Production and operation management an introduction

advertisement

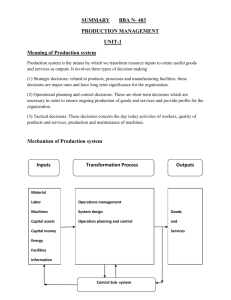

Production and Operations Management (POM): An Introduction Presented by: Anamika Sharma 1 Introduction • Production and operations management (POM) is the management of an organization’s production system. • A production system takes inputs and converts them into outputs. • The conversion process is the predominant activity of a production system. • The primary concern of an operations manager is the activities of the conversion 2 process. DEFINITION OF PRODUCTION MANAGEMENT It may be defined as: (i) The performance of the management activities with regards to selecting, designing, operating, Controlling and updating production system. (ii) It is the processes of effectively planning, coordinating and controlling the production, that is the operations of that part of an enterprise, it means to say that production and operations Management is responsible for the actual transformation of raw materials into finished products. Operations Management Operations Management (OM) Operations management is defined as the design, operation, and improvement of the systems that create and deliver the firm’s primary products and services. (Development and administration of the activities involved in transforming resources into goods and services.) Processes and Operations Internal and external customers • • • • • • • • Inputs Workers Managers Equipment Facilities Materials Services Land Energy Processes and operations 1 3 5 2 4 Information on performance Outputs • Services • Goods Scope of POM Maintena nce mngt Locationof facilities Material management Scope of p.o.m. Quality control Production planningand control Plant layout Product design Process design Key OM Concepts • Efficiency - Doing something at the lowest possible cost • Effectiveness - Doing the right things to create the most value for the organization • Value - Quality divided by price 8 Service or Good? • “If you drop it on your foot, it won’t hurt you.” (Good or service?) • “Services never include goods and goods never include services.” (True or false?) 7 Product Manufacturing system often produces standardized products in large volumes. The plant and machinery have a finite capacity. The facilities constitute fixed costs, which are allocated to the products produced. Variable costs, such as, labor cost and materials costs. While manufacturing the product use value and economic values are added to the product. Hence the product is a store of values added during manufacture. Because the input costs and output costs are measurable, the productivity can be measured with certain degree of accuracy. Product can be transported to the markets and stored physically until it is sold. Service Service system present more uncertainty with respect to capacity and costs. Services are produced and consumed in the presence of the customer. We cannot store the service physically. Because of this the service organizations, such as Hotels, Hospitals, Transport Organizations and many other service organizations the capacity must be sufficiently or consciously managed to accommodate a highly variable demand. Sometimes services like legal practice and medical practice involve Professional or intellectual judgments, which cannot be easily standardized. Because of this the calculation of cost and productivity is difficult. Types of production system Manufacturing system Service system Continuous production Intermittent production Batch production Mass production(flow Processing production Job production Production system • The production system is the framework with in which production activities of an organization are carried out. At one end of the production system are the inputs and at the other end outputs. Input and output are linked by certain operations or process or activities imparting value to the inputs. The processes, operations or activities may be called production system. The nature of production system may differ from company to company or from plant to plant in the same firm. Basic production system • Continuous production system ( production to stock or make to stock). • Intermittent production system ( production to order or make to order (a) Continuous production system • It involves a continuous or almost continuous physical flow of material. It makes use of special purpose machines (SPMs) and produced standardized items in large qualities. Characteristics • Division of labor is done more efficiently. • Material handling is minimized. • Small work in progress and less supervision Advantages • Reduced labour cost. • Reduce material handling. • Better methods of material control. • Better return on investment. Disadvantages • Adjustment to new situations and specifications because difficult, particularly in the present period where stock demand is causing huge losses Types of continuous production • 1. Mass production Mass and flow production is a production system designed to produce several standard products in mass quantities. This type of system has a capability to produce large quantities of products there by providing the management with the advantage of economic of scale. Only one type of product or maximum 2 or 3 types of products are manufactured in large quantities and much emphasis is not given to retail consumer orders. • Example: petrochemical industry, cement industry, steel industry, sugar industry, cigarette industry, fertilizer industry etc. 2. Process production • Process production is defined as a system for production where a similar product is produced continuously in large quantities, year after year. This system is used for manufacturing those items whose demand is continuous or high. Here, single raw material can be transformed into different kinds of products at different stages of the production process. • Example: wire drawing, alloy steel manufacturing (ASP, durgapur), rolling mills, crude oil refinery- kerosene, gasoline, etc. can be procured at different stages of production Characteristic • Special purpose machines with built in controls. • Low skilled labour. • Negligible work in progress. • Limited production planning and control functions Intermittent production system • In this system, the goods are manufactured specially to fulfill orders by customers rather than producing against stock. Here, the flow of materials is intermittent. Intermittent systems are those where the production facilities are flexible enough to handle a wide variety of products and size (e.g. switchgear industry). Considerable storage between operations is required so that individual operations can be carried out independently for further utilization of men and machines. Characteristics of IPS • Products are manufactured in small quantities. • Highly skilled workers are required. • Large work in progress. • Flexible to suit production varieties. Advantages IPS • Can adjust to new situation and specifications. • Items can be manufactured according to order and hence fluctuations in demand can easily be taken care of. Disadvantages IPS • As production is in small quantities, the cost of production per unit is high. • Initial heavy investment. • More inventory and large space required Types of intermittent • 1. Job production • Job production is production of a single complete unit by one operator or a group of operators. Here, whole project is considered as one operation and work is completed on each project before passing on to the next. Each product is a class by itself and requires a distinct and separate job for production process. The system requires versatile and highly skilled labour with high capital investment. • Example: bridge building, dam construction, ship building etc Characteristics • Small production runs. • Highly competent knowledge supervision • Large work in progress. • Discontinuous flow of materials Batch production • . • Here, items are processed in lots or batches and a new batch is undertaken for production only. When the production on all items of a batch is complete. In fact, batch type production can be considered as an extension of job type system. Example: chemical industry, production of machine tools and printing press etc. Characteristics • Short runs • Skilled labour in specific trades. • Large work in progress. • Flexibility of production schedule Project production • It can be defined as a set of activities performed to produce a single product. There product here is immobile and different agencies with different skill sets are deployed on that product to complete it. • Example: road lying companies, construction companies, large scale fabrication companies etc. • Characteristics • Definite beginning and definite end. • High cost over runs. • Scheduling and control. Difference between cps-Ips cont Continuous production Intermittent production 1. There is continuous flow of row material The flow of row material is in batch es or lots. 2. It is not against a specific order but against a stock order. It is against order. 3. It is not flexible. It is flexible and can be shifted to other places. 4. It include two methods a. Mass production b. Process production It include three methods Job,Batch,project production 5. Cost of labour is low Cost of labour is very high Operations Management Decision Types • •Strategic (long-term) •Tactical (intermediate-term) •Operational planning and control (short-term) Strategic Decisions • These decisions are of strategic importance and have long-term significance for the organization. • Examples include deciding: – the design for a new product’s production process – where to locate a new factory – whether to launch a new-product development plan 29 Operating Decisions • These decisions are necessary if the ongoing production of goods and services is to satisfy market demands and provide profits. • Examples include deciding: – how much finished-goods inventory to carry – the amount of overtime to use next week – the details for purchasing raw material next month 30 Control Decisions • These decisions concern the day-today activities of workers, quality of products and services, production and overhead costs, and machine maintenance. • Examples include deciding: – labor cost standards for a new product – frequency of preventive maintenance – new quality control acceptance criteria 31 32