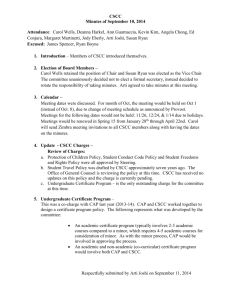

II. Discussion - Columbus State Community College

advertisement

Mechanical Engineering Technology Program Outcomes Validation July 15, 2010 _______________________________ Dick Bickerstaff, Department Chairperson _______________________________ Shane Bendele _______________________________ Jeffery Woodson _______________________________ Adele Wright Executive Summary In order to determine if the current Mechanical Engineering Technology program outcomes are valid and adequate to meet the needs of the industries we serve, we employed three methods. 1. Advisory Committee Input: Meeting Held June 9, 2010 2. External: Survey of Like-Colleges’ Outcomes and Programs of Study 3. Internal: Departmental Review We found that our current outcomes are valid and require no changes. We will, however, use information gathered to guide us in our S2S process. Current Outcomes 1. Apply basic knowledge of manufacturing and engineering technology, procedures, symbols, and graphics skills to the reading and production of sketches, drawings, blueprints and specifications, assist in establishing tolerances related to production, by utilizing manual and/or computerized methods. 2. Make significant contributions to the production of manufactured goods by utilizing skills and knowledge of: drafting, computers and automation technology, sound manufacturing practices, quality measures, machine capabilities/limitations, and assist in the selection of product equipment. 3. Contribute to the solution of engineering and design problems involving mechanical systems, by utilizing knowledge and skills in electrical and mechanical principles, material performance and selection, basic machine elements, sound design and engineering practices. Apply computers and computer language to the solution of engineering problems. 4. Utilize various quality tools and techniques such as SPC and TQM to support production in manufacturing areas and other applicable work situations to improve any and all quality measures. Program Profile Degree Offered: Associate of Applied Science in Mechanical Engineering Technology Certificates Offered: Engineering Assembly Technician Engineering Technician Manufacturing Maintenance Technician Computer Aided Drafting Technician Description: From the US Bureau of Labor Statistics, Mechanical Engineering Technicians: “Apply theory and principles of mechanical engineering to modify, develop, and test machinery and equipment under direction of engineering staff or physical scientists.” (www.bls.gov/oes, June 28, 2010) From Knowledge, Resources and Planning: Program Related Student Profile WI 2009 Sex F M AI AS 1 1 BL 1 23 HS 1 2 NR BL 2 16 HS 1 1 NR 2 AS 1 3 AI AS HS NR UK 1 2 BL 2 15 1 1 3 AI AS HS NR UK 1 5 BL 3 16 5 1 3 1 UK 7 WH 5 91 SP 2009 Sex F M AI UK 7 WH 5 86 SU 2009 Sex F M WH 2 54 AU 2009 Sex F M WH 6 102 Retention Total majors AU 2008: 113 Number Retained Following Autumn: 58 Percent Retained: 51.33% FTE WI 2009 44.93 SP 2009 56.47 SU 2009 28.67 AU 2009 51.73 Distance FTE WI 2009 Not received SP 2009 22.33 SU 2009 2.67 AU 2009 16.20 Degrees Awarded AU 2008 to SP 2009 AU 2008: 2 WI 2009: 3 SP 2009: 5 Advisory Committee Input The joint EMECH/MECH advisory Committee met on June 9, 2010. Minutes from the meeting, including a list of attendees, can be found in Appendix A. Prior to the meeting, all members were sent a ‘survey’ which included a list of the outcomes for them to consider and asked if they agreed or disagreed with the outcome and if they had any recommendations to modify the outcome. During the meeting each outcome was discussed and feedback was collected. One member who could not attend the meeting emailed his survey responses. Results: Outcome 1: All participants agreed with this outcome. One suggestion was made to include relevant standards that the students would encounter when utilizing those skills. One member commented that reading and interpreting drawings and specifications are a must in his industry. Outcome 2: All participants agreed with this outcome, except one who said it didn’t apply to his company’s needs. A suggestion was made to include time studies and lean manufacturing. In addition, a comment was made regarding the importance of the distinction between design and engineering – for example developing the requirements for a motor vs. selecting a motor that meets those requirements. Outcome 3: All participants agreed with this outcome. Significant discussion took place regarding the need for students to get hands on, practical experience with these skills, not just computer skills. This would not necessitate changing the outcome, but