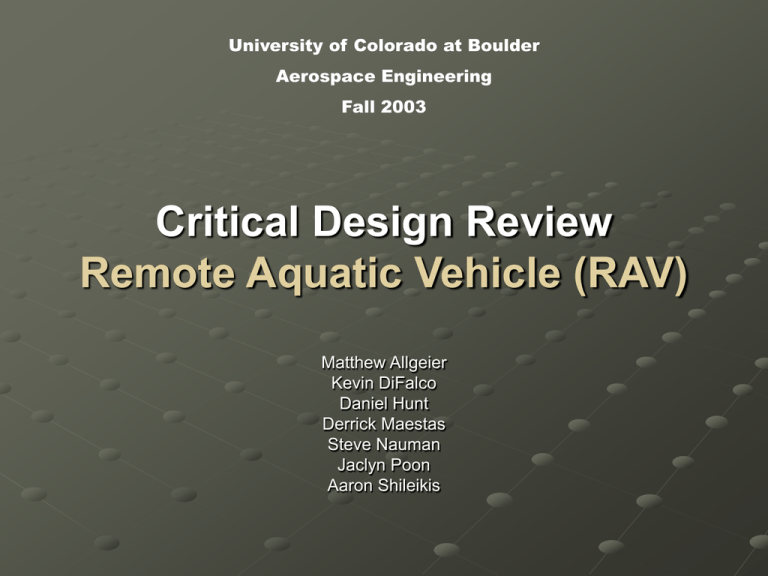

CDR - University of Colorado Boulder

advertisement

University of Colorado at Boulder Aerospace Engineering Fall 2003 Critical Design Review Remote Aquatic Vehicle (RAV) Matthew Allgeier Kevin DiFalco Daniel Hunt Derrick Maestas Steve Nauman Jaclyn Poon Aaron Shileikis Presentation Outline RFA’s and Changes since PDR System Architecture Subsystems Design Elements Analysis Mechanical Design Electrical Design Subsystems Testing & Verification Integration Plan Verification & Test Plan Project Management Plan 03 Dec 03 RAV CDR Presentation 2 RFA’s Request for Action (RFA) Double Pressure Hull Design Required Range & Mission Goal Clarification Top Speed Test Location Detailed Monetary Budget Battery Specifications 03 Dec 03 Requested By Reply Dr. Maute Manufacturing Limits & Limited Internal Volume Dr. Lawrence Clarified Mission Goals & Range addressed in Objectives Overview & Test Section Dr.Peterson Lowered Top Speed and Determined Location Dr.Peterson Detailed Budget addressed in Project Management Plan Trudy Schwartz Subsystem's Battery Specifications addressed in Electrical Design RAV CDR Presentation 3 Overview of Objectives Mission Statement The main objective for team RAV is to conceive, design, fabricate, integrate, verify and test a versatile proof of concept for a remotely controlled aquatic vehicle capable of both high speed, long range and low speed, short range maneuverability in challenging aquatic environments. Objectives Summary 3-axis High Speed Manueverability Low Drag, High Speed & Long Range 3-axis Low Speed Manueverability Active Buoyancy Yaw Rotation and Strafing Small Size Navigation of Challenging Obstacles Ease of Deployment Logistics Ease of Manufacturing Specifications Derived from Facility, Monetary & Volume Limitations and Subsystems Requirements Detailed Final Objective in Verification & Testing Section Test Illustration at Carlson Pool 03 Dec 03 RAV CDR Presentation 4 Overview of Requirements Structure Pressure rated to 44 psi (20m Depth) Buoyancy Functional to 66 ft. (20 m) RC Controllable to 2ft* Depth Ascent/Descent Rate of 0.5 ft/sec* Propulsion 5 knots Reversible Variable speed Low Speed Maneuvering (LSM) Rotation Rate of 0.33 rev/min* Minimal Drag during High Speed Maneuvering *changed from PDR 03 Dec 03 RAV CDR Presentation 5 Overview of Mechanical Design 03 Dec 03 RAV CDR Presentation 6 Overview of Electrical Design Battery (24V) Speed Control Motor Servos Receiver Battery Receiver Battery(12V) Battery(12V) LSM Control Buoyancy Control LSM Jets Buoyancy Motor Pressure Transducer Anemometer HOBO Subsystems 03 Dec 03 RAV CDR Presentation 7 Subsystems Design Elements Hydrodynamics & Structure Buoyancy Propulsion LSM Communication 03 Dec 03 RAV CDR Presentation 8 Hydrodynamic & Structural Analyses Fluid Mechanics Subsystem Design 5 Knot Speed Goal Minimize Drag 20 Meter Depth Goal (45 psi) Aluminum Hull Lower Cost & Ease of Procurement Testable Sealing Machine In-House Hyperbaric Chamber See additional chart CSU Chamber Pressure Transducer & HOBO Stress Analysis 6" Outer Diameter 03 Dec 03 RAV CDR Presentation Acrylic Nose Cone Aluminum Tail Section 9 Drag Reduction Flowchart Goal: Minimize Drag Decrease Outer Diameter HydroBuff Shape Myring Hull Contour 6" Outer Diameter Decrease # of Control Surfaces 1m Overall Length Aluminum Hull due to Availability High Speed Trimmability Nose Cone and Tail Piece Shapes Trim Vertically if CB is off Aluminum Airfoils Trim Laterally if CG is not on centerline NACA 0012 3" X 3" Alreco Aluminum Sealing Servo Specs From Propulsion Use of Shroud FINAL DRAG COMPUTATION 03 Dec 03 RAV CDR Presentation 10 Hull Design Myring Hull Contour Design [H1] 3 compartments: Nosecone Mid-section Tailpiece Max outer diameter ≤ 6 in. Tailpiece Machining Limitation