MANU 293 - WordPress.com

advertisement

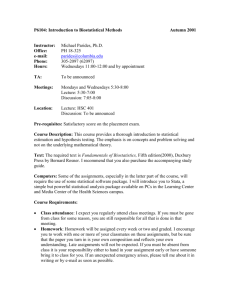

Program: Course: CAD/CAM Engineering Technology Course Description: Your studies will focus on quality assurance in a manufacturing environment. The importance of quality products and services will be emphasized. You will become familiar with the statistical sampling and analysis tools used to achieve and verify quality goals. MANU 290, CALC 190 64 4 10 Written Assignments (20%), Midterm Exam (35%), Final Exam (45%) 60% Quality Planning and Analysis, Gryna; (4thEd.) McGraw-Hill Higher Education. Instructor-prepared handouts. Library. 1. Discuss basic quality concepts. 2. Explain the need for a quality assessment. 3. Relate quality improvement to costs. 4. Explain how quality improves sales income. 5. Discuss quality control. 6. Examine process management. 7. Examine quality management. 8. Solve quality problems using statistical calculations. 9. Appraise the effects of quality on customers. 10. Design for quality. 11. Analyze supply chain management principles. 12. Explain the role of quality in manufacturing. 13. Analyze quality using statistical process control. 14. Evaluate acceptance based on inspection results. 15. Discuss quality standards. Brian Murdoch June, 2005 Brian Murdoch June, 2005 Arnold Boldt June, 2005 Pre Requisites: Co Requisites: Course Hours: Credit Units: Student Assessment: Grade/Passing Grade: PLAR Method: Learning Resources: Learning Outcomes: Prepared by: Date: Approved by Program Head: Date: Approved by Dean of Technology: Date: Page 1 of 8 MANU 293 - Quality Assurance/Manufacturing Management MANU 293 MECHANICAL ENGINEERING TECHNOLOGY Learning Outcomes/ Assessment Tools 1. Discuss basic quality concepts. Assessment Tools: Written Assignments, Exams 2. Explain the need for a quality assessment. Assessment Tools: Written Assignments, Exams 3. Relate quality improvement to costs. Learning Steps 1.1 1.2 1.3 1.1.1 Lecture and reading. 1.2.1 Lecture and reading. 1.3.1 Lecture and reading. 1.4 Define quality. Describe the quality function. Describe the relationship between productivity, cycle time, quality and value. Describe the triology of quality processes. 2.1 2.2 2.3 Explain the four elements of quality assessment. Discuss the different categories of quality costs. Explain the objectives of a quality evaluation. 2.1 1 Lecture and reading. 2.2.1 Lecture and reading. 2.3.1 Lecture and reading. 3.1 3.2 3.3 3.4 3.5 3.1.1 Lecture and reading. 3.2.1 Lecture and reading. 3.3.1 Lecture and reading. 3.4.1 Lecture and reading. 3.5.1 Lecture and reading. 3.7 Compare static to chronic quality problems. Discuss the steps to set up and carry out a quality improvement project. Discuss ways to come up with projects. Discuss problem solving techniques. Explain how analysis tools such as control charts, check lists, histograms, Pareto diagrams, scatter plots and flow charts are used to help solve quality problems. Compare worker controllable errors to system/management controllable errors. Discuss how to select an initial project. 4.1 4.2 4.3 4.4 Discuss how quality affects sales. Discuss how quality and market share effect profitability. Discuss levels of quality benchmarking. Explain benchmarking steps. 4.1.1 4.2.1 4.3.1 4.4.1 Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. 5.1 5.2 5.3 5.4 5.5 Explain the control process. Explain how measurement is part of planning, improvement and control. Define self-control. Select control subjects for s a given process. Select control locations for a given process. 5.1.1 5.2.1 5.3.1 5.4.1 5.5.1 Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. 3.6 Assessment Tools: Written Assignments, Exams 4. Explain how quality improves sales income. Assessment Tools: Written Assignments, Exams 5. Discuss quality control. Page 2 of 8 Learning Activities/Resources 1.4.1 Lecture and reading. 3.6.1 Lecture and reading. 3.7.1 Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools Assessment Tools: Written Assignments, Exams 6. Examine process management. Assessment Tools: Written Assignments, Exams 7. Examine quality management. Learning Steps 6.1 6.2 6.3 6.4 6.5 6.6 6.7 Choose units of measure. Set goals. Create measurement sensor. Compare measurements to goals. Interpret difference between measurement and goals. Determine if action needs to be taken. Determine whether an operator is In a state of self-control. 6.1.1 6.2.1 6.3.1 6.4.1 6.5.1 6.6.1 6.7.1 7.1 7.2 Discuss strategic quality management. Compare the roles of quality circles, quality improvement teams and quality councils. Explain how quality culture effects quality. Explain how to develop a good quality culture. 7.1.1 Lecture and reading. 7.2.1 Lecture and reading. 