would instead impact instructional approaches. Outcome 4: All participants agreed with this outcome, except one who said it didn’t apply to his company’s needs. One member wanted us to stress the combination of SPC and TQM as is done in quality systems such as Six Sigma, and wondered if more advanced topics in this area could be included as an elective. One member commented that these skills are used regularly in his industry. Survey of Like Colleges Outcome Comparison Method: An investigation of the outcomes for programs already on the semester system in OH was undertaken. According to the Ohio Board of Regents semester conversion website (regents.ohio.gov/calendar-conversion, June 6, 2010), the following schools are currently on semesters. Also listed are the closest relevant degrees, if applicable: 1. Bowling Green State University – B.S. Engineering Technology, Mechanical Design Specialization 2. Central State University – B.S. Manufacturing Engineering 3. Cleveland State University – B.S. Mechanical Engineering Technology (2nd part of a 2+2 program only) 4. *Cuyahoga County Community College – A.A.S. Manufacturing Industrial Engineering Technology 5. *Eastern Gateway Community College – A.A.S. Mechanical Engineering Technology 6. *Edison Community College – A.A.S. Mechanical Engineering Technology 7. Kent State University – B.S. Industrial Technology, Manufacturing Systems Concentration 8. *Lakeland Community College – A.A.S. Mechanical Engineering Technology 9. *Lorain County Community College – A.A.S. Manufacturing Engineering Technology 10. *Miami University – A.A.S. Mechanical Engineering Technology 11. *Northwest State Community College – A.A.S. Mechanical Engineering Technology 12. Owens State Community College 13. *Rio Grande Community College – A.A.S. Manufacturing Technology 14. Shawnee State University 15. *Stark State College of Technology – A.A.S. Mechanical Engineering Technology 16. *Terra Community College – A.A.S. Mechanical Engineering Technology 17. *University of Akron – A.A.S. Mechanical Engineering Technology 18. University of Toledo - B.S. Mechanical Engineering Technology 19. *Youngstown State University – A.A.S. Mechanical Engineering Technology The programs with a similar A.A.S. degree to ours are indicated by an asterisk *. A search of the web sites of the schools listed yielded program outcomes for 9 of these programs. The outcomes from each of these programs were compared to the 4 Mechanical Engineering Technology outcomes and matches were indicated (criteria, 80% match). Some of the other school’s outcomes were written in such a specific manner that they were matched with an individual CSCC course instead of a CSCC outcome. If the outcome was a match for one of our Gen Eds, the specific Gen Ed was listed by number (as per the CSCC catalog, page 64). The comparison grids can be found in Appendix B. Results: In general, our outcomes match well with those in similarly titled programs. The following gaps were noted: Time management & teamwork (Cuyahoga County CC) – while both are incorporated into our program, they are not formally referenced in an outcome Occupational safety (Cuyahoga County CC, Rio Grande CC) – not included in our outcomes; in the program of study as a technical elective. Basic electric principles (Eastern Gateway CC) – a course on this used to be in the program of study, but is no longer Ethics (Edison CC) Performing, analyzing and reporting laboratory experiments (Lakeland CC, Youngstown State U) Currency and advocacy for field through membership in professional organizations (Rio Grande CC, Stark State College of Technology, Youngstown State U) POS Comparison Method: Using the same list of programs as for the outcome comparison, the Plans of Studies were compared to our proposed semester plan of study, which of course hasn’t been finalized (we are about 80% there). Courses were organized by type. Appendix C contains the course listings (with credit hours) for each program. Results: College Success: 3/11 schools offer some type of 1 credit course. It looks like we will be required to do so, so it doesn’t really matter what others do. Intro to Engineering Technology: 9/11 schools have something like this, in a 1 or 2 credit course format. We plan on doing 2 credits in 8 weeks. Computer Skills: 4/11 schools require an introductory software course. We have in the past, and plan to keep it, but only 2 credits over 8 weeks. As the computer skills of incoming students increase, this may become obsolete, but the content on how computers work (such as DOS) is new to most students. Drafting/CAD: All programs require this, with most still requiring