Chapters 9-15 - Lancaster City Schools

advertisement

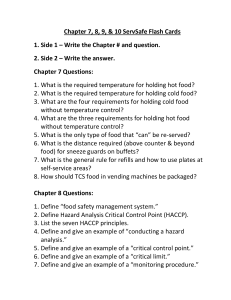

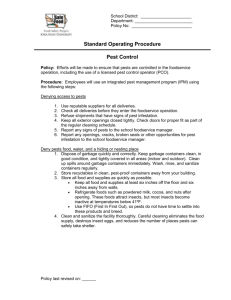

General Rules for Holding Food Temperature: 9-2 Hold TCS food at the correct temperature o Hot food: 135˚F (57˚C) or higher o Cold food: 41˚F (5˚C) or lower Check temperatures at least every four hours o Throw out food not at 41˚F (5˚C) or lower o Check temperatures every two hours to leave time for corrective action General Rules for Holding Food Temperature: NEVER use hot-holding equipment to reheat food unless it’s designed for it o 9-3 Reheat food correctly, and then move it into a holding unit Holding Food Without Temperature Control Cold food can be held without temperature control for up to six hours if: It was held at 41˚F (5˚C) or lower before removing it from refrigeration It does not exceed 70˚F (21˚C) during service o It has a label specifying o o 9-4 Throw out food that exceeds this temperature Time it was removed from refrigeration Time it must be thrown out It is sold, served, or thrown out within six hours Holding Food Without Temperature Control Hot food can be held without temperature control for up to four hours if: 9-5 It was held at 135˚F (57˚C) or higher before removing it from temperature control It has a label specifying when the item must be thrown out It is sold, served, or thrown out within four hours Service Staff Guidelines Handling dishes and glassware: Correct Incorrect 9-6 Kitchen Staff Guidelines Prevent contamination when serving food: Wear single-use gloves whenever handling ready-to-eat food o 9-7 As an alternative use spatulas, tongs, deli sheets, or other utensils Use clean and sanitized utensils for serving o Use separate utensils for each food o Clean and sanitize utensils after each task o At minimum, clean and sanitize them at least once every four hours Kitchen Staff Guidelines Prevent contamination when serving food: 9-8 Store serving utensils correctly between uses o On a clean and sanitized food-contact surface o In the food with the handle extended above the container rim Preset Tableware If you preset tableware: Prevent it from being contaminated o Wrap or cover the items Table settings do not need to be wrapped or covered if extra settings: 9-9 Are removed when guests are seated Are cleaned and sanitized after guests have left Refilling Returnable Take-Home Containers for Food Some jurisdictions allow the refilling of take-home food containers. Take-home food containers must be: 9-10 Designed to be reused Cleaned and sanitized correctly Refilling Returnable Take-Home Containers for Beverages Some jurisdictions allow the refilling of take-home beverage containers. These can be refilled for the same customer with non-TCS food. The container must be: 9-11 Able to be effectively cleaned at home and at the operation Rinsed with fresh, pressurized hot water before refilling Refilled using a process prevents contamination Re-serving Food Safely NEVER re-serve: Food returned by one customer to another customer Plate garnishes Uncovered condiments Uneaten bread or rolls Generally, only unopened, prepackaged food in good condition can be re-served: 9-12 Condiment packets Wrapped crackers or breadsticks Self-Service Areas To prevent contamination: 9-13 Use sneeze guards o Must be located 14" (36 cm) above the counter o Must extend 7" (18 cm) beyond the food Identify all food items o Label food o Place salad dressing names on ladle handles Self-Service Areas To prevent contamination: 9-14 Keep raw meat, fish, and poultry separate from ready-to-eat food Do NOT let customers refill dirty plates or use dirty utensils at self-service areas Stock food displays with the correct utensils for dispensing food Labeling Bulk Food in Self-Service Areas A label is not needed for bulk unpackaged food, such as bakery products, if: 9-15 The product makes no claim regarding health or nutrient content No laws requiring labeling exist The food is manufactured or prepared on the premises The food is manufactured or prepared at another regulated food operation or processing plant owned by the same person Off-Site Service When delivering food off-site: 9-16 Use insulated, food-grade containers designed to stop food from mixing, leaking, or spilling Clean the inside of delivery vehicles regularly Check internal food temperatures Label food with a use-by date and time, and reheating and service instructions Store raw meat, poultry, and seafood, and ready-to-eat items separately Off-Site Service When catering: 9-17 Make sure the service site has the correct utilities o Safe water for cooking, dishwashing, and