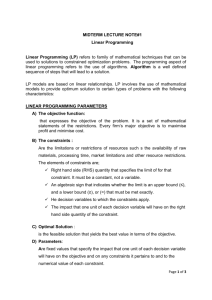

WinQSB Chapter 2

advertisement

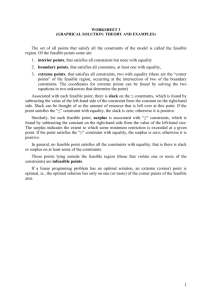

Linear Programming 1 Objectives – Requirements for a linear programming model. – Graphical representation of linear models. – Linear programming results: • • • • Unique optimal solution Alternate optimal solutions Unbounded models Infeasible models – Extreme point principle. 2 Objectives - continued – Sensitivity analysis concepts: • • • • • • Reduced costs Range of optimality--LIGHTLY Shadow prices Range of feasibility--LIGHTLY Complementary slackness Added constraