Team Special T

A.T.G (All Terrain Grill)

S. Ducko, E. Emmanoulopoulos, T. Goodman; D. Hopper; W. Lee

December 11, 2013

ME 455 Analytical Product Design

Fall 2013

Prof. D. Brei

ABSTRACT

This report presents a complete overview of the business objectives, product description, market

analysis, and financial planning and forecasting for the All-Terrain Grill (A.T.G.). Appended to

this report are the fully detailed sections for each of these four primary areas. Product definition

and market analysis includes research on the customer persona, current competition, and market

value. Concept development and down selection methods to reach the proposed A.T.G. concept

are outlined. Product design in its entirety is presented from development methods all the way

through proof of concept fabrication and validation. The final appendices details the financial

analysis of the initial investment costs, estimated profit model, and projected financial forecast.

Table of Contents

1.

2.

3.

4.

Business Objective……………………………………………………..

Product Description……………………………………………………

Market Analysis………………………………………………………..

Financial Plan…………………………………………………………..

3

4

5

7

Appendix A: Product Definition and Market Analysis…………………

Executive Summary: Product Definition…………………………………

1. Market Research Methods…………………………………………….

2. Persona/Scenario……………………………………………………….

3. Product Definition……………………………………………..............

4. Competition Analysis…………………………………….....................

5. Market Value Proposition……………………………………..............

9

10

11

13

14

17

19

Appendix B: Product Concept……………………………………............

Executive Summary: Product Concept…………………………………..

1. Conceptualization Methods……………………………………...........

2. Functional Decomposition……………………………………..............

3. Concept Tree……………………………………...................................

4. Top Concepts……………………………………...................................

5. Concepts Selection……………………………………..........................

6. Proposed Concept Description……………………………………......

20

21

22

23

25

28

31

33

Appendix C: Detailed Product Design……………………………………

Executive Summary: Detailed Product Design………………………….

1. Technical Development Methods……………………………………..

2. Parameter Analysis…………………………………….........................

3. Design for X…………………………………….....................................

a. Design for Manufacturing/Assembly…………………………

b. Design for Environment…………………………………….....

c. Design for Human (Aesthetics, Beauty, and Variability)……

d. Design for Testing……………………………………..............

4. Final Design……………………………………....................................

5. Manufacturing Plan…………………………………….......................

6. Proof of Concept…………………………………….............................

7. Validation……………………………………........................................

8. Design Recommendations……………………………………..............

35

36

38

40

47

48

48

50

53

53

56

86

109

111

Appendix D: Financial Analysis…………………………………………..

1. Cost Model…………………………………….......................................

2. Profit Model……………………………………....................................

3. Conjoint Analysis……………………………………...........................

4. Financial Forecast……………………………………..........................

114

116

118

120

122

Appendix E: Information Sources……………………………………......

126

2

BUSINESS OBJECTIVE

Some, perhaps even most people might look at the A.T.G. (All-Terrain Grill), especially in its

fully deployed state, and think to themselves “it looks like just another charcoal grill to me”.

This however is precisely where the old phrase “don’t judge a book by its cover” comes from.

The A.T.G. has the potential to fill a valuable market niche that is not currently being met.

The market for grills, both stationary and portable, is not “saturated”, but they both possess

plentiful and well established competition. This means that in order for a product to successfully

infiltrate the market it must have features that make it better than the existing competition at

satisfying a customer need. The A.T.G. is a product with the capability to do exactly this. There

are plenty of gigantic grills and BBQ’s out there with loaded a laundry list of fancy features and

gadgets and possessing the cooking capacity to roast a small pig. There are also a plethora of

portable grills available that are advertised as the ideal product for grilling on the go. Some

mobile grills even claim to be full size grills that can simply be broken down and taken with you.

This led to the question of, “What really constitutes the perfect grill for customers on the go?”

First off, what legitimately makes a device portable? Looking at the current portable grills on the

market, many not only lack in features that customers are used to from their large grill at home,

but they’re also not genuinely portable. Sure, almost all of them can be taken with the customer

everywhere they go, but most can’t be used everywhere. Many are small apparatuses that

require some sort of table to elevate them to a usable height. Models on the market that do

deploy and become stand-alone all require some sort of level ground in order to provide a level

cooking surface. These are two factors that limit true portability. A grill that can go anywhere

with a customer is only useful if they can also actually grill once they’re at their destination.

The A.T.G. is a product that efficiently solves this problem. It combines the full size cooking

capacity and the amenities of grills customers have on their back patio with the portability of the

current mobile grills on the market, all while being able to be used on nearly any surface. The

four legs of the A.T.G. (which conveniently fold flat for storage/transport) have inner sections

that telescope down and can lock independently at the desired height. Each leg has ten total

inches of adjustability to allow for level set-up on even the most extremely uneven of surfaces.

The leg locking/unlocking operates in pairs (left side and right side) and is actuated by a handle

that is nested inside tracks of the two primary carrying handles and is connected to tension cables

directly attached to the locks of each leg. This allows for full mechanism functionality with

minimal user input. In addition to this key element, the four hinges that the legs are attached to

also lock in the open (110⁰) and closed (0⁰, flush to the base of the kettle) positions.

The A.T.G. also possesses many other useful features that further increase its function and

desirability. Housed inside the bottom quarter of the kettle is an easy removal ash/drippings

drawer for quick clean-up of the mess made during the grilling process. Remove it using its

sturdy handle, dump the waste, and insert it back into the kettle. Side tables fold and lock in two

positions: open, to function as a place to set food, drinks, and seasonings during grilling, and

closed, to serve a secure top when the grill is stowed for transport. Underneath this top, inside

the kettle, the grill lid and cooking grate are stored safely from the elements. When cooking and

cleanup are finished simply pull on the same handles that control the leg locks and spring loaded

support pins will retract allowing the grate and lid to drop down into their stored location while

3

simultaneously releasing the legs. Allow the weight of the grill to return the legs to minimum

height, fold up all four legs, fold and lock the side tables and the A.T.G. is good to go!

PRODUCT DESCRIPTION

The mass manufactured concept for the A.T.G. is pictured below in figures 1 and 2 in both its

fully stowed and fully deployed forms. Aesthetically, the goal was to create a stowable, portable

grill that would resemble current stationary charcoal grills on the market when it was fully

deployed. Whereever the grill is in use the customer should feel like they are at home grilling on

a full-size, fully-outfitted piece of cooking equipment. The difference is that when the cooking is

finished, the A.T.G. is quick and painless to collapse into storage, toss into the car, and take to

the next venue. The real kicker is that this venue can be nearly any type of terrain. From loose

top soil to ground covered in dips and mounds, even planes of completely different heights, a

level, stable cooking surface can always be achieved. There’s also no skimping on the number of

friends that join. With over 341 square inches of cooking surface there will no burger left behind

and no man left hungry. The A.T.G. will transform any customer into a one man grilling

machine who can provide enough food to satisfy the entire party.