handwashing o Garbage containers stored away from food-prep, storage, and serving areas Use insulated containers to hold TCS food Store ready-to-eat food separately from raw food Provide customers with directions for handling leftovers Vending Machines To keep vended food safe: Check product shelf life daily o 9-18 Refrigerated food prepped on-site and not sold in seven days must be thrown out Keep TCS food at the correct temperature Dispense TCS food in its original container Wash and wrap fresh fruit with edible peels before putting it in the machine Food Safety Management Systems Food safety management system: 10-2 Group of practices and procedures intended to prevent foodborne illness Actively controls risks and hazards throughout the flow of food Food Safety Management Systems These are the foundation of a food safety management system: 10-3 Personal hygiene program Food safety training program Supplier selection and specification program Quality control and assurance program Food Safety Management Systems These are the foundation of a food safety management system: 10-4 Cleaning and sanitation program Standard operating procedures (SOPs) Facility design and equipment maintenance program Pest control program Active Managerial Control Focuses on controlling the five most common risk factors for foodborne illness: 1. Purchasing food from unsafe sources 2. Failing to cook food adequately 3. Holding food at incorrect temperatures 4. Using contaminated equipment 5. Practicing poor personal hygiene 10-5 Active Managerial Control There are many ways to achieve active managerial control in the operation: Training programs Manager supervision Incorporation of standard operating procedures (SOPs) HACCP These are critical to the success of active managerial control: 10-6 Monitoring critical activities in the operation Taking the necessary corrective action when required Verifying that the actions taken control the risks factors The FDA’s Public Health Interventions The FDA provides recommendations for controlling the common risk factors for foodborne illness: 10-7 Demonstration of knowledge Staff health controls Controlling hands as a vehicle of contamination Time and temperature parameters for controlling pathogens Consumer advisories HACCP The HACCP approach: 10-8 HACCP is based on identifying significant biological, chemical, or physical hazards at specific points within a product’s flow through an operation Once identified, hazards can be prevented, eliminated, or reduced to safe levels HACCP To be effective, a HACCP system must be based on a written plan: 10-9 It must be specific to each facility’s menu, customers, equipment, processes, and operations A plan that works for one operation may not work for another HACCP The seven HACCP principles: 1. Conduct a hazard analysis 2. Determine critical control points (CCPs) 3. Establish critical limits 4. Establish monitoring procedures 5. Identify corrective actions 6. Verify that the system works 7. Establish procedures for record keeping and documentation 10-10 HACCP Principle 1: Conduct a hazard analysis 10-11 Identify potential hazards in the food served by looking at how it is processed Identify TCS food items and determine where hazards are likely to occur for each one; look for biological, chemical, and physical contaminants HACCP Principle 2: Determine critical control points (CCPs) 10-12 Find points in the process where identified hazards can be prevented, eliminated, or reduced to safe levels—these are the CCPs Depending on the process, there may be more than one CCP HACCP Principle 3: Establish critical limits 10-13 For each CCP, establish minimum or maximum limits These limits must be met to o Prevent or eliminate the hazard o Reduce it to a safe level Critical Limit HACCP Principle 4: Establish monitoring procedures Determine the best way to check critical limits o 10-14 Make sure they are consistently met Identify who will monitor them and how often HACCP Principle 5: Identify corrective actions 10-15 Identify steps that must be taken when a critical limit is not met Determine these steps in advance HACCP Principle 6: Verify that the system works Determine if the plan is working as intended Evaluate the plan on a regular basis using 10-16 o Monitoring charts o Records o Hazard analysis Determine if your plan prevents, reduces, or eliminates identified hazards HACCP Principle 7: Establish procedures for record keeping and documentation Keep records for these actions: 10-17 Monitoring activities Corrective actions Validating equipment (checking for good working condition) Working with suppliers (invoices, specifications, etc.) HACCP These specialized processing methods require a variance and may require a HACCP plan: 10-18 Smoking food as a method to preserve it (but not to enhance flavor) Using food additives or components such as vinegar to preserve or alter food so it no longer requires time and temperature control for safety Curing food Custom-processing animals HACCP These specialized processing methods require a variance and may require a HACCP plan: 10-19 Packaging food using ROP methods including o MAP o Vacuum-packed o Sous vide Treating (e.g. pasteurizing) juice on-site and packaging it for later sale Sprouting seeds or beans Crisis Management To build a crisis-management program: 10-20 Create a crisis-management team Prepare for different types of crises Create a written plan tailored to your operation Test your plan Crisis Management To prepare for a crisis: 10-21 Create a crisis-management team Create an emergency-contact list Develop a crisis-communication plan Crisis Management To prepare for a foodborne-illness outbreak: 10-22 Develop a food safety program Train staff on food safety policies and procedures Create a foodborne illness incident report form o Get legal guidance when developing it o Train staff to use it Crisis Management The foodborne illness incident report form should document the following: 10-23 What and when the customer ate at the operation When the customer first got sick, what the symptoms where, and how long they were experienced When and where the customer sought medical attention What other food was eaten by the customer Crisis Management When responding to a crisis: 10-24 Work with the media Communicate directly with your key audiences (customers, stockholders, the community) Fix the problem and then communicate what you have done Crisis Management When responding to a foodborneillness outbreak: 10-25 Take the complaint seriously and express concern Complete an incident report form Contact your crisis-management team and the local health department Follow your crisis-communication plan Responding to a Foodborne-Illness Outbreak If: 10-26 Then: A customer calls to report a foodborne illness Take the complaint seriously and express concern Don’t admit responsibility Ask for general contact information Complete the foodborne-illness incident report form Responding to a Foodborne-Illness Outbreak If: 10-27 Then: There are similar customer complaints of foodborne illness Contact the crisis-management team Identify common food items to determine the potential source of the complaint Contact the regulatory authority to assist with the investigation if an outbreak is suspected Responding to a Foodborne-Illness Outbreak If: 10-28 Then: The suspected food is still in the operation Set aside the suspected product and identify it to prevent further sale Label the product with a “Do Not Use” and “Do Not Discard” label Log information about the product including a description, product date, and lot number If possible, obtain samples of the suspect food from the customer Responding to a Foodborne-Illness Outbreak If: 10-29 Then: The suspected outbreak is caused by a sick staff member Maintain a list of food handlers scheduled at the time of the suspected contamination Interview them about their health status Exclude the suspected staff member from the operation following requirements Responding to a Foodborne-Illness Outbreak If: 10-30 Then: The regulatory authority confirms your operation is the source of the outbreak Cooperate with the regulatory authority to resolve the crisis Provide appropriate documentation including temperature logs, HACCP documents, staff files, etc. Crisis Management To recover from a foodborne-Illness outbreak: Investigate to find the cause of the outbreak Work with the regulatory authority to resolve issues Throw out all suspected food Clean and sanitize all areas of the operation Establish new procedures or revise existing ones based on the investigation results Develop a plan to reassure customers that the food served in your operation is safe 10-31 Construction Plan Review Construction plans will require approval by the local regulatory authority. Benefits of a regulatory review: 11-2 Ensures design meets regulatory requirements Ensures safe flow of food May save time and money Ensures contractors are constructing the facility correctly Ensures approved equipment is being used Facility Design A well-designed kitchen will address: 11-3 Workflow o It must keep food out of the temperature danger zone as much as possible o It must limit the number of times food is handled Facility Design