"A Continuous Lean" visits the Imperial Stock Ranch

advertisement

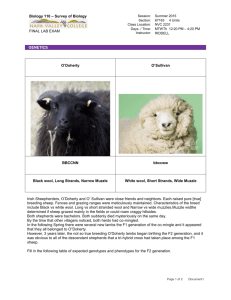

The Ralph Lauren Olympic Collection | A Conversation with Jeanne Carver Jan 23rd, 2014 | Categories: A Conversation With, Americana | by Jake Gallagher Over the years on ACL, we’ve interviewed designers, shopkeepers, authors, and even a filmmaker, yet we’ve never spoken to anyone quite like Jeanne Carver. Carver is not some freshfaced designer, nor is she an eccentric New York creative, in fact in our interview she never uttered the word “fashion,” and only mentioned “clothing” twice, under the most practical of terms. This is because Carver’s life exists roughly 2,850 miles removed from the frenzy that is New York City’s fashion industry, on The Imperial Stock Ranch, which has been raising sheep and cattle for over one hundred forty years. Carver’s story is not a common one, after all, it was centurion ranches such as hers that helped to establish the western frontier back in the late 1800’s. What makes Carver (along with her husband Dan who also runs the ranch) so extraordinary, is that she was given a chance to have her story told. The wool trade is the largely ignored backbone of our entire clothing industry. We often highlight designers, factories, and shops, but these institutions represent the final steps of clothing production. Rarely, does anyone go to the source, and rarely is this source ever even considered. Which is reason to applaud Ralph Lauren, who after recognizing their error in having past Olympic uniforms produced overseas, decided to take a concerted effort to produce this years U.S. Winter Olympic uniforms entirely in America. In doing so Ralph not only gave a fair amount of work to stateside textile factories and farms, which often go overlooked by large apparel corporations that are more interested in margin, but it also found people like Jeanne, people who embody the spirit of hard work and determination that our nation’s clothing industry was founded upon way back when. Ralph Lauren contacted Jeanne because the wool that she and her husband produce on their Shaniko, Oregon ranch is of an incredibly high quality, and was perfect for Ralph Lauren’s opening ceremony sweater, which is being unveiled today. I was fortunate enough to have a chance to speak with Jeanne to get her story, as well as her perspective on this U.S. made collection, and the state of America’s garment industry today. ACL: First off, could you give us a bit of background on your ranch and how long you’ve been raising sheep? Jeanne Carver: Established in 1871, the Imperial Stock Ranch has been raising sheep and cattle, and producing grains and hay for more than 142 years. It’s the only ranch in Oregon designated a National Historic District, that is still in operation. Sheep have been present on this landscape probably since they appear on the county tax roll in 1873. The Imperial Stock Ranch story began in 1852 on the Oregon Trail, when Richard Hinton was born in an oxcart as his family came West. They came to farm in the fertile Willamette Valley, and young Richard grew up seeing the valley become fenced, plowed and overpopulated. He dreamed of being a stockman, not a farmer, so at the age of 19, he struck out on his own with his saddle horse, a pack-horse and his six-gun, to homestead in Oregon’s vast interior. Hinton filed on a 160-acre homestead claim, brought in sheep and cattle, planted grains and cut hay in the natural meadows, developing a four commodity operation. His claim eventually became Oregon’s largest individually owned land and stock holdings, and one of the largest sheep empires in the American West. Recognizing the potential for raising fine wool sheep in the cold semiarid climate of the high desert, Hinton began a crossbreeding program in the late 1800’s with fine wool breeds, that would prove to be very successful, and would eventually lead to a new breed of sheep in America. Production still continues in all original commodity areas, and the ranch is family owned and operated. Today, we (Dan and Jeanne Carver) believe in living and working in balance with nature. We have focused on stewarding the land and the animals that thrive on it. We tend the ranch’s grasses that capture energy from sunlight. The grasses nourish the ranch’s native wildlife and domestic livestock, and the grazing animals revitalize plants through carefully managed grazing rotations. Together these strong interconnected relationships sustain the land, the animals and the people who depend on them for survival…which is all of us. We are grateful for these timeless life-sustaining gifts. With my husband Dan Carver at the helm, Richard Hinton’s dream lives on. Today the Imperial Stock Ranch spans about 35,000 acres and continues as a four-commodity operation with cattle, sheep, grain and hay production. Most of the original agricultural buildings are not only still standing, but still in use, and the historic Hinton House, once the showpiece of Hinton’s empire, serves as the headquarters for Imperial Stock Ranch’s promising descendant business: Imperial Yarn. We are regionally and nationally recognized and awarded, for our conservation work and leading agricultural practices. By the late 1990’s, infrastructure for processing and manufacturing wool and textile products had seen a devastating collapse in the U.S. Unable to continue selling our wool as a commodity in a severely diminished U.S. market, we began to explore new ways to do business with the wool harvest. Heritage was our motivation, and a belief that we are called to honor the relationship sheep have had with man’s survival for thousands of years. In 1999, we began a creative approach to selling the ranch’s beautiful raw wool by creating and selling premium wool yarns. As a spinoff of the historic Imperial Stock Ranch, Imperial Yarn was born. Once a year the luxurious wool is harvested, custom milled, and sold across the country and beyond. ACL: How did your relationship with Ralph Lauren come about? JC: Since 1999, we’ve been seeking to sell our wool as a