Myring Hull Contour [H1] Aluminum 6061 Mid Section Availability, Machinability, Cost & Strength Mid-section 24 in. long x 1/8 in. thick Maximum Internal Volume Mid-Section Passes Structural Compression Test 03 Dec 03 RAV CDR Presentation RAV Design 11 Nose Cone & Tailpiece Design RAV Nose Cone 03 Dec 03 Nose Cone & Tailpiece designed using Myring Hull Contour Shape Nosecone: 6 in. long Tailpiece: 12 in. long Nose Cone constructed of acrylic Machine Shop Surplus of acrylic Future Camera Use Decreased Outer Diameter ≤ 6 in. Tailpiece machinable “inhouse” Aluminum 6061 Tailpiece Dissipate Heat from Motor Final Total Drag 16.1 N at 5 knots Antenna deployed at 6 in. RAV CDR Presentation 12 Control Surface Design Control Surfaces for Trimming Dive Planes size determined by Force difference between CB & CG Rudder size determined by force from CG displacement from centerline 4 Uniform Control Surfaces Identical Design due to Horizontal and Vertical Trim Requirements Manufacturing Ease 4 Individual Servo’s Motor Interference & Accessibility Future Roll Control Ideal Airfoil 03 Dec 03 Drag Polar Equation Short Chord Long Span RAV Tail Piece & Control Surfaces RAV CDR Presentation 13 Control Surface Sizing Conclusions Selected NACA 0012 airfoil Chord: 3 in. Span: 3 in. long 1/8 in. servo shaft Control surfaces & servo shaft Aluminum - excellent strength to weight ratios. Servo selection 03 Dec 03 15 deg. Control Surface deflection in 0.5 sec Torque required 20.95 oz-in Rated to 44.0 oz-in RAV CDR Presentation 14 Control Surface Sealing Design Withstand Pressure = 45.0 psi Dynamic Seals Low Friction Servo Movement SCLS Brass Linkage Seal Small 0.39 in. x 0.59 in. length Contains an O-ring to prevent water seepage Seal will be pressed into tail section and sealed with epoxy to ensure no pressure leakage 1/8 in. diameter stainless steel shaft will pass from servo to control surface Coupler will be used to attach servo to shaft Pins will be used to attach shaft to control surface 03 Dec 03 RAV CDR Presentation Control Surface Sealing Design 15 Structural Verification and Test Plan Pressure/Sealing Verification Description: Verify entire assembly can withstand pressures of ~45psi (20m depth) without leaking using a hyperbaric chamber. Accomplished by measuring pressure change inside. Location: CSU hyperbaric chamber Written confirmation obtained from Dr. Alan Tucker Method and Measurements: Increase pressure in hyperbaric chamber Record pressure change inside hull Test will be run at 45 psi for 30 minutes to correspond to the maximum amount of time the sub will be in the water for the Final Full-Systems Integrated Test. Tests indicating pressure changes ≤ 0.2 psi will be considered a success If failure occurs at ~45 psi it will be run again at 20 psi to ensure no leakage during pool tests Analysis: Pressure vs. Time inside and outside hull Any pressure change greater than 0.2 psi indicates leakage Sensors: PX236 Pressure Transducer (Omega) Range: 0 – 60 psi Bandwidth: 2 Hz Resolution: 0.1 psi Accuracy: +/- 1.5% 03 Dec 03 RAV CDR Presentation 16 Buoyancy Analysis Buoyancy Subsystem Design Inputs: Overall Weight & Volume 35 lbs 1034 cu3 Ascent/Decent Rate 0.5 ft/s Operational Depth 20 m System Volume 500 mL Mass Flow Rate required Mdot = 1.57 kg/s @max rpm 11.64 kg/s Pressure Force on Piston @20 m 139 lbf Cylinder Length 5 in Inner Diameter 2 in Overall Size 8.5" x 2.25" 03 Dec 03 Motor Selection Small Johnson Motor Stall Torque = 78.7 oz-in Force Produced on Piston Head = 141 lbf RAV CDR Presentation 17 Buoyancy Mechanical Design Johnson Electric Motor (12V) High rpm (16,000 rpm@12V) Lightweight (7.50 oz per motor) Alexander Engel Gear Set Proven for piston systems Threaded Piston Rod 6 mm Piston Head Aluminum Machined in-house Cylinder Aluminum Machined in-house ID x