Figure 1: The A.T.G. in its fully stowed, transportable state

Figure 1 shows the A.T.G. in its fully stowed initial state. From this position the user would use

the carrying handles to transport the grill from their vehicle to the desired cooking location. The

first step is to set the grill down, unlock/open the side trays, remove the lid, and close the trays

back up. From here, lay the A.T.G. down on the back side of the kettle and move all the legs to

the open postion (where they will lock automatically). Once this is completed simply hold the

grill upright above the ground by the carrying handles and pull on the actuation handles, this will

deploy the telescoping legs. After the legs have released fully, use the weight of the grill to get

all for legs into the appropriate position to obtain a level cooking surface (do not release the

actuation handles during this period). After a level surface is achieved, release the actuation

handles and all four legs will securely lock into place. To finish the set-up, re-open the side

tables, pull out the drawer (which houses both the charcoal and cooking grates during transport)

and place the cooking grate on top of the support pins. Lastly, place the drawer back in the kettle

and the A.T.G. is ready for grilling! (This entire process should be able to be completed in less

4

than 1 minute.) When this process is competed the grill should resemble figure 2 (see next

page), with an obvious difference being the telescoping legs locked at various heights.

Figure 2: The A.T.G. in its fully depolyed position

With the A.T.G. is this position it is a fully functional lean mean grilling machine! Once the

cooking is done and the party is over, clean-up is a breeze. It’s even easier than the set-up as a

matter of fact. After using the drawer to dump all of the ash and food drippings, all the user has

to due is pull the actuation handles. This will drop the cooking grate and the grill lid down inside

the kettle (on top of the drawer and charcoal grate) as well as unlock and collapse all of the legs

to their minimum height. From here, leave the grill standing in the upright position and close and

the lock the side tables. Lastly, put the grill on its back side, unlock and all four legs and move

them to their closed position (where they will once again automatically lock). After this, the

A.T.G. is fully stowed and ready to be transported to the next grilling destination.

MARKET ANALYSIS

The unique features of the A.T.G. make it a product that could acquire mass appeal, however it

was designed with a specific customer sector as the primary target market. Customer feedback

was gathered from multiple surveys throughout the design process. The demographic of the

survey respondents turned out to be largely college age males, and the unity in the answers

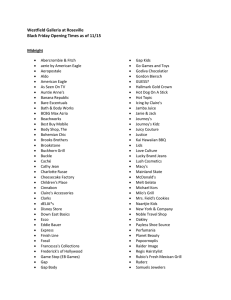

across the board was overwhelmingly conclusive. Shown on the following page in figure 3 are

the results of responses to some key survey questions.

5

Figure 3: Key survey results used to determine consumer preferences and characteristics.

Q 8: For how many people do you cook?

Q 11. Where do you cook outdoors?

Q 24: Where do you live?

Q 1: How often do you cook outdoors?

These responses clearly indicate that the majority of consumers cook outdoors with relative

frequency and are cooking for groups of either 2 to 4 or 5 to 10 people over 91% of the time. It

can also be seen that over 75% of respondents live in either urban or suburban areas, but do

almost 86% of their outdoor cooking in public areas away from their home. From this it can be

directly inferred that a large majority of the time, consumers have a need for a product with large

cooking capacity that can be transported with them from their house to their destination. Delving

a little deeper and using some firsthand knowledge, many college students live in apartments or

housing without much surrounding property. This means that any grill owned would most likely

be stored inside the living quarters. Therefore the area of design focus was attempting to create

the optimal combination of portability and large cooking capacity. Portability in this case

meaning being able to efficiently store the grill at home as well as during transport and also

having the capability to use the grill as a stand-alone entity at any site the customer should so

choose. The product positioning chart shown in figure 4 depicts the target area of the market for

the A.T.G. in relation to what was deemed to be the top current portable grill competition.

Figure 4: Product position showing a need for a portable grill with large cooking capacity.

Portable

Inconvenient

6

The consumer surveys were created using Sawtooth Software. This software allowed for the

implementation of conjoint analysis. Conjoint analysis is a tool uses statistical comparison to

determine how consumers value different features of a product. This analysis enabled the

determination of the market preference for the A.T.G. using it’s the price, cooking capacity, and

storage size versus that of the top three competitors (same three in figure 4). Figure 5 below

displays these results.

Figure 5: Results of conjoint analysis simulation show consumers prefer the A.T.G. over the

Coleman RoadTrip and Kingsford Portable Charcoal Grill.

Conjoint Analysis Showing Market Share

From all of the above information it can clearly be seen that there is both a market niche and

customer demand for the A.T.G. With the necessary capital investment and the proper

marketing techniques the A.T.G. has the potential to be the most successful portable grill on the

market in the near future.

FINANCIAL PLAN

In order for any product to be deemed legitimately successful it must eventually generate a

profit. After thorough analysis, the potential market for the A.T.G. was found to not only be

existent, but also quite profitable. This conclusion was reached by creating a cost model of the

A.T.G., a profit model with market analysis, a conjoint analysis of the market and products to

further refine price, and a financial forecast to ensure that there will always be cash reserves.

The cost model was used to find the total cost to produce the A.T.G., breaking it down by each

part. Total cost of the grill was determined to be $60.52 including other costs such as sales,

marketing, and stocking. Manufacturing costs were determined by selecting the appropriate

methods such as sheet stamping and die casting for parts based on selection indices found in CES

with overhead being estimated in similar fashion, as well as labor rates based on current

statistics. The total manufacturing cost was found to be $14.98. Additional costs from sales,

marketing, distribution and general office overhead brought the grand total for production cost to

$86.82. Setting the sale price at $100, as determined through a variety of factors to be

appropriate, there will be ~15% profit per unit. Shown at the top of the next page in figure 6 is

the profitability chart for the A.T.G.

7

Figure 6: Profitability chart showing the initial investment for machinery, the annual

profit and net cash flow indicating a break-even point after 2.8 years

Break Even:

2.82 yrs.

Profit analysis began with a discounted cash flow analysis which examines the flow of money in

and out of a business and accounts for the discounted value of future earnings with an assumed

discount rate of 15%. The initial tooling, launch, and equipment costs were estimated to be

$517,000 (the red in figure 6) with an assumed launch cost of $100,000. An assumed tax rate of

37% was used. Additionally, production was assumed to increase by 5000 units each year

starting at 20,000 and ending at 40,000 (moving from 2% to 4% of the portable grill market).

The internal rate of return was determined to be 39.4%. Finally, it was found that the A.T.G.

enterprise will break even in 2.83 years, or the third quarter of the 2nd year and operate as a

profitable entity from this point forward.

8

APPENDIX A

Product Definition and Market Analysis

9

EXECUTIVE SUMMARY

The first step of the design process begins with choosing a market sector and trying to define a

current problem within it. A hypothesis of interest is the starting point, but it must soon be

followed by market research that either aids in its validation or refutation. The sector chosen by

the group was outdoor grilling. The hypothesis was that customers had issues with forgetting,

misplacing, and/or losing equipment when attempting to cook outdoors and away from the

comfort of their own home. Market research conducted began with talking to potential

customers about their outdoor grilling experiences and problems, venturing to local stores to

view current grill/cookware inventory, and searching the internet for the wide variety of items

offered. A few items were found that at least partially solved what was believed to be the

potential problem. These items were centered on multi-functionality, compactness, and mobility.

These are all attributes that we felt would reduce the risk of losing or forgetting utensils or

cookware.

In order to fortify the hypothesis and obtain a legitimate problem statement for the final product

a survey was created and distributed to the potential customer base. The survey contained

questions ranging from as general as, “How often do you cook outdoors?” to as specific as

“What utensils and cooking method do you frequently use and/or prefer?” It was also desired to

know what people valued in their grills/cookware along with the problems they had experienced.