A well-designed kitchen will address: Contamination o The risk of cross-contamination must be minimized o Place equipment to prevent splashing or spillage from one piece of equipment to another Equipment accessibility o 11-4 Place equipment so staff can easily clean the facility and all equipment Material Selection for Interior Construction Flooring must be: Smooth Durable Nonabsorbent Easy to clean For use in these areas: 11-5 Walk-in coolers Prep and food-storage Dishwashing Restrooms Dressing and locker rooms Material Selection for Interior Surfaces Coving: 11-6 Curved, sealed edge placed between the floor and wall Eliminates sharp corners or gaps that are hard to clean Must be glued tightly to the wall to o Eliminate hiding places for pests o Protect the wall from moisture Interior Walls and Ceilings Materials must be: 11-7 Smooth Nonabsorbent Durable Easy to clean Handwashing Stations Handwashing stations must be conveniently located and are required in: Restrooms or directly next to them Food-prep areas Service areas Dishwashing areas Handwashing sinks must be used only for handwashing. 11-8 Handwashing Stations Handwashing stations must have: Hot and cold running water Garbage container 11-9 Soap A way to dry hands Signage Equipment Standards Look for the NFS mark when purchasing equipment: 11-10 Ensures food equipment surfaces are o Nonabsorbent o Smooth o Corrosion resistant o Easy to clean o Durable o Resistant to damage Dishwashing Machines Dishwashers must be installed: 11-11 So they are reachable and conveniently located In a way that keeps utensils, equipment, and other food-contact services from becoming contaminated Following manufacturer’s instructions Dishwashing Machines When selecting dishwashers make sure: 11-12 The detergents and sanitizers used are approved by the local regulatory authority They have the ability to measure water temperature, water pressure, and cleaning and sanitizing chemical concentration Information about the correct settings is posted on the machine Three-Compartment Sinks Purchase sinks large enough to accommodate large equipment and utensils. 11-13 Installing and Maintaining Equipment Floor-mounted equipment must be either: 11-14 Mounted on legs at least six inches (15 centimeters) high Sealed to a masonry base Installing and Maintaining Equipment Tabletop equipment should be either: 11-15 Mounted on legs at least four inches (10 centimeters) high Sealed to the countertop Installing and Maintaining Equipment Once equipment has been installed: 11-16 It must be maintained regularly Only qualified people should maintain it Set up a maintenance schedule with your supplier or manufacturer Check equipment regularly to make sure it is working correctly Water Supply Acceptable sources of drinkable water: 11-17 Approved public water mains Regularly tested and maintained private sources Closed, portable water containers Water transport vehicles Plumbing Cross-connection: 11-18 Physical link between safe water and dirty water from o Drains o Sewers o Other wastewater sources Plumbing Backflow: Reverse flow of contaminants through a cross-connection into the drinkable water supply Backsiphonage: 11-19 A vacuum created in the plumbing system that sucks contaminants back into the water supply o Can occur when high water use in one area of the operation creates a vacuum o A running hose in a mop bucket can lead to backsiphonage Plumbing Backflow prevention methods: Vacuum breaker 11-20 Air gap Sewage If there is a backup of sewage in the operation: The affected area should be closed right away The problem must be corrected The area must be thoroughly cleaned If the backup is a significant risk to food safety: 11-21 Service must be stopped The local regulatory authority must be notified Lighting Consider the following when installing and maintaining lighting: 11-22 Different areas of the facility have different lighting intensity requirements Local jurisdictions usually require prep areas to be brighter than other areas All lights should have shatter-resistant lightbulbs or protective covers Replace burned out bulbs with correct size bulbs Ventilation Ventilation systems: 11-23 Must be cleaned and maintained to prevent grease and condensation from building up on walls and ceilings o Follow manufacturer’s recommendations o Meet local regulatory requirements Garbage Garbage: Remove from prep areas as quickly as possible o Clean the inside and outside of containers frequently o 11-24 Be careful not to contaminate food and food-contact surfaces Clean them away from food-prep and storage areas Garbage Indoor containers must be: