Challenges of.. Asabe 2013 Poster

advertisement

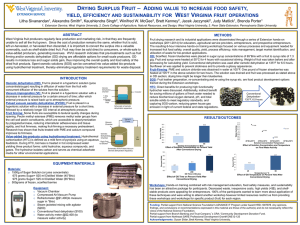

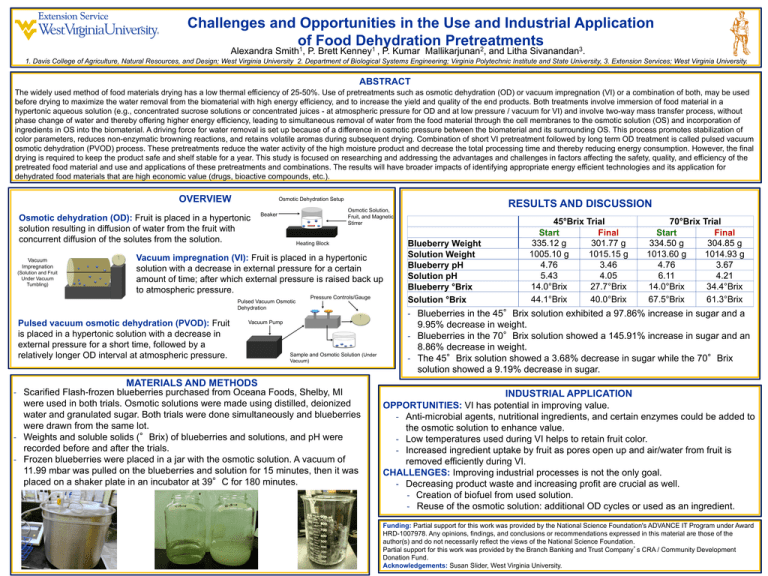

Challenges and Opportunities in the Use and Industrial Application of Food Dehydration Pretreatments 1 1 2 3 Alexandra Smith , P. Brett Kenney , P. Kumar Mallikarjunan , and Litha Sivanandan . 1. Davis College of Agriculture, Natural Resources, and Design; West Virginia University 2. Department of Biological Systems Engineering; Virginia Polytechnic Institute and State University, 3. Extension Services; West Virginia University. ABSTRACT The widely used method of food materials drying has a low thermal efficiency of 25-50%. Use of pretreatments such as osmotic dehydration (OD) or vacuum impregnation (VI) or a combination of both, may be used before drying to maximize the water removal from the biomaterial with high energy efficiency, and to increase the yield and quality of the end products. Both treatments involve immersion of food material in a hypertonic aqueous solution (e.g., concentrated sucrose solutions or concentrated juices - at atmospheric pressure for OD and at low pressure / vacuum for VI) and involve two-way mass transfer process, without phase change of water and thereby offering higher energy efficiency, leading to simultaneous removal of water from the food material through the cell membranes to the osmotic solution (OS) and incorporation of ingredients in OS into the biomaterial. A driving force for water removal is set up because of a difference in osmotic pressure between the biomaterial and its surrounding OS. This process promotes stabilization of color parameters, reduces non-enzymatic browning reactions, and retains volatile aromas during subsequent drying. Combination of short VI pretreatment followed by long term OD treatment is called pulsed vacuum osmotic dehydration (PVOD) process. These pretreatments reduce the water activity of the high moisture product and decrease the total processing time and thereby reducing energy consumption. However, the final drying is required to keep the product safe and shelf stable for a year. This study is focused on researching and addressing the advantages and challenges in factors affecting the safety, quality, and efficiency of the pretreated food material and use and applications of these pretreatments and combinations. The results will have broader impacts of identifying appropriate energy efficient technologies and its application for dehydrated food materials that are high economic value (drugs, bioactive compounds, etc.). OVERVIEW Osmotic Dehydration Setup Osmotic dehydration (OD): Fruit is placed in a hypertonic solution resulting in diffusion of water from the fruit with concurrent diffusion of the solutes from the solution. Vacuum Impregnation (Solution and Fruit Under Vacuum Tumbling) Osmotic Solution, Fruit, and Magnetic Stirrer Beaker Heating Block Vacuum impregnation (VI): Fruit is placed in a hypertonic solution with a decrease in external pressure for a certain amount of time; after which external pressure is raised back up to atmospheric pressure. Pulsed Vacuum Osmotic Dehydration Pulsed vacuum osmotic dehydration (PVOD): Fruit is placed in a hypertonic solution with a decrease in external pressure for a short time, followed by a relatively longer OD interval at atmospheric pressure. RESULTS AND DISCUSSION Pressure Controls/Gauge Vacuum Pump Sample and Osmotic Solution (Under Vacuum) MATERIALS AND METHODS - Scarified Flash-frozen blueberries purchased from Oceana Foods, Shelby, MI were used in both trials. Osmotic solutions were made using distilled, deionized water and granulated sugar. Both trials were done simultaneously and blueberries were drawn from the same lot. - Weights and soluble solids (°Brix) of blueberries and solutions, and pH were recorded before and after the trials. - Frozen blueberries were placed in a jar with the osmotic solution. A vacuum of 11.99 mbar was pulled on the blueberries and solution for 15 minutes, then it was placed on a shaker plate in an incubator at 39°C for 180 minutes. Blueberry Weight Solution Weight Blueberry pH Solution pH Blueberry °Brix Solution °Brix 45°Brix Trial Start Final 335.12 g 301.77 g 1005.10 g 1015.15 g 4.76 3.46 5.43 4.05 14.0°Brix 27.7°Brix 44.1°Brix 40.0°Brix 70°Brix Trial Start Final 334.50 g 304.85 g 1013.60 g 1014.93 g 4.76 3.67 6.11 4.21 14.0°Brix 34.4°Brix 67.5°Brix 61.3°Brix - Blueberries in the 45°Brix solution exhibited a 97.86% increase in sugar and a 9.95% decrease in weight. - Blueberries in the 70°Brix solution showed a 145.91% increase in sugar and an 8.86% decrease in weight. - The 45°Brix solution showed a 3.68% decrease in sugar while the 70°Brix solution showed a 9.19% decrease in sugar. INDUSTRIAL APPLICATION OPPORTUNITIES: VI has potential in improving value. - Anti-microbial agents, nutritional ingredients, and certain enzymes could be added to the osmotic solution to enhance value. - Low temperatures used during VI helps to retain fruit color. - Increased ingredient uptake by fruit as pores open up and air/water from fruit is removed efficiently during VI. CHALLENGES: Improving industrial processes is not the only goal. - Decreasing product waste and increasing profit are crucial as well. - Creation of biofuel from used solution. - Reuse of the osmotic solution: additional OD cycles or used as an ingredient. Funding: Partial support for this work was provided by the National Science Foundation's ADVANCE IT Program under Award HRD-1007978. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation. Partial support for this work was provided by the Branch Banking and Trust Company’s CRA / Community Development Donation Fund. Acknowledgements: Susan Slider, West Virginia University.