The end of the survey posed demographic questions such as age, gender, marital status, and

income level in order to pinpoint the ideal demographic to target. The results of the survey were

not quite as expected, but they did guide the way to a market sector with need. It was found that

almost no customers had issues with losing or forgetting cookware/utensils. However, it was

discovered that the customer base shared many characteristics which pointed out the clear

direction of a common need in the market.

Many of the customers said that they cooked out somewhere between a few times a year to a few

times a month, but that activity was heavily increased during the summer months, as might be

expected. Almost 75% of the customers surveyed stated they were single, but over 90% of the

feedback stated that cooking was typically done for either 2-4 or 5-10 people (about 45% each).

This means that people are gathering together to cookout. The setting that outdoor cooking most

frequently took place in was at a campsite or recreation area; however, 75% of customers

surveyed reported living in an urban or suburban setting. Therefore, customers are not only

coming together to cook outdoors, but they are also traveling to a common public place to do so.

The preferred method of cooking was charcoal or gas, totaling 78%. Putting all of the above

information together a new problem was discovered in our market. This problem is the lack of a

portable grill that combines full-size cooking capacity with the compactness to be easily

transported. This is a problem definitely has the potential be exploited and solved with the

introduction of a new product.

Full-size grills are typically heavy and/or bulky making them difficult to transport. Lots of

portable grills have features such as collapsible legs, wheels, and removable components.

However, there does not seem to be a grill on the market that allows for easy and convenient

transportation from a person’s home (in urban suburban areas) to recreational sites/campgrounds

(in predominately rural areas). The product currently being developed will look to fill the niche

of a grill that has full-size cooking capacity, but is also completely stow-able/deployable for

10

efficient transport, set-up, grilling, cleaning, teardown, and storage. The target location for

primary use will be wherever customers are away from their home while grilling. The customer

survey also provided desired requirements for the product to fulfill as a standalone entity, as well

as allowing the determination of measurable metrics for these attributes. The Quality Function

Deployment or “QFD” diagram shown later in this report gives the full breakdown of the

customer requirements, the metrics, and the internal relationships and trade-offs between them.

The top customer requirements are those that make-up the target market niche; large cooking

capacity and compactness (for portability) while being cost competitive. The QFD also

benchmarks what has been deemed to be the leading current market competition to the future

product. As the design process continues there will need to be deeper delving into the product

definition as well as continued product scope refinement.

MARKET RESEARCH

In order to find a problem, and define it well, it is best to talk to those most likely to experience

it. The user can provide powerful insight into their needs, problems, and wants. The group first

conducted basic research methods into market segments of interest. Once the market was

narrowed to the outdoors, with focus on cooking, the team took several steps to further gain

insight into the users by conducting market research. Methods used include a basic observation

of customers and asking simple questions, implementing a survey, and using empathetic methods

to better understand the situation. From these, design metrics were determined and listed below

in Table A.1, with their respective market research source(s).

Table A.1: Design metrics and the market research method(s) they were derived from.

Metric

User Interview Observation Empathy

Survey

Cooking Capacity

X

X

X

X

Weight

X

X

Compact Size

X

Inexpensive

X

X

Durable

X

X

X

Ease of use

X

Ease of cleaning

X

X

All Terrain Stability

X

Heat Resistant

X

Good Looking

X

X

Easy to Assemble

X

X

Safe to Use

X

X

X

Observations

We went to several environments in which potential customers might use or purchase the

equipment necessary to cook outdoors. Stores targeted were Walmart and Meijer for the lower to

middle income customer, and Cabela’s for the more enthusiastic sportsman or outdoors

enthusiast. We also spoke to potential users and found that customers want tools that they can

transport with them (mobility), relative affordability, durability and therefor value, ability to

clean easily, that are good looking, and made in the United States because many people

identified as patriotic. In addition, experts in the industry were consulted by asking salespeople

about customer trends, complaints and demographics. This was also conducted online.

11

Empathetic Methods

Several people attended cookouts and tailgating events to not only observe but also experience

the situation as the user. From this, it was found that tools for cooking would benefit from being

lightweight and easy to transport in a bag or truck, easy to clean with little access to water or

other solvents, able to withstand rain and other elements, resistant to direct flame, U.S. made to

support the patriotic user, and readily available either online or a big box retailer to ensure a

lower cost and greater convenience because the user wants to enjoy the outdoors at their leisure.

Survey

In order to further distinguish the potential user, their problems, and see if our problem in fact is

substantive and potential solutions we composed a set of online survey questions. While creating

the questions, we strived to remain impartial, and give the user clear questions that started broad

and then moved to more precise. Our demographic questions were added to better understand the

user and their background while being sensitive to their situation. Open ended questions were

provided to get a wider range of user feedback.

Key survey results are indicated in fig. A.1 below and referenced by question number. It was

found that most cook for a group of 2 to 10 people seen in Q 8 and do so at so at a recreation

area, Q11. Some key demographics indicate that the average user is a single male or female in

their early 20’s who is a recent college graduate or similar making around 25 thousand dollars a

year, living in an urban or suburban environment as seen below Q 23 and Q 24. The most

common season to cook is summer seen in Q 5, with most people cooking out a few times a year

seen in Q 1. Price, durability, and functionality were also found to be important aspects of a

cooking equipment.

Fig. A.1: Key survey questions and results used to determine customer preferences and

characteristics.

Q 8: For how many people do you cook?

Q 11. Where do you cook outdoors?

Q 24: Where do you live?

Q 23. What best describes your income level?

Q 5: During What seasons do you cook?

Q 1: How often do you cook outdoors?

12

PERSONA/SCENARIO

The primary consumer for our product is Fred, a middle class individual, who is single, age 23.

Fred just graduated from college with a degree in Marketing and now resides in an urban setting,

near the beach in the Chicago land area.

Fred predominately cooks at summer cookouts with his two roommates for his group of five

friends, who all live relatively close by. He uses mostly charcoal at campgrounds or recreation

areas for their grilling. Fred also likes sports, television, and hanging out with friends and

generally enjoys outdoor recreation. This includes but is not limited to outdoor family BBQ’s,

outdoor parties or graduations, camping trips, hunting trips, fishing trips, sports tailgate parties

and block/house parties.

Fig. A.2: Fred with his fellow Alumni cooking outdoors

(thecollegejuice.com)

He has strong family values and traditions passed down from previous generations, such as

grilling secrets. He is proud to purchase a product that is “Made in America”. That said, Fred

owns a small vehicle handed down from his family, which restricts his ability to transport bulky

camping and cooking equipment.

Fig. A.3, A.4: Fred with grilling equipment.

(www.thefoodfather.com)

(www.vat19.com)

Fred is looking for a product that he will be proud to talk about and show off to his friends when

he invites them over for his cookout.

13

PRODUCT DEFINITION

This section describes the product attributes our team selected after reviewing the customer

survey responses, and which represent the needs of our customer majority feedback.

Cooking Capacity: Our product must be able to fit approximately 8 quarter-pound burgers or be

able to handle a similar volume since most customers usually cook in/for groups of people.

Compact: The product should be relatively small. The measurable metric is, therefore, volume.

By small we mean it should either easily fit in a car/bag or be collapsible. The degree of mobility

is strongly affected by how compact it is.