7.3 7.4 Assessment Tools: Written Assignments, Exams Page 3 of 8 Learning Activities/Resources Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. 7.3.1 Lecture and reading. 7.4.1 Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools 8. Solve quality problems using statistical calculations. Learning Steps 8.1 8.2 Compare variable data to attribute data. Prepare a histogram. 8.3 8.4 8.5 Compare tow measures of central tendency. Compare three measures of dispersion. Estimate the portion of a population that will be within the specification limits using the normal distribution. 8.6 Calculate the probability that a unit will fail before a given time using the exponential distribution. 8.7 Calculate the probability of finding a given number or more defectives in a sample using the binomial equation. 8.8 Calculate the probability of finding a given number or more defectives in a sample using the Poison equation. 8.9 Calculate the probability of finding a given number or more defectives in a sample using the Poison tables. 8.10 Calculate confidence limits. 8.11 Compare a new process to an existing process using the hypothesis method. 8.12 Make OC curves for hypothesis analysis. 8.13 Use OC curves for hypothesis analysis. 8.14 Use the t-distribution to make quality projections. 8.15 Use the Weibull Probability Distribution to make projections. Assessment Tools: Written Assignments, Exams 9. Appraise the effects of quality on customers. Page 4 of 8 9.1 9.2 9.3 9.4 Compare three different classes of customers. Compare different levels of customer satisfaction. Compare methods of determining customer dissatisfaction. Rank quality problems using Pareto analysis. 9.5 Compare features to freedom from deficiencies. Learning Activities/Resources 8.1.1 Lecture and reading. 8.2.1 Lecture, reading, exercise and assignment. 8.3.1 Lecture and reading. 8.4.1 Lecture and reading. 8.5.1 Lecture, reading, exercise and assignment. 8.6.1 Lecture, reading, exercise and assignment. 8.7.1 Lecture, reading, exercise and assignment. 8.8.1 Lecture, reading, exercise and assignment. 8.9.1 Lecture, reading, exercise and assignment. 8.10.1 Lecture, reading, exercise and assignment. 8.11.1 Lecture, reading, exercise and assignment. 8.12.1 Lecture, reading, exercise and assignment. 8.13.1 Lecture, reading, exercise and assignment. 8.14.1 Lecture, reading, exercise and assignment. 8.15.1 Lecture, reading, exercise and assignment. 9.1.1 9.2.1 9.3.1 9.4.1 Lecture and reading. Lecture and reading. Lecture and reading. Lecture, reading, in-class exercise and assignment. 9.5.1 Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools Assessment Tools: Written Assignments, Exams 10. Design for quality. Learning Steps 10.1 10,2 Differentiate between accuracy, precision and bias. Assess accuracy and precision of statistical data. 10.3 Use statistical methods to analyse sources of product quality variation. 10.4 10.5 Apply Failure Mode Effect Analysis techniques. Calculate capability ratios and capability indexes. 10.6 10.7 Compare the relevance of capability indexes and ratios in selecting and adjusting a process. Calculate required reliability of components. 10.8 Calculate failure rate of a system. 10.9 Calculate reliability of a system using the normal distribution. 10.10 Calculate reliability of a system using the exponential distribution. 10.11 Calculate reliability of a system using the Wielbul distribution. 10.12 Calculate availability of a system. 10.13 Discuss approaches to improving maintainability. 10.14 Discuss the effect of tolerance on manufacturing cost. 10.15 Calculate total tolerance of an assembly. Assessment Tools: Written Assignments, Exams 11. Analyze supply chain management principles. Page 5 of 8 11.1 11.2 11.3 11.4 11.5 11.6 Discuss modern trends in supplier relations. Discuss supplier assessment. Explain the buyer’s responsibilities. Compare different levels of supplier certification. Analyze suppliers using Pareto analysis. Select units to measure supplier quality. Learning Activities/Resources 10.1.1 Lecture and reading. 10.2.1 Lecture, reading, in-class exercise and assignment. 10.3.1 Lecture, reading, in-class exercise and assignment. 10.4.1 Lecture and reading. 10.5.1 Lecture, reading, in-class exercise and assignment. 10.6.1 Lecture, reading, in-class exercise and assignment. 10.7.1 Lecture, reading, in-class exercise and assignment. 10.8.1 Lecture, reading, in-class exercise and assignment. 10.9.1 Lecture, reading, in-class exercise and assignment. 10.10.1 Lecture, reading, in-class exercise and assignment. 10.11.1 Lecture, reading, in-class exercise and assignment. 10.12.1 Lecture, reading, in-class exercise and assignment. 10.13.1 Lecture and reading. 10.14.1 Lecture and reading. 10.15.1 Lecture, reading, in-class exercise and assignment. 