tender documents for chemicals/glassware

advertisement

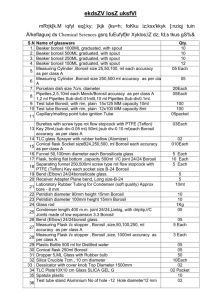

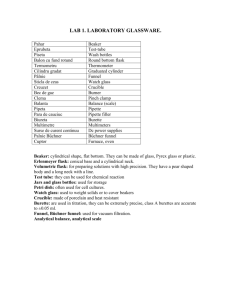

HAZARA UNIVERSITY, MANSEHRA CHEMICALS/GLASSWARE/EQUIPMENT TENDER DOCUMENTS HAZARA UNIVERSITY,MANSEHRA OFFICE OF THE PROCUREMENT OFFICER Phone No. 0997-414178, Fax No. 0997-414111 1. GENERAL i. Any bid without 5% earnest money of the total amount will not be entertained. ii. Conditional/incomplete bid will not be entertained. iii. The prices quoted must be valid for at least 90 days from the date of tender opening for the evaluation of tender. iv. The successful bidders will be required to supply the items up-to the end of financial year 2015-2016. The bid can be extended for further period as per KPPRA rules, if both the parties agree. v. Telephonic/telexed/faxed/telegraphic quotations will not be entertained. vi. The bid must accompany the following: a. Firm Registration Certificate with the Federal/Provincial Government. b. National Tax Number c. Sales Tax Registration Certificate Number. d. Certificate to the effect that they have never been blacklisted by any Government/ Semi Government Organization. e. Dealership Certificate from original manufacturer for Pakistan (where necessary / required) f. All bids must be properly sealed and delivered through mail. g. The provision of quoted rate in soft form is also required. 2. SCOPE OF SUPPLY The bidder shall supply the items according to the prescribed specifications. Any deviation will cause rejection of the supply order. 3. BID PRICE The bidder shall indicate in his offer, list of items with prescribed specifications, the unit price and total bid prices of the items. Taxes levied by the Government, if any, shall be recoverable from the bidder as per rules. 4. CURRENCY OF BID The Price should be quoted in Pakistani Rupees. 5. BID VALIDITY The bid should remain valid and open for acceptance of purchase for CFY 2015-16 from the date of opening of bids 6. PERFORMANCE GURANTEE The winner of bid shall submit a performance guarantee of 10% in form of demand draft/pay order/Bank Guarantee in favor of Treasurer Hazara University Mansehra. 7. BIDS PROPOSAL The bid should comprise a single package containing two separate envelopes. Each envelop should contain separately the financial proposal and technical proposal. The envelopes shall be marked as “FINANCIAL PROPOSAL” and “TECHNICAL PROPOSAL" in bold letters. Initially the technical proposal will be opened whereas the financial proposal will be retained in the custody without being opened. The committee will evaluate the technical proposals. The Technical proposal not confirming to the requirements of the university will be rejected, the financial proposal of bids found technically non-responsive will be returned un-opened to the respective bidders. An affidavit in the technical proposal stating that a bid security amounting to 5 percent without indicating the figure in the letter, has been placed in the financial proposal or bid. Otherwise the technical proposal will be considered non-responsive and will be returned to the bidder after being examined by the procurement committee. Financial proposals of the technically responsive bids will be opened publicly at the time, date and venue which will be communicated well in time to the respective bidders. The above stated standard evaluation criteria will be binding upon the bidders and will have no liability, on the University. 