Objective: Provide information necessary to relate customer

advertisement

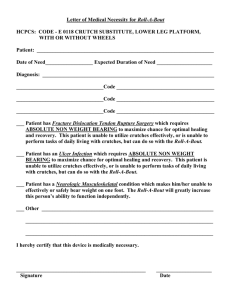

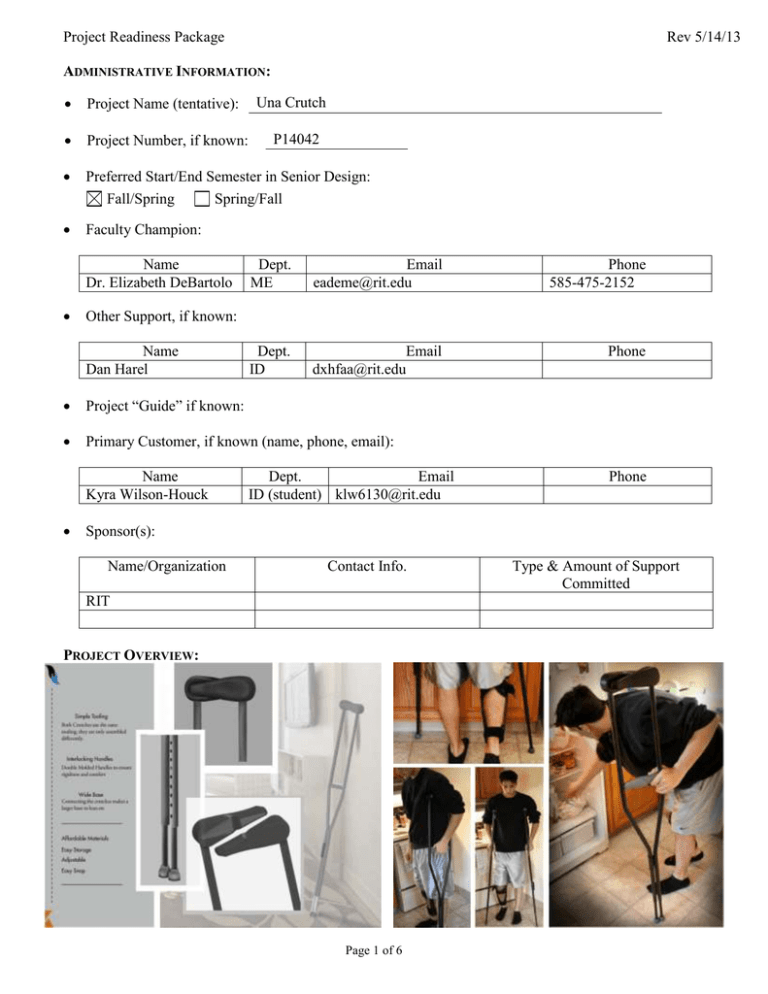

Project Readiness Package Rev 5/14/13 ADMINISTRATIVE INFORMATION: Project Name (tentative): Project Number, if known: Preferred Start/End Semester in Senior Design: Fall/Spring Spring/Fall Faculty Champion: Name Dr. Elizabeth DeBartolo Una Crutch P14042 Dept. ME Email eademe@rit.edu Phone 585-475-2152 Dept. ID Email dxhfaa@rit.edu Phone Other Support, if known: Name Dan Harel Project “Guide” if known: Primary Customer, if known (name, phone, email): Name Kyra Wilson-Houck Dept. Email ID (student) klw6130@rit.edu Phone Sponsor(s): Name/Organization Contact Info. RIT PROJECT OVERVIEW: Page 1 of 6 Type & Amount of Support Committed Project Readiness Package Rev 5/14/13 This project was developed by Kyra Wilson-Houck, who is an Industrial Design major. She came up with the idea for one of her classes after her boyfriend injured his leg (pictured above left). She observed that when he was moving around the house, he preferred to use only one crutch at a time. This left her with the responsibility of carrying the extra crutch around for him. If she was not nearby, he would leave the crutch lying around the house and have to relocate it when he wanted to use two again. Kyra's response to this issue was to design the Una Crutch—a two-crutch design that snaps together when the user only requires one crutch. Currently Kyra's design is just a prototype (pictured above right). There has been no mechanical analysis done on the model and it still requires some ergonomic analysis as well. The current connecting mechanism is a snap-fit lock the attaches the two lower legs of the crutches. The shoulder and hand supports conform together when they are connected; however, because of the way they conform, the crutches cannot be comfortably used. She would like to have a different snapping mechanism and would also like to make overall crutch equivalent to a normal crutch in every other aspect. The estimated production costs are currently very high, so she would like those to be reduced as well. DETAILED PROJECT DESCRIPTION: Customer Needs and Objectives: Functional Decomposition: Potential Concepts: Specifications (or Engineering/Functional Requirements): House of Quality: See Appendix A Page 2 of 6 Project Readiness Package Rev 5/14/13 Project Deliverables: This product will result in a drastic improvement over the current prototype of the Una Crutch. The final product will ideally be able to support users up to 250 pounds and it will adjust to fit users of varying heights. The crutch will have a connecting mechanism that is strong enough to hold the crutches together but not so strong that the crutches are difficult to disconnect. The connecting mechanism will not cause discomfort to the user and the resulting shape of the crutch will ideally be more comfortable than a normal crutch. The crutches will not be too heavy and won’t be expensive to produce in mass. Budget Estimate: The materials that this project will definitely require are: stock aluminum, rubber padding, push button locks (for the adjusting feature and possibly for the connecting mechanism). The project could potentially require some custom molding for the rubber parts and may need work to be done on the crutches that the students are not capable of (for example, welding). The group could elect to make more than one prototype in order to try