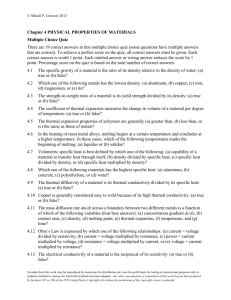

2 MB PowerPoint

advertisement

Overview of the Thermoelectric Properties of Yb-filled CoSb3 Skutterudites Gary A. Lamberton, Jr.1 Terry M. Tritt2 R. W. Ertenberg3 M. Beekman3 George S. Nolas3 1 National Center for Physical Acoustics, University of Mississippi 2 Department of Physics and Astronomy, Clemson University 3 Department of Physics, University of South Florida Outline • Introduction to Thermoelectric Materials • Previous Skutterudite Research and Promising Results • Description of Measurements • Research and Results • Conclusions Thermoelectric Applications • Power Generation • Radioisotope Thermal Generators (RTGs) • Cassini, Voyager missions • Lifespan of more than 14 years • Waste Heat Recovery • Large scale – Power Plants •Small scale - Automobiles Thermoelectric Applications •Active Cooling/Warming • Localized cooling • CPUs • Biological specimens • Commercial Coolers/Warmers • Luxury Vehicles – Cool/Warm Seats Thermoelectric (TE) Effects Seebeck Effect Material A Differential Thermocouple T + T T Vab α= ΔT Material B Material B V TE Effects Electric Current Peltier Effect Material Difference in A εF between Materials A and B Material B Heat Absorbed or Expelled TE Couple and Module Heat Source P N Heat Sink I Power Generation Mode Active Cooling P N Heat Rejection I Cooling Mode Operating Modes of a Thermoelectric Couple T. M. Tritt, Science 31, 1276 (1996) Modules www.marlow.com Thermoelectric Materials Figure of Merit: 2T ZT ( e g ) - Seebeck Coefficient - Electrical Resistivity - Thermal Conductivity e – Electronic ≈ L0T/ρ (W-F relation) g – Lattice Current Materials AgPbmSbTe2m Terry M. Tritt & Mas Subramanian MRS Bulletin TE Theme, March 2006 ZT Requirements For a ZT = 1, e.g. Optimized Bi2Te3 (300 K) – Resistivity ~ 1.25 mΩ-cm – Thermopower ~ 220 μV/K – Thermal Conductivity ~ 1.25 Wm-1K-1 For a ZT > 2, Assuming a hypothetical g = 0, a Thermopower ≥ 220 μV/K is required → Semiconductors and Semi-metals Skutterudite Structure 2M8Pn24 or M4Pn12 Metal Atom (Co, Rh, Ir) Pnicogen Atom (P, As, Sb) Void Space/Filler Ion History • Discovered in Skutterud, Norway • Studied in the 1950s-60s for potential thermoelectric applications (binary) • Sparse research until the early 1990s – Slack’s Phonon Glass – Electron Crystal Concept T ZT e g 2 IrSb3 and Ir0.5Rh0.5Sb3 • Mass fluctuation scattering reduces the lattice thermal conductivity to 58% of the original value • ‘Rattling’ ion concept suggested as a means to reduce g Slack et al., J. Appl. Phys 76, 1665 (1994) • Order of Magnitude Reduction • Ge substitution could only reduce to 30% • CeFe4Sb12 has g 10% of that of FeSb3 • “Rattling” of Void Filling Ion is the source of the reduced g Lattice Thermal Conductivity (mW/cmK) “Rattlers” Reduce g Temperature (K) G.S. Nolas, et al., J. Appl. Phys. 79, 4002 (1996) Previous Work CeFe4-xCoxSb12: ZT ~ 1.4 (900 K) JPL Fleurial, et al., Proc. 16th International Conference on Thermoelectrics, IEEE Catalog Number 97TH8291, Piscataway, NJ, p. 1 (1997) Ce “Rattlers” in CoPn3 • Fe4Sb12 has largest cage size • More efficient scattering with heavier atoms in the