blueprint reading and drafting before CAD. We will continue to do so as well, but this (hand drafting) is something that may be eliminated in the future. Math: We are planning on requiring one semester of Tech Math, at 5 credits. This seems to be less than what others are doing; generally 2 semesters of math are required, with total credits varying from 4 to 10. Also, some schools require algebra/trigonometry, while others require Calculus. Clearly this is an area without consensus. In addition, we have a course on Engineering Statistics, which isn’t housed in the math department. Three other programs include a course on quality which is similar to our statistics course. Materials Science, Manufacturing Processes, and Machine Tools: We have merged Materials Science and Manufacturing Processes into one. 9/11 programs include a course on Materials, as do 9/11 on Manufacturing Processes. About half of the programs merged Manufacturing Processes with Machine Tools instead. Clearly, all 3 topics need to be included in some way, and our way seems as good as any. Statics & Strength of Materials: All programs offer these 2 courses, generally at 3 credits each. This is a TAG sequence and we will leave ours alone! Dynamics: We offer Mechanisms and Drives, which is an alternative to the traditional Dynamics course – more applied and fitting to our student population. 5/11 programs include Dynamics or Kinematics. Fluid Power/Hydraulics: 10/11 programs include one of these two courses. We used to require this course, but it is now a technical elective. Perhaps we should re-think that. GD & T (Gage, Dimension, & Tolerances): 3/11 programs include this topic. We feel that it doesn’t work well as a standalone course, and will integrate it into the curriculum in courses which include drafting and machining activities. CNC (Computer Numerical Control): 5/11 Programs include this topic – one as a two course sequence. We are still trying to decide what to do with this and our Robotics course. No other program includes Robotics. Machine Design/CAM (Computer Automated Manufacturing): We have merged these 2 courses. All programs require some sort of Machine Design, often as a capstone course. Some programs have it as a 2 course sequence. Three programs have separate CAM courses. Electronics: 3/11 programs include an electronics course. We used to, but do not any longer. Students going on to the 2+2 program with Miami of Ohio need to take several as bridge courses. One program includes an Electro-mechanical course. We have one as a technical elective. Thermodynamics: 3/11 programs include this topic. All three programs also require Calculus, as it is necessary to cover this topic. Our program doesn’t require Calculus, nor are we considering adding it. It used to be included in the Miami program of study, but is no longer. Miscellaneous: Courses in only one program of study include Pipe/Map Drafting, Problem Solving, and Safety. Occupational Safety is one of our technical electives. Physics: All programs require at least 4 credits of Physics. 7/11 programs require 2 courses, from 3 to 5 credits each. We plan on requiring one course, and are waiting to hear from/work with the Physics department to see how many credits it will be. Students going on to the 2+2 program with Miami of Ohio can take their second (required by MUOH) Physics course as a technical elective. Composition: All programs require at least one 3 credit course, which matches the OBOR rules. 5/11 programs require a second course. We will include the composition course provided by the English department. Technical Writing & Oral Communication: 6/11 programs include Technical Writing, 5/11 require speech, and 2/11 have a course that appears to be a combination of the two. We are hoping to work with the Communication Skills Department on a combination course (Technical Communication?), but no discussions have taken place yet. HUM/SSCI: Many programs just require 3 credits of each, without specifying any courses. One required Ethics, which is something we are considering based on the outcomes comparison. Another course that is sometimes specified is Microeconomics, which is something we are considering as well. Departmental Review The three full time department faculty members (Shane Bendele, Jeff Woodson, and Adele Wright) met weekly throughout SP 2010. The purpose of these meetings was to evaluate the program outcomes/curriculum and commence S2S conversion. During these meetings, we considered several options for the program. One option was to redevelop program courses to fit into 8 week mini terms. Another thing we considered/did was to break down the program