Leak proof, waterproof, and pest proof Easy to clean Covered when not in use Designated storage areas: 11-25 Store waste and recyclables separately from food and food-contact surfaces Storage must not create a nuisance or a public health hazard Garbage Outdoor containers must: Be placed on a smooth, durable, nonabsorbent surface o 11-26 Asphalt or concrete Have tight-fitting lids Be covered at all times Have their drain plugs in place Cleaners Cleaners must be: Stable and noncorrosive Safe to use When using them: 12-2 Follow manufacturers’ instructions Do NOT use one type of detergent in place of another unless the intended use is the same Cleaners Types of detergents: General-purpose detergents o Heavy-duty detergents o 12-3 Remove dirt from floors, walls, ceilings, prep surfaces and most equipment surfaces Remove wax, aged or dried dirt, and baked-on grease Cleaners Degreasers: Have ingredients for dissolving grease Work well on burned-on grease o 12-4 Backsplashes, oven doors, and range hoods Cleaners Delimers: 12-5 Used on mineral deposits and other dirt that other cleaners can’t remove o Steam tables o Dishwashers Cleaners Abrasive cleaners: 12-6 Have a scouring agent that helps scrub hard-to-remove dirt Used to remove baked-on food Can scratch surfaces Sanitizing Surfaces can be sanitized using: 12-7 Heat o The water must be at least 171˚F (77 ˚ C) o Immerse the item for 30 seconds Chemicals o Chlorine o Iodine o Quats Sanitizing Chemical sanitizing: 12-8 Food-contact surfaces can be sanitized by either o Soaking them in a sanitizing solution o Rinsing, swabbing, or spraying them with a sanitizing solution In some cases a detergent-sanitizer blend can be used o Use it once to clean o Use it a second time to sanitize Sanitizer Effectiveness Concentration: 12-9 Sanitizers should be mixed with water to the correct concentration o Not enough sanitizer may make the solution weak and useless o Too much sanitizer may make the solution too strong, unsafe, and corrode metal Sanitizer Effectiveness Concentration: 12-10 Check concentration with a test kit o Make sure it is designed for the sanitizer used o Check the concentration often Change the solution when o It’s dirty o The concentration is too low Sanitizer Effectiveness Temperature: Follow manufacturer’s recommendations for the correct temperature Contact time: 12-11 The sanitizer must make contact with the object for a specific amount of time Minimum times differ for each sanitizer Sanitizer Effectiveness Water hardness and pH: 12-12 Find out what your water hardness and pH is from your municipality Work with your supplier to identify the correct amount of sanitizer to use Guidelines for the Effective Use of Sanitizers Chlorine Water temperature Water pH Water hardness Sanitizer concentration range Sanitizer contact time 12-13 ≥100˚F (38˚C) ≥75˚F (24˚C) ≤10 ≤8 As per manufacturer’s recommendations 50–99 ppm 50–99 ppm ≥7 sec ≥7 sec Guidelines for the Effective Use of Sanitizers Water temperature Water pH Water hardness Sanitizer concentration range Sanitizer contact time 12-14 Iodine Quats 68˚F (20˚C) 75˚F (24˚C) ≤5 or as per manufacturer’s recommendations As per manufacturer’s recommendations As per manufacturer’s recommendations ≤500 ppm or as per manufacturer’s recommendations 12.5–25 ppm As per manufacturer’s recommendations ≥30 sec ≥30 sec How and When to Clean and Sanitize How to clean and sanitize: 1. Scrape or remove food bits from the surface 2. Wash the surface 4. Sanitize the surface 12-15 3. Rinse the surface 5. Allow the surface to air-dry How and When to Clean and Sanitize Food-contact surfaces must be cleaned and sanitized: 12-16 After they are used Before working with a different type of food Any time a task was interrupted and the items may have been contaminated After four hours if the items are in constant use How and When to Clean and Sanitize Cleaning and sanitizing stationary equipment: Unplug the equipment Take the removable parts off the equipment o 12-17 Wash, rinse, and sanitize them by hand or run the parts through a dishwasher if allowed Scrape or remove food from the equipment surfaces Wash the equipment surfaces How and When to Clean and Sanitize Cleaning and sanitizing stationary equipment: Rinse the equipment surfaces with clean water Sanitize the equipment surfaces o 12-18 Make sure the sanitizer comes in contact with each surface Allow all surfaces to air-dry Put the unit back together How and When to Clean and Sanitize Clean-in-place equipment: 12-19 Equipment holding and dispensing TCS food must be cleaned and sanitized every day unless otherwise indicated by the