CFL - IEA 4E - Standby Power Annex

advertisement

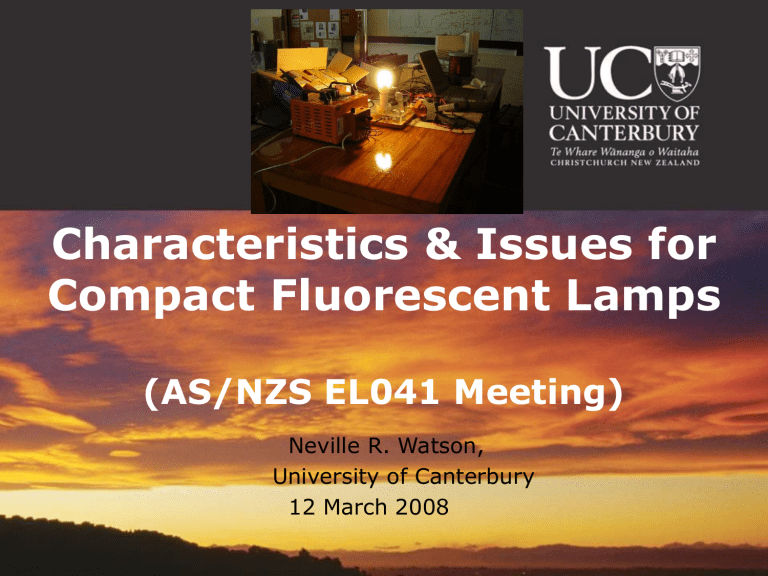

Characteristics & Issues for Compact Fluorescent Lamps (AS/NZS EL041 Meeting) Neville R. Watson, University of Canterbury 12 March 2008 Outline 1. Background 2. Types of CFLs 3. Direct Harmonic Penetration Study 4. Detailed Transient Simulations 5. Other Studies 6. Standards 7. Conclusions Missing Components Fuse on Input Filter Capacitors missing Same brand September 2007 Does have PTC No Fuse No place for Filter Capacitors PTC missing 3rd Pro. Project 2008 Switching Box PC with Data Acquisition Card Power-factor Active power Power-Factor Total Apparent Power 1 T v.idt 0 T VRMS I RMS N V I n 1 n n cos(n ) VRMS I RMS V1 I1 cos(1 ) I1 cos(1 ) V1 I RMS I RMS Distortion-Factor×DPF Types of CFL Ballasts Types of CFL No Power-Factor Control Passive Power-Factor Control Valley-Filling (or equivalent) Active Power-Factor Control Eclipse 20W CFL Eclipse CFL Schematic OSRAM DuluxStar 20W (2007) +ve OSRAM DULUXSTAR 20W 2007 C3 R1 C L1 D1 D3 C1 T1 R3 C4 B D7 L4 E R2 C2 C B L3 R5 L2 T2 D2 E D4 R4 -ve L5 PTC E-Lite CFL (July 2007) +ve Elite D5 D6 C4 R1 C Fuse L1 D1 D3 C6 C1 D7 T1 R3 C5 B E D8 L4 R2 C2 C3 C B L3 R5 L2 T2 D2 E D4 R4 -ve D9 L5 Eco-Bulb (2007) +ve Not fitted C D7 D1 B Red E J1 R3 C9 RJ1 A 10uF C2 C1 C D6 J2 B R2 T2 D2 PTC C6 R1 D8 D3 C8 T1 E D5 D4 -ve C5 R4 RJ2 C7 Not fitted Ecobulb 20W Schematic P = 81.57 Main : Graphs 0.0001 [ohm] 1.0 [uF] 1.0 [uF] 1.0 [uF] y (A) 0.0001 [ohm] 0.0001 [ohm] y (A) y (A) y (A) 250 [ohm] 0.0001 [ohm] D D Is_11 D Is_10 220[ohm] 250 [ohm] D D 15 [ohm] 0.005 [H] Is_10 Vs_10 250 [ohm] D D D D D D D 180.0 [uF] D D 2.0 [uF] D 180.0 [uF] 2.0 [uF] Is_3 D 180.0 [uF] Is4 VF D V_doubler 1.00 Vs_9 Is_10 180.0 [uF] A V D Is_9 250 [ohm] Vs_3 D 15 [ohm] 0.005 [H] D 180.0 [uF] D 2.0 [uF] Is_3 D 2.0 [uF] D P = 57.3 0.80 D 0.60 0.40 0.20 0.00 -0.20 -0.40 -0.60 -0.80 D 2.0 [uF] D 180.0 [uF] D D Is improved VF V_doubler Is_9 D D Is_8 Is9 180.0 [uF] 2.0 [uF] Is_2 Vs_8 180.0 [uF] A V Is VF V_doubler 250 [ohm] Vs_2 D 180.0 [uF] D 2.0 [uF] Is_2 D 15 [ohm] 0.005 [H] 2.0 [uF] D P = 57.07 D 1.00 0.75 0.50 0.25 0.00 -0.25 -0.50 -0.75 -1.00 Is_8 2.0 [uF] D D D 180.0 [uF] D 2.00 1.50 1.00 0.50 0.00 -0.50 -1.00 -1.50 -2.00 180.0 [uF] 2.0 [uF] Is_oVF D Is8 2.0 [uF] A V Is original VF 250 [ohm] Vs_oVF D D Is_7 180.0 [uF] Is_oVF 2.0 [uF] D D 1.0 [uF] P = 62.23 D 15 [ohm] 0.005 [H] Vs_7 0.0001 [ohm] D 0.0001 [ohm] D 0.0001 [ohm] y (A) Is_1 Is7 Is_7 250 [ohm] A V Is7 90.0 [uF] Vs_1 Is simple 4.0 3.0 2.0 1.0 0.0 -1.0 -2.0 -3.0 -4.0 250 [ohm] Is_1 D 90.0 [uF] 0.0001 [ohm] D D 220[ohm] D 1 Trig1 Trig1 Trig_IGBT Idc_p2 D D 0.950 Vs_6 0.960 0.970 D 1.0 [uF] 0.940 y (A) 0.0001 [ohm] 360.0 [uF] 0.930 D 15 [ohm] 0.005 [H] 0.980 0.990 Is_6 D D 1.000 2.0 [uF] Is_5 0.920 2 Trig_IGBT 0.910 D Is_6 0.001 [H] ... ... ... 