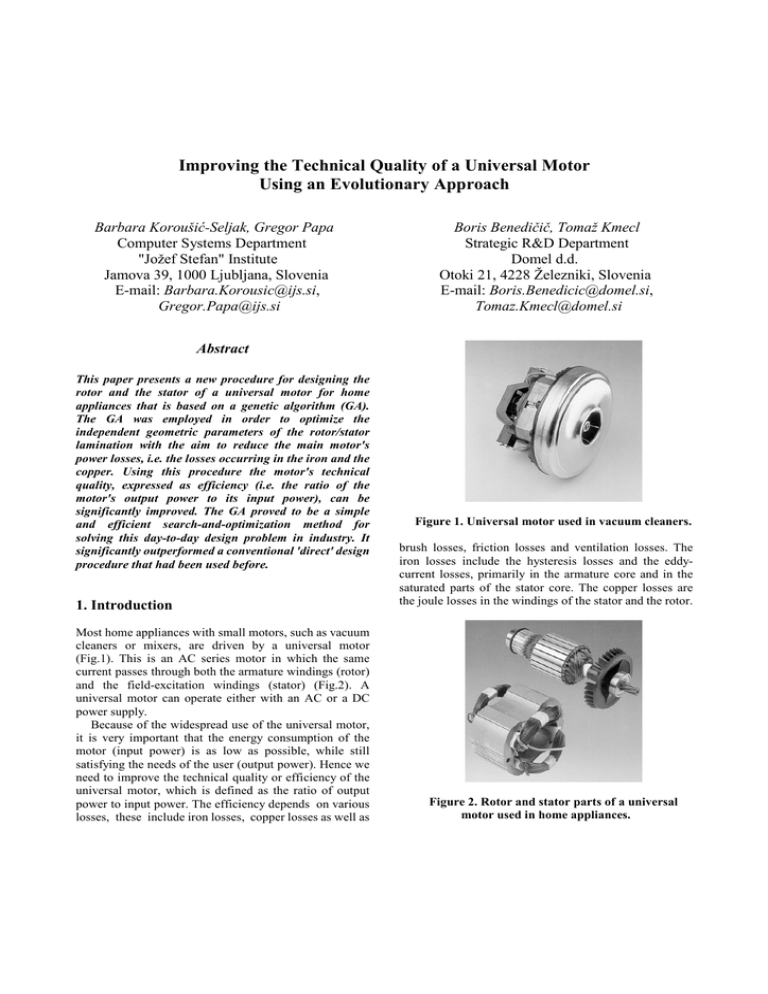

Improving the Technical Quality of a Universal Motor Using an Evolutionary Approach Barbara Koroušić-Seljak, Gregor Papa Computer Systems Department "Jožef Stefan" Institute Jamova 39, 1000 Ljubljana, Slovenia E-mail: Barbara.Korousic@ijs.si, Gregor.Papa@ijs.si Boris Benedičič, Tomaž Kmecl Strategic R&D Department Domel d.d. Otoki 21, 4228 Železniki, Slovenia E-mail: Boris.Benedicic@domel.si, Tomaz.Kmecl@domel.si Abstract This paper presents a new procedure for designing the rotor and the stator of a universal motor for home appliances that is based on a genetic algorithm (GA). The GA was employed in order to optimize the independent geometric parameters of the rotor/stator lamination with the aim to reduce the main motor's power losses, i.e. the losses occurring in the iron and the copper. Using this procedure the motor's technical quality, expressed as efficiency (i.e. the ratio of the motor's output power to its input power), can be significantly improved. The GA proved to be a simple and efficient search-and-optimization method for solving this day-to-day design problem in industry. It significantly outperformed a conventional 'direct' design procedure that had been used before. 1. Introduction Most home appliances with small motors, such as vacuum cleaners or mixers, are driven by a universal motor (Fig.1). This is an AC series motor in which the same current passes through both the armature windings (rotor) and the field-excitation windings (stator) (Fig.2). A universal motor can operate either with an AC or a DC power supply. Because of the widespread use of the universal motor, it is very important that the energy consumption of the motor (input power) is as low as possible, while still satisfying the needs of the user (output power). Hence we need to improve the technical quality or efficiency of the universal motor, which is defined as the ratio of output power to input power. The efficiency depends on various losses, these include iron losses, copper losses as well as Figure 1. Universal motor used in vacuum cleaners. brush losses, friction losses and ventilation losses. The iron losses include the hysteresis losses and the eddycurrent losses, primarily in the armature core and in the saturated parts of the stator core. The copper losses are the joule losses in the windings of the stator and the rotor. Figure 2. Rotor and stator parts of a universal motor used in home appliances. The main losses, i.e. those from the iron and the copper, can be reduced by optimizing the geometry of the rotor and stator. Because of the high magnetic saturation of the iron in universal motors, this is a highly non-linear problem. Due to the complexity of the solution originating in this non-linearity, the GA [1] was used to optimize the geometry of the rotor and stator. Detail A 2. Geometry of the Rotor and the Stator The geometry of the rotor and the stator was defined parametrically. There were three parameter types (shown in Fig.3 and Fig.4): Invariable (constant): Among several constant parameters one was extremely important from the motor-manufacturer’s point of view, namely the stator's outer radius. This roughly defined the amount of material (iron and copper) used for the motor and consequently also the price of the motor. By holding the amount of material constant during the optimization, all the optimized motor solutions had a similar mass. Variable: - Mutually independent: like the external radius of the rotor, the rotor-pole width, the rotor-jag diameter, the stator-jag radius, etc. - Dependent: e.g. the stator's inner radius. These were defined indirectly from the constant and the independent parameters. Only mutually independent variable parameters were altered using the GA. Figure 3. Geometrical parameters of the stator. Figure 4. Geometrical parameters of the rotor. 