manufacturer Check local regulatory requirements Machine Dishwashing High-temperature machines: Final sanitizing rinse must be at least 180˚F (82˚C) o 165˚F (74˚C) for stationary rack, single-temperature machines Chemical-sanitizing machines: 12-20 Clean and sanitize at much lower temperatures Follow the temperature guidelines provided by the manufacturer Dishwasher Operation Guidelines: 12-21 Clean the machine as often as needed Scrape, rinse, or soak items before washing Use the correct dish racks NEVER overload dish racks Air-dry all items Check the machine’s water temperature and pressure Monitoring High Temperature Dishwashing Machines When using high-temperature dishwashing machines, provide staff with tools to check the temperature of the items being sanitized. Options include: 12-22 Maximum registering thermometers Temperature sensitive tape Manual Dishwashing Setting up a three-compartment sink: 12-23 Clean and sanitize each sink and drain board Fill the first sink with detergent and water at least 110˚F (43˚C) Fill the second sink with clean water Fill the third sink with water and sanitizer to the correct concentration Provide a clock with a second hand to let food handlers know how long items have been in the sanitizer Three-Compartment Sinks Steps for cleaning and sanitizing: 12-24 1. Rinse, scrape, or soak items before washing them 2. Wash items in the first sink 4. Sanitize items in the third sink 5. Air-dry items on a clean and sanitized surface 3. Rinse items in the second sink Storing Tableware and Equipment When storing clean and sanitized tableware and equipment: 12-25 Store them at least six inches (15 cm) off the floor Clean and sanitize drawers and shelves before items are stored Store glasses and cups upside down on a clean and sanitized shelf or rack Storing Tableware and Equipment When storing clean and sanitized tableware and equipment: 12-26 Store flatware and utensils with handles up Cover the food-contact surfaces of stationary equipment until ready for use Clean and sanitize trays and carts used to carry clean tableware and utensils Cleaning the Premises When cleaning the premises: 12-27 Clean nonfood-contact surfaces regularly o Includes floors, ceilings, walls, equipment exteriors, etc. o Prevents dust, dirt, food residue and other debris from building up Cleaning the Premises Cleaning up after people who get sick: Diarrhea and vomit in the operation must be cleaned up correctly o 12-28 It can carry Norovirus, which is highly contagious Correct cleanup can prevent food from becoming contaminated and keep others from getting sick Check with your local regulatory authority regarding requirements for cleaning up vomit and diarrhea. A written cleanup plan may be required. Cleaning the Premises Consider the following when developing a plan for cleaning up vomit and diarrhea: 12-29 How you will contain liquid and airborne substances, and remove them from the operation How you will clean, sanitize, and disinfect surfaces When to throw away food that may have been contaminated What equipment is needed to clean up these substances, and how it will be cleaned and disinfected after use When a food handler must wear personal protective equipment Cleaning the Premises Develop a plan for cleaning up vomit and diarrhea: 12-30 How staff will be notified of the correct procedures for containing, cleaning, and disinfecting these substances How to segregate contaminated areas from other areas When staff must be restricted from working with or around food or excluded from working in the operation How sick customers will be quickly removed from the operation How the cleaning plan will be implemented Cleaning the Premises Storing cleaning tools and chemicals: Place in a separate area away from food and prep areas The storage area should have: 12-31 Good lighting so chemicals can be easily seen Hooks for hanging cleaning tools Utility sink for filling buckets and washing cleaning tools Floor drain for dumping dirty water Cleaning the Premises NEVER: 12-32 Dump mop water or other liquid waste into toilets or urinals Clean tools in sinks used for o Handwashing o Food prep o Dishwashing Using Foodservice Chemicals Chemicals: 12-33 Only purchase those approved for use in foodservice operations Store them in their original containers away from food and food-prep areas If transferring them to a new container, label it with the common name of the chemical Using Foodservice Chemicals Chemicals: 12-34 Keep MSDS for each chemical When throwing chemicals out, follow o Instructions on the label o Local regulatory requirements Developing a Cleaning Program