2 Trig_IGBT 250 [ohm] A V 180.0 [uF] 180.0 [uF] 1.0 [uF] 0.0001 [ohm] 0.4 Level B Comparator D D 2.0 [uF] 0.0001 [ohm] A 2.0 [uF] Vs_5 Is6 0.0001[ohm] 10.0 7.5 5.0 Idc_p 2.5 0.0 [H] 0.001 -2.5 -5.0 -7.5 -10.0 D 250 [ohm] Is_5 2.0 [uF] D Idc_p D D D P = 2971 220[ohm] D 360.0 [uF] D D Is5 80 60 40 20 0 -20 -40 -60 D -80 180.0 [uF] y (A) Is_12 y (A) 330 [ohm] 2.0 [uF] 0.0001 [ohm] A V D 250 [ohm] 2.0 [uF] Is_12 Vs_12 D D Is_11 250 [ohm] D Vs_11 180.0 [uF] D P = 64.02 220[ohm] 15 [ohm] 0.005 [H] Is_11 2.0 [uF] D D D 180.0 [uF] D Is12 2.00 1.50 1.00 0.50 0.00 -0.50 D -1.00 -1.50 -2.00 2.0 [uF] 2.0 [uF] Is_4 -1.00 250 [ohm] Vs_4 A V 180.0 [uF] Is_4 2.0 [uF] 0.0001 [ohm] P = 60.8 100 100 70 Simple Orig VF 90 Improved VF Active 80 Table 3 70 60 60 50 50 40 40 30 30 20 20 10 10 90 % Fundamental 80 0 0 10 20 30 Order 40 0 50 800 v t iMeasured(Osram) 600 iMeasured(Philips) Current (mA) 400 Bad Brand PSCAD/EMTDC Simple 200 0 -200 -400 -600 -800 0 0.005 0.01 Time (s) 0.015 0.02 400 i Measured vt 300 Orig VF +RFI Current (mA) 200 100 0 -100 -200 -300 -400 0 0.005 0.01 Time (s) 0.015 0.02 100 PSCAD/EMTDC Simple Osram Philips Bad Brand 90 80 70 50 h I (%) 60 40 30 20 10 0 0 5 10 15 20 Harmonic Oder 25 30 What is possible for a CFL 400 300 CFL for North American Market Current (mA) 200 100 0 -100 -200 -300 -400 0 0.005 0.01 Time (s) 0.015 0.02 What is possible for a CFL 250 Current (mA) 200 150 100 50 0 0 5 10 15 20 Harmonic order 25 30 35 400 Basic, no filtering 600 Active Power-Factor Control 300 400 200 Current (mA) Current (mA) 200 0 -200 -100 -300 -600 0.005 0.01 Time (s) 0.015 0.02 -400 0 Basic, with filtering 600 0.005 600 400 400 200 200 Current (mA) Current (mA) 0 -200 -400 0 100 0 -200 -400 -400 -600 -600 0.005 0.01 Time (s) 0.015 0.02 0.015 0.02 Valley-fill or Equivalent 0 -200 0 0.01 Time (s) 0 0.005 0.01 Time (s) 0.015 0.02 250 90 Basic, no filtering 80 200 70 60 Current (mA) RMS Current (mA) Active Power-Factor Control 50 40 150 100 30 20 50 10 0 0 5 10 15 20 Harmonic Oder 25 0 0 30 90 Basic, with filtering 80 70 70 60 60 RMS Current (mA) RMS Current (mA) 10 15 20 Harmonic order 25 30 35 90 80 50 40 30 40 30 20 10 10 5 10 15 20 Harmonic Oder 25 30 Valley-fill or Equivalent 50 20 0 0 5 0 0 5 10 15 20 Harmonic Oder 25 30 180 Notice: form bands based on circuit type 160 I THD (% fundamental) 140 120 