Lightweight: The mass of our product should be low; it should not exceed 5 kg. Being compact

does not necessarily guarantee low density. Light materials may jeopardize durability.

Inexpensive: The product should be targeted to the average income user and will not be a

luxurious item. Its cost will be measured in US dollars; this could conflict with durability.

Durable: The product should not show any significant signs of wear and tear that could

jeopardize functionality for at least 5 years. If the customer has to change it every time they go

camping or cook outdoors, then they will avoid it. Of course, the product lifetime will strongly

depend on the target group, circumstances and frequency of use.

User-friendly: Our product will need to be mobile, since it targets the outdoors market. Its

handle should be easy to grip and should be made of material that acts as a heat insulator. The

degree of mobility can be defined by whether it is definitely going to be taken with depending on

the mode of transportation used based on further research.

Easy-to-clean: The product should have a coating that keeps food from sticking to it;

unfortunately this may be an issue when trying to keep costs low.

Weather-resistant: The product should be usable under different temperature and precipitation

conditions in all four seasons of the year and in different climates. This can be measured in

temperature and humidity change resistance; overlaps with heat resistance.

Readily available: The product needs to be obtained by the customer within 3-5 business days;

other; local inventory and delivery methods may conflict with the low price of the product.

Domestically/Locally sourced: The product should be produced in the US so that consumers

will choose it when trying to support domestic industry. It would be even better if the product is

produced locally in order to reduce delivery costs.

Aesthetically appealing: Many users choose products based on their aesthetics. For instance

two exact same technologies may compete through cool shapes that resemble animals etc. This

can be measured in proportions, colors and texture type; this attribute may conflict with price.

14

Heat resistant: Since the product is going to be used for cooking purposes, it needs to be able to

resist temperatures of 700 degrees Fahrenheit. This attribute will also enhance weather

resistance.

Ease/Absence of assembly: The product needs to be sold fully assembled.

Safe to stow/deploy: The product should not exceed a pinch factor in order to avoid lawsuits in

case of accidents. The precise value is yet to be determined.

All-terrain stability: The product must be stable on height variations of a maximum of 10”.

Analysis of Requirements and Competitor Products

The QFD table listed below in Fig. A.5 on page 15 was an excellent analysis tool for important

product attributes. It takes into account the end user, manufacturer, and other stakeholders as

well as uses market and competitor research to get an accurate picture of the market. The metrics

chosen come from the market research done and customer survey results. In the Table, the

importance of an issue is ranked from 1-9 with (9 being most highly correlated).

The numerical values assigned in the QFD to customer importance, manufacturing importance

and seller importance were assigned a weight-ranking from 1 to 12 based on importance (1 being

the most important). The customer importance was determined from market surveys and the

seller importance was based on conversations had with retail store employees in sporting and

recreational retail outlets. The manufacturing importance for the QFD was assigned based on

knowledge and experience the team has working in industry.

For the given problem no governmental regulations impose any restrictions to be considered.

However, product development is limited by the team’s main business design objective, which is

an investment cap of three hundred dollars for the concept development. The attributes that

differentiate the team’s solution from its competition are discussed in the top concepts section of

the report.

15

Target

#1 Kingsord Deluxe Charcoal

Grill

#2 Uniflame Gas Tailgating

Grill

#3 Coleman Roadtrip Gas Grill

N/A

N/A

N/A

0"

No

N/A

91%

Yes

N/A

N/A

N/A

0"

No

N/A

94%

Yes

4

4

7

Lightweight

3

9

4

3

2

1

Inexpensive

1

5

2

3

9

Durable

1

9

6

9

8

4

User-friendly

3

1

7

11

10

11

Easy-to-clean

8

10

12

8

All-terrain stability

9

7

11

10

Ease/Absences of assembly

10

5

1

2

Safe to stow/deploy

11

8

5

3

Aesthetically appealing

12

12

6

12

Heat resistant

9

1

1

1

16

1

3

3

3

1

8

9

10

11

12

3

3

1

3

3

3

9

9

3

9

9

1

3

9

1

9

Pinch factor less than X

X% of customers find it appealing

Withstand fuel temperatures up to X⁰F

#3 Coleman Roadtrip Gas Grill

7

#2 Uniflame Gas Tailgating Grill

6

#1 Kingsord Deluxe Charcoal Grill

3

700⁰F

3

1

Yes

3

5

Sold fully assembled

Correlations

>90%

9

4

Stable on height differences up to X"

QFD: House of Quality

73%

9

> X Pinch

factor

Compact

3

Less than X sec to clean (soap & water)

3

N/A

6

Sold fully

assembled

9

2

Set-up time less than X sec

1

No

6

Up to 10"

variation

2

0"

1

<5 min

3

N/A

9

<60 sec

9

N/A

Large cooking capacity

1

Survive X product tip overs

1

X tip overs

1

N/A

Retail cost less than $X dollars

5

1

<$75

9

$45.00

7

3

$89.00

1

3

$176.18

Weight less than X kg

1

Customer

Requirements

<20 kg

Column #

8.4 kg

9

16.8 kg

1

22.9 kg

Collapsed dimensions less than X*Y*Z cm

3

Weak

60x30x40

cm

9

92x33x56 99x25x46 64x43x48

cm

cm

cm

Can hold 16 burgers (4" round burger)

Strong

Moderate

16 burgers

1

14

burgers

Seller Importance

3

Weak

16

burgers

Manufaturer Importance

9

16

burgers

Customer Importance

Strong

Moderate

Functional

Requirements

Row #

Fig. A.5: QFD Analysis, Template from [A.4]

T e m pla t e by: C hris t o phe r B a t t le s

P ublis he d: A pril 23, 2010 P o s t e d in: DFSS

To o ls, Design & Engineering, QFD

Relationships

1

3

3

1

3

1

4

5

5

3

2

2

5

4

3

1

5

4

2

3

2

3

4

3

4

4

4

3

3

1

1

1

1

1

1

4

4

4

3

5

5

5

5

5

COMPETITION ANALYSIS

In order to assess our problem statement, and potential place for our solution we needed to

conduct rigorous research into existing products, how they’re made, product strengths and

weaknesses and potential market issues. From this we can identify market risks, important

aspects for a viable product and create a product position chart to identify the market gap.

Patent and In Store

Through the web, several patents were found for portable style grills. They were similar in nature

and function but different in methods of application. A portable grill consisting of metal panels

with slits constructed over an open flame with removable grill slits [9] by Weyandt is somewhat

crude in its design and still requires assembly. This would be cheap to produce but not appealing

to most customers. Another notable design was a stake with adjustable grilling grate similar to

test tube apparatus [8] by Walker is novel in its height adjustment and lack of many parts.

However the stake poses a danger in transport and the parts are not very compact. Local in store

research at locations such as Cabela’s, Walmart, and Meijer failed to yield a wide range of

portable grilling options. The reason for this could that with the change from summer to fall, the

inventory is turning over, which means grills would be taken off of the show floor because they

are out of season. To compensate for this possibility, all of the online retail was also checked.

This turned out to be beneficial because this is where formidable competitors were discovered.