To develop an effective cleaning program: 12-35 Create a master cleaning schedule Train your staff to follow it Monitor the program to make sure it works Developing a Cleaning Program To create a master cleaning schedule, identify: 12-36 What should be cleaned Who should clean it When it should be cleaned How it should be cleaned Developing a Cleaning Program Monitoring the cleaning program: 12-37 Supervise daily cleaning routines Check cleaning tasks against the master schedule every day Change the master schedule as needed Ask staff for input on the program Integrated Pest Management (IPM) Program An IPM program: 13-2 Uses prevention measures to keep pests from entering the operation Uses control measures to eliminate any pests that get inside Will be successful if you work closely with a licensed pest control operator (PCO) Integrated Pest Management (IPM) Program The 3 rules of integrated pest management: 1. Deny pests access to the operation 2. Deny pests food and shelter 3. Work with a licensed PCO to eliminate pests that do enter 13-3 Denying Pests Access to the Operation To keep pests from entering with deliveries: Use approved, reputable suppliers Check deliveries before they enter the operation o 13-4 Refuse shipments that have pests or signs of pests (egg cases, body parts such as legs or wings) Denying Pests Access to the Operation To keep pests from entering through openings in the building: 13-5 Screen windows and vents Install self-closing devices, door sweeps, and air curtains on doors Keep exterior openings closed tightly Denying Pests Access to the Operation To keep pests from entering through openings in the building: 13-6 Fill holes around pipes Cover drains with grates Seal cracks in floors, walls, and around equipment Deny Food and Shelter To deny pests food and shelter: 13-7 Dispose of garbage quickly and correctly o Keep containers clean o Keep outdoor containers tightly covered o Clean up spills around containers immediately o Wash and rinse containers often Deny Food and Shelter To deny pests food and shelter: 13-8 Store recyclables correctly o Keep recyclables in clean, pest-proof containers o Keep containers as far away from the building as regulations allow Deny Food and Shelter To deny pests food and shelter: 13-9 Store food and supplies quickly and correctly o Keep them away from walls and at least 6” (15 cm) off the floor o Rotate food so pests cannot settle into them and breed Clean the facility thoroughly o Clean up food and beverage spills immediately o Clean toilets and restrooms as needed o Train staff to keep lockers and break areas clean o Keep cleaning tools and supplies clean and dry o Empty water from buckets to keep from attracting rodents Identifying Pests Cockroaches: Often carry pathogens Live and breed in places that are: 13-10 o Dark o Warm o Moist o Hard to clean If you see them in daylight, you may have a major infestation Identifying Pests Signs of a cockroach infestation include: 13-11 Strong, oily odor Droppings (feces) that look like grains of black pepper Capsule shaped egg cases o Brown, dark red, or black o Leathery, smooth, or shiny Identifying Pests Signs of a rodent infestation include: Gnaw marks Droppings o o Dirt tracks along walls Nests o o o o 13-12 Shiny and black (fresh) Gray (old) Cloth, hair, feathers, grass, scraps of paper In quiet places Near food and water Next to buildings Illustration courtesy of Orkin Commercial Working with a Pest Control Operator (PCO) Before choosing a PCO: 13-13 Check references Make sure the PCO is licensed if required by your state Require a written contract outlining work to be performed Using and Storing Pesticides When pesticides will be applied: Wait until you are closed for business and staff are not on-site Remove food and movable food-contact surfaces Cover equipment and food-contact surfaces that can’t be moved Afterwards: 13-14 Wash, rinse, and sanitize food-contact surfaces Using and Storing Pesticides If pesticides will be stored on the premises: 13-15 Keep them in their original containers Store them in a secure location away from food, utensils, and equipment Dispose of them per manufacturers’ directions and local regulations Keep corresponding MSDS on the premises Government Agencies Responsible for Preventing Foodborne Illness Government agencies: 14-2 The Food and Drug Administration (FDA) U.S. Department of Agriculture (USDA) Centers for Disease Control and Prevention (CDC) U.S. Public Health Service (PHS) State and local regulatory authorities Government Agencies Responsible for Preventing Foodborne Illness The FDA Food Code: 14-3 Outlines