100 80 60 40 20 100 120 140 160 180 Voltage (Volts) 200 220 240 1 0.95 DPF 0.9 0.85 0.8 0.75 0.7 100 120 140 160 180 Voltage (Volts) 200 220 240 Analysis Methods Frequency Domain Advantages - Can handle large systems - Models frequency dependency very well Time Domain Advantages - Can model accurately interactions (i.e. non-linear load <-> ac system non-linear load <-> non-linear load) Disadvantages - Harmonic Currents specified Disadvantages (No interaction between non-linear - Can only model a very small device and AC System, No system in this detail interaction between non-linear - Does not represent frequency devices). dependence of components well Frequency Domain Analysis Direct Harmonic Penetration Study CFL Characteristics CFL Characteristics AC System Test System 1 Islington 220kV 100 MVA X=10% Islington 33kV 2 ….. x6 28,800 (15 4 10 8 6) customers modelled 33kV Feeder Sockburn 33kV 3 Zone Substation 10 MVA X=8% Sockburn 11kV 11kV Feeder ….. x8 4 5 ….. x10 ….. x10 300 kVA X=4% 6 LV Feeder ….. x4 ….. x4 7 ….. x15 8 House Load Service Mains ….. x15 ….. x15 ….. x15 Breakdown of Losses into Branches Branch No. Description 9 House Loads 8 Service Mains 7 LV Feeders 6 300 kVA Transformers 5 11 kV Feeders 4 33/11 kV Transformers 3 33 kV Feeders 2 33/220 kV Transformers 1 220kV System Breakdown of Harmonic Losses into Frequencies 4 x 10 Difference in Active Power (kW) 2 1.5 P(incandescent)-P(CFL) for Underground System This is like comparing apples and oranges Good Average Poor AS/NZS 61000-3-2 1 0.5 0 Loss_h Loss_50 Loss_Total P_Load Quantity P_Diff 20 P (Watts) 15 10 5 100 120 140 160 180 Voltage (Volts) 200 220 240 Power Loss in Underground System 2500 Active Power (kW) 2000 Good 1500 Average Poor AS/NZS 61000-3-2 1000 500 0 Loss_50 Loss_h Loss_Total Power Loss in Overhead System 2500 Active Power (kW) 2000 Good Average Poor AS/NZS 61000-3-2 1500 1000 500 0 Loss_50 Loss_h Loss_Total Voltage Total Harmonic Distortion 50 THDV V i 2 V1 2 i 100 % 21st Harmonic (1050 Hz) Distortion Level Detailed Transient Simulations 500 CFL 0 (domestic supply) CFL 0 (sinewave) SineWave 400 300 Current (mA) 200 100 0 -100 -200 -300 -400 -500 0 Effect of voltage distortion on current waveform 0.005 0.01 Time 0.015 0.02 Harmonics Very peaky current waveform rich in harmonics 80 Philips B1 Philips B2 Eco Bulb1 HPF Eco Bulb2 HPF 500 Philips B1 Philips B2 Eco Bulb1 HPF Eco Bulb2 HPF 400 70 300 60 200 Current (mA) 50 Current (mA) 100 0 -100 40 30 -200 20 -300 10 -400 -500 0 0.002 0.004 0.006 0.008 0.01 0.012 Time (sec.) 0.014 0.016 0.018 0.02 0 0 5 10 15 20 Harmonic