Biosurface Modification

advertisement

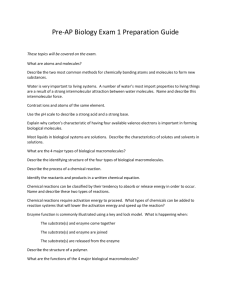

Surface Modification for Biomaterials Applications Topics: •Protein Adsorption •Physiochemical Surface Modification Techniques •Biological Surface Modification Techniques •Surface Patterning Techniques MSE-536 Protein Adsorption Factors affecting adsorption: •Surface energy (or tension), g •Surface hydrophobicity •Surface charge Definitions: Hydrophobic: water fearing Hydrophilic: water loving Definitions: Adsorption: adhesion to solid surface Absorption: penetration of molecules into bulk MSE-536 Surface Tension Fgas/liquid q Fsolid/liquid Fsolid/gas For wetting to occur, Fs/g > Fs/l + Fg/l cos(q) Wetting Non-Wetting MSE-536 Adding molecules that prevent adsorption is called steric hindrance. In this example polyethylene glycol (PEG) attaches to the surface (hydrophobic) preventing protein adhesion Like attracts like MSE-536 Physicochemical Surface Treatments Covalent and non-covalent coatings describes how materials is attached to the surface Surface modification with no overcoat, and laser methods for surface modification make surface locally attractive for adhesion of desired species MSE-536 MSE-536 Methods of surface coating: Plasma Discharge Charged particles are attracted to the sample surface, which acts as the cathode. Particles may be positive or negative ions, free radicals, electrons, atoms, molecules or photons. Often used to add OH or NH2 groups to surface as a precursor to further modification MSE-536 Plasma Discharge • Advantages: – – – – – – – – Coatings are conformal Free of voids/pinhole defects Easily prepared Sterile when removed from reactor Produce low amount of leachable substances Demonstrate good adhesion to substrate Allow unique film chemistries to be produced Easily characterized • Disadvantages – – – – Chemistry within reactor may be undefined Equipment often expensive Uniform reaction within long, narrow pores may be difficult Care must be taken in sample preparation to prevent contamination MSE-536 Vapor Deposition: Physical (PVD) Physical Vapor Deposition (PVD) may be from evaporation or sputtering. Sometimes a plasma is used to create high energy species that collide with target (right) MSE-536 Vapor Deposition: Chemical (CVD) In Chemical Vapor Deposition (CVD) a reactive gas is passed over the substrate to be coated, inside of a heated, environmentally controlled reaction chamber. In this case (right) CH4 gas is introduced to create a diamond-like coating MSE-536 Radiation Grafting and Photografting • Substrate is exposed to a radiation source of high energy, which forms a reactive species at the surface to create covalent bonding of the coating to the underlying material • Often employed to bind hydrogels to hydrophobic substrates • Biomaterial substrate may be placed in a monomer solution the irradiated by electrons of gamma rays to form a polymerized coating. MSE-536 Self-Assembled Monolayers (SAMs) SAMs are amphiphilic, having both hydrophilic (polar) and hydrophobic (nonpolar) parts. They are made up of 3 parts: •The attachment group •A long hydrocarbon chain •The functional (polar) head group MSE-536 In the picture, hydroxyl groups form a strong attachment to the substrate. A strong exothermic reaction attaches the Silane to the OH MSE-536 Physiochemical coatings Physiochemical coatings are used to coat biomaterials with biologically active molecules. These methods include solution coatings and Langmuir-Blodgett films (right) Coatings are amphiphilic, having a hydrophilic head and hydrophobic tail. This causes the heads to remain in the water and the tails to extend above the surface. The molecules at the head may be tailored to enable crosslinking with other molecules or to the biomaterials surface MSE-536 Surface Modifying Additives Surface Modifying Additives (SAMs) are atoms or molecules that, when added to the bulk material, will spontaneously rise to the surface, producing a coating with characteristics dictated by the properties of the SMA. SMAs may be used with metals (e.g. Cr in steel) to create a corrosion resistant surface, or in polymers (right). Here the A copolymer anchors into the material, leaving the B copolymer exposed, which provides the desired surface properties. MSE-536 Physicochemical Surface Modifications with no Overcoat These techniques are designed to modify existing atoms at the surface, and include: •Ion beam implantation •Plasma treatment Conversion coatings create an oxide layer at a metal surface, 5 – 500-nm thick, to prevent corrosion •Conversion Coatings •Bioactive Glasses Bioactive glasses come from the range of compositions depicted in the phase diagram. These dissolve and combine with natural biomaterials depending upon the ratios of CaO, Na2O, and SiO2 The IB index is a measurement of the bioactivity of these materials MSE-536 Ion beam implantation This method can create surfaces with high hardness, wear, corrosion resistance and biocompatibility It can also cause surface damage in the form of sputtering of surface atoms, surface roughness and changes in the crystal structure. MSE-536 Biological Surface Modification Biological surface Techniques modification attach biologically active molecules to a substrate through a variety of means that they then interact with specific target areas on cells or other tissue components Biomolecule attachment has been successfully achieved on: •Soluble polymers •Solid Polymers •Porous solid polymers •Hydrogels MSE-536 Methods for the covalent attachment of biomolecules to a biomaterial surface. (a-c) attachment via post fabrication methods (d-e) attachment during synthesis. The biomolecule may be attached with or without a spacer arm in any of these methods Many of these methods can be used to attach enzymes to solid substrates, and have been used in many areas, including biosensors, controlled release devices and protein analysis Heparin, a hydrophobic molecule, may be attached by (a) adding a hydrophobic region to the heparin or (b) adsorption of the heparin (which has a strong negative charge) to a positively charged MSE-536 surface Surface Patterning Techniques Surface or substrate patterning is used to alter the surface properties of biomaterials in a controlled manner, resulting in a geometric design of welldefined regions with very different characteristics. It may be used on both metals and polymers. Microcontact printing (right) creates a “stamp” that is inked with the desired biomaterial and printed on the substrate. This method employs many of the techniques used in making integrated circuits MSE-536