lattice Watcharapasorn et al., J. Appl. Phys 91, 1344 (2002) • Partial Filling Yields Largest Reduction • Increased Disorder • Less Impact on Band Structure Lattice Thermal Conductivity (mW/cmK) Partial Void Filling La-filled CoSb3 Temperature (K) G.S. Nolas, J. L. Cohn, and G. A. Slack, Phys. Rev. B 58, 164 (1998) Eu0.42Co4Sb11.37Ge0.50 • Reduced Thermal Conductivity • Increased Carrier Mobility • Maintained favorable electronic properties Lamberton et al., Appl. Phys. Lett. 80, 598 (2002) Sample Synthesis Dr. George S. Nolas (USF/Marlow) • Stoichiometric amounts of high purity elements mixed and reacted at 800 ˚C under Ar atmosphere for 2 days, ground, and reacted at 800 ˚C for 2 additional days • Resulting polycrystalline powders were densified using a HIP at 600 ˚C for 2 hours • Compositional analysis by Electron Microprobe Measurement of Electrical Resistivity and Seebeck Coefficient (10 – 300 K) • Helium flow cryostat and closed-cycle refrigerator • High Density of Data 2 samples simultaneously – 24 hours per experiment •Typical sample size: 2-4 mm x 2-4 mm x 6-10 mm •Mounted on chip that plugs into system Pope et al, Rev. Sci. Instrum. 72, 3129 (2001) Resistivity and Thermopower Heater I+ VTEP + IHeater Cu block VR+ Sample VRVTEP I- Heater Power, P = I2R, creates ΔT for Thermopower Measurement T VR 4-probe Resistivity Measurement: Current Reversed to Subtract Thermoelectric Contribution IR VTEP - - I R - VTEP Cu block 2 High Temperature Resistivity and Seebeck Measurement Cu Block PRT Sample Ceramic Posts Cartridge Heater • Operating Range of 100 – 700 K • Standard 4-probe Resistivity Measurement • Voltage vs. ΔT Sweeps at Each Temperature Thermal Conductivity Closed Cycle Helium Cryostat 12 – 300 K Strain Gauge Sample Cu block Differential Thermocouple mil) (1(1mil) Solid State Heat Flow Method P KT L κ K A A. L. Pope et al., Cryogenics 41, 725 (2001) Thermal Conductivity Analysis -1 -1 Thermal Conductivity (Wm K ) Thermal Conductivity Extrapolation 3.5 • TC Measured from 10 – 300 K 3.0 2.5 • measured from 10 – 300 K and from 100 – 700 K 2.0 1.5 Measured Curve Fit Total Wiedemann-Franz 1.0 Lattice = 0.5 - Total g e g Wiedemann-Franz Curve Fit + WF g e e 0.0 0 100 200 300 400 500 600 700 800 Temperature (K) • e calculated using WiedemannFranz relation from 10 – 700 K YbxCo4GeySb12-y Dilley et al. • Intermediate valence detected in YbFe4Sb12 between 2+ and 3+ • Heavy Fermion behavior at low temperature • Low carrier density leads to relatively high resistivity, ~ 3 m-cm at 300 K • ZT < 0.02 at 300 K Dilley et al., Phys. Rev. B 58, 6287 (1998) Dilley et al., Phys. Rev. B 61, 4608 (2000) Motivation for YbxCo4Sb12 • RE-filled Skutterudites have shown relatively large Figures of Merit – Reduced Lattice Thermal Conductivity • Yb – Large Mass, Small Atomic Radius – Electronic Properties Sensitive to Doping Level • Reported Mixed Valence in YbFe4Sb12 – Heavy Fermion Behavior • Increased Seebeck Coefficient Reduce g + Increase High ZT High Figure of Merit • Suggests rigidband behavior (maintain electronic properties) with varying Yb concentration (x = 0.066, 0.19) • HF behavior leads to high power factor