3. Design Procedure for the Rotor and the Stator In a conventional (‘direct’) motor design procedure the initial estimation of the geometry of the rotor and the stator is based on experience. The appropriateness of this geometry is then usually analyzed by means of a numerical simulation of the electromagnetic field. In our case, the analysis was performed with ANSYS commercial software [2], which applies a finite-element method with an automatic finite-element mesh generation. When the results of the numerical simulation show an inconvenient electromagnetic field structure, the ‘direct’ design procedure is repeated until the motor geometry is optimized. The new motor design procedure described in this paper is also a ‘direct’ system, but it is based on the GA. This is a stochastic process providing a robust and yet flexible search in the wide and complex space of the problem solutions in order to find the optimum global solution in a short time. The concept of the applied design system can be roughly explained as follows (see Fig.5): the GA provides a set of problem solutions (i.e. different configurations of rotor-and-stator independent geometrical parameters). To enable the calculation of a fitness value, each geometrical configuration is analyzed using the finite-element program. After the calculation of the fitness, the reproduction of individuals and the application of genetic operators to a new population are J= Initial lamination’s geometry Genetic algorithm Optimized lamination’s geometry Solution candidates Decode each candidate Lamination’s geometry I⋅N A (1) PCuSlot = I 2 ⋅ R = J 2 ⋅ A ⋅ ρ ⋅ l turn (2) J .......... current density I........... current N ......... number of turns A.......... slot area ρ .......... specific resistance of copper turn ........ length of winding turn The overall copper losses are as follows: Finite-element program Repeat until time-out Power losses (fitness) for each candidate Figure 5. New design procedure for the rotor and stator. made. The GA repeats this procedure until a predefined number of iterations are accomplished. 4. Calculation Of Copper, Iron And Other Losses In order to solve the electromagnetic problem, the finiteelement program needs the following data: well-defined geometry of the analyzed element, appropriate finite-element mesh, material properties (iron B-H function, copper specific resistance), density of the electric current in the conductor area. A typical run for such a numerical problem takes about 30 iterations and needs approximately 7 minutes on a Pentium III Computer Station to achieve a convergent numerical solution. The result of the solution is a magnetic vector potential on every node of the finiteelement mesh. From this potential we can calculate the values of flux density, field strength, and magnetic energy. With a special module, we can also calculate the electromagnetic torque on selected regions (rotor). The output power of a motor is a product of the electromagnetic torque and the angular velocity. 4.1. Calculation of copper losses Copper losses per slot (stator and rotor) are calculated by the following equations: PCu = ∑P (3) CuSlot ,i i 4.2. Calculation of iron losses Because of the nonlinear magnetic characteristic, the ironloss calculation is less exact. The iron losses are separated into two components: the hysteresis loss and the eddycurrent loss. An empirical formula for the hysteresis loss is defined as follows: Ph = k h ⋅ B n ⋅ f ⋅ m (4) kh ......... eddy-current material constant at 50 Hz B.......... maximum magnetic flux density f ........... frequency m ......... mass n .......... exponent between 1.6 and 2.0 (material dependent) The eddy-current loss is defined as follows: Pe = k e ⋅ B 2 ⋅ f 2 ⋅ m (5) ke ......... hysteresis material constant at 50 Hz The frequency of the magnetic field density in a stator is 50 Hz (the frequency of the power supply), while in a rotor the frequency is much higher and depends on the motor's speed. If the motor was running at 50.000 min-1, the main rotor frequency would be 833 Hz. Since the eddy-current losses depend on the square of the frequency, and the hysteresis losses increase linearly with the frequency, the main iron losses of the rotor are the eddy-current losses. Since these losses depend on the square of the flux density, and the hysteresis losses in the rotor are neglected, the iron losses of the rotor can be calculated using (5), where B2 is obtained from the finiteelement solution for each node. As a result, the overall B2 of the rotor is calculated