of study into units and try to re-think the paradigm of how/when these units were brought together into courses. In the end, we did neither, but instead took advantage of recent changes made to the curriculum to streamline the program. Conclusions/Implications After reviewing the data, the department faculty have concluded that no changes to the outcomes are needed at this time – they are valid and complete. Instead, we are focusing our efforts of the S2S process. A revised F&S chart was not prepared, as a completely new chart will be developed as part of the S2S process. The current version of the semester plan of study is included in Appendix D. Parts of this POS which have not been finalized include the HUM and SOC requirements as well as Robotics and CAM. For a humanities requirement, we are considering offering a selection of courses from which to choose. Current ideas include Economics and History of Architecture. We are also considering a selection of Social and Behavioral Science courses. Current ideas include Ethics and Psychology. Appendix A – Advisory Committee Meeting Minutes COLUMBUS STATE COMMUNITY COLLEGE EMEC/MECH Advisory Board Committee Meeting Minutes June 9, 2010 Present: Dick Bickerstaff, Chairman; Adele Wright, Chris Haggy, Rodger Rhinehart, Hague Quality; Tim Van Voorhis, PK Controls; Jeff Smith, Liebert Corp.; Dan Carson, Kennametal Inc.; Mark Braniger, Wothington Cylinders; Scot McLemore, Honda of America; Jeff Woodson, Shane Bendele, Diane Dean I. Introductions The meeting started off with a welcome by Dick Bickerstaff and introductions from all. II. Discussion Shane and Chris highlighted notable accomplishments of the Mechanical Engineering students: one who has designed a tailgate for pick-ups, which Pick-Ups Plus is interested in, and a student who won the 3-D Design contest. Adele began the discussion of curriculum for MECH and how the program works. She explained the Statics, Mechanics of Materials, and Manufacturing Materials & Processes sequence: from designing a part to what materials are used, and the importance of the use of Math and Physics in the classes. Suggestions were made from each committee member to aid in this process: Jeff and Shane gave an overview of the EMEC and MECH programs stressing how the goal is not to try and make machinists out of the students but to teach them the basics of Engineering graphics, blueprint reading and basics of industrial equipment. Jeff discussed the outcomes for EMEC and explained how Electro-Mechanical Engineering is a marriage of Electronics and Mechanical classes with a little Automation. Teaching Hydraulics and Pneumatics and defining what is motion? What makes motion happen? There are three classes unique to EMEC, Motors & Controls, Control & Control Logic, and PLC Programming. Once we move into semesters they will move into new software such as Solid-Works, Mitsubishi, Omron. Digital Proto-Typing class will begin in the fall of 2012 upon converting to semesters. Students are currently working on a mini Baja car. Adele discussed the outcomes of MECH and opened up a question and answer session to the committee. Questions were addressed as what do employers expect our graduates to do? Committee members were asked to give input that would help improve future outcomes based on industry standards. Roger commended Adele for teaching students more but was concerned about students applying for employment who lacked the skills to meet their employer’s general needs. More practical skills and not just computer skills. Training on basic electrical systems and troubleshooting. Adele mentioned that welding has come back to CSCC and our students are taking the course in addition to MECH courses. Scot added that companies look for machine tools trades but don’t ask for it. He stressed how companies need to include these skill sets in their job description. Tim suggested that more PLC training and a hands-on training such as torque, voltage, relays, and safety be taught to students. He commented that the labs are the best things we can do. Shane stated that we can’t change who comes here and we only have two years in which to prepare the students. And that we can’t force them to learn. We have to stay within the scope of what we’re teaching. Adele summarized the committee’s comments by saying that the outcome does not need to change, maybe amended to how we teach things. She also stated that our students apply themselves more when they know what their job is going to be. However, most of our students don’t know what their job is going to be. Shane added that we don’t just teach design on computers but stressed that we do teach our