order 25 30 35 100 CFL 0 (domestic supply) CFL 0 (sinewave) 61000-3-2 limit 90 80 Current (mA) 70 60 50 40 30 20 10 0 0 5 10 15 Order 20 25 30 Ecobulb Magnitude of Current 5 4 3 2 1 330 0 0 st 21 Harmonic Current 240 0.2 150 0.4 60 0.6 Level of V 0 Angle of V h h Elite Osram 40 Magnitude of Current Magnitude of Current 25 20 15 10 5 30 20 10 330 0 0 330 0 0 240 0.2 240 0.2 150 0.4 150 0.4 60 0.6 Level of V h 0 Level of V Angle of V h 60 0.6 h 0 Angle of V h Ecobulb 90 60 0 0.2 0.4 0.6 3 120 30 90 2 60 120 30 Imaginary Part 1 90 150 120 150 180 180 30 0 0 150 0 180 330 0 -1 60 330 210 300 330 240 270 -2 210 300 240 210 -3 -4 -3 -2 -1 0 Harmonic Current 300 240 -4 st 21 270 270 1 Real Part 2 3 4 5 Osram 180 210 210 240 180 150 Imaginary Part 240 300 300 330 330 120 90 30 0 60 90 0 5 Real Part 60 90 -15 120 120 330 90 300 120 270 -20 150 -30 10 15 -20 300 270 240 180 180 -10 300 270 150 240 180210 150 60 30 -5 330 30 0 210 -30 30 -20 -10 0 0.2 0.4 0.6 330 0 60 -25 90 60 0 -10 120 120 330 0 -15 150 270 0 30 90 210 180 300 -10 60 -5 270 270 0 150 240 -5 30 Imaginary Part 0 Elite 0 0.2 0.4 0.6 210 0 Real Part 240 10 20 4. Detailed Transient Simulations Load Point 1 CFL 0 Load Point 2 CFL 1 CFL 2 Fixed Injection Model CFL 0 Load Point 1 Load Point 2 CFL 1 CFL 2 PSCAD/EMTDC Study SCR System Strength Loading 0.1500 + j0.0750 pu 0.3000 + j0.1500 pu 0.4500 + j0.2250 pu R=0.0075 L=8.0214e-5 Run 1 Load Point 1 = 5398.7378 Run 5 Load Point 1 = 2699.3689 Run 9 Load Point 1 = 1799.579 R=0.075 L=8.0214e-4 Run 2 Load Point 1 = 539.8738 Run 6 Load Point 1 = 269.9369 Run 10 Load Point 1 = 179.9579 R=0.75 L=8.0214e-3 Run 3 Load Point 1 = 53.9874 Run 7 Load Point 1 = 26.9937 Run 11 Load Point 1 = 17.9958 Run 8 Load Point 1 = 2.6994 Run 12 Load Point 1 = 1.7996 R=7.5 L=8.0214e-3 Run 4 Load Point 1 = 5.3987 CFL Current (Run 1) Psn 0 (A) 0.5 0 -0.5 0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.005 0.01 0.015 0.02 0.025 Time (s) 0.03 0.035 0.04 Psn 1 (A) 1 0 -1 0 Psn 2 (A) 1 0 -1 0 CFL Harmonic Currents (Run 1) Magnitude (A) 0.1 0.08 0.06 0.04 Note magnification of injection for CFLs along feeder 0.02 0 0 Phase Angle (Degrees) Psn 0 Psn 1 Psn 2 20 40 60 Harmonic Order 80 100 20 40 60 Harmonic Order 80 100 200 100 0 -100 -200 0 Magn. [Psn 0] (A) Magn. [Psn 1] (A) Magn. [Psn 2] (A) CFL Harmonic Currents (Run 1) Detailed Model Fixed Injection 0.05 0 0 20 40 60 Harmonic Order 80 100 20 40 60 Harmonic Order 80 100 20 40 60 Harmonic Order 80 100 0.05 0 0 0.05 0 0 Magn. [Psn 0] (V) Magn. [Psn 1] (V) Magn. [Psn 2] (V) Harmonic Voltages (Run 1) Detailed Model Fixed