as an average of the B2 values of all the rotor nodes. When calculating the stator losses, the hysteresis loss and the eddy-current loss must be added together. In addition, we must roughly estimate the factor n. Since the overall stator losses are approximately five times smaller than the rotor losses, even a non-exact estimation of the factor n does not have a significant influence on the overall iron-loss calculation. Consequently, the iron loss of a motor can be expressed by the following formula (6): PFe = k e ⋅ B 2 ⋅ f rot2 ⋅ mrot + 2 + k e ⋅ B 2 ⋅ f stat ⋅ mstat + k h ⋅ B 2 ⋅ f stat ⋅ mstat (6) The sum of the iron and copper losses (PCuFe) represents a so-called objective function for the GA. PCuFe = PFe + PCu (7) 4.3. Calculation of other losses Besides the iron and copper losses, there are three additional types of losses in a universal motor. These are: PBrush ........brush losses PVent ..........ventilation losses PFrict..........friction losses All three types of losses mainly depend on the motor speed. Since the motor speed is equal for all solutions, these losses are considered as constant in our analysis. Taking into account all the above-mentioned losses, the overall efficiency of a universal motor is defined as follows: η= P2 P2 + PBrush + PVent + PFrict + P CuFe (8) P2 .............output power Consequently, the goal of the present investigation is to maximize this efficiency. 5. Genetic Algorithm (GA) The GA was proposed by J.H. Holland in 1975 [3] as a heuristic search-and-optimization method. Since then it has been applied with great success to various optimization and classification problems, in areas ranging from economics and game theory to control-system design [4,5]. The GA manipulates strings representing the problem's potential solutions in a way that is analogous to the role played by DNA in evolution. Each solution corresponds to a sample point in a search space. The initial set of sample points (i.e. the population of strings) is randomly generated. New sample points are generated by recombining the information from two 'parent' strings drawn from the current population. Another key element of the GA is the use of selective pressure to allocate reproductive trails. Allowing strings that represent aboveaverage solutions in the current population to 'reproduce' more often than strings that represent below-average solutions (i.e. the elitism strategy), the GA allocates more trials to regions in a hyperspace that tend to contain above-average solutions. The GA mechanism is as follows: Step 1. Encode parameters of the problem's search space as finite-length strings over some finite alphabet. The GA works with a coding of the parameter set, not the parameters themselves! Step 2. Initialize the population of strings. Step 3. Calculate the fitness for each member in the population using an objective function. This information is used to perform an effective search for better solutions. There is no need of other auxiliary knowledge! Step 4. Select and reproduce individuals to form a new population according to each member's fitness. The GA tends to take advantage of the fittest solutions by giving them greater weight, and concentrating the search in the regions of the search space with likely improvement. Step 5. Perform genetic operators (i.e., probabilistic transition rules) such as crossover and mutation on the population. Step 6. Go to step (3) until some condition is satisfied. It has been proved that the GA outperforms traditional search-and-optimization methods in several aspects: It requires little information to search effectively in a large and complex search space. The GA is capable of performing a global search of a space because to guide the search it relies on hyperplane sampling instead of searching along the gradient of a function. Its intristic parallelism (in evaluation function, selections) allows working from a broad database of solutions in the search space simultaneously, climbing many peaks in parallel. Thus, the risk of converging to a local optimum is low. The random decisions made in the GA can be modeled using Markov chain analysis to show that each finite GA will always converge to its global optimum