students about bolts, threads, etc. Jeff interjected that we do cover what companies are asking for but it’s up to the student to apply it. Jeff Smith suggested that we take the 270 class (Statistics) to another level to complete the degree to know how to read and create charts. Shane then opened the meeting up to the committee for general questions and suggestions. Members suggested: a) More emphasis could be put on soft skills, attendance and employees taking pride in what they do. b) Informing students of what employers are looking for. c) Make sure you make a distinction between a Design Engineer and Mechanical Engineer. Appendix B – Like-College Outcome Comparison Communicate effectively and efficiently with diverse individuals and teams, all levels of employees, customers, and suppliers by means of verbal, written (memos, reports, emails, etc.), graphics, symbols, and effective listening skills and using appropriate technology. Complete tasks and projects on schedule through the effective use of time management, appropriate math skills, and teamwork that fosters inclusion, synergized efforts in problems identification, and troubleshooting for successful resolution of problems towards the achievement of set goals and objectives. Apply quality systems, principles concepts and utilize appropriate math, measurement and statistical tools and technology to improve processes, product quality, and to enhance productivity. Incorporate safety awareness, principles and practices in every aspect of work and as a way of life, including machine safety, environmental safety, chemical safety, and personal/employee protection. Apply knowledge of machine principles an operation, tools and materials, requisite mathematics and physics, to select operation parameters in order to program, setup, and operate production manufacturing equipment, and also to be able to troubleshot and diagnose both numerically/computer numerically (NC/CNC) controlled machines, and programmable logic controlled (PLC) equipment. Apply the knowledge of material science, machine tolerances, blueprint/schematics, and hands on skills in welding, burning, pipefitting, rigging, the use of basic hand tools and mobile equipment for the fabrication of designed parts incorporating accepted industry methods. Apply the knowledge of the principles of drafting and the communication of ideas, designs and visualization skills as the language of the engineering field, including the creation and interpretation of drawings using proper dimensioning and tolerancing for size and geometry, and use of computer aided drawing programs to incorporate proper industry acceptable standards and conventions. Apply the basic principles of equipment maintenance, troubleshooting and problem solving techniques to maintain industrial machines that ensures the production of quality products. Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Cuyahoga County Community College – A.A.S. Manufacturing Industrial Engineering Technology 2 Technical Elective ENVR 170 1. Demonstrate professional conduct and interpersonal communication skills (verbal and written) with co-workers and other technical personnel. 2. Apply basic concepts of kinetics and kinematics of bodies in motion or at rest. 3. Demonstrate knowledge of basic electrical principles used in electrical systems. 4. Demonstrate knowledge of manufacturing processes on different machines, tools and materials by operating a variety of manual and/or CNC (Lathe & Milling) machines. 5. Demonstrate proper use of drafting tools and equipment and produce finished drawings using manual techniques. 6. Demonstrate proficiency in the use of CAD system to produce engineering drawings. Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Eastern Gateway Community College – A.A.S. Mechanical Engineering Technology 2 MECH 260 & PHYS 117 7. Apply computers to solve engineering and related problems using knowledge of computer language. 8. Demonstrate the ability to apply mathematical and geometric concepts. 9. Demonstrate basic understanding of hydraulic and pneumatic concepts, components and systems used in the manufacturing environment and in manufactured products. 10. Demonstrate knowledge of the fundamental laws of physics: mechanics/heat/light/sound. 11. Apply concepts of statics to analyze and compute the forces on and in structures that are at rest or moving with uniform velocity. 12. Apply principles of strength and performance of materials to select and design structural components and systems. 