federal recommendations for food safety regulations for the foodservice industry Created for city, county, state, and tribal agencies Although FDA recommends adoption by each state, it cannot require it Government Agencies Responsible for Preventing Foodborne Illness State and local control: 14-4 Regulatory authorities write or adopt food codes that regulate retail and foodservice operations Food codes differ widely by state or locality In large cities the local regulatory authority will probably be responsible for enforcing requirements In smaller cities or rural areas, a county or state regulatory authority may be responsible for enforcement State and local health inspectors conduct foodservice inspections in most states The Inspection Process Foodservice inspections: 14-5 Required for all operations Lets an operation know if it is meeting minimum food safety standards Often based on the 5 CDC risk factors and the FDA public-health interventions The Inspection Process Risk designations for evaluating facilities: Priority items o Priority foundation items o Support priority items (e.g., soap at a handwashing station) Core items o 14-6 Prevent, eliminate, or reduce hazards (e.g., handwashing) Relate to general sanitation, the facility, equipment design, and general maintenance, (e.g., keeping equipment repaired) Steps in the Inspection Process Inspection guidelines: 14-7 Ask for Identification Cooperate with the inspector Take notes Keep the relationship professional Be prepared to provide requested records Discuss violations and time frames for correction Act on all deficiencies noted in the report Closure An inspector may close an operation when there is: 14-8 Significant lack of refrigeration Backup of sewage into the operation Emergency, such as a fire or flood Significant pest infestation Long interruption of electrical or water service Clear evidence of a foodborne-illness outbreak related to the operation Self-Inspections The benefits of self-inspections: Safer food Improved food quality Cleaner environment for staff and customers Higher inspection scores When conducting a self inspection: 14-9 Use the same type of checklist that the regulatory authority uses Identify all risks to food safety After the inspection, meet with staff to review problems Training Staff A food safety training need: 15-2 Gap between what staff needs to know to do their job and what they actually know Can be identified by: o Observing performance on the job o Testing food safety knowledge o Identifying areas of weakness Training Staff Training and monitoring: 15-3 Train staff to follow food safety procedures Provide initial and ongoing training Provide all staff with general food safety knowledge Provide job specific food safety training Retrain staff regularly Monitor staff to make sure they are following procedures Document training Critical Food Safety Knowledge Staff members should receive training in: Good personal hygiene o o o o o 15-4 How and when to wash hands Where to wash hands Other hand-care guidelines (fingernail length, nail polish, covering wounds) Correct work attire Reporting illness Critical Food Safety Knowledge Staff members should receive training in: 15-5 Controlling time and temperature o TCS food o How to measure the temperature of food o Holding and storing TCS food o How to label food for storage o Temperature requirements when thawing, cooking, cooling, and reheating food Critical Food Safety Knowledge Staff members should receive training in: 15-6 Preventing cross-contamination o Preventing cross-contamination of food during storage, preparation, and service o Preventing cross-contamination when storing utensils and equipment o What to do if cross-contamination happens o What to do for people who have food allergies Critical Food Safety Knowledge Staff members should receive training in: 15-7 Cleaning and sanitizing o How and when to clean and sanitize o The correct way to wash dishes in a three-compartment sink and in a dishwasher o How to handle cleaning tools and supplies o Handling garbage o Spotting pests Ways of Training Methods for delivering training: 15-8 On-the-job training Classroom training o Information search o Guided discussion o Games o Role-play o Demonstrations o Jigsaw design o Training videos and DVDs Delivering Training Methods for delivering training: Technology-based training o Online training Technology-based training is most appropriate when: 15-9 Staff work in different locations and/or need the same training at different times It is too costly to bring staff to the same place Staff need to learn at their own pace