region (but sometimes it has trouble reaching the exact optimum location) [6]. It can be applied to a non-linear problem. Therefore we decided to apply the GA to increase the efficiency of a universal motor with respect to the geometry of its rotor and stator unit. 5.1. Genetic algorithm in the design procedure of the rotor and stator The most important job when putting the new design procedure for the rotor and the stator into practice was to define the encoding method of the solution candidates, the genetic operators and the termination criteria. We had to select a method for evaluating the relative performance of the solution candidates for identifying the better solutions. 5.2. Encoding The parameters of the problem's search space were coded as strings over the alphabet — of real (floating-point) values. Using a symbolic presentation of a string with 11 characteristics (rotor-and-stator independent geometric parameters) gives: S= s1s2s3s4s5s6s7s8 s9s10 s11 Here, each si represents a geometrical parameter of a single stator or rotor, where each characteristic may take on a real value from —. For example, in the particular string: 0.0078⊥0.0070⊥0.0340⊥0.0315⊥... s1 is 7.8E-003, s2 is7.E-003, etc. The rotor-and-stator independent geometric parameters of an existing universal motor were used to form a starting string, which was reproduced (n-1) times to generate an initial population of n strings. A random value distributed linearly on ± ∆ was added to each characteristic value of the starting string to define a reproduced string. Each characteristic had its lower and upper limit defined. If its value exceeded either limit, it was set to the closest one. Roughly speaking, the strings of this 'artificial genetic system' are analogous to the chromosomes in biological systems. In natural terminology, chromosomes are composed of genes, which may take on some number of values called alleles. The entire set of strings upon which the GA operated was called a population. 5.3. Genetic operators To allow the best solution candidate to evolve, the GA employed the genetic operators of selection, crossover and mutation for manipulating the strings in a population. The GA used these operators to combine the strings of the population in different arrangements, seeking a string that maximizes the objective function. This combination of strings resulted in a new population. The first genetic operator used by the GA for creating a new generation was selection. To create two new strings (or children) two strings had to be selected from the current population as parents. Most fit strings were selected for reproduction. We had applied the elitism strategy, where a randomly selected number of least-fit members of the current population were interchanged with an equal number of the best-ranked strings. Crossover proceeded in two steps. First, strings were mated randomly, using a given probability, pc, to pair off the couples. Second, mated string couples crossed over, using a random probability to select the one-point crossing sites. An integer position, k, was selected between 1 and the string length minus one [1,l-1]. Swapping all characteristic values between the positions k+1 and l inclusively created two new strings. For example, considering strings A and B: A= a1a2a3a4|a5a6a7a8a9a10a11 B= b1b2b3b4|b5b6b7b8b9b10b11 Suppose, choosing a random number between 1 and 10, we obtained k=4. The resulting crossover yielded two new strings A' and B': A'= a1a2a3a4| b5b6b7b8b9b10b11 B'= b1b2b3b4| a5a6a7a8a9a10a11 Moreover, we might use a constant probability, pr, to select a case in which the values of the swapped characteristics were calculated as a mean (average) value of the parent characteristic values. While the first crossover approach ensured that the child solutions preserved the 'genetic material' from both parents, the second one helped to seek for other solutions near to solutions that appeared to be good. Mutation was a process by which the strings resulting from selection and crossover were perturbed. It served to create random diversity in the population. Each string was subjected to the mutation operator. Mutation was performed on a characteristic-bycharacteristic