Fig. A.6: Competitor products in order; #1Kingsford, #2 Uniflame, #3 Coleman

#1, Charcoal

#2, Propane

#3, Propane

Online Competitors

Of all the competition found there were three grills chosen that best represented the niche of the

target market. All three, pictured above in fig. A.6 have large cooking capacities (14-16 burgers)

and all are considered to be portable. Two use propane for heat and one uses charcoal; but since

heat source doesn’t rule out capacity or compactness they can all be considered legitimate

competition. The first model (1) is a “Kingsford Deluxe Portable 17in. Charcoal Grill”. The

cooking area is 240” sq., along with an 85” sq. warming rack and only weighs 8.4 kg, retailing

for $45. However this grill is not collapsible at all and it only stands 19” high. The next product

(2) is a “Uniflame 15,000 BTU Gas Tailgating Grill”. The cooking area of this grill is an

impressive 294” sq. and it also stands 39” high when erect. This grill is meant to be transported

across the ground using its collapsible scissor legs, with two of the feet being wheels. The grill

17

weighs 16.8 kg and is reasonably priced at $89, but more importantly it is very lengthy when

collapsed, making it awkward to pick up/carry and also difficult to store indoors. It also only

possesses a single burner to heat its large grate. This grill is pictured in fig. 6. The last of the top

tier competition (3) is a “Coleman RoadTrip 20,000-BTU 2 Burner Gas Grill”. This 285” sq.

cooking area is more than respectable and two independent burners are used to heat it. The lid,

side tables, legs, and drip pan are all detachable/removable; but this all requires substantial user

input. This grill is pricey at a minimum of $176 and is also quite heavy at 22.9 kg. These grills

all possess some favorable traits, but none combine the traits of the full market niche into one

complete device. Additional products researched but not included are references [1, 2, 4].

Analysis

From the products found, and by taking a look at their features we were able to find some market

opportunities. All the leading competition possess large cooking surface and this was a feature

that was of the utmost importance to almost every user surveyed. However, what none of the

competition possesses is a truly portable form that can be easily transported and then deployed to

full size once the cooking destination is reached. This is where there is market space to be filled

within the target group previously described (especially in warm climate during the summer

seasons). The survey results show that primary drivers of the market are cooking capacity and

price; but, there is also a third driver that can be concluded from combining multiple survey

results together. This driver is the ability to easily store and transport the grill. With undercutting

competitor price being a difficult area to devote product focus to, the key will be to stay in the

competitive price range while creating a product that is far more portable than those currently in

the market. Seen below in fig. A.7 is a product positioning chart that shows a very realistic

market opportunity.

Fig. A.7: Product position showing a need for a compact grill with large cooking capacity.

Portable

.

Inconvenient

18

MARKET VALUE PROPOSITION

The competition research and product positioning combined with the results of our market

research reveal the problem and segment of the market we aim to satisfy as apparent from a gap

in competing products, the typical target customer and producer needed to meet our goals.

Customer Segment

To be effective we have narrowed our focus down to specific target customer segments with the

main focus being on males in their twenties, who are recent college graduates and live in an

urban or suburban environment. These are individuals who like to be active in the outdoors and

are sociable. As a recent graduate the product needs to be inexpensive and provide the customer

with a good value by being durable. Because they will be cooking for a medium sized group of

friends, cooking capacity is essential, and this combined with the portability of such a product is

the main goal of our product. Current market competition exists from grills that are either overly

expensive, have a large cooking capacity but are bulky and hard to transport (Uniflame and

Coleman), or those that are middle of the road in terms of cooking size and compactness

(Kingsford). The team’s product will fill the void seen on pg.17 in fig. A.7 by being compact or

portable yet still retain the cooking capacity of a full size grill. As indicated from market value

research, this combination would be best suited to fit our target customer’s needs. The design

will require a producer who can provide metalworking and steel forming experience at a good

value. The product can then be offered at retail outlets and outdoors specialty stores in key areas.

As with entering any new market there will be some inherent risks that the team needs to

mitigate in order to develop a robust and successful product. In terms of the product, there is

significant safety risk. The use of burning hot coals or cooking is by itself a dangerous task, but

when using such a compact design it is possible that the grill will not necessarily be stable. If a

grill where to fall, collapse or burn an individual this would be unacceptable. Therefore, the team

has decided to focus on a stable design over a moderately uneven terrain, will have precautions

such as nonmetallic grip or handling surfaces, and will dissipate heat fast enough to not be a

danger when transported. Another risk is not being able to significantly distinguish the product

from the rest of the market which has been controlled by well-known firms. This can be

mitigated by creating a design that is very different and fulfils the target customer’s needs.

Problem Statement

From our research we have been able to refine our original problem statement to the following:

we aim to solve the problem of a lack of a portable grill that has a large cooking capacity with a

compact and easy to use design. From market research, and the QFD seen in pg. 8, there are set

metrics the team must accomplish to make a successful product. Most important to the consumer

is the cooking capacity because they will be with a group of friends, and a compact and

lightweight design that is safe and easy to set up because they want to store this at home and

bring to local parks. The grill should be stable and level on a varying terrain that might be

encountered. A reasonable price and a durable product are needed to provide value to the

customer. As with any tool in food preparation it should be easy to use, clean and be heat

resistant, because the cookout is only part of the greater overall experience. Lastly, the product

should be good looking so that it instills a sense of pride in the owner. With the aforementioned

product specifications satisfied, the target customer will be drawn to the team’s product.

19

APPENDIX B

Product Concept

20

EXECUTIVE SUMMARY

This phase of the design stage was dedicated to product concept development. The problem that

the product is aiming to solve is the need for a portable grill that has the capacity to cook for up

to ten people at a single time and can be easily transported by a single person from their home in

an urban/suburban setting to a recreation area. Therefore the attributes essential to the final grill

concept were that it needed to be completely stow-able/deployable (both the grill itself as well as

the support system) and house a grate with a large enough cooking capacity. On the basis of

safety and further product differentiation (from the current market) it was decided that the grill

would need to be able to be leveled on uneven terrain.

In order to bring about the best product design possible many conceptualization methods were

applied including brainstorming, sketching, a functional decomposition, concepts trees, and three

dimensional mock-ups. The combination of methods assured that the chosen product concept

was formed from an “all-encompassing” idea pool. Initially, brainstorming, sketches, and mockups were used to transform ideas from thought into potential design solutions. Other methods

were invoked at a later stage. The functional decomposition provided a way to break the grill

down into objectives that were required throughout the entire grilling process and helped open up

new design pathways. Operations ranged from original storage and transport, through set-up,

cooking, and cleaning, and finished with waste elimination, and stowage. Concepts trees were

generated for the three main functional aspects; grill heating element, grill stow and deployment,

and the grill support system. Through feasibility and go/no-go analysis the concept tree for the

heating element was eliminated and charcoal was deemed to be the superior choice. The tree for

grill stowing and deployment was divided into four main categories of flexible, rigid noncollapsing, rigid collapsing, and hybrid solutions. The tree for the grill support/leveling system

was divided first based on what would achieve the leveling; the grill itself or the support

mechanism. These branches were then further subdivided based on automation vs. user input.

Both of the trees were then filled down with an abundant variety of solutions.

Five concepts were generated from combinations of solutions from varying tree branches. This

was done to ensure concrete distinction among features including appearance, size, support type,

grill stowing/deploying, and overall function. The concepts were then entered into a down

selection matrix where a net score for each grill was determined. This was done through the use

of the QFD customer requirements coupled with scores given to each concept per requirement.

These scores were had a combined weight factor that encompassed customer, seller, and

manufacturer importance. The net scores were used to rank the concepts from best to worst.

