Introduction Smurfit Kappa Roermond Papier

advertisement

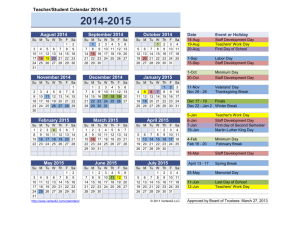

Experiences on mill scale with enzymes Final Seminar of Subproject 3 of ECOTARGET Tuesday 1 April, 2008 at STFI-Packforsk Ir. Loud van Kessel Senior Process Engineer Smurfit Kappa Roermond Papier Content Introduction Smurfit Kappa Roermond Papier Fluctuations: long term Fluctuations: short term The effect of enzyme treatment on the paper production performance Conclusions 2 Introduction Smurfit Kappa Roermond Papier Production facilities: Europe Operations Finland Mills/Depots (42) Solid Board (14) Russia Paper Sacks (13) Lithuania Corrugated Plants (230) Graphic Board (2) Czech Republic Slovakia Specialities (15) Switzerland Generating employment for approx. 34,000 4 5 Mill key information 6 Products Testliners, fluting and chip (Schrenz) Customers Packaging industry Production 525,000 ton/year paper testliner : 100 - 220 grs/m² fluting : 105 - 180 grs/m² chip : 90 - 140 grs/m² 15 kt/year Rofire Paper machines 3 Employees 260 Logistics 2006 7 Recovered paper is main raw material consumption + 570,000 ton/year (22 % of NL) + 11,000 tons/week delivery + 85 lorries/day stocks: + 3 weeks of production max. stock capacity 30,000 ton Produced paper + 525,000 ton / year shipment: + 75 lorries / day max. stock 18,000 ton Utilities 2006 Energy usage 160,000 MWh Own power plant 4 turbines 14 MW producing 114,000 MWh 35,000 household equivalent Gas 89 million m3/year 45,500 household equivalent Civil water usage 169,000 m3/year 3,550 person equivalent Water treatment 8 4,750 m3/day 130,000 civil equivalent Kappa Roermond Papier 9 Evolution of the recovered paper utilisation and the recycling rate in Europe (CEPI 2002) Utilisation 45 56% 40 54% 35 52% 30 50% 25 48% 20 46% 15 44% 10 42% 5 40% 0 38% 1991 10 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 Recycling rate R.P. Utilisation (Million tonnes) Recycling rate Price fibres (€ ) average 2003 300 250 200 Virgin Fibre 150 100 50 Recycled Fibre 0 11 Effects of recycling Fibre damage Change in physical properties Change in surface properties Accumulation of additives 12 Fibre damage Fibre shortening Minor influence Creation and accumulation of fines Great influence on process and product 13 Identification of fine particles in recycled fibre pulp Fibre chunks 14 Identification of fine particles in recycled fibre pulp Fibre fibrils 15 Identification of fine particles in recycled fibre pulp Ash 16 Ash content Mixed (PM2) 22 20 Asch content (%) 18 16 14 12 10 8 6 1970 17 1975 1980 1985 1990 1995 2000 2005 2010 Ash content Mixed (PM2) 22 20 Asch content (%) 18 16 14 12 10 8 6 1970 18 1975 1980 1985 1990 1995 2000 2005 2010 Ash content Mixed (PM2) 22 20 Asch content (%) 18 ? 16 14 12 10 8 6 1970 19 1975 1980 1985 1990 1995 2000 2005 2010 Ash content Mixed (PM2) 22 20 Asch content (%) 18 ? 