basis, each characteristic mutating with a probability pm. Assuming that pm is a constant of 0.001, with eleven characteristic positions we expected 11◊0.001=0.011 characteristics to undergo mutation during a given population. However, since a high mutation rate resulted in a random walk through the GA search space, pm had to be chosen to be somewhat smaller. There was also a possibility of annealing the mutation rate, where pm was a variable mutation probability that was decreasing linearly with each new population. In another words, we assumed that each new population was generally more fit than the previous one. Such an approach was used to overcome a possible disruptive effect of mutation, and to speed up the convergence of the GA to the optimum solution. 5.4. Fitness evaluation Following selection and reproduction, crossover, and mutation, the new population was ready to be evaluated. To do this, each new string (solution candidate) created by the GA was decoded into a set of the independent geometrical parameters for the rotor and stator, and its fitness was estimated by running the finite-element program (ANSYS). First, a finite-element numerical simulation was performed. Then, the power losses of the iron and the copper (using the equations of (6) and (3), respectively) were calculated. Their sum (see (7)) corresponded to the solution's fitness. The fitness of above-average strings corresponded to the lowest power (iron and copper) losses. By applying the elitism strategy, fitter solutions had a greater chance of reproducing. But when the number of least-fit solutions to be exchanged with best-fit ones (the selection criteria) was too high, the GA was trapped too quickly in a local optimum solution. However, this number was subject to the population size. Too high a mutation rate introduced too much diversity and took a longer time to reach the optimum solution. Too low a mutation rate tended to miss some near-optimum solutions. Using the annealing strategy (a linearly decreasing mutation probability rate with each new generation) the effects of a too high or too low mutation rate could be overcome. 6. Evaluation First, the efficiency of an existing universal motor was calculated. An outline of the rotor/stator lamination of this motor is shown in Fig.6. The power losses of this motor were 313W and the output power was 731W. In the outline, the levels of magnetic flux density through the rotor/stator lamination are shown, expressed as T. The darkest grey color indicates areas with the highest level of magnetic flux density, which results in a high iron loss. 5.5. Termination criteria The GA operated repetitively, with the idea that, on average, the solutions of the population defining the current generation had to be as good (or better) at maximizing the fitness function as those of the previous generation. When a certain number of populations had been generated and evaluated, the system was assumed to be in a non-converging state. This criterion was a 'timeout' approach. The fittest member of the current generation at the time the GA terminated was taken to be the solution of the design problem. 5.6. Parameter settings Finding good settings for the parameters of the GA that worked for the problem was not a trivial task. Robust parameter settings had to be found for population size, number of generations, selection criteria and genetic operator probabilities: If the population was too small, the GA converged too quickly to a local optimum solution and might not find the best solution. On the other hand, large populations required a long time to converge to a region of the search space with significant improvement. Figure 6. Existing rotor/stator lamination. After several runs of the GA, a set of promising solution candidates was collected. For each candidate a finite-element numerical simulation followed by the calculation of the objective function value (fitness) was performed. Most of the solutions show a significant reduction of power losses in comparison with the losses in the existing motor. The best solution results in a powerloss reduction of 16%, and gives us a motor with copper and iron losses of 264W (see Fig.7). A comparison of the magnetic flux densities in the existing and the optimized motors shows a clear reduction Table 1. Evaluation results. input power (W) efficiency (%) output power (W) iron&copper losses (W) analytic calculation initial new 1044 1037 70.0 74.5 731 773 313 264 prototype measurement initial new 1100 1100 69.7 72.6 767 799 333 301 non-exact iron losses. 