Opportunities for Catalysis in The 21 Century

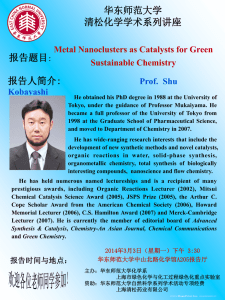

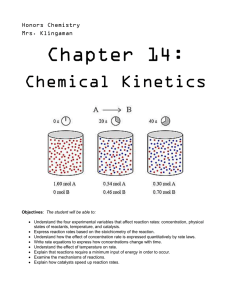

advertisement