8. DEADLINE FOR SUBMISSION OF BIDS All bids must reach and be received by the University on or before the prescribed deadline at 10.30 hours. The bids will be opened at 11.30 hours on the same day in the conference room, Hazara University in presence of the bidders or their authorized representatives, who wish to be present. 9. LATE BIDS Any bid received in the university after the prescribed deadline shall not be entertained. 10. CANVASSING Unsolicited advice / clarifications and any personal approached at any stage of evaluations of bids are strictly prohibited and may lead to disqualification. 11. DELIVERY The bidders shall make delivery of the items within 25 days from date of issuance of supply order. A penalty of 2% of the item price per day subject to the maximum of 10% may be charged after expiry of the delivery time till the supply of the items. The delivery of items, their installation, testing and functioning, shall be made at Hazara University Mansehra by the suppliers, at their own expense, and transportation arrangements. . 13. MODE OF PAYMENT No advance payment will be made as per Government rules. Bill payment will be made to the supplier after inspection of supplied items by a committee of experts constituted by the University after the successful and complete supply, installation and functioning of the items. 10% performance guarantee will be released after 6 months from the date of satisfactory supply of items. 14. PRICE The price of items will be inclusive of transportation and all taxes etc. No separate payment will be made by the University on this account. 15. TAXES All Government taxes shall be deducted at source according to the relevant rules. 16. ARBITATION The decision of the University in all relevant matters will be final and unchallengeable in any court of law anywhere. SPECIAL CONDITIONS OF THE CONTRACT 1. Inspection of Equipments/materials. All Equipments/Glassware shall be subject to inspection and shall be approved by Hazara University Purchase committee/Technical Committee before the same are fabricated or installed in position. The committee may reject such materials as are considered by him to be below standard specifications, size or quality. The Contractor shall provide all labour at his own expense for handling during inspection. Any materials rejected by the committee shall not be used and shall be removed from site by the Contractor. 2. Work to be opened for inspection. All supply/works under or during the course of execution in pursuance of the Contractor, whether at site or at Contractor's workshop shall, all times, be opened for inspection and supervision of the Hazara University Purchase committee/Technical Committee at all times during the usual working hours, the contractor should either himself be present to receive the instructions or any responsible agent duly accredited in writing, present for this purpose. Instructions given to the Contractor's agent should be considered to have the same force as if these had been given to the Contractor himself. 3. Responsibility against damages Before and up to the whole of the Supply/works are completed and have been finally handed over to the University and a proper completion certificate thereof obtained by the Contractor, the Contractor shall be responsible for all and any damage caused to the materials or installed works/equipments thorough accident, improper handling, transport or any other cause whatsoever and shall repair, remove or replace the same and compensate the University against all such losses. 4. 