Chapter 9

Six-Sigma Quality

McGraw-Hill/Irwin

Copyright © 2011 The McGraw-Hill Companies, All Rights Reserved

Learning Objectives

1. Understand total quality management.

2. Describe how quality is measured and

be aware of the different dimensions

of quality.

3. Explain the define, measure, analyze,

improve, and control (DMAIC) quality

improvement process.

4. Understand what ISO certification

means.

9-2

Key Six Sigma Concepts

• Critical to quality: attributes most important

to the customer

• Defect: failing to deliver what customer wants

• Process capability: what your process can

deliver

• Variation: what customer sees and feels

• Stable operations: ensuring consistent,

predictable processes to improve what the

customer sees and feels

• Design for six-sigma: designing to meet

customer needs and process capability

LO 1

9-3

Total Quality Management (TQM)

•

•

Total quality management:

managing the entire organization so

that it excels on all dimensions of

products and services that are

important to the customer

Two fundamental operational goals:

1. Careful design of the product or service

2. Ensuring that the organization’s systems

can consistently produce the design

LO 1

9-4

Malcolm Baldridge National Quality

Award

• Established in 1987 by Department of

Commerce

• Goal is to help companies review and

structure their quality programs

• Has requirement that suppliers

demonstrate they are measuring and

documenting their quality practices

LO 1

9-5

Quality Specifications and Quality

Costs

• Design quality: inherent value of the

product in the marketplace

• Conformance quality: degree to which

the product or service design

specifications are met

• Quality at the source: the person who

does the work takes responsibility for

making sure it meets specifications

LO 1

9-6

The Dimensions of Design Quality

• Performance: primary product or

service characteristics

• Features: added touches, bells and

whistles, secondary characteristics

• Reliability/durability: consistency of

performance over time

• Serviceability: ease of repair

• Aesthetics: sensory characteristics

• Perceived quality: past performance

and reputation

LO 2

9-7

Cost of Quality

•

Basic cost assumptions

1. Failures are caused

2. Prevention is cheaper

3. Performance can be measured

•

Cost of quality

1.

2.

3.

4.

Appraisal cost

Prevention cost

Internal failure cost

External failure cost

LO 2

9-8

Six-Sigma Quality

• Six-sigma is a philosophy and methods

used to eliminate defects

• Seeks to reduce variation in the

processes

• One metric is defects per million

opportunities (DPMO)

LO 2

9-9

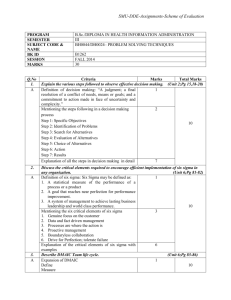

Six-Sigma Methodology

• Uses many of the same statistical tools

as other quality movements

– Used in a systematic project-oriented

fashion through define, measure, analyze,

improve, and control (DMAIC) cycle

• More detailed version of Deming PDCA cycle

• Continuous improvement: seeks

continual improvement in all aspects of

operations

– Also uses scientific method

LO 2

9-10

DMAIC Methodology

1. Define

–

–

–

Identify customers and their priorities

Identify a project

Identify critical-to-quality characteristics

2. Measure

–

–

Determine how to measure the process

Identify key internal processes

3. Analyze

–

–

Determine most likely causes of defects

Understand why key defects are generated

LO 3

9-11

DMAIC Methodology

Continued

4. Improve

– Identify means to remove causes of

defects

– Confirm the key variables

– Identify the maximum acceptance ranges

– Modify process to stay within acceptable

range

5. Control

– Determine how to maintain improvements

– Put tools in place to track key variables

LO 3

9-12

Analytical Tools for Six Sigma and

Continuous Improvement

•

•

•

•

•

•

•

Flowcharts

Run charts

Pareto charts

Checksheets

Cause-and-effect diagrams

Opportunity flow diagrams

Control charts

LO 2

9-13

Six Sigma Roles and

Responsibilities

1. Executive leaders must champion the

process of improvement

2. Corporation-wide training in Six Sigma

concepts and tools

3. Setting stretch objectives for

improvement

4. Continuous reinforcement and

rewards

LO 3

9-14

ISO 9000 and ISO 14000

• Series of standards agreed upon by the

International Organization for

Standardization (ISO)

– Adopted in 1987

– More than 160 countries

• A prerequisite for global competition?

• ISO 9000 an international reference for

quality, ISO 14000 is primarily

concerned with environmental

management

LO 4

9-15