Operations - Select Strategies for Revision

advertisement

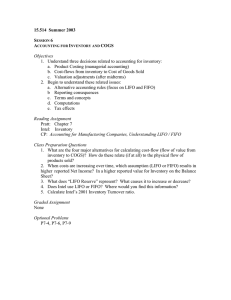

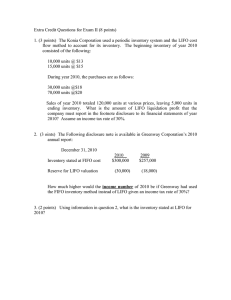

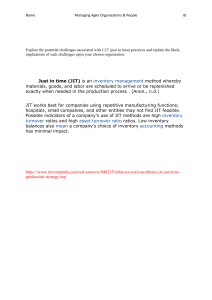

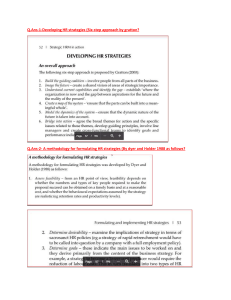

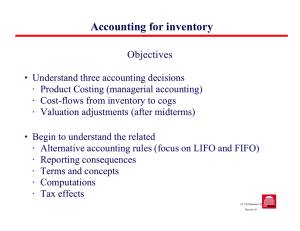

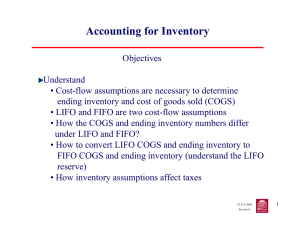

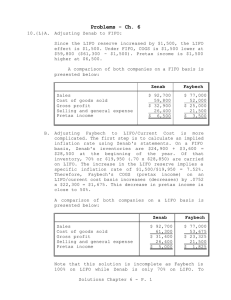

OPERATIONS STRATEGIES – select strategies for revision operations strategies performance objectives – quality, speed, dependability, flexibility, customisation, cost new product or service design and development supply chain management – logistics, e-commerce, global sourcing outsourcing – advantages and disadvantages technology – leading edge, established inventory management – advantages and disadvantages of holding stock, LIFO (last-in-first-out), FIFO (first-in-first-out), JIT (just-in-time) quality management - control - assurance - improvement overcoming resistance to change – financial costs, purchasing new equipment, redundancy payments, retraining, reorganising plant layout, inertia global factors – global sourcing, economies of scale, scanning and learning, research and development INVENTORY and QUALITY MANAGEMENT Instructions match the defintion with the term Definition This focuses on managing the total business to deliver quality to customers . It is a ‘holistic’ approach. LIFO These are the 4 key areas of which Quality Management concept: 1. benchmarking 2. employee empowerment 3. customer improvement 4. continuous improvement This method of pricing inventory assumes that the first goods purchased are also the first goods sold. Usually for perishable items These are all the processes that a business undertakes to ensure consistency, reliability, safety and fitness of purpose of product This is an ongoing commitment to improving a business’s goods or services This is the method of pricing inventory where the last goods purchased are the first goods sold. Usually for products without an expiry date eg machinery This involves the use of a system to ensure that set standards are achieved in production FIFO This inventory management approach ensures that the exact amount of material inputs will arrive only as they are needed in the operates processes…that is - just in time to be sold JIT This involves the use of inspections at various points in the production process to check for problems and defects Term OVERCOMING RESISTANCE TO CHANGE The first step in overcoming resistance to change is identifying reasons for resistance to change. There are Driving and Restraining forces Driving forces: all those forces that initiate, encourage and support change eg Restraining forces: all the forces that create resistance to change eg Draw the model (Lewin) Resistance to Change Catagorising - Instructions catagorise the following reasons for resitance to change into financial or psychological/emotional Reason for resistance to change Retraining This describes the feeling of uncertainty or fear of the unknown Purchasing new equipment Reorganising the plant layout Redundancy payout Change Management Strategies change agents (internal or external) Kurt Lewin’s unfreeze/change/refreeze model John Kotter’s 8 step model financial or psychological/emotional