Injection 0.05 0 0 20 40 60 Harmonic Order 80 100 20 40 60 Harmonic Order 80 100 80 100 0.05 0 0 0.1 Magnification of Voltage along feeder 0.05 0 0 20 40 60 Harmonic Order CFL Current (Run 2) Psn 0 (A) 0.5 0 -0.5 0 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.005 0.01 0.015 0.02 0.025 0.03 0.035 0.04 0.02 0.025 Time (s) 0.03 0.035 0.04 Psn 1 (A) 1 0 -1 0 Psn 2 (A) 1 Weaker system so oscillations at lower frequency 0 -1 0 0.005 0.01 0.015 CFL Harmonic Currents (Run 2) Magnitude (A) 0.1 0.08 0.06 0.04 0.02 0 0 Phase Angle (Degrees) Psn 0 Psn 1 Psn 2 20 40 60 Harmonic Order 80 100 20 40 60 Harmonic Order 80 100 200 100 0 -100 -200 0 Measurements made on a Domestic Supply 500 CFL 0 (domestic supply) CFL 0 (sinewave) SineWave CFL 1 (domestic supply) 400 300 200 Oscillations Current (mA) 100 0 -100 -200 -300 -400 -500 0 0.005 0.01 Time 0.015 0.02 CFL Current (A) CFL Current (A) CFL Current (A) CFL Harmonic Currents (Run 3) 0.5 Detailed Model Fixed Injection 0 -0.5 0.02 0.025 0.03 0.035 0.04 0.025 0.03 0.035 0.04 0.025 0.03 Time (S) 0.035 0.04 0.5 0 -0.5 0.02 0.5 0 -0.5 -1 0.02 CFL Current (A) CFL Current (A) CFL Current (A) CFL Harmonic Currents (Run 4) 0.5 Detailed Model Fixed Injection 0 -0.5 0.02 0.025 0.03 0.035 0.04 0.025 0.03 0.035 0.04 0.025 0.03 Time (S) 0.035 0.04 0.5 0 -0.5 0.02 0.5 0 -0.5 0.02 0.5 Detailed Model Fixed Injection 0 -0.5 0.02 CFL Current (A) CFL Current (A) CFL Current (A) CFL Harmonic Currents (Run 5) 0.025 0.03 0.035 0.04 0.025 0.03 0.035 0.04 0.025 0.03 Time (S) 0.035 0.04 1 0 -1 0.02 1 0 -1 0.02 For each harmonic there is a systemCFL Current (h=5) strength and loading where a maxima occurs 0.06 Magnitude (A) 0.05 0.04 0.03 0.02 0.01 0 4 3 3 2.5 Decreasing 2 2 1.5 System Strength 1 1 Increasing System Loading CFL Current (h=5) Phase Angle (A) 200 100 0 -100 -200 4 3 3 2.5 Decreasing 2 2 1.5 System Strength 1 1 Increasing System Loading For each harmonic there is a systemCFL Current (h=7) strength and loading where a maxima occurs 0.04 Magnitude (A) 0.03 0.02 0.01 0 4 3 3 2.5 Decreasing 2 2 1.5 System Strength 1 1 Increasing System Loading THD (Voltage) Psn 2 3 Magnitude (%) 2.5 2 1.5 1 0.5 0 4 3 3 2.5 Decreasing 2 2 1.5 System Strength 1 1 Increasing System Loading Other Studies 5. Other studies Study 1: D.J. Pileggi, T.J. Gentile, A.E. Emanual,… et al, “The Effect of Modern Compact Fluorescent Lights On Voltage Distortion”, IEEE Trans. Of Power Delivery, Vol. 8, No. 4, Oct. 1993, pp 2038-1042 Study 2: F.V. Topalis, “Efficiency Of Energy Saving Lamps And Harmonic Distortion In Distribution Systems”, IEEE Trans. of Power Delivery, Vol. 8, No. 4, Oct. 1993, pp 2038-1042 Study 3: T.