Nolas et al., Appl. Phys. Lett. 77, 1855 (2000) Concurrent Research • Anno et al – ZT ~ 1 (700 K) in Yb0.25Co4Sb12 and Yb0.25Co3.88Pt0.12Sb12 • UCSD and GM: YbyCo4Sb12-xSnx – x > 0.8 reduces Seebeck Coefficient • p-type if x > 0.83 – Lattice Thermal Conductivity reduced • Dependent upon Yb concentration • Unaffected by Sn compensation Resistivity (m-cm) YbyCo4Sb12-xGex Yb 0.066 4 12 Yb Co Sb Yb Co Ge Sb Yb Co Ge Sb Yb Co Ge Sb Yb Co Ge Sb 0.19 20 Co Sb 0.49 0.65 0.46 0.46 10 4 4 4 4 4 12 1.00 0.96 0.79 0.86 10.92 11.21 11.21 11.13 0 0 200 400 600 Temperature (K) 800 • Different Temperature Dependence • Magnitude Scales with Ge Concentration • Decreased Mobility 0 -100 -200 -300 Seebeck Coefficient (V/K) YbyCo4Sb12-xGex 0 Total 0 n n p p n p Yb0.066Co4Sb12 Yb 0.066 Co Sb 4 12 Yb Yb CoCoSb Sb 0.190.19 4 4 1212 -100 Yb CoCoSb Sb (Sales) (Sales) Yb0.20 0.20 4 4 1212 Ge Sb Sb Yb Yb0.49 CoCoGe 4 1.00 10.92 0.49 -200 Yb Yb 4 Co Ge 4 Co Ge 0.65 0.65 1.00 4 10.92 0.96 Sb Sb 11.21 0.96 11.21 Yb Co Ge Sb Yb Co Ge Sb 4 0.79 11.21 Yb0.460.46 Co4Ge Sb 0.79 11.21 -300 Yb 0 200 200 400 600 Temperature 400 600 (K) 800 800 0.46 0.46 4 Co Ge 4 0.86 0.86 Sb 11.13 11.13 y = 0.066 5 • Reduction over Parent CoSb3 ~ 8 Wm-1K-1 @ 300K SK181 Sk193 SK281 Sk282 SK283 SK284 -1 -1 (Wm K ) Lattice Thermal Conductivity YbyCo4Sb12-xGex 3 y > 0.19 1 0 100 200 Temperature (K) 300 • Varies More Than Sn Compensated Samples (Yang et al) YbXCo4GeYSb12-Y Figure of Merit – Yb-filled CoSb3 1.2 Yb Co Sb Yb Co Sb Yb 0.066 0.19 12 Co Sb 12 0.066 4 12 4 Co Sb Yb Co SbYb0.19 (Sales) 4 12 0.8 ZT 0.2 Yb Co Sb Yb 0.49 Yb 0.65 200 400 600 Temperature (K) 800 3.88 0.12 Yb 4 12 Co Pt 3.88 (Anno) 0.25 12 Yb Co Sb Co Ge 0.25Sb4 4 12 0.49 4 Sb 1.00 Yb0.96 Co11.21 Ge 0.65 4 Sb 12 (Anno (Anno) Yb1.00 Co10.92 Ge Co Ge 4 0.12 0.96 Sb Sb 10.92 11.21 Yb Co Ge Yb Yb Co Ge Yb Sb Co Ge Sb 0.46 4 0.86 11.13 0.46 0 12 Sb (Anno) (Sales) Co Yb Pt0.2CoSb 4 12 0.25 0.4 4 Yb 0.25 0.0 4 0.46 4 4 Sb Co11.21 Ge Sb 0.79 0.46 4 0.79 11.21 0.86 11.13 Sales, B., March APS (2002) H. Anno et al., Mat. Res. Soc. Symp. Proc. Vol. 691, 49 (2002) G. S. Nolas, M. Kaeser, R. T. Littleton IV, and T. M. Tritt, Appl. Phys. Lett. 77, 1855 (2000) ZT vs. Yb Concentration 1.2 •Sensitive to Yb Concentration 0.8 Yb Solubility Limit ZT (600 K) 1.0 0.6 0.4 0.2 0.0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 Yb Concentration •Maximum Figure of Merit ~ 0.20 Yb Concentration Conclusions • Yb-doped skutterudites show significant promise for thermoelectric applications • Figure of Merit - Sensitive to Yb concentration • Ge Charge Compensation – Reduces Seebeck Coefficient at Elevated Temperatures – Reduces Carrier Mobility Leading to Increased Resistivity Future Direction • Yb ~ 0.20 concentrations • High temp YbxCo4Sb12-ySny data y 0.80 • Focus on keeping large magnitude thermopower while incorporating ‘rattling’ atoms – Beware of charge compensating – Perhaps Co site Acknowledgements • Dr. Terry M. Tritt (Dissertation Advisor) • Dr. George S. Nolas – Synthesis • NASA South Carolina Space Grant • Project Supported through: – Clemson - DOE EPSCoR Partnership Grant No. DOE-DE-FG02_00ER45850