13. Demonstrate basic knowledge of automated manufacturing systems used in industry and build a manufacturing cell. 4 Technical Elective ENGT 131 PHYS 117 & Technical Elective PHYS 118 MECH 130 MECH 242 Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Edison Community College – A.A.S. Mechanical Engineering Technology 1) Demonstrate basic competence in developing 2D and 3D engineering drawings/models. 2) Demonstrate basic competence in engineering design and analysis using applications of mathematics, physics and engineering mechanics. 3) Demonstrate familiarity with basic manufacturing processes. 4) Explain the mechanical and physical properties of various engineering materials. 5) Design parts/products in accordance with specified design parameters, utilizing problem-solving skills as required. 6) Explain the ethical considerations involved in the design of a product per industry standards. 7) Demonstrate effective written and oral communication skills. 8) Apply effective interpersonal and teamwork skills. 2 3 (1) solve technical problems typical of those encountered in mechanical engineering technology careers using creativity, current technology, and the principles of mathematics and applied science (2) perform and evaluate laboratory experiments, interpret and report on the results, and make recommendations for improvements (3) work and communicate effectively in a diverse multi-disciplinary team in an industrial and academic Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Lakeland Community College – A.A.S. Mechanical Engineering Technology 2 setting (4) understand modern quality principles, professional issues, and the need to pursue lifelong learning 1. Interpolate and complete engineered drawings using orthographic projection, isometric views, and proper dimensioning practices, then employ the use of Computer-Aided-Design (CAD) software. 2. Describe the different manufacturing processes and demonstrate proper use of precision measuring devices and instruments. 3. Examine the physical and chemical properties of engineering materials, analyze and calculate the properties of fluids. 4. Analyze and calculate the resolution of forces on rigid bodies; determine the stress, strain, and deflection, then design machines and mechanisms. Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Northwest State Community College – A.A.S. Mechanical Engineering Technology MECH 130, MECH 242, & MECH 261 • Demonstrate the ability to follow all safety rules and regulations, including lock/out-tag/out. • Demonstrate the ability to read mechanical blueprints. • Demonstrate their understanding of the entire manufacturing process. Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Rio Grande Community College – A.A.S. Manufacturing Technology • Demonstrate the ability to use common measuring devices used in manufacturing. • Demonstrate comprehensive capabilities in metal working machine operations. • Recognize unsafe or hazardous conditions of machine operation. • Understand the quality aspect of the entire manufacturing process. Technical Elective ENVR 170 • Adopt a sense of advocacy for the field of manufacturing by participating in the professional organizations and associations related to their general area of manufacturing and to continue their education to keep their skills updated. 1. Mechanical Ability The ability to relate to mechanical systems or processes in the engineering environment is the desired outcome. Developing, analyzing, and visualizing various types of engineering drawings and specifications are required activities. Mechanical ability is developed by Technical Specialty Courses and Basic Sciences. 2. Accuracy The ability to solve engineering problems properly and systematically is the desired outcome. A thorough understanding of mathematics and the design process is required. Accuracy is developed by Basic Sciences and Basic specialty Courses. 3. Manual Dexterity The ability to use a wide variety of "mechanical tools", comparable to those used by mechanical technicians, is the desired outcome. A respect for these "tools" and a pride in one's workmanship is developed. Manual dexterity is developed by Technical Specialty Courses and Technical Electives. 4. Creativity & Confidence The ability to communicate engineering principles both practically and theoretically is the desired COMM 105 & 204, MECH 115 Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Stark State College of Technology – A.A.S. Mechanical Engineering Technology outcome. The variety of courses allows for some improvising in the solutions to the problems at hand. Creativity is developed by Technical Specialty Courses. 