From these five concepts the final concept was an alteration of one of the five that incorporated

superior features from two of the other concepts. The final proposed design concept used a

support leveling system consisting of four independent and fully adjustable telescoping legs to

allow for “all-terrain” variability. The legs will fold up flat under the kettle for storage and will

possess both quick release and automatic locking mechanisms. These will minimize user input

during deployment. The grill stowing/ deployment is accomplished using a rigid-non collapsing

structure. The lid and grate are stowed inside the kettle and there will be side trays that fold up

and lock, securing the system closed and ready for transport. There will be a handle on the kettle

for transport through carrying; and feasibility dependent, two of the hinges may also house

wheels for the capability to transport the grill in the same manner as a rolling suitcase.

21

CONCEPTUALIZATION METHODS

Several methods were used to come up with a wide range of products in order to find the best

solution to our customer’s problem including brainstorming, sketching, a concept tree, mock ups,

and functional decomposition.

Brainstorming

The first method that was used to generate concept ideas was brainstorming. This is a traditional

yet effective method. The main use was to get any and every idea that was floating around in

thought form out and on to paper. Initially brain storming was done individually to make sure no

ideas were inhibited by judgment of others. After individual brainstorming had taken place the

ideas were brought together for group discussion, and further brainstorming was done as a team.

Time was spent writing, talking, and writing some more. The goal was to leave no idea for a

grill, grill component, or even an included grill accessory off the table. References 1-10 were

used to get general concept ideas for mechanisms and other features.

Sketching

Sketching is a useful method to introduce immediately after brainstorming. The ideas generated

during brainstorming are sometimes difficult for others to follow or visualize from simple text

alone. Sketching was used to help bring clarification and life to verbal and textual concepts. This

also brought about the beginning of feasibility considerations. Seeing concepts pictured for the

first time shed light on how complicated, unrealistic, or even too simplistic different designs

could be. The combination of similar designs and compatible concepts was also done at this time

through creation of further hybrid sketches. At the end of this stage there were a few good ideas

for potential grill designs.

Concept Tree

Created and used in conjunction with the functional decomposition were some concept trees.

Rather than one tree for the entirety of the grill, two separate trees were created, one for the grill

support system and one for the grill stow/deployment system. This is the conceptualization

method that served in some radical new concept generation. Being forced to come up with

functional achievements through “opposing” methods led to a plethora of ideas by the time the

bottom of the trees were reached. Combining different branches from each of the two trees led

to even more concepts.

Mock-Ups

The last conceptualization method used were some simple concept mock-ups. These weren’t on

the level of alpha prototypes, but rather more low level 3-D models using components such as

scrap paper, tape, pencils, and other miscellaneous supplies. These were used to try to get a

better comparison between models that seemed favorable after other conceptualization methods

had been used.

Functional Decomposition

Functional decomposition is a systems level approach to design that seeks to isolate certain

necessary actions or functions into their most basic components in an attempt to deal with

complex interactions. This is accomplished by drawing the individual functions needed to

22

achieve the overall task into segments, which include the name of the part and action being

performed on it. Into and out of the box can flow material as a solid and dark line, energy such as

electrical or mechanical as a thin line, and a signal as a dashed line. Therefore, each box has

inputs and outputs and the law of conservation of energy and matter must be adhered to.

FUNCTIONAL DECOMPOSITION

The functional decomposition for the portable grill is seen on pg. 23 in fig. B.1. The grill will

start off stored most likely at the owner’s house. Therefore it will need to be transported to the

outdoors for use. Once arrived, the user will have to operate the grill to deploy it, and this should

be secure from motions like vibration or gravity, such as being locked at a set height. Then the

cooking surface must be supported and level. All of these actions require energy input for which

there will mostly be frictional losses. Now heat must be generated by some means which will

require mass in to produce heat with heat losses. The heat must be applied to the food requiring

food in, the heat generated, with more losses of heat to the surroundings but resulting in cooked

food. There needs to be a mechanism to control the heat, such as flame temperature or grill air

temperature, which will take air in but also lose heat and produce waste. These wastes will need

to be disposed of somehow, requiring energy. Then once the grill is no longer in use and cooled

down, it will need to be stowed for transport and storage, again requiring energy with losses.

23

24

Fig. B.1

1B.:

CONCEPT TREE

Creating a concept tree for a collapsible, freestanding, self-leveling portable grill was an intricate

process. The approach was to create the tree based on the grill’s functions rather than its

features. Listing features does help with the conceptualization process, but there are so many

(possible) features in a device such as portable grill that the tree turns into a random and

seemingly infinite list instead of a narrowing hierarchy of design possibilities. The main

functional components of the grill are its heating element, its stowing/deployment mechanism,

and its support system/leveling mechanism. After a few trials it was found that rather than one

large tree, three individual trees (one for each main function) were more suitable.

The first function examined was the heat source. With portability being of vast importance, the

source needed to be mobile, yet effective. There are many energy sources that can create heat,

but singling out charcoal as the top choice for our portable grill was not very difficult. It is a

mobile, readily available, time tested, and affordable source of heat for cooking. After creating

and examining a list of other heat sources, they simply could not measure up to charcoal. For

example electricity requires a plug, wood requires large quantity and volume, solar or battery

power could not provide enough energy, and nuclear power is just unsafe. The only energy

source that was even feasible was propane. It is actually a more common fuel source for portable

grills in today’s market; but the key eliminating factors for our design were the added weight,

volume, complexity, and safety issues that a propane heating element brings.

Concept Tree #1, seen on pg. 25 in fig. B.2 displays the options for the support/leveling system

of the grill. The pros and cons of this tree stem mainly from a feasibility standpoint. Aspects

such as cost, practicality, weight, and engineering complexity are all key factors that were scaled

against achieving genuine “all-terrain leveling” vs. “height-adjustable leveling”. The ideal

scenario was to create a mechanism that was simple enough to be designed and manufactured

cost-effectively while providing leveling in all three dimensions.

The grill stowing/deployment mechanism possibilities are shown in Concept Tree #2 on pg. 26

fig. B.3. There are many ways to make an item compact for storage, each with its own pros and

cons. A stackable or foldable system could allow for a completed set up that resembles current

grills on the market. This is both a pro and a con in the sense that familiarity could attract

customers and give them vote of confidence to the product’s successful functioning; however, it

could also deter them from purchasing a product that may be “too similar”. The successful

design of a crushable or roll-able grill possesses the same good-cop/bad-cop feel. Either would

be a revolutionary emergence in the market, but they would also be difficult to enter the market

with and convince customers to spend their hard-earned money on.

25

26

Fig. B.2: Concept Tree #1 for grill support system. Highlighting indicated the selected design.

27

Fig. B.3: Concept Tree #2 for grill deployment system. Highlighting indicated the selected design.

TOP CONCEPTS

In order to meet customer demands of a portable, lightweight, adjustable grill that can cook for a

group of 2-10 people, we have generated concepts which we believe meet these. Below are the 5

most viable concepts that were chosen from the conceptualizations methods, functional

decomposition and concept tree described previously. These designs were chosen by group

consensus based on a wide range of the most realistic options that were deemed feasible to

construct while meeting user demands through an iterative process. This was assessed using a

table of pros and cons with final say left to engineering judgment. Some designs were preserved

beyond feasibility to provide a wider range of design alternatives. Their design and operation

will be discussed with images to help demonstrate functionality.