5. Specifications The work shall comply to the requirement/ specification laid down in the B.O.Q of the tender. Quality of each item should be supreme quality. Laboratory Test The Hazara University Purchase committee/Technical Committee has the power to order for conducting Equipments/material quality assurance test which he deems necessary and cost of such tests will be borne by the contractor. No claim in this regard will be entertained for payment. Hazara University - Mansehra List of Equipment, Chemicals & Glassware S.# Name of Equipment Specifications Qty Price / Remarks Specifications should be: 01 02 03 Na Bond Electro-spinning & Spray Unit 01 Easy to use Make nanofibers at lowest cost Can produce nanofibers with diameter of 20-1000nm More than 100 raw materials can be used. Independent temperature control for individual syringes Single nozzle & multi nozzles available. Coaxial nozzle available. High Voltage Power Supply Device 0-50KV, digital display 2-Channel Syringe Pump 10ml syringe:0.1-300ml/h 20ml syringe:0.1-400ml/h 50ml syringe:0.1-600ml/h Inner Diameter of Nozzle 0.1-1.6mm Syringe Traverse Speed 10-100 mm/min Drum Rotation Speed 400-1250 rpm (standard type) Temperature Room Temp. to 80℃ Make: Spain/UK/USA or Germany or Equivalent Specifications should be: 01 Cold Wall CVD Reactor Muffle Furnaces CVDWinPrC™ based process control software for Real Time Process Control, Data Logging and Display, Recipe Generation and Editing Standard Configuration: Quartz Process Chamber Wafer Size to 50mm Resistance Heater for Temperatures up to 1000 °C Temperature Controlled Showerhead Wafer Rotation Molybdenum or SiC Coated Graphite Susceptor Adjustable Distance between Wafer and Showerhead Low Pressure Operation from 100 mtorr - 700 torr Automatic Substrate Loading/Unloading UHP Gas Lines Metal Organic Liquid Source Bubblers User Settable Warnings and Alarms Comprehensive Software and Hardware Safety System Semi - S2/S8 and CE Compliant Make: Spain/UK/USA or Germany or Equivalent Specifications should be: Features: <> Exhausted Gas Outlet port <> 1200C Maximum <> Microprocessor PID Controller <> Program Pattern, 16 Segment <> 3 Program pattern <> Auto on-off time setting Function 01 Technical Specifications: Controller: Digital PID controller Temp. Up-to 1200C Max. Output Regulator: SSR unit control Thermocouple: K type CA sensor Heating element: Kanthal Insulation: Vacuum Molded Ceramic Fiber Material: Stainless Steel Make: UK/Germany/Korea or Equivalent Specification Should be: 04 01 Laboratory Oven Digital PID Control Tempered Safety Glass Window Safety and Convenience Dust Free Gravity Flow Convection Temp. Range: Ambient +5C to 250C Display: LED 4 Digital Display Controller: PID Multi-Function Controller Timer: 99min 59sec./ 99hr59min/ 99 days 24hr/ Continues Selectable Material: Inner: Stainless Steel (SUS 304) Material: Outer: Powder Coating Steel Safety: Over Heat Protector over current & Leakage Breaker Electric Supply: 110V, 60 Hz or 220V, 50/60 Hz Make: Spain/UK/USA/Germany or Korea or Equivalent Specifications should be: 01 05 06 07 08 Vacuum Pump <> Basic Vacuum pump for laboratory applications <> Oil free and low maintenance <> Low noise level (55dB to 60dB) during operation <> Large rubber feet add stability and act as vibration dampers <> Easy replacement of moisture trap and filter <> Vacuum level adjustment up-to 650 mm Hg Make: UK/Germany/Korea or Equivalent Specifications should be 01 Capacity: 100 liters With good specifications Make: UK/Germany/Korea or Equivalent Specification Should be: 02 Plate Material: Glass ceramic Plate dimensions: 160 x 160 