product (yarn), and it’s been a 14 year effort to overcome many obstacles and challenges. We’ve evidently made some progress, because when Ralph Lauren decided to search for an American yarn, they found us. The journey with Ralph Lauren began in July of 2012, with what has become known as “The Call.” I was outside in the back yard when I took a phone call, and there was a group of sheep on the hillside behind the headquarters. They had come to the spring for a drink, and were starting to head out, grazing their way toward sunset and the night time bedding grounds up on the ridge. I could see from the number on the phone that this wasn’t a local call, and as the gentleman on the other end jumped right in with questions about our yarns, I assumed he was with a yarn store. I asked him which yarn shop he was with, and he replied that he was with product development for Ralph Lauren in New York. It took me just a few seconds for that to process, and then I said, “You’re kidding me!” He said, “No, I’m sitting right here on Madison Avenue.” And I replied, “That’s incredible! I’m sitting out here in the Oregon desert. In fact, I’m outside right now, can you hear my sheep?” I held up the phone and let him listen to a symphony of sheep sounds — ewes and lambs calling to each other and the jingling of sheep bells — which transported him for just a moment, into our world. We carried on a long conversation, and that night I put together a packet of information and samples to send off to New York. It shipped out the next day. About a month later (August 2012), a Ralph Lauren design team came to Oregon, from New York to visit us. They were interested in everything about the ranch, including the yarns, and we had a fantastic day touring the landscape and groups of animals, historic buildings and plenty of conversation. After that, we filled a couple small orders for sampling and the process continued for quite a few months, with them ordering a couple more significant amounts of yarn for sample sweaters. Five to six months after the initial call (late December), they placed a production order. We did not know through this whole process, what the yarn was being used for. It was simply a “special project” for one of their teams. Eventually, in 2013, we learned what the special project was. ACL: Over the past decade or so, there has been a significant push for more American made goods on the market overall. How has this impacted your business (aside from the Ralph Lauren partnership of course) and the American textile industry overall? JC: For Imperial Stock Ranch, this renewed interest in Made in America has been fairly new in just the past 3 years or so, and it melts my heart. 15 years ago, all I heard was wool had no value anymore. People weren’t wearing wool that much. It was out of favor. Newer high tech performance fabrics and recycled plastics had flooded the markets. In addition, it seemed everything was made off shore. We were continually running up against two themes, “You can’t make things here anymore; and wool has no value.” And all I could think was why not? When did this naturally renewable “gift of creation” (wool) become unimportant? How does that feel? How do we so nonchalantly dismiss something that has provided us with life? On the contrary, we believed we should honor it. So we did. And why do we have to cross an ocean to get something as basic as clothing? We decided we wouldn’t. I’m not an expert, but the textile industry in this country lost perhaps 90% or more of its infrastructure in the offshoring movement. We gave up the equipment, knowledge and in many cases the skilled personnel necessary to support a robust industry. At some point, it began to become evident that there were negative consequences to this change — environmental, economic and cultural. Any interest in a return to America for manufacturing is positive. We need to follow this interest with real steps. I am getting more and more inquiries from designers and apparel companies who want to make things here in the U.S. It’s important, however, to ask a lot of questions. Much “made in America” yarn, is not American fiber, and not dyed here. I’d like to see companies desire fiber grown, processed, spun and dyed in the U.S. It’s not always clear what “American made” yarns are composed of. In many cases, it’s foreign sourced fiber, that’s been dyed off shore, then brought here and spun. In general, value chain partners (mills, dye houses, etc.) are also experiencing increasing interest, but I’m not sure if that has yet resulted in increases in manufacturing jobs. I know of a number of new knitting factories opening, and some are even getting contracts from larger corporations who have recently returned here for production. The bottom line to all this is the consumer. If the consumer demands traceability and support for U.S. raw materials and manufacturing, they will effect a positive change in investment in infrastructure needed again to grow manufacturing in this country. Renewed interest is great. Factories that are at less than 30 to 50% capacity right now, need real orders to support retraining and adding jobs back. Consumers are the key. Influencers like Ralph Lauren can have a solid impact with their leadership. ACL: Why do you believe that it’s important to protect our country’s manufacturing heritage? JC: What a great question! I had never really thought about this issue, until we faced the possibility of going out of the sheep business, or finding a new market and way forward. This journey has taught us many lessons. It’s really quite simple. Producing what we need to live on a daily basis — food, clothing and shelter — is the strength of every nation and culture. It’s as important to this country as it is to every other. America has a culture, and agriculture is an important part of it. So are the traditional skills of spinning, weaving, knitting, and sewing. Manufacturing built this country. These basic industries are essential to our culture and spirit, and fundamental to our economic strength. ___________________________________