different shapes/connecting mechanisms as well. Overall these goods should not be too expensive, so a budget of $500 to $1000 should suffice. Intellectual Property (IP) considerations: There is definitely patent potential for this project as there is no existing crutch that features a connecting aspect. Kyra has expressed a desire to market this product in the future, so there may be some concern over the confidentiality of the project. Certain aspects (mainly the connecting mechanism and ergonomic shape) may need to be kept from the public. This could be an issue since senior design is supposed to be an open source project and these elements are the main focus of the entire project. Other Information: The major risk that is associated with this project is that there is simply too much to do. It could be beneficial to remove or reduce the importance of some of the customer needs. Developing the shape of the crutch and the functionality of the mechanism, while meeting the constraints associated with those, is going to be a very time consuming process. For this iteration of the project, it might be necessary to remove the need for design appeal and/or for adjustability. These are all future improvements that can be added after the functionality of the crutch is developed (possibly in another senior design project). STUDENT STAFFING: Skills Checklist: Mechanical Engineering 2 3D CAD MATLAB programming 2 Machining (basic) 1 Stress analysis (2D) 3 Statics/dynamic analysis (2D) Thermodynamics Fluid dynamics (CV) LabView (data acquisition, etc.) Statistics Aerodynamics CFD Biomaterials Vibrations Combustion engines GD&T (geometic dimensioning & tolerancing) Linear controls Composites DFM Robotics (motion control) Page 3 of 6 Project Readiness Package Rev 5/14/13 1 FEA Heat transfer Modeling of electromechanical & fluid systems 4 Fatigue & static failure criteria (DME) Specifying machine elements Composites Other: Other: Other: Reviewed by (ME faculty): 1 2 5 1 4 Industrial & Systems Engineering Statistical analysis of data – regression Materials science Materials processing – machining lab Facilities planning – layout, material handling Production systems design – lean, process improvement Ergonomics – interface of people & equipment (procedures, training, maintenance) Math modeling – linear programming), simulation Project management Shop floor IE – methods, time study Programming (C++) DOE Systems design – product/process design Data analysis, data mining 3 Manufacturing engr. Engineering economy – ROI Quality tools – SPC Production control – scheduling DFx -- Manuf., environment, sustainability Other: Other: Other: Reviewed by (ISE faculty): Anticipated Staffing Levels by Discipline: Discipline EE ME How Many? 0 2 CE 0 ISE 1 Anticipated Skills Needed (concise descriptions) CAD Modeling, ANSYS analysis, Good understanding of statics and dynamics, Materials Ergonomics, Materials, Manufacturing, Project Management Page 4 of 6 Project Readiness Package Other (Industrial Design) Rev 5/14/13 1 Kyra would like to be on the project as well – Modeling, Ergonomics OTHER RESOURCES ANTICIPATED: Category Faculty Description Materials Expert Ergonomics Expert Environment Machine Shop Senior Design Room Medical Testing Facility (for final product testing) Equipment Welding (possibly) CAD Software Materials Other Page 5 of 6 Resource Available? Project Readiness Package Prepared by: Rev 5/14/13 Ryan Muckel Date: APPENDIX A (HOUSE OF QUALITY): Page 6 of 6 5/14/2013