mm Description Heating Area: 120 x 120 mm Heating Power: 500 W Max. Plate Temp. : 450 C Max. Plate (RPM): 100 - 1500 Max. Stirring Capacity: 15 liter Electrical supply: 230V, 50 Hz, 750W Make: Spain/UK/USA/Germany or Korea or Equivalent Specifications should be 01 LN2 Dewar Magnetic Stirrer with Hot Plate Ultrasonic Bath Tank capacity: 4,3 liter Ultrasonic frequency: 40 / 33 KHz Timer setting (min): 1 -60 min with auto swich-off Heating temperature: 80°C Heating power: 100 W Ultrasonic power: 120 W Basket dimensions (WxDxH): 190×100×85mm Little basket dimensions (Dia. x Height): 78×60mm Tank dimensions (WxDxH): 230×126×150mm Unit dimensions (WxDxH): 315×215×270mm Make: UK/Germany/Korea or Equivalent Specifications should be: 09 Water circulation set up (for refluxing reaction) 01 Features: Water pump Water storage tank Piping Specifications: Low pressure of water pump Tank capacity 15 – 20 Liters 10 Stock Apparatus Bottles for stock apparatus 10 Make: Local Specification should be: All glass Could bear vacuum as below as 10-3 mbar On/off valves Contact line to vacuum pump Contact line to N2 For LN2 Dewar With good specifications 01 03 Specifications should be: 01 11 Heating Mantle 12 Xenon Lamp with AM 1.5 filter CHEMICALS: S.# Controlled up to 450ºC Range of sizes available Tough lightweight, easy to clean aluminum casing Integrated clamp fitting Capacity: 500ml, 1000ml & 2000 ml Make: UK/Germany/Korea or Equivalent Xenon Lamp with AM 1.5 filter With good specifications Item with Specifications 1. Silica gel with indicator; 2. Liquid Nitrogen 3. Nitrogen Gas Cylinder with gas and regulator 4. Zinc Chloride; 5. Dimethylzinc solution; 6. Diethylzinc (C2H5)2Zn; 7. Tin(II) chloride; 8. Tin(IV) chloride; 9. Trimethyltin chloride; Qty 2.5 kg Liter 1 100 gm 50 ml 100 g 100 g 200 g 20 g 01 Price / Remarks 10. Lithium aluminum hydride (LiAlH4); 11. Aluminum chloride (AlCl3); 12. Sodium; 13. Mercury; 14. Paraffin oil; 15. 2-propanol; 16. Tert-Butanol; 17. Acetonitrile; 18. Phenol; 19. 2,4,6-trimethylphenol; 20. 2,4,6-tri-tert-butylphenol; 21. BuLi; (2.5 M in hexane) 22. Diethyl Ether; 23. Benzene; 24. Toluene; 25. Chloroform; 26. Methanol; 27. Ethanol; 28. THF; 200 g 200 g 500 g 1 kg 3 liters 3 liters 3 liters 1 liter 750 ml 200 ml 200 gm 1 liter 7.5 liters 3 liters 7.5 liters 2 liters 7.5 liters 7.5 liters 5 liters 29. N,N’-dimethylaminoethanol; 250 ml 30. Polyvinylpyrrolidone; 600 g 31. Graphite Block (4” x 4” x 12” ); 1 piece 32. Substrates (Silicon Wafers); 33. Substrates (Stainless steel); 34. N3 dye; 35. Phthalocyanine; 36. Meso-tetraphenylporphyrin; 2 pks. x 5 3 pks. x 5 2.5 g 5g 5g 37. 1-butyl -3-methyl imidazolium; 38. Iodine; 39. Guanidine Thiocyanate; 40. H2PtCl6; (8% sol. in H2O) 41. FTO Glass (3 x 5); 42. Tetraethoxysilane (TEOS); 43. Commercial ethanol; 44. Benzophenone; 10 g 50 g 50 g 25 mL 1 pks x 5 100 g 20 liters 100 g GLASSWARE: Item with Specifications Qty 1 Beakers, Graduated; 25 mL 12 2 Beakers, Graduated; 50 mL 12 3 Beakers, Graduated; 100 mL 6 4 Beakers, Graduated;250 mL 2 5 Beakers, Graduated; 500 mL 1 6 Centrifuge Tubes (15ml,) Plastic Autoclave able; 12 7 Centrifuge Tubes (50ml,) Plastic Autoclave able; 12 8 Centrifuge Tubes (100ml,) Plastic Autoclave able; 12 9 Cylinder, Graduated; 10 ml; 6 10 Cylinder, Graduated; 25 ml; 6 11 Cylinder, Graduated; 50 ml; 6 12 Cylinder, Graduated; 100 ml; 6 13 Eppendorft tubes 1.5 ml; 2 packets 14 Filter Paper (No. 42); 5 packets 15 Glass Pipettes; 1ml; 6 16 Glass Pipettes; 2 ml; 6 17 Glass Pipettes; 5 ml; 6 18 Glass Pipettes; 10 ml; 6 19 Glass Pipettes; 50 ml; 6 20 Glass Pipettes; 100 ml; 6 21 Reagent Bottles 50 ml; 6 S.