The Intelligent Systems & Robotics Center at Sandia National

advertisement

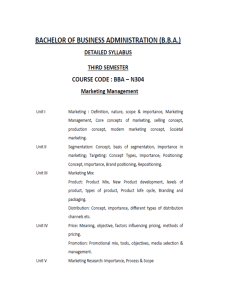

The Intelligent Systems & Robotics Center at Sandia National Laboratories Mark L. Swinson, Ph.D., P.E. Deputy Director mlswins@sandia.gov For more information: www.sandia.gov/isrc PPTElec020701.ppt PG 1 Intelligent Systems & Robotics Center Steve Roehrig, Director Current funding level: ~$30M Technical Staff: ~70 Number of robots: ~60 Heavy labs: 12 Light labs: 29 Total labs: 41 A “Research-Development-Application” Organization PPTElec020701.ppt PG 2 Where did we start Nuclear Weapons Legacy Munitions Stealth Fighters Cows Surgery have in common? • Process as lot size of one • Amortization issues • Strict process constraints: quality, safety • Sandia’s Intelligent Systems & Robotics Center PPTElec020701.ppt PG 3 DOE Defense Programs Accomplishments Stage Right, storage and monitoring of retired pits, hot operation in 1996 Automated disassembly of explosive gas generators, hot operation in 1997 Pit Weigh and Leak Check System, awaiting completion of Readiness Review. Thermal Spray Inspection Station, areal desisty measurements of applied materials, 2 operational in NGPF Today Robocal, Automated NDA, Readiness Review @ LANL complete Canout, Automated SNM packing and processing for removal from glovebox, cold operation at LANL Automated Thermal Spray Station, increase process quality and coating uniformity, operational @ NGPF in 7/01 Automated Particulate Removal System, reduces operator exposure during cleaning, operational at NGPF 2/01. Strategic Reserve Stage Right, storage and monitoring of stockpile pits, deployment @ Pantex in FY01 Over Time, in the Future Microassembly, research, develop and apply technologies for LIGA and MEMS component assembly Campaign.ppt 4 Surveillance and Monitoring Robot, provide remote near-human presence Laser Engineered Net Shaping, develop full 3-D capability Safe Secure Storage, integrate microengineered sensors, automation, and command and control First-time-right components, integrate virtual design and manufacturing process prototyping Desired End State Process Model Part Model Robot Model Magic Happens Workcell Model PPTElec020701.ppt PG 5 Program Out Process Constants (outside factors) Time, throughput, cost,staffing, . . . DoD Non-warfighting Accomplishments F-117 Robotic Coating System Customer: Air Force F-117 SPO Developed & deployed cost-effective robotic system to apply stealth coating for 50 aircraft fleet Demilitarization Hazardous Operation Risk Reduction Customer: Army DAC Demonstrated automated disassembly of inert 40mm munitions at Army ammunition plant CVX Trade-off Studies Customer: Navy CVX PM/LM Moorstown Recommend manning reduction opportunities for new aircraft carrier under design F-22 Robotic Coating Upgrades Customer: Lockheed Martin, Marietta Developing & implementing hardware & control improvements to existing robotic coating system Smart Crane Customer: Navy NSWC Demonstrating swing-free ship off-loading with sea-state compensation on Navy transport ship 155 mm Automated Disassembly Customer: Army DAC Developing automated system to disassemble projectiles containing grenade & antipersonnel mine submunitions Today Over Time, in the Future B-2 Robotic Coating System Customer: Air Force B-2 SPO/Northrop Grumman Develop & deploy cost-effective automated coating system for 20 aircraft fleet Campaign.ppt 6 LM/SNL Shared Vision project Developing automated assembly / disassembly & human motion planner for aircraft logistics & maintenance operations Advanced Logistical Support Operations Developing intelligent autonomous robot technologies to transport supplies from warehouses to aircraft DoD Warfighting and NP&MC Today US Special Forces Command Reconnaissance US Marine Corp Distributed Site Protection DARPA Source Detection and Isolation Counter-Terrorism Ruggedized Robots for Highspeed Deployment Over Time, in the Future DARPA Advanced Mobility for Minefield Maintenance US Marine Corp Sensor Delivery for Ship-toObjective Maneuver US Army Future Unmanned Ground Combat Vehicle Micro-robots will be broadly useful, and will motivate many Sandia tech base elements • The future things should include examples in which a) we will be selling to a customer, b) we will support someone in their sales to a customer, and/or c) we intend to team with industry teaming with industry PPTElec020701.ppt PG 7 We Developed Umbra to Study Diverse Systems Issues Search Backup Robotic Vehicles • Network-Centric Systems Behavior & Controls Umbra is a systems analysis tool – Developed for robotics, Umbra’s capabilities go beyond robotics problems. • Umbra was designed for complex systems analysis because robotics questions are inherently “between grid” questions. • Umbra brings together disjointed analytical tools – Supports rapid integration of NLT Technologies • C4ISR, Human modeling, Terrain analysis, Genetic algorithms … – Interfaced with Army’s Joint Virtual Battlespace PPTElec020701.ppt PG 8 Rotate Track Umbra was Developed For and By Systems Engineers • Directly expresses systems engineering ideas – Physics-based models – Components modeled with transfer functions – Events & non-linear interactions supported Time Sensor Sensor Behav. Control Physics Graphic Sensor F • Multiple Worlds – Lets agents work together as collections and communicate in non-linear ways – Flexibly combines simulation, control & other elements – Enables Umbra’s flexible HLA implementation PPTElec020701.ppt PG 9 Dynamic Run-Time Environment Supports what-if analysis Partnerships IBP Goodyear Lund Boat Ultramax Accomplishments Develop sensors and cutters in a fat trimming machine Litton-Ingalls Shipyard Proprietary design and manufacturing tools MicroDexterity Systems Design of automation for boat manufacture Constraint-based interactive assembly analysis and planning software tool Numotech ETI Today Automatic generation of weld path trajectories Automated assembly of automatic transmission assemblies Design and manufacture cushion that mitigates pressure sores Established products for manufacture and distribution Seattle Orthopedic Group And into the Future Campaign.ppt 10 Joint Ventures with private firms e.g: • Equipment teleoperation • SwingFree cranes • Networkable robots • Flexible manufacturing Integration of multiple prosthetic devices into a single system IED Robotics control and manipulators Active Sketch (patent pending) Master-slave manipulator for teleoperation (patents issued)