Concept 1: Stow-A-Leg

The first design seen below in fig. B.4 is composed of a rectangular charcoal kettle (A) that has

four sides that can fold over to lay nearly flat. Below the kettle base is a small recessed area. The

two side folding tables (B) would fold to cover this open area. On each of the side tables is a

locking mechanism (C), and two legs (D) that lie parallel to the surface and rotate to a full

vertical position with the tables folded out. These store compactly within the base of the

collapsed kettle. The rectangular lid (E) will serve as the storage box with the grate (F) in it,

tools, and the collapsed kettle and leg assembly. This will have handles to carry or be worn as a

backpack. The charcoal and debris will have to be removed by manually dumping prior to

folding the mechanism.

Fig. B.4: Rectangular collapsible kettle

with folding stow-able legs.

E

A

C

B

D

F

28

Concept 2: Portable Tire Grill (Hot Wheel)

The second design is seen on below in fig. B.5, and is composed of a wheel (A) and handle (B)

that breaks down into pieces in order to form a fixed height grill grate (C) on a single stand (D).

This stand would either utilize a base (E) or would just allow insertion in the ground in the case

of cooking on a soft surface such as grass (city park) or sand (beach). At its fully collapsed form,

the grill resembles a kid’s toy. It is composed of a wheel and a handle for the user to pull the

wheel back to their car from the cooking grounds. The wheel splits up into separate parts; the

charcoal container, the grate, a lid, and the base support. The handles are the supports for the

grill, either as stakes or the struts connecting the base to the kettle.

Fig. B.5: Rolling wheel with charcoal

canister and supports.

Fig. B.6: Backpack grill with

collapsing telescoping legs in the basin.

A

E

D

B

A

E

D

C

C

B

Concept 3: Backpack with Telescoping Legs (Port-a-grill)

The third design, seen above in fig. B.6 is composed of a rectangular box shape kettle (A)

supporting a rectangular grill grate (B) with telescoping legs (C) that can be lengthened and

shortened in three discrete increments and will fit into the corners of the kettle when stored. The

lid (D) which covers the top of the grill has straps (E) like a backpack, so that when the grill is

fully broken down, the kettle, grill grate and telescoping legs fit into the box and if the top of the

box is covered by the lid, it becomes a backpack. This aspect helps people carry it easily. In

addition, utensils and cooking tools are attached inside of the lid. The lid is also made of heat

insulating material so that people do not feel any heat and get burned while carrying it over their

29

shoulder. When grilling is done, the scoop shape tool attached inside of the lid could be used to

scoop and dump the leftover charcoal out of the box.

Concept 4: Folding legs (ORi-Grill-Me)

The fourth design is seen below in fig. B.7. The top half of the grill is composed of the

rectangular main grill body (A), which is where the cooking grate (B) rests on recessed pins

below the top plane. These are removable so the grate can be lowered and the lid (not pictured)

when flipped upside down will fit above the grate and below the plane of the top surface. The

grate will rest on a removable ash catching tray (C) at the bottom of the kettle that will be where

coals are placed when in use. Two side folding tables, (D) will be hinged to fold parallel to the

top plane of the grill and then will flip over the top surface and latch creating a cover to keep the

grate and lid in place. The lid will have a built-in thermometer and the base will have a small

level and handles on the shorter sides of the rectangular grate made of a temperature resistant

plastic. Each of the shorter sides will have a leg mechanism made of 2 bars (E) connected

together at the bottom with a base (F) by a pin joint within slots similar to exercise benches. This

mechanism will fold upon itself for storage where the base protrudes from the sides to allow for

carrying. Wheels can be added to the pin joint of one side to allow for the grill to be transported

like a wheeled backpack. There will be a locking/release mechanism to allow the legs to be

stowed safely and another mechanism to lock them in the fully extended position by supporting

the central knee joints of the linkage.

Fig. B.8: Rolling wheel with charcoal

canister and supports.

Fig. B.7: Rolling wheel with charcoal

canister and supports.

B

D

C

C

B

C

A

E

C

A

G

C

F

C

D

C

E

C

F

30

Concept 5: Pneumatic piston legs (JackD Up)

The fifth design, seen on page 29 in fig. B.8 has pneumatically actuated legs which deploy to the

user- desired height. The top half of the grill is composed of the kettle (A), which is where the

charcoal is placed. The grate (B) would rest on folding tabs within the kettle. The grate can be

lowered into the kettle and the lid (C) will cover the grill when in operation and latch to the

kettle when being transported. It has handles to allow for the grill to be carried. On each of the

shorter of the two sides of the kettle will be a support structure similar to a folding table. Two

telescoping legs (D) at each corner will connect to a fixed base (E) and pivot under the grill main

body for storage. A lever will release the locking pin to store them in that manner allowing them

to swing outward and down at an angle greater than 90 degrees for stability. Then the user can

pull another lever as lifting up the grill. This will serve to open a valve in a pneumatic gas

cartridge (F) at the center of each support mechanism. When puled, the user can lift the grill to

the desired height and level with ease. Releasing the handle will stop the motion. To collapse the

mechanism, the user again pulls this handle but this time pushes down on the grill to collapse it,

then pulls the other lever to fold it up and lock in place for transport. There will be wheels (G) at

the end without the levers, and the other short end of the grill will have a pulling handle to

facilitate transportation.

CONCEPT SELECTION

During the transition stage of the product development, the weakest concepts were excluded

using a down-selection pool. By taking into account the three-hundred dollar-budget, the parts

that already exist in the market, the duration until delivery, and the 3 weeks to build and test the

proof of concept for the design expo, the two ME Machine Shop supervisors were consulted in

order to determine the difficulty of fabricating potential designs. These steps concluded the

technology readiness assessment, and eventually a go/no-go screening, which also evaluated

artistic principles and marketability of the product. These methods were combined in order to

select the top five concepts for final consideration. From here, a more sophisticated process was

formulated in order to adopt the final design by developing a down-selection matrix, as seen in

fig. B.9 on pg. 31. This matrix utilizes the data from the QFD as well as both absolute and

relative comparison against the requirements needed to solve the market problem:

The top five concepts for the final design were #1 Stow-A-Leg, #2 Hotwheel, #3 Port-A-Grill, #4

Ori-Grill-Me, and #5 JackD Up. Individual ratings per criterion were assigned on a 1-5 scale

with 1,2,3,4,5 representing worst, worse, same, better, and best respectively. These ratings were

devised by choosing the best concept in that category, assigning a 3-rating and then assigning the

rest comparatively. The weight factors represent an average of customer, manufacturer and seller

importance according to the QFD. In the QFD, the ranking ranges from 1-12 with 1 being the

most important and 12 being the least. These are assigned based on information gathered through

surveys and manufacturing experience as explained in the Analysis of Requirements and

Competitor Products section of the Initial Hypothesis Market Testing and Evaluation for Gate

Review 1 appendix. The rankings have been normalized in this case by subtracting the ranking

from 12 and then averaging. Therefore, in fig. B.9, the highest weight factor is eventually given

to the criterion of greatest average importance. Then weighted scores per category are calculated

by multiplying the rating by the normalized weight. Finally, the net score for each concept was

derived by dividing the sum of the weighted scores per concept by the sum of the normalized

weight factors. The best score was then adopted and the next two highest concepts’ features were

31

also considered for incorporation into the winning concept, leading to the creation of a hybrid

with folding and telescoping legs. Despite certain advantages, Hotwheel and JackD Up were

eventually ruled out. Although the Hotwheel was to be particularly compact, inexpensive and

easy to use on variable terrain it was eliminated due to low cooking capacity, and even more

importantly due to its requirement of extensive user-input. The JackD Up concept was not

chosen because it would be very costly, heavy and hard to assemble despite requiring minimal

user input.