7. Conclusion Figure 7. Optimized lamination. of areas with the highest levels of magnetic flux density in the optimized motor. The iron and copper losses of the initial and the optimized lamination design are shown in Tab.1. In the new (optimized) lamination, the copper losses in the rotor and the stator are significantly lower than in the initial lamination. On the other hand, the iron losses are higher than in the initial lamination. The reason for this effect is that the slot area in the stator of the optimized lamination is larger. The number of ampere-turns in the optimized lamination that are necessary for obtaining the required torque are lower in comparison with the initial lamination due to the optimized lamination design. If J in (2) is substituted with (1), the equation is as follows: (I ⋅ N ) References 2 PCuSlot = A In this paper, an evolutionary optimization technique for designing a universal motor for home appliances, with constraints on the geometry of the rotor/stator lamination, is presented. An approach that uses the GA at a very early stage of the motor design when an optimum configuration of the geometrical parameters has to be found, is described. The GA generates sets of solution candidates, which are evaluated using the finite-element method. We demonstrated that by repeating the process by which the GA generates sets of solutions an optimum configuration with reduced power losses can be found in a very short time. Using the GA the iron and copper losses of an existing universal motor were reduced by at least 10%. Increasing the GA running time or setting its parameters more appropriately could improve this result, still further, however, the additional effects of other motor components should also be investigated. ⋅ ρ ⋅ l turn (9) From the equation above it is clear that the copper losses increase with the square of the number of ampereturns and are inversely proportional to the slot area. In the rotor, the slot area is slightly decreased, but the effect of reducing I⋅N is much stronger, and this results in lower copper losses in the rotor. The iron losses are increased in both the rotor and the stator, mainly because of the slightly larger iron area in the optimized design. The magnetic flux density in the stator remains in the same range as in the initial design. In rotor, the magnetic flux density is decreased, but the iron area of the rotor is larger. Overall, the optimized design has a much better torque capability, and this results in a total loss reduction of 16%. We next made a prototype of the motor and measured the real losses and efficiency of the motor. These values are shown in Tab.1 and are slightly different from the calculated ones. The main reason for the difference is the [1] D.E.Goldberg, Genetic Algorithms in Search, Optimization, and Machine Learning. Addison-Wesley Publishing Company, Inc., 1989. [2] ANSYS User's Manual, ANSYS version 5.6, 2000. [3] J.H. Holland, Adaptation in natural and artificial systems. Ann Arbor: The University of Michigan Press, 1975. [4] G.Papa, Using Simulated Annealing and Genetic Algorithm in the Automated Synthesis of Digital Systems, Nikos E. Mastorakis (editor), Recent advances in Circuits and Systems, World Scientific, Singapore, 1998, pp. 377-381. [5] B.Koroušić-Seljak, Heuristic Methods for a Combinatorial Optimization Problem - Real-Time Task Scheduling Problem, In C.H.Dagli et al (editors): Smart Engineering System Design: Neural Networks, Fuzzy Logic, Evolutionary Programming, Data Mining, and Complex Systems, ASME Press Series on Intelligent Engineering Systems through Artificial Neural Networks, Volume 9, 1999, pp. 1041-1046. [6] C.L. Karr et al, Solving inverse initial-value, boundary-value problems via genetic algorithm, Engineering Applications of Artificial Intelligence, Volume 13, Number 6, December 2000, pp. 625-633.