# Price / Remarks 22 Reagent Bottles 100 ml; 6 23 Reagent Bottles 250 ml; 6 24 Reagent Bottles 500 ml; 6 25 Microscope Slides; 5 packets 26 Glass Petri Dishes (120 mm); 24 27 Round bottom flask; 10 ml; 12 28 Round bottom flask; 25 ml; 12 29 Round bottom flask; 50 ml; 12 30 Round bottom flask; 100 ml; 12 31 Round bottom two neck flask; 50 ml; 12 32 Round bottom two neck flask; 100 ml; 12 33 Round bottom two neck flask; 250 ml; 6 34 Round bottom three neck flask; 100 ml; 6 35 Round bottom three neck flask; 250 ml; 12 36 Reflux condenser; 4 37 Dropping funnel with pressure equalizing side arm; 25 ml; 6 38 Dropping funnel with pressure equalizing side arm; 50 ml; 6 39 Dropping funnel with pressure equalizing side arm; 100 ml; 6 40 Dropping funnel with pressure equalizing side arm; conical shape 500 ml; 3 41 Dropping funnel with pressure equalizing side arm; conical shape 1000 ml; 3 42 T-shaped glass tubes with stopper and mouth heads; 12 43 Cross-shaped glass tubes with stopper and mouth heads; 12 44 Magnetic bars; small size; 12 45 Magnetic bars; medium size; 12 46 Magnetic bars; large size; 6 47 Oil bath tub; 6 48 Filtering fritted funnels with pressure equalizing side arm; 25 ml; 6 49 Filtering fritted funnels with pressure equalizing side arm; 50 ml; 6 50 Filtering fritted funnels with pressure equalizing side arm; 100 ml; 6 51 Stoppers (Glass) for round bottom flaks; 48 52 Glass caps; 48 53 Sublimation tubes with cooling jackets; 6 54 Spatula kit; 1 55 Wash bottles; 100 ml; 6 56 Laboratory thermometer; 2 57 Distillation Apparatus; 2 58 Oil bubbler; 3 59 Round bottom Schlenk flask; 500 ml; 6 60 Round bottom Schlenk flask; 1000 ml; 6 61 Adapter; 12 62 PTFE beaker; 25 ml; 3 63 PTFE beaker; 50 ml; 3 64 PTFE beaker; 100 ml; 3 65 Desiccators; 2 66 Joint Clips (metal); 24 67 Joint Clips (polyacetal); 24 68 Test Tube Rack (20 holes); 3 69 Pipette rinser; 2 70 Rubber Pipette Fillers; 12 71 Tweezers/forceps set; 1 72 Condenser for solvent collection setup; 2 73 Sodium wire press; stainless steel; 1 74 Pressure equalizing side arm solvent collection funnel; 3 75 NMR tubes; 6 76 Capillary tubes; 2 packets 77 Standard schlenk line; 2 78 Wafers Sample storing cases; 12 79 Glass slides; 2 packets 80 PVC coated Nickel Sheet / Plate 1000mm x 1000mm x 1.2mm Thick; 12 81 PVC coated Aluminium Sheet / Plate 1000mm x 1000mm x 1.2mm Thick; 12 82 PVC coated Iron Sheet / Plate 1000mm x 1000mm x 1.2mm Thick; 12 83 Volumetric Flasks 10 ml; 12 84 Volumetric Flasks 50 ml; 12 85 Volumetric Flasks 100 ml; 6 86 Solvent trap (glass); 6 87 Solvent trap adopter; 6 88 Desiccation tubes (glass); 6 89 Stopcock; 6 90 Quickfit socket (glass); 24 91 Media lab bottles; 25 ml; 6 92 Media bottles; 50 ml; 6 93 Condenser Air; medium size; 3 94 Crucible; medium size; 6 95 Conical flask; 25 ml; 6 96 Conical flask; 50 ml; 6 97 Conical flask; 100 ml; 3 98 Filter tubes socket neck; 6 99 Pear shape flask single neck; 10 ml; 12 100 Septums (rubber); 12 101 Round bottom flask stands; 12 102 Funnel; medium size; 3 103 Tapered PTFE sleeves; 12 104 Water flow indicator; 6 105 Watch glass; 12 106 Wall mountable draining rack; 1 107 Stirring rods; 6 108 Straight bore glass stopcock with glass key; 6 109 Socket tubes; capacity about 50 ml; 12 110 Pasteur Pipettes; 2 packets 111 Pasteur pipette bulk; 6 112 Syringes; 1ml; 1 packet 113 Syringes; 2ml; 1 packet 114 Syringes; 5ml; 1 packet 115 Syringes; 10ml; 1 packet 116 Syringe needles; 1 packet 117 Agate Mortar and Pestle; 1