OD x thickness: 2” x 2.25” x 0.125” Batteries 4 DuraTrax Receiver NiCd Flat Pack 6 Volt 2200mAh (600mAh required per motor) Length x Width x Height: 3-1/4“ x 1-3/4“ x 5/8" Weight: 4.8 oz Sealing Precision Associates Inc. Piston Head Seal 75-1.840 End Cap Seal 25-237 03 Dec 03 1.84” ID x 0.075” C/S x 2.0” OD Buoyancy Tanks 0.237” ID x 0.025” C/S x .287” OD RAV CDR Presentation 18 Buoyancy Electrical Design Ballast Tank switch (BTS-II) Proven system for remote submarines Electronic (no servos) Connects directly to Receiver Stop-full micro switch Stop-empty micro switch Trim switch Buoyancy Electrical Schematic 03 Dec 03 RAV CDR Presentation 19 Buoyancy Verification & Test Plan Static Motor Strength Test (Feb 7th) Verify System Produces force to operate at a depth of 20m Horizontal Load Cell Resolution: 1 lb Range: 50 lb – 400 lb Accuracy: +/- 1 lb Expected Results: 141 lb force Requirements: 140 lb force Buoyancy Subsystem Test (April 5th) Verify descent and ascent rate Antenna Marking w/ Stopwatch Range: 0 – 6 ft Resolution: 0.5 ft [B1] Expected Results: 3.0 ft/sec Minimum Requirement: 0.5 ft/sec Overall System Test (April 12th) Verify system remains neutrally buoyant at given depth PX236 Pressure Transducer Range: 0 – 60 psi Bandwidth: 2 Hz Resolution: 0.1 psi Accuracy: +/- 1.5% 03 Dec 03 Expected Results: 3.0 ft/sec with neutral buoyancy (< 0.2 psi change) Minimum Requirement: 0.5 ft/sec with 1 minute neutral buoyancy RAV CDR Presentation 20 Propulsion Analysis Propulsion Design Motor Selection BN28-36AF-01LH 210-262 W Speed Requirement V = 5 knots Controller BDO-Q2-50-18 Required Amps 9A Operational Voltage 24 V Required Duration 90 sec/test 1.2 V/cell Safety Factor of 1.5 V = 7.5 knots Drag 33 N Pitch 6 inches RPM 1576 Number of Tests 10 Power = D * V Efficiency Motor 0.80 System Component Inefficiencies Required mAh 2200 mAh Efficiency Propeller 0.85 2600 mAh/cell Efficiency Battery 0.90 System Power Out Required 187 W 03 Dec 03 Battery Type NiMH 2600 mAh 20 Cells RAV CDR Presentation 21 Propulsion Mechanical Design Major Components Motor BN28-36AF-01LH Dimensions Diameter = 2.25 inch Length = 3.6 inch Weigh: 46 oz Controller BDO-Q2-50-18 Dimensions L = 6.69 inch W = 3.54 inch H = 1.73 inch Weight: 13.76 oz NiMH Batteries 20 Cells 1.2 V/cell 2600 mAh Shaft Hardened steel Dictated by rotary shaft seal requirements Propeller 5.1 inch diameter 6.0 inch pitch Shroud (specs) Max outer diameter: 5.5 inches Min outer diameter: 5.22 inches Max inner diameter: 5.3 inches Min inner diameter: 4.62 inches Complex contour 03 Dec 03 RAV CDR Presentation Mounting, accessories Mounting Motor to tail Shroud to tail Controller and batteries Bearing Ball bearing, double shielded Outer diameter: 5/8 inch Inner diameter: 1/4 inch 2nd point of contact for stability Rated to 52,300 RPM Bal Rotary Shaft Seal 71x model 60 psi 12,030 RPM Splined shaft Simplify assembly 22 Propulsion Electrical Design Closed loop feedback system BDO-Q2-50-18 Input Transducer v Input Potentiometer BN28-36AF-01LH Controller r volts e + - volts Servo Amplifier Plant m Load c Servomotor volts Propeller radians Feedback Elements b volts Encoder 03 Dec 03 RAV CDR Presentation 23 Propulsion Velocity Test 9.14 m CU Carlson Pool Diagonal will be used Safety Net Progressive testing Trim Increasingly faster < 20 m to accelerate to 5 knots, 2.75 m/s Required acceleration: 0.134 m/s2 Sensors: Extech Mini-Anemometer Range: 0.5 - 54.3 knots Bandwidth: 3 Hz Resolution: 0.3 knots Accuracy: +/-(3% rdg+0.6 knots) Data Collected 22.86 m 24.62 m Distance vs. time Velocity vs. time Controlled Variables Input voltage Pool Testing Diagram 03 Dec 03 RAV CDR Presentation 24 LSM Analysis LSM Subsystem Design System design 4 synthetic vortex jets actuated by solenoids Design Requirements 1/3 rpm Drag Analysis / Modeling