5. Effective Communication The ability to confidently communicate engineering information and concepts by oral presentation or technical reports, in a manner that would gain customer approval and support, is the desired outcome. Another element of confidence is proper social adjustment, which requires positive interaction among colleagues and customers. This is accomplished by a variety of technically-oriented projects required by the MET and General Studies Division. Confidence is developed by Humanities Courses and Communication Courses. 6. Technical Currency MET students are encouraged to actively participate in the local, technical societies as student members. The intent is to encourage exposure to "state of the art" MET practices. Technical currency is developed by ASME, ASQC, AEMS, etc. and Technical Societies. Prepare drawings on Computer-Aided Design (CAD), to completely describe a part for manufacture, including views and tolerances. Produce parts using various types of manual machines. Inspect parts that were produced using various types of tools. MECH 240 Program and produce parts on a variety of Computer Numerical Control (CNC) equipment. Utilize CAD skills to present a design including assemblies for approval. MECH 253 Complete a design from start to finish. MECH 261 Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Terra Community College – A.A.S. Mechanical Engineering Technology Learning Outcome 1: be able to apply principles of mathematics and applied science, to perform technical calculations and solve technical problems of the types commonly encountered in mechanical engineering technology careers. (consistent with TAC/ABET Criterion 2 Outcomes a, b, f ); Learning Outcome 2: demonstrate the ability to identify, formulate, and present creative solutions to technical problems in a variety of specialty areas within the broad field of mechanical engineering technology. (consistent with TAC/ABET Criterion 2 Outcome d); Learning Outcome 3: be able to function competently in a laboratory setting, making measurements, operating technical equipment, critically examining experimental results, and properly reporting on experimental results, including their potential for process improvement. (consistent with TAC/ABET Criterion 2 Outcomes a, b, c, f, g); Learning Outcome 4: be able to use modern computational tools for technical problem solving, including scientific calculators, computers and appropriate software. (consistent with TAC/ABET Criterion 2 Outcomes a, b, f); Learning Outcome 5: demonstrate a broad education and knowledge of contemporary issues in a global and societal context, as necessary to develop professional and ethical responsibility, including responsibility to employers and to society at large. (consistent with TAC/ABET Criterion 2 Outcomes i, j); Learning Outcome 6: recognize the need for life-long learning, especially concerning maintenance and improvement of technical skills (consistent with TAC/ABET Criterion 2 Outcome h); and Learning Outcome 7: demonstrate an ability to communicate effectively and function effectively with members of multi-disciplinary teams and with other workers in an industrial setting, including those from a variety of backgrounds. (consistent with TAC/ABET Criterion 2 Outcomes e, g, j). Gen Ed Outcome CSCC Outcome 4 CSCC Outcome 3 CSCC Outcome 2 School Outcomes CSCC Outcome 1 Youngstown State University – A.A.S. Mechanical Engineering Technology 4 3 2 Appendix C – Like-College Program of Study Comparison School CSCC Cuyahoga CC Program Title MET Manuf Industrial Eastern Gateway CC MET Edison CC Lakeland CC Lorain Cnty CC MET MET Mech Design Northwest State CC MET Miami MET Stark State College MET Terra CC MET Univ of Akron MET Youngstown State Univ MET Survey of Mech (2) Software for Tech (1) Intro to ENGT (3) Course Type College Success Student Success (1) Intro Intro to ENGT (2) Computer Apps (2) Technology Orient (2) Computer Apps (2) Engineering Graphics (3) Engineering Drawing (2) Drafting I (3) CAD I (3) 2D Auto CAD (2) Drafting II 3) CAD II (3) Advanced Auto CAD (3) Tech Math (5) Computer Skills Drafting Math Materials & Processes (3) Machine Tools (3) College 101 (1) Intro to Eng (1) Print Reading & Sketching (2) CAD I (3) CAD I (3) Tech Math I (4) Tech Algebra (3) Tech Math II (5) Statistics (3) Other Technical Succeeding in College (1) Career Success (1) Engineering Materials (3) Machine Tools and Manuf Intro to Technology (2) 1st year seminar (1) Intro to ENGT (2) Intro to ENGT (1) Comp Concepts & Program (3) ENGT seminar (1) Computer Apps (3) Blueprint Reading (2) Print Reading & sketch (3) Intro to CAD (3) Intro to CAD (2) CAD I (4) CAD (3) CAD Elective (2) Intro to SolidWorks (3) CAD II (4) Com Aided Design (3) Calc I (5) Tech Math I (4) Detailing & Dimensioning (3) 3D Drafting/Modeling (3) Tech Math I (4) Precalc (5) Algebra (4) Algebra (3) Math III (2) Alg & Transc Functions (5) Tech Trig (3) Tech Math II (4) Tech Math II (4) Calc I (5) Quality Assurance (2) Trigonometery (1) Process Improv./Lean (3) Appl Calc 1 (4) Quality Concepts (2) Trigonometery (1) Precalc (4) Math IV (3) Tech Calculus (3) Appl Geometry & Trig (3) College Algebra (3) Trigonometry (3) Engineering Materials (2) Intro to Manuf Processes (3) Materials Technology (3) Manuf Processes (4) Materials (2) Engineering Materials (3) Manuf Processes I (3) Manuf Processes I (3) Manuf Processes (3) Manuf Processes II (3) Manuf Processes II (3) Engineering Materials (3) Eng. Drawing (3) Blueprint Reading (2) Tech Drawing (3 CAD or ProEngineer (3) CAD I (3) CAD (3) CAD II (3) Calc or Anal. Geometry (3/4) Materials Science (2) CAD Tech 2 (4) Elements of Calc (3) Material Technology (3) Manuf Processes Manuf. Systems (3) or Machine Tools (3) Manuf. Processes (3) CAD Tech 1 (4) Prop/Strength of Matls. (4) Mfg Techniques (3) Processes (3) Statics (3) Statics (3) Statics (3) Mechanics I (3) Statics (3) Statics (3) Statics (3) Strengths (3) Mechanisms & Drives (3) Strengths (3) Dynamics (2) CAD II or Hydraulics (2-3) Strengths (3) Dynamics (3) Hydraulics and Pneumatics (3) Strengths (3) Strengths (3) Strengths (3) Strengths (3) Fluid Power (3) Fluid Power (3) Fluid Mechanics (3) GD&T (2) GT &T (2) Precision Measurement (3) Fluid Power or GD&T (2-4 ) CNC CNC (3) CNC (3) Machine Design/CAM (4) CAD/CAM (3) Mechanical Component Design (3) Mechanics II (3) Statics & Strengths (4) Adv Strengths (2) Dynamics (2) Statics (3) Statics (3) Strengths (3) Fluid Power (4) Hydraulics (3) Strengths (3) Kinematics (3) Fluid Power (2) Intro to CNC (2) Machine Design (3) Design & Manuf Capstone (3) Machine Design (3) Machine Design (3) CAM I (3) Machine Design (4) CAM II (3) Product Development and Manuf (3) IT & Engineering Practicum (1-2) Design of Machine Elements (2) Fluid Dynamics (3) Robotics Physics Composition Tech Writing Pipe/Map drafting (2) 3 Electives (3 each) Physics I Physics I (4) Physics I (4) Physics I (5) Applied Physics I (3) Physics II (4) Physics II (4) Physics II (5) Applied Physics II (3) Composition I (3) Composition II (3) Composition I (3) Composition I (3) Composition II (3) Fund of Commun. (3) Composition I (3) Composition (3) Tech Comm (?) 3 Tech Elective (5) Tech and Prof Writing (3) Public Speaking (3) 3 Electrical Circuits I (3) Circuit Analysis I (3) Elec Circuits & Devices (4) Problem Solving (3) Elective Oral Commun. HUM Electromechanics (2) Tech Project Mech and Design (2) Micro Thermo & Heat Transfer (3) Machine Design (3) Intro to Mech Design (3) Mech Design II (5) Mech Design 1 (3) Thermal Energy I (2) Thermo (3) Safety (1) Physics I (4) Composition I (3) Composition I (3) Composition II (3) Tech Composition (3) 3 3 Mech Design 2 (3) ThermoFluids lab (1) Physics I (4) Physics I (4) Physics I (5) Physics II (4) Composition II (3) 3 CNC (3) Tech Elective (3) Physics I (5) Fluid Mechanics (3) CNC (3) CAM (3) Analysis of Machine Components (3) Mechanics 1 (3) Mechanics 2 (3) Composition I (3) Composition (3) Composition I (3) Tech Physics I (4) Tech Physics II (4) English (4) Physics 1 (5) Physics 2 (4) Writing 1 (3) Writing 2 (3) Tech Writing (3) Tech Report Writing (3) Tech Writing (3) Public Expression or Interp Comm (3) Microeconomics Speech (3) Effective Speaking (3) Econ I (3) Tech Report Writing (3) Effective Oral Comm (3) Human Comm Thy/Pract (3) economics (3) (3) 2 SSCI 3 Relations (3) 3 3 Intro to Ethics (3) 3 3 3 Critical Thinking (3) World or US Culture (3) Am Urban Soc (3) Phys Ed (1) Science Elective (4) General Elective (3) Total 64 68-70 61-63 66 72 66/67 69 Pers/Soc (3) Soc/Inst (3) 64 68/69 64 70 69 Appendix D – Current Rendition of Semester Plan of Study First Semester Autumn Second Semester Class ENGT 1115 ENGT 1101/ 1100 Mech 1150 Math 1113 contact CR contact Engineering Graphics B 3 5 Mech 1145 CAD I T 3 6 Computer Apps (8 wks) + Intro (8 wks) Manuf Matls and Processes Tech Math Student Success B T G 4 3 5 1 4 4 Mech 1240 Mech 1130 Machine tools Statics Physics SOC & Behav T T G G 3 3 5 3 6 4 Total Credit hours Third Semester Mech 2215 Mech 2242 Mech 2260 CR Spring 16 Autumn Fourth Semester CAD II Strengths Basic Mechanisms/Drives Elective Composition T T T B G Total Credit hours Technical Non-Technical Student Success Grand Total 17 15 31 General Related Total 3 3 3 3 3 19 13 32 01 64 6 4 6 Mech 2299 Mech 2270 Mech Machine Design/CAM Engineering Statistics Robotics/CNC ART & HUM Tech Communication Total Credit hours Spring T T T G B 4 3 3 3 3 16 6 4 5