11.1.1 11.2.1 11.3.1 11.4.1 11.5.1 11.6.1 Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools Assessment Tools: Written Assignments, Exams 12. Explain the role of quality in manufacturing. Assessment Tools: Written Assignments, Exams 13. Analyze quality using statistical process control. Learning Steps 12.1 12.2 12.3 12.4 12.5 Explain why quality is important to manufacturing. Explain how error-proofing can be used to improve quality. Explain the 5S approach. Explain how self-control is important to manufacturing. Explain the different methods of dealing with worker controllable problems to those used to deal with management controllable problems. 12.6 Explain how control system dominance affects the quality plan. 12.7 Explain the advantages of self inspection. 12.8 Explain the criteria needed for self inspection. 12.1.1 12.2.1 12.3.1 12.4.1 12.5.1 13.1 Determine when to use C, P, X-bar and R statistical control charts. 13.2 Prepare X-bar and R charts 13.3 Plot data on X-bar and R charts. 13.4 Analyze quality based on X-bar and R charts. 13.5 Prepare P charts. 13.6 Analyze quality based on P charts. 13.7 Prepare C charts. 13.8 Plot data on C charts. 13.9 Analyze quality based on C charts. 13.1.1 Lecture, reading, exercise and assignment. 13.2.1 Lecture, reading, exercise and assignment. 13.3.1 Lecture, reading, exercise and assignment. 13.4.1 Lecture, reading, exercise and assignment. 13.5.1 Lecture, reading, exercise and assignment. 13.6.1 Lecture, reading, exercise and assignment. 13.7.1 Lecture, reading, exercise and assignment. 13.8.1 Lecture, reading, exercise and assignment. 13.9.1 Lecture, reading, exercise and assignment. 13.10.1 Lecture and reading. 13.10 Explain advantages of SPC. Assessment Tools: Written Assignments, Exams Page 6 of 8 Learning Activities/Resources Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. Lecture and reading. 12.6.1 Lecture and reading. 12.7.1 Lecture and reading. 12.8.1 Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools 14. Evaluate acceptance based on inspection results. Learning Steps 14.1 14.6 Discuss disposition decisions (conformance, fitness for use and communication). Discuss the disposition of non conforming product. Make an inspection plan. Calculate the variability (std. dev.) of a product that has variability from several causes. Calculate the variability of a product accounting for instrument variability. Calculate the break even point of quantity to inspect. 14.7 Evaluate quality using the ANSI/ASQZ1.4 sampling plan. 14.8 Make and use OC curves for sampling plans. 14.2 14.3 14.4 14.5 Assessment Tools: Written Assignments, Exams 15. Discuss quality standards. Assessment Tools: Written Assignments, Exams Page 7 of 8 15.1 Explain the difference between quality product standards and quality system standards. 15.2 Discuss the advantages of setting up a formal Quality program and the added advantages of having it comply with and be registered to a specific quality standard. 15.3 Name three quality system standards used in Canada. 15.4 Name at least three accredited registrars for the ISO9000 series of standards in Canada. 15.5 Discuss the registration process to become registered under ISO9000 series of standards. 15.6 Discuss ISO 9001 to ISO 9002 and ISO 9003 and how the 2000 version of ISO 9001 deals with scope. 15.7 Discuss what information should be put in a quality manual for any give element. 15.8 Discuss how the emphasis has changed with the new standard. 15.9 Explain considerations in making a form to record information for a quality program. 15.10 Discuss the things auditors look for. Learning Activities/Resources 14.1.1 Lecture and reading. 14.2.1 Lecture and reading. 14.3.1 Lecture and reading. 14.4.1 Lecture, reading, in-class exercise and assignment. 14.5.1 Lecture, reading, in-class exercise and assignment. 14.6.1 Lecture, reading, in-class exercise and assignment. 14.7.1 Lecture, reading, in-class exercise and assignment. 14.8.1 Lecture, reading, in-class exercise and assignment. 15.1.1 Lecture and reading. 15.2.1 Lecture and reading. 15.3.1 Lecture and reading. 15.4.1 Lecture and reading. 15.5.1 Lecture and reading. 15.6.1 Lecture and reading. 15.7.1 Lecture and reading. 15.8.1 Lecture and reading. 15.9.1 Lecture and reading. 15.10.1 Lecture and reading. MANU 293 CAD/CAM Engineering Technology Learning Outcomes/ Assessment Tools Learning Steps Learning Activities/Resources Copyright Saskatchewan Institute of Applied Science and Technology No part of the work(s) contained herein may be reproduced or copied in any form or by any means - graphic, electronic, or mechanical including photocopying, recording, taping of information and retrieval systems - without written consent of the Saskatchewan Institute of Applied Science and Technology. Page 8 of 8