Equation Improve Design Attach Film to Return Stroke Placement / Moment Arm Sealing Verify Equation with 4" Model Sub Testing Decrease Size of Solenoid Housing Accurate Modeling Equation for Prediction Air Bubble Escape Solenoid Selection to Meet Moment Design Mechanical System Volume (Mount/cavity, housing) Choose Exit Hole Diameter Optimize Choose Frequency Final Design Test & Verify 8 jet configuration as alternative Aluminum mount and solenoid housing Permanently attached mount Detachable housing Latex diaphragm O-ring seals Circuit for control 12V NiMH Batteries Integrate and Test 03 Dec 03 RAV CDR Presentation 25 LSM Drag Model Cd vs. Re for a Cylinder 6 4 3 2 1 0 500 1000 1500 Reynolds Number 2000 2500 Cd and Velocity from Center (0) to Edge of Cylinder 6 Cd Velocity 5 Coef. of Drag Drag model for 4” diameter sub with 7” moment arm to rotate 2/3 rpm Required Thrust = 0.0321 N Required Moment = 0.5311 N*cm 4” sub test results: Exp Moment = 0.4896 N*cm Error = 7.8 % Coef of Drag 5 4 3 2 1 0 0 2 4 6 8 Length(inches) 10 12 14 [LSM1] Drag model for 6” diameter sub with 9” moment arm to rotate 2/3 rpm (SF2) Required Thrust = 0.2952 N Required Moment = 5 N*cm -3 8 Moment from Center (0) to Edge of Cylinder x 10 7 6 Drag model for 6” diameter sub with 9” moment arm to rotate 1/3 rpm Required Thrust = 0.0841 N Required Moment = 1.523 N*cm 03 Dec 03 RAV CDR Presentation Moment (N*cm) 5 4 3 2 1 0 0 2 4 6 8 Length(inches) 10 12 14 26 LSM Analysis D (Exit Diameter) Jet theory L/D=4 Displaced volume (V1) = Exit volume (V2) Thrust provided by jet Required moment = 5 N*cm / jet Moment vs. Frequency for various exit diameters Requirements for 0.6” exit diameter to rotate 2/3 rpm: Minimum frequency of 32Hz Stroke length of 0.38” L/D=4 V2 L V1 Thrusting Moment vs. Frequency 9 Exit Exit Exit Exit Diameter = Diameter = Diameter = Diameter = 0.5 in 0.55 in 0.6 in 0.65 in 8 7 Moment (N*cm) 6 5 4 3 2 1 0 5 03 Dec 03 RAV CDR Presentation 10 15 20 25 30 Frequency (Hz) 35 40 45 50 27 LSM Solenoid Selection Soft-Shift Solenoid Slow, smooth motion with high starting force Return spring available Solenoid selection based on: Size: 1.875” x 1.935” Stroke: 0.400 ± 0.030” Typical frequency at 50% duty cycle = 35 Hz Stroke length deteriorates as frequency increases [LSM2] 03 Dec 03 RAV CDR Presentation 28 LSM Mechanical Design Solenoid Spring loaded, Soft Shift 12V, 24W at 50% duty cycle Max frequency of 58Hz .44 lbs Housing Aluminum or PVC 0.35 lbs Plungers 2 mm thick Mount Aluminum (Welded to Hull) 0.27 lbs Sealing O-rings (not shown) Overall Weight ~1.06 lbs (excluding control circuit) Final design pending (Exit Diameter) based on testing and optimization 03 Dec 03 Solenoid Housing Plunger Mount RAV CDR Presentation LSM Exploded View 29 LSM Electrical Design Control Receiver Electronic RC switch Oscillator Circuit Power RSGEX RC Switch Oscillator Circuit 12V at 1500 mAh/jet NiMH batteries Left Turning Jets Battery (12V) Oscillator Circuit Right Turning Jets +12V RA 1k 1 Gnd555Vcc 8 2 Trg Dis 7 3 Out Thr 6 4 Rst Ctl 5 C1 .01uF + + RB 20k CT [LSM3] RSGEX RC Switch Oscillator Circuit 03 Dec 03 RAV CDR Presentation 30 LSM Verification and Test Plan Spin Rate Verification an Optimization Description: Verify theoretical drag model with 4” sub. Using PVC model of RAV, different exit diameters and frequencies will be input, while the resulting rotational speed will be measured. Optimal exit diameter and frequency will be verified for final design. Location: CU Carlson Pool Measurements and method: Visually record and determine rotation rate Analysis: Plot rotational speed vs. frequency and exit diameter Choose frequency and exit diameter which provide optimal thrust if different than theoretical model Expectations: Jets will be optimal for an exit diameter of 0.6” Minimal frequency