16 14 Germany 12 10 8 6 1970 20 1975 1980 1985 1990 1995 2000 2005 2010 Fines in head box Fines in headbox 0,58 0,57 0,56 Fines (%) 0,55 0,54 0,53 0,52 0,51 0,50 0,49 16-10-06 20:24 21 16-10-06 21:36 16-10-06 22:48 17-10-06 0:00 17-10-06 1:12 17-10-06 2:24 17-10-06 3:36 17-10-06 4:48 17-10-06 6:00 17-10-06 7:12 17-10-06 8:24 Examples: Paper properties Berst and SCTd of Fluting 105 grs 1,9 340 1,85 1,8 1,75 300 280 1,7 Berst SCTd 1,65 1,6 260 1,55 1,5 240 1,45 220 5-jan 22 1,4 5-jan 5-jan 5-jan 6-jan 6-jan 6-jan 6-jan 6-jan 7-jan 7-jan SCTd (kN/m) Berstpressure (kPa) 320 Examples: Paper properties Berst and SCTd of Fluting 105 grs 1,9 340 1,85 1,8 1,75 300 280 1,7 Berst SCTd 1,65 Specifications 1,6 260 1,55 1,5 240 1,45 220 5-jan 23 1,4 5-jan 5-jan 5-jan 6-jan 6-jan 6-jan 6-jan 6-jan 7-jan 7-jan SCTd (kN/m) Berstpressure (kPa) 320 Examples: Paper properties Berst and SCTd of Fluting 105 grs 1,9 340 1,85 1,8 1,75 300 280 1,7 Berst SCTd Excess of raw material/additives 1,65 1,6 260 1,55 1,5 240 1,45 220 5-jan 24 1,4 5-jan 5-jan 5-jan 6-jan 6-jan 6-jan 6-jan 6-jan 7-jan 7-jan SCTd (kN/m) Berstpressure (kPa) 320 Energy consumption 150 100 kg steam / ton 50 0 week nr. -50 10 20 30 40 50 8 18 28 38 48 -100 -150 -200 2003 -250 25 2004 2005 5 15 25 Energy consumption 150 100 kg steam / ton 50 0 week nr. -50 250 kg steam per ton 10 20 30 40 50 8 18 28 38 > 5 Euro per ton 48 -100 -150 -200 2003 -250 26 2004 2005 5 15 25 Enzymes Improved drainability and porosity without strength loss and without significant loss of mass Increased relative bonded area, flexibility and fibrillation without affecting fibre length 27 Influence of enzymes (cellulase) on dewatering speed Increase of the dewatering speed (%) Influence of enzyme activity on the dewatering speed 25% 20% 15% 10% 5% 0% 0 5 10 15 20 25 Time (min) 28 30 35 40 45 Prevention - Compression refining Beating degree development 45 o Beating degree [ SR] 40 35 Speed difference in PFI-mill [m/s] 30 2 6 12 25 20 15 10 5 0 0 1000 2000 3000 4000 PFI revolutions 29 5000 6000 7000 Washing Effect of washing on refining curves Results pilot scale trials 40 Tensile Index [Nm/g] 35 30 25 20 15 Maximum washed (21% loss, 7.4% Ash) 10 Minimum washed (7% loss 14% Ash) 5 Mixed Waste Reference (17% Ash) 0 20 25 30 35 40 Beating degree [0SR] 30 45 50 55 Sustainable paper production in the future Zero emission strategy Raw Material Recycled Paper 32 94% Paper fibre 5% Organic material 1% Inert, inorganic material (metal, glass, sand etc.) Upgrading Recycled Paper Fluting + Testliners Secondary fuel - Rofire® 33 Process Scheme 34 The Rofire® Rational Better use of valuable raw materials Advanced separation process Useful, new product with good market conditions 35 Rofire® and Environment (1) Roermond 30,000 tonnes less waste disposal p.a. 16,000 Rofire® p.a. 12,000,000 m³ natural gas p.a. Biomass content 50% 36 Rofire® and the Economics Rofire® average price 15 €/ton Equivalent coal 50 € Equivalent natural gas 90 € CO2 reduction 37 Rofire® and Environment Europe 1,300,000 tonnes less waste disposal p.a. 700,000 tonnes Rofire® p.a. 525,000,000 m³ natural gas p.a. 38 Return of investment: Savings on reject costs: € 4.000.000,- a year* A pay-back of 2 years on the described installation * 39 Based on landfill costs of €160,-/tonne (Netherlands 2003) Forbonium The biology of the water treatment plant at Roermond Papier has a lack of the element phosphorous: phosphoric acid is used as a nutrient. A food producer in Holland needs to de-phosphorize baby food products. There is an emission (waste) of a phosphorous concentrate. Both companies invested in a storage and dosing unit in Roermond to reduce both on variable costs. 40 A paper mill has different costumers, depending on the point of view: Core competence from different views: Customer Shareholder Employee Neighbourhood Environment 42