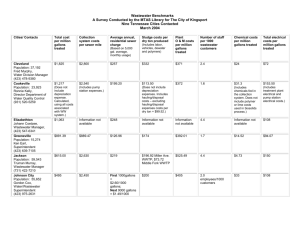

Practices And Policies

advertisement