of actuation at 32 Hz Sensors: 03 Dec 03 Digital camcorder and stop watch RAV CDR Presentation 31 LSM Verification & Test Plan LSM Test Matrix Controlled Variables: Exit diameter Frequency Resultants: Moment generated by jets Predictions: Optimal exit diameter of 0.6” Minimum frequency of 32 Hz 03 Dec 03 Test Frequency (Hz) Diameter (in) 1.1 10 0.5 1.2 15 0.5 1.3 20 0.5 1.4 25 0.5 1.5 30 0.5 1.6 35 0.5 2.1 10 0.55 2.2 15 0.55 2.3 20 0.55 2.4 25 0.55 2.5 30 0.55 2.6 35 0.55 3.1 10 0.6 3.2 15 0.6 3.3 20 0.6 3.4 25 0.6 3.5 30 0.6 3.6 35 0.6 4.1 10 0.65 4.2 15 0.65 4.3 20 0.65 4.4 25 0.65 4.5 30 0.65 4.6 35 0.65 RAV CDR Presentation Expected Moment (N*cm) 0.165 0.372 0.661 1.033 1.488 2.025 0.293 0.659 1.172 1.831 2.636 3.588 0.494 1.111 1.975 3.086 4.443 6.048 0.259 0.582 1.034 1.616 2.327 3.167 Resulted Moment (N*cm) 32 Communication Analysis RC controller Power out ¾ W Frequency Selection Attenuation of Air Antennae Design Refraction Index Antennae Drag Attenuation of Water Structural Analysis Power Gain Reciever Range 03 Dec 03 RAV CDR Presentation 33 Communication Design Futaba 8UAPS/8UAFS and matching FP-R148DP Receiver (FM/PCM 1024) Free Loan from Aerobotics Research Laboratory – Budget Constraints 8 Channels Available, RAV requires 7 0.75 W output Receiver Power Gain Unknown 72.330 MHz, ¼ wavelength whip antenna = 3.23 ft. long Signal Loss at 72.330 MHz Refraction Loss = 53.00 dB Attenuation of Chlorinated Water = ~300 dB/m Conductivity varies with Chlorine Concentration (Avg Value = 200 µMhos/cm) Antenna Design ¼ wavelength vertical antenna Fiberglass Antenna Mast = 2ft. X 1/8 in. Static Seal Antenna Rise above Surface to avoid Losses Run Propulsion Subsystems Test 6 in. below surface Run to 75% Underwater Fail-Safe Depth for Full-Systems Integrated Test (if Tested) Antenna Drag 14.41 N at 7.5 knots 6.40 N at 5.0 knots Antenna Bending Moment Conclusion R/C not ideal for actual end goal – sufficient for Proof of Concept 03 Dec 03 RAV CDR Presentation 34 Communication Test Plan Range Test Move away from RAV until Fail Safe Initiates Distance Step Function Stretch Goal - Repeat with RAV Underwater Quantify Receiver Power Gain Quantify Antenna Design Parameters 03 Dec 03 RAV CDR Presentation 35 Data Acquisition HOBO H8 4-Channel data logger 32K External Input Channel Measurement Range: 0-2.5 DC Volts External Input Channel Accuracy: ±10 mV ±3% of reading Boxcar software for analysis 03 Dec 03 RAV CDR Presentation 36 Integration Plan Drawing Tree Purchased & Fabricated Parts Assembly Flow Diagram Order in which parts go together Functional Test Plan (Subsystems Test Plans!!) Test Parts Test Assemblies Identify Critical Path Elements LSM Testing Propulsion Ordering Nosecone & Tailpiece Manufacturing Facility Access Hyperbaric Testing Leak Testing 03 Dec 03 Buoyancy Static Test RAV CDR Presentation 37 Drawing Tree - Sample 03 Dec 03 RAV CDR Presentation 38 Assembly Flow Diagram Buoyancy Tail Buoyancy Buoyancy Tail LSM Testing LSM Testing Buoyancy Tail Buoyancy Buoyancy Tail LSM Testing LSM Testing Buoy Testing Tail Control Seals Control Seals Tail LSM Manu LSM Manu Buoy Testing Tail Control Seals Control Seals Tail LSM Manu LSM Manu Hull Manu Main Flange / Seals Control Seals Control Seals Motor Seal & Shaft LSM Manu LSM Manu Hull / Buoy Main Flange / Seals Payload Tray Antenna Motor Seal & Shaft LSM Manu LSM Circuit Hull / Buoy Main Flange / Seals Payload Tray Antenna Motor Seal & Shaft LSM Manu LSM Circuit Nose Payload Tray Nose Shroud Integration Integration Integration Integration Integration Integration Integration 03 Dec 03 RAV CDR Presentation 39 Verification and Test Plan Full Integration Test Plan Description At point A, dive to depth of 2.5 ft (0.5 ft/sec) Remain Buoyant for 2 min Accelerate to 3 knots and stop at point B Rotate counterclockwise 