-M. Zhou, X.-Y. Zhu, Y.-L. He, W. Cheng and J. Schlejen, “Preliminary Investigation to the Effect of Harmonic Distortion by CFL on Quality of Electric Power Systems”, (Published?) Study 4: N. Gothelf, Power Quality Effects of CFLs– A Field Study, RIGHT LIGHT 4, 1997 VOLUME 2, pp. 77-81 Study 1 “Electronically ballasted fluorescent lights with highly distorted current may jeopardize the reliability of the distribution system and the “quality” of the electric power delivered.” D.J. Pileggi, T.J. Gentile, A.E. Emanual,… et al, “The Effect of Modern Compact Fluorescent Lights On Voltage Distortion”, IEEE Trans. Of Power Delivery, Vol. 8, No. 4, Oct. 1993, pp 2038-1042 Study 2 “These conclusions permit the formulation of the opinion that the extensive future use of the energy efficient lamps must be associated with simple and low cost filtering and power factor correction techniques” F.V. Topalis, “Efficiency Of Energy Saving Lamps And Harmonic Distortion In Distribution Systems”, IEEE Trans. of Power Delivery, Vol. 8, No. 4, Oct. 1993, pp 2038-1042 Study 3 T.-M. Zhou, X.-Y. Zhu, Y.-L. He, W. Cheng and J. Schlejen, “Preliminary Investigation to the Effect of Harmonic Distortion by CFL on Quality of Electric Power Systems” Four Cases: Single Lamp Home Lab retrofit Field Experiment Study 3 “Our experiments show that for CFL THD according to the new IEC 1000 proposal, in extremely high home applications (5 CFLs per home), the contribution to the V-THD is negligible, compared to TV and much less than computer.” Home Experiment THDI PC 120% (NZ 66.6%) ? ? CFL 101-103% (NZ 120%) TV 90% (NZ 120%) Lab. Retrofit Test V-THD variation 1.5-2%. Experiment repeated 8 times Study 4 The test was divided in two phases: Phase 1: Measurements in a one-family house. The measurements were taken first without CFLs and then after installing five CFLs. Phase 2: Measurements in a residential district. The measurements were taken in a residential district consisting of 17 houses at existing load and then after installing of three and six CFLs respectively in each house. Study 4 “The study shows that replacement of incandescent lamps with CFLs is beneficial both for users and for utilities. The main advantages of CFLs are: - reduced energy consumption - long lifetime - released capacity of the distribution system High harmonic distortion is the main reason that utilities hesitate to advocate increased use of CFLs. They focus mainly on the high relative current distortion. It is true that for CFLs, the relative