Venturi Wind Tunnel – Lab Report

advertisement

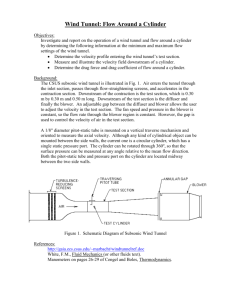

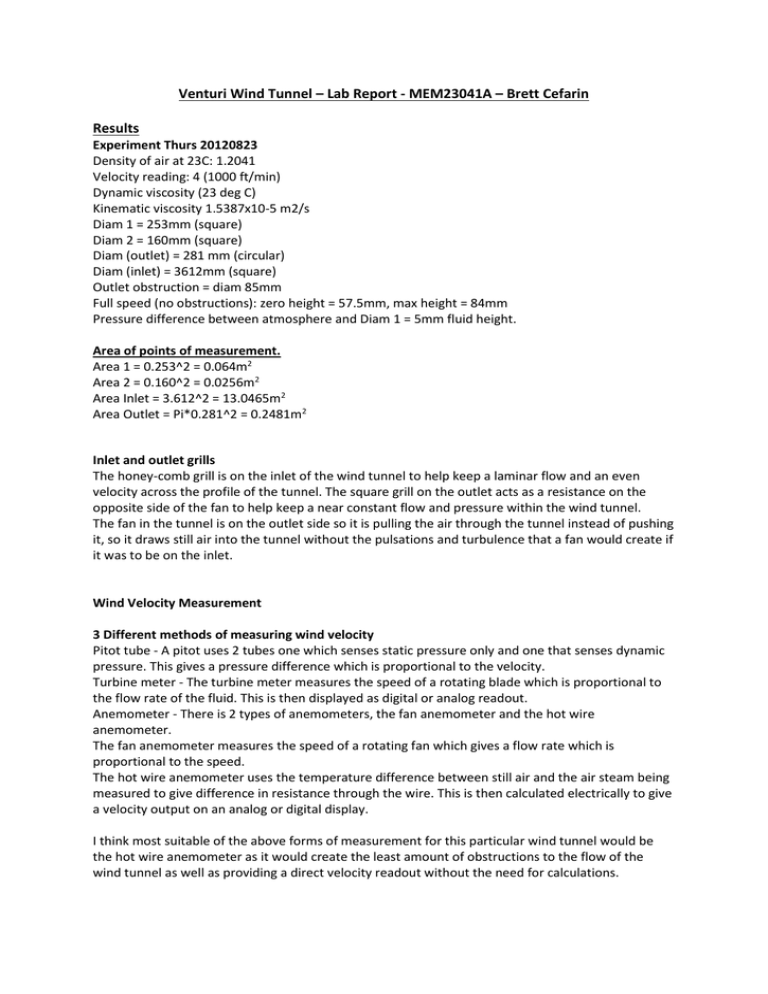

Venturi Wind Tunnel – Lab Report - MEM23041A – Brett Cefarin Results Experiment Thurs 20120823 Density of air at 23C: 1.2041 Velocity reading: 4 (1000 ft/min) Dynamic viscosity (23 deg C) Kinematic viscosity 1.5387x10-5 m2/s Diam 1 = 253mm (square) Diam 2 = 160mm (square) Diam (outlet) = 281 mm (circular) Diam (inlet) = 3612mm (square) Outlet obstruction = diam 85mm Full speed (no obstructions): zero height = 57.5mm, max height = 84mm Pressure difference between atmosphere and Diam 1 = 5mm fluid height. Area of points of measurement. Area 1 = 0.253^2 = 0.064m2 Area 2 = 0.160^2 = 0.0256m2 Area Inlet = 3.612^2 = 13.0465m2 Area Outlet = Pi*0.281^2 = 0.2481m2 Inlet and outlet grills The honey-comb grill is on the inlet of the wind tunnel to help keep a laminar flow and an even velocity across the profile of the tunnel. The square grill on the outlet acts as a resistance on the opposite side of the fan to help keep a near constant flow and pressure within the wind tunnel. The fan in the tunnel is on the outlet side so it is pulling the air through the tunnel instead of pushing it, so it draws still air into the tunnel without the pulsations and turbulence that a fan would create if it was to be on the inlet. Wind Velocity Measurement 3 Different methods of measuring wind velocity Pitot tube - A pitot uses 2 tubes one which senses static pressure only and one that senses dynamic pressure. This gives a pressure difference which is proportional to the velocity. Turbine meter - The turbine meter measures the speed of a rotating blade which is proportional to the flow rate of the fluid. This is then displayed as digital or analog readout. Anemometer - There is 2 types of anemometers, the fan anemometer and the hot wire anemometer. The fan anemometer measures the speed of a rotating fan which gives a flow rate which is proportional to the speed. The hot wire anemometer uses the temperature difference between still air and the air steam being measured to give difference in resistance through the wire. This is then calculated electrically to give a velocity output on an analog or digital display. I think most suitable of the above forms of measurement for this particular wind tunnel would be the hot wire anemometer as it would create the least amount of obstructions to the flow of the wind tunnel as well as providing a direct velocity readout without the need for calculations. Calculate Reynolds Number Re = ρ u dh / μ = u dh / ν Re = Reynolds Number (non-dimensional) ρ = density (kg/m3) = 1.2041kg/m3 u = velocity based on the actual cross section (m/s) = 4000ft/min = 20.32m/s μ = dynamic viscosity (Ns/m2) = 0.000018527486Pas ν = kinematic viscosity (m2/s) = 0.000015387m2/s dh= hydraulic diameter (m) = 4A/P = 4x0.0256/(0.160*4) = 0.16m Re = 20.32*0.16/0.000015387 = 211295.25 Reynolds number is much greater than 4000 so the flow is turbulent. The pressure difference at full speed. P= gh = 0.826*1000 = 826kg/m3 g = 9.81m/s h = 0.084-0.0575 = 0.0265m P = 826*9.81*0.0265 = 214.731Pa The pressure difference across the manometer (points 1&2) is 214.731Pa P= gh = 0.826*1000 = 826kg/m3 g = 9.81m/s h = 0.005m P = 826*9.81*0.005 = 59.386Pa The pressure difference between atmosphere and point 1 is 40.515Pa Total pressure difference (atmosphere to point 2) is 255.246Pa Velocities and flow rates. P0 = 0 (atmosphere) P1 = -40.515Pa P2 = -255.246Pa v0 = 0 v1 = ? v2 = 20.32m/s Find velocity v1: v12/2g + P1/pg = 0 v1 = 0-(P1*2/p)^0.5 v1 = 0-(-40.515*2/1.2041)^0.5 v1 = 8.203m/s Find flow rates: V1 = v1A1 = 8.203m/s*0.064m2 = 0.525m3/s V2 = v2A2 = 20.32m/s*0.0256m2 = 0.520m3/s V1 should be equal to V2, however there is slight difference, this could be due to error in measurement of cross sectional area of wind tunnel. Find mass flow rate: m = Vp = 0.520m3/s *1.2041kg/m3 = 0.626kg/s Fluid power at full speed H (Total head) = P2/pg + v22/2g = (-255.246/(1.2041*9.81)) + (20.322/(2*9.81)) = -0.563m Find fluid power: P = mgH = 0.626*9.81*0.563 = 3.457W Brett Cefarin Student No. 328916410 Course: 9154