90° (45 sec) Accelerate to 2 knots and stop at point C Rotate clockwise 270° (2.25 min) Arrive at point D by maneuvering around obstacles using Buoyancy and LSM Rotate counterclockwise 90° (45 sec) Return to point A and surface using buoyancy Repeat Testing Test Time = 10 min/Lap Location CU Carlson Pool 03 Dec 03 RAV CDR Presentation 40 Verification & Test Plan Expectations: All subsystems tests will be verified on fully integrated Sub Top speed of 5 knots Demonstrate active buoyancy Rotational speed of 1/3 rpm Sensors Depth (Active Buoyancy) PX236 pressure transducer Speed Extech mini-anemometer Rotational Speed Digital camcorder and stopwatch 03 Dec 03 RAV CDR Presentation 41 Project Management Plan Organizational Responsibilities Work Breakdown Structure Schedule Budget Specialized Facilities & Resources 03 Dec 03 RAV CDR Presentation 42 Organization Chart RAV Team Advisor Dr. Kamran Mohseni Advisor Dr. Scott Palo Systems Engineer Steve Nauman Safety Engineer Dan Hunt Structures Group Webpage Manager Kevin DiFalco Electronics Group External Structure & Fluid Mechanics Matt Allgeier Internal Structure & Buoyancy Dan hunt 03 Dec 03 Project Manager Aaron Shileikis Chief Financial Officer Jaclyn Poon Controls Group Communications Aaron Shileikis Low Speed Maneuverability Jaclyn Poon Data Acquistion & Instrumentation Derrick Maestas Propulsion Kevin DiFalco RAV CDR Presentation 43 Work Breakdown Structure RAV Team 1.0 Project Management 2.0 Systems Engineering 3.0 Design 4.0 Fabrication 5.0 Integration 6.0 Verification & Testing 7.0 Technical Report 1.1 Organization & Division of Labor 2.1 Project Objectives 3.1 Fluid Mechanics & External Structure 4.1 External Structure 5.1 Sub-Assemblies 6.1 Data Acquisition & Instrumentation Testing 7.1 PDD 1.2 Work Breakdown Structure 2.2 Design Integration 3.2 Buoyancy 4.2 Buoyancy Subsystem 5.2 Nose 6.2 Communications Testing 7.2 PDR 1.3 Schedule 2.3 CAD Drawings 3.3 Communications 4.3 Propulsion Subsystem 5.3 Tail 6.3 Hyperbaric Chamber & Leak Testing 7.3 CDR 1.4 Task Management 2.4 Internal Configuration 3.4 Data Acquisition & Instrumentation 4.4 LSM Subsystem 5.4 Hull 6.4 Buoyancy Testing 1.5 Budget 2.5 External Configuration 3.5 Low Speed Maneuverability 6.5 Propulsion Testing 1.6 Specialized Facilities & Resources 2.6 Mass & Power Budget 3.6 Propulsion 6.6 LSM Testing 6.7 Full Systems Testing 1.7 Information Nodes 03 Dec 03 7.4 Final Report RAV CDR Presentation 44 MS Project Schedule 03 Dec 03 RAV CDR Presentation 45 Task List - Sample LSM subsystem task list 03 Dec 03 RAV CDR Presentation 46 Manufacturing & Integration Time Estimates Section Time (Hours) Nose 30.0 Mid-Section 36.5 Tail 86.0 Control Surfaces 41.0 Buoyancy 45.0 LSM 96.0 Electronics 30.0 Integration 30.0 TOTAL 394.5 TOTAL * 2 789.0 Weeks 10.0 Students 7.0 Hours/Student/Week 03 Dec 03 12.0 Total Hours Available 840.0 Margin -51.0 RAV CDR Presentation 47 Budget Budget Summary Structure $425.00 Buoyancy $532.73 Communication $149.38 Data Acquisition $290.00 Propulsion $1,149.35 LSM $935.00 Accessories $45.00 Support Equipment $179.99 Testing Facilities $435.00 Parts Total $4,141.45 Shipping (5% Parts) $207.07 Grand Total $4,348.52 Available $4,950.00 Goal 90% $4,455.00 Margin (Grant Total - 90% Goal) 03 Dec 03 RAV CDR Presentation -$106.48 48 Specialized Facilities & Resources CSU Hyperbaric Chamber Dr. Alan Tucker (access granted in writing) 150 ft. x 10 ft. 67 psi CU Carlson Pool John Meyer (access granted in writing) 25m x 12m x 1m Aerobotics Laboratory Cory Dixon (access granted in writing) Aerospace Engineering Department & ITLL 03 Dec 03 Walt Lund, Trudy Schwartz, Matt Rhode & Bill Ingino Testing Support Equipment RAV CDR Presentation 49 References Fluid Mechanics [1] Myring, D F. A Theoretical Study of Body Drag in Subcritical Axisymmetric Flow. Aerospace Quarterly. Volume 3. 