current distortion expressed in percent of the fundamental may exceed 100%. However, since fundamental current is very low …, the values of harmonic currents are very low too. Study 4 “The results indicate, that the harmonic generated by the CFLs in residential districts have only a minor effect on power quality of the supply network.” N. Gothelf, Power Quality Effects of CFLs– A Field Study, RIGHT LIGHT 4, 1997 VOLUME 2, pp. 77-81 This current waveform is significantly better than most we see in sold in New Zealand Some of the Brands Tested Basix Marexim Canopower Mirabella Connection Nelson Lamps Dura Lamp No Frills Eclipse Osram Ecobulb Panasonic Elite Philips Everyhome Results GE Signature Range Kempthorne SmartLamp LuxTec Toshiba Wotan Other Appliances Current drawn by Electronic Equipment 1.5 PC Scanner TV VCR DVD Stereo CFL 1 CFL 2 1 Current (Amps) 0.5 0 -0.5 -1 -1.5 0 0.005 0.01 Time (seconds) 0.015 0.02 Current Harmonics from Electronic Equipment 100 90 Current (% Fundamental) 80 70 60 PC Scanner TV VCR DVD Stereo CFL 1 CFL 2 50 40 30 20 10 0 0 1 2 3 4 5 6 7 8 9 1011121314151617181920212223242526272829303132 Harmonic Order Current drawn by Household Appliances 15 Microwave Oven Washing Machine Pumping Washing Machine3 10 Current (Amps) 5 0 -5 -10 -15 0 0.005 0.01 Time (seconds) 0.015 0.02 Washing Machine 8 Standard washing 6 1.9 Amps THDI = 132% Current (Amps) 4 Spinning and Pumping 7.9 Amps THDI = 34% 2 0 -2 -4 -6 -8 0 0.005 0.01 Time (seconds) 0.015 0.02 Appliances Tested TV Microwave ovens VCR Mills DVD Halogen lights Stereo Fluorescent Lamps Clock/radio Fridge/freezers Home entertainment systems Freezers PCs Dryers Monitors Plug packs Printers Scanners Washing machines Heat-pump tests 2008 6. Conclusions The wide-spread use of CFLs can be expected to reduce power quality. The weaker networks exhibit less correlation in the harmonic current injection than stronger networks. Resonances between CFL and ac network magnifies some frequency components (even for a relatively strong ac network) Acknowledgements Tas Scott & Stephen Hirsch, Orion N.Z. Ltd Vinod Kumar, Whisper Tech Limited Joseph Lawrence, EPE Centre Manager Lance Frater Ken Smart Geoff Neville, Enermet N.Z. Ltd. The End Any Questions? Valley Fill Circuit (Cct. 2) AC Input RFI Filter DC Output Improved Valley Fill Circuit Improves current waveform near cross-over point AC Input Remove charging current spike at the voltage cross-over point. RL DC Output Remove charging current spike at the voltage peak. Active Power-Factor Control AC Input Power-Factor Control Drive DC Output