Fig. B.9: Down-selection matrix used to determine the selected concept.

Among the three concepts that were combined to form the final concept, the Stow-A-Leg

concept was not very user-friendly, or all-terrain stable but certainly was safe to stow and

deploy, while also meeting the lightweight requirement. Port-A-Grill, which was found to be the

best, is characterized by an overall satisfactory level (3-rating) for all criteria, with higher ratings

in the cases of user-friendliness, weight, stability and safety. Finally, the last concept whose

features were used for our hybrid, the Ori-Grill-Me, was heavy and lacked good stability but was

very favorable in design for assembly and aesthetics.

32

PROPOSED CONCEPT

With the aid of concept selection techniques such as down-selection and extensive discussion a

final design was able to be synthesized from three of the existing concepts, one, three, and four.

This ensured that only the best features of each feasible design were used to offer the customer

the most portable inexpensive grill with a full size cooking grate that can be made level on many

surfaces encountered by the user during the intended operation.

Fig. B.11: Photos of the prototype in the

fully deployed and stowed modes.

Fig. B.10: Drawing showing collapsible

tables, grate position, ash tray, and the

folding and telescoping legs.

Deployed

E

F

C

Top Sect.

A

D

B

Stowed

Bot. Sect.

G

B

DEVELOPMENT TEAM

Leg/ Kettle

Interface

The final design is seen above in fig. B.10 in conceptual drawing form and again in fig. B.11 as

photographs of the alpha prototype. This prototype serves both as a functionality and feasibility

check and also gives potential users or decision makers a better understanding in three

dimensions. From the grill concept tree, this follows the path of a rigid, non-collapsible design

with stacking grill elements and removable ash-dump drawer. Notice the top half of the grill is

composed of a rectangular kettle (A), which will have adjustable vents for airflow, an opening at

the bottom front and a built in level. Situated in this opening is the removable ash catch can (B)

which will also store the grill grate (C) when in the stored position and the charcoal during

cooking. The grate will rest on spring-loaded pins (D) on the shorter of the two sides and will be

slightly recessed below the top plane of the kettle. A lid (E) will rest over the crate and be

33

secured by the raised edge of the kettle while in use and stored in the kettle after the spring pins

are released and the grate falls into the ash tray. The lid will have a thermometer in it, a

temperature resistant handle, an adjustable opening to control flame temperature and space

underneath to secure tools. The folding side tables and supports (F) will extend to be parallel to

the top plane of the kettle when in use and provide space to store items. For storage, the tables

will fold over the now packed lid and sit flush with the kettle upper edges. A weather-strip will

be used to create a seal between the two and also prevent items from rolling off the tables or

debris from entering the kettle. A latching mechanism will keep the tables (doors) shut while in

motion. The grill itself will have handles on the shorter edges for carrying when in transport with

an optional wheel set on one end and extendable handle on the other. This comprises the top half

mechanism, which is its own subsystem and will interface with the supporting bottom section at

mounts to the kettle.

From the concept tree for the supports, the bottom half of the design is a telescoping mechanism

composed of four folding legs (G) with adjustable independent height and bar clamp style locks

to be actuated by a lever or other input with safety mechanism. In this case, the independent

supports provide the grill leveling. A pivot mechanism will lock the legs in the stored position as

well as at and beyond 90 degrees and will allow rigid rotation only in one plane. These legs will

store in a section below the kettle base and hidden from view by having the kettle exterior sheet

metal extend below the visible plane of the folded legs thus ensuring a safe and compact design.

34

APPENDIX C

Detailed Product Design

35

EXECUTIVE SUMMARY

The third phase of the design process focused on the creation of the complete design and

manufacturing plan for the proof of concept model of the All-Terrain Grill (A.T.G.). An alpha

prototype was created for the chosen concept, but this concept needed to be transformed from a

prototype into a fully functioning grill. When generating the A.T.G. there were key drivers that

influenced design decisions. These drivers were determined by looking at feedback from market

research, evaluating user interaction with the grill at multiple phases, and most importantly by

focusing on the safety of the product. It was found that the key design drivers for the A.T.G. are

the stability and strength of the telescoping legs/leg locks, the size and weight of the stowed grill

in relation to storage and transport, a large cooking capacity, proper heat distribution and

cooling, and lastly, minimal/simple user input for both deployment and stowing.

With these drivers in mind, design specifications were further refined. The first order of business

was to find a grate with large cooking capacity. The grate is the keystone component of the grill

because it (directly or indirectly) dictates the sizing of every other part. Grill grates are available

for purchase independently, and by making a quick trip to the local Lowes it was easy to

compare all makes and models. A steel 24.375 by 14 inch grate was chosen for the prototype to

give maximum cooking capacity while also coming close to achieving the golden shape ratio at a

relatively inexpensive price. A steel grate of this side would be self-manufactured for production

of the A.T.G. Next up was determining material type for the grill kettle, lid, and ash drawer.

Research was conducted on current charcoal grills in the market to find out what material type

and thickness is currently successfully being used in industry. Sixteen-gauge steel was found to

be the most common material used to construct the kettle/lid. The material properties of this steel

were then analyzed and compared to alternatives using CES EduPack 13 to be sure it was the

best option to meet the needs of the A.T.G. This evaluation found steel to be the most

appropriate material based on its properties of melting temperature, yield strength, fracture

toughness, and hardness. Looking to work with a local supplier to save time, Alro Steel was

discovered. They are located in Ann Arbor and have the ability to supply and cut the steel to the

desired dimensions. Keeping with the mentality of using components that were both cost and

time efficient, McMaster Carr was looked in to. Here the design team was able to find and

compare (pre manufactured) telescoping tubing along with all types of hinges, handles and other

assorted components needed to build the A.T.G. proof of concept. McMaster Carr has been a

successful supplier in the past and always provides efficient shipping of very high quality

parts/materials. All hardware for the mass manufactured model will be purchased from bulk

suppliers along with the steel tubing to construct the telescoping legs. The specifics of all

components to be ordered/manufactured were established by applying basic engineering

principles (static force and moment analysis) and FMEA analysis. These calculations along with

comparison tables of cost, availability, material properties, etc. are thoroughly explained in a

later section of this report.

There were many facets that needed to be carefully analyzed when designing the A.T.G. Not

only does the grill need to be designed for cost effective, efficient production; but, designing for

aspects such as manufacturability, the environment, human interaction, and testing also have

very important roles to play. The A.T.G. was designed with ease of manufacturing and assembly

in mind. If this product were launched, the goal would be to have to it be both manufactured and

assembled in house. This means that the only tasks the customer would have to carry out are

36

going to the store, purchasing the grill, taking it out of the box, and throwing on some burgers.

Components were designed to be simple and intuitive, with shapes that are aesthetically pleasing

yet quickly manufacturable. There is also a need to be able to thoroughly test a product before