1976. Aerodynamics Book Dynamics Book Library Book Buoyancy [B1] www.subconcepts.com Mr. Fred Grey, subconcepts.com Propulsion Argrow Paper MooG (Co. Documentation) LSM [LSM1] http://scienceworld.wolfram.com/physics/CylinderDrag.html & http://astron.berkeley.edu/~jrg/ay202/node20.html#drag-coefficient & http://astron.berkeley.edu/~jrg/ay202/node21.html & www.eng.fsu.edu/~alvi/EML4304L/webpage/exp7description.doc [LSM2] http://www.ledex.com [LSM3] Robotics Sporting Goods [LSM4] Murdock. Fluid Mechanics and its Applications. 1976. AIAA Papers: 2001-2773. 2002-0124. 2002-0126. Systems Engineer Matt Data Acquisition Walt Communications ARRL Handbook Shevell Vable Text Books: Richardson. PADI Open Water Diver Manual. International PADI, Inc. 1999. Burcher and Rydill. Concepts in Submarine Design. Cambridge University Press. 1994. Robertson. Systems/Subsystems Investigation for a Multi-Sensor Autonomous Underwater Vehicle Search System. US Gov Agencies. April 1990. Vable.l Mechanics of Materials. Oxford University Press. New York. 2002. Shevell. Fundamentals of Flight (2nd Edition). Prentice Hall. New Jersey. 1989 Cengel. Introduction to Thermodynamics and Heat Transfer. Irwin McGraw-Hill. 1997. Reed. The ARRL Handbook for Radio Amateurs 2002.The American Radio Relay League, Inc. 2001 03 Dec 03 RAV CDR Presentation 50 Supplemental Slides Fluid Mechanics Supplemental Slides FM - Top level Design 4 Previous Designs considered 03 Dec 03 Florida Atlantic University’s “Squid II” Mass. Institute of Technology’s “Orca 2” Cornell University’s “CUAV” University of Colorado’s HydroBuff R5-L UUV RAV CDR Presentation 53 MINIMIZE DRAG GOAL HydroBuff Shape Decrease Outer Diameter Decrease # of Control surfaces High Speed trimmability 6 inch outer diameter Aluminum hull due To availability Trim vertically if center of Buoyancy is off Trim laterally if c.g. is not on centerline Aluminum Airfoils NACA 0012 Myring Hull Contour 1 m overall length Nose cone and tailpiece shapes 3 in x 3 in Alreco Aluminum From Propulsion Sealing Servo Specs Use of Shroud 03 Dec 03 FINAL DRAG RAV CDR Presentation COMPUTATION 54 FM - Mid-section Material Comparison Cost Machinability Compressive Strength Density Risk Comments Stainless Steel High (about $50 per foot) Moderate High High (7.8 g/cm^3) Moderat e Adds excessive weight which will reduce maneuverabilit y. Aluminum Low (about $14 per foot) Excellent Moderate Low (2.10 g/cm^3) Moderat e Available in desired sizes from manufacturer in Colorado PVC Low (about $10 per foot) Excellent Weak (only up to 150 psi) Low (1.37 g/cm^3 Low (Used last year) Not available in desired sizes from manufacturer in Colorado 03 Dec 03 RAV CDR Presentation 55 FM - Preliminary Exterior Structure Conclusions Outer diameter of Mid-section was determined to be 6 inches. 03 Dec 03 Tubing is typical made with outer diameters of 4, 6 or 8 inches. Diameter was needed to be decreased from last years 8 ¼ inch outer diameter in order to meet maneuverability and speed requirements. A nominal diameter of 4 inches was determined to be too small to fit all required components inside the hull. RAV CDR Presentation 56 FM - Control Surface Configuration Considering 2 possible control surface configurations Configuration 1: 2 dive planes and two rudders mounted on rear of tailpiece Configuration 2: 2 dive planes mounted on the nosecone and one rudder located aft of the propeller. Determined that vertical and horizontal stabilizers are unnecessary. 03 Dec 03 RAV CDR Presentation 57 FM - Control Surface Airfoil Selection Lift Max α (Max CL) (degrees) Drag Comments (CD at Max CL) Area Risk Required for Trim NACA 0006 0.92 9 deg 0.010 183 cm2 Servo shaft will have to be about 1/8 inch Symmetric airfoil NACA 0009 1.32 13.4 deg 0.016 127 cm2 Servo shaft will have to be less than ¼ inch Symmetric airfoil NACA 0012 1.50 15 deg 0.025 110 cm2 Excessive drag may impede on velocity goals Symmetric airfoil 03 Dec 03 RAV CDR Presentation 58 FM - Airfoil Sizing vs. Shaft Sizing Thickness Max Shaft size Surface (to allow for 0.05 Area inches on either side) required NACA 0009 w/ 3 inch chord 0.27 inches 0.17 inches NACA 0009 w/ 3.5 inch chord NACA 0012 w/ 3 inch chord 03 Dec 03 Drag Coefficient 127 cm2 0.016 0.315 inches 0.215 inches 127 cm2 0.016 0.36 inches 110 cm2 0.025 0.26 inches RAV CDR Presentation 59 FM - Airfoil Sizing Conclusions A NACA 0012 airfoil with a 3 inch chord was selected. This will allow us to use a 1/8 inch Servo shaft In order to use a 1/8 inch Servo Shaft with a NACA 0009 airfoil, the chord length will have to be at least 3 inches long. Span required for this airfoil is 3 inches long Aluminum was selected for material to be used for control surfaces and Servo Shaft due to excellent strength to weight ratios 03 Dec 03 Acrylic was not selected due to structural problems with last years design. RAV CDR Presentation 60 FM - Final Drag Computation Final Drag Elements Myring Hull Contour 4 NACA 0012 airfoils Shroud w/ surface area of 669 cm^2 Final Drag computed to be 14.59 N at 5 knots Reynolds Number = 2.5669 * 10^6, which makes flow in the turbulent regime Drag will not be tested directly. Drag data will be based on thrust test data. 03 Dec 03 RAV CDR Presentation 61 Propulsion Supplemental Slides Torque Profile Intermittent operation is based on a 20% duty cycle of one minute on, four minutes off. RPM @ 5 knots Torque as RPM changes 03 Dec 03 RAV CDR Presentation 63 Acceleration T*V = η*P Fix Power to 187.4 W Step through V’s by 0.5 Find efficiency and thrust F = ma (Thrust – Drag)/mass = a Problems Efficiency is an approximation Slippage and cavitations not analyzed Mass of vehicle Added mass due to water Acceleration values are much larger than needed and expected 03 Dec 03 RAV CDR Presentation 64 Rotary Shaft Seal O ring Bal Seals: 71x Series Temp Range Continuous: -20ºF to +200ºF Intermittent: to +250ºF Pressure: 60 PSI RAV: 45 PSI max Surface Speed: 4 m/s RAV: 0.673 m/s @ 10 knots Rated to 12,030 RPM Coiled spring 03 Dec 03 RAV CDR Presentation 65 Propulsion Test Stopping Mechanism Catch net Nylon Seine net PVC or wood frame on two sides Tension applied by 2 RAV team members 03 Dec 03 RAV CDR Presentation 66 LSM Supplemental Slides LSM - Detailed Drag Analysis Method: Cd vs. Re plot Cd Ftotal = FDrag + Finertia Moment = F*r Variables: ρ = density r = distance from axis of rotation ω = spin rate D = diameter dl= section length CD = coef of drag l = length of RAV 03 Dec 03 [LSM1] L/2 FDrag 2 0 1 (r ) 2 ( Ddl )CD dr 2 FInertia (l ) 2 D 2 L/2 Moment 2 0 RAV CDR Presentation 1 (r ) 2 ( Ddl )CD rdr 2 68 LSM - Solenoid Analysis 50% Duty Cycle ON time/(ON + OFF) time Maximum ON time doesn’t exceed the specs Specs Stroke: 0.4±0.03” Spring Rate: 4.41 lb/in; 0.45 lb ±30% preload Weight: 12 oz Dimensions: 1.875” x 1.935” [LSM2] 03 Dec 03 RAV CDR Presentation 69 LSM - Comparison to previous jets Similarities Differences Soft-Shift Solenoid Overall plunger/latex design Theoretical Model Integrated drag & moment Inertia Mount / Cavity Minimize axial drag Air bubble removal 03 Dec 03 Solenoid housing Latex return Use of o-rings Circuit (not microcontroller) RAV CDR Presentation 70 Buoyancy Supplemental Slides Buoyancy - MATLAB Analysis 03 Dec 03 RAV CDR Presentation 72 Buoyancy - Stress Analysis & Mass Flow Rate Calculation 03 Dec 03 RAV CDR Presentation 73 Project Management Supplemental Slides Drawing Tree - Full 03 Dec 03 RAV CDR Presentation 75 Detailed WBS 03 Dec 03 RAV CDR Presentation 76 Task List - Full 03 Dec 03 RAV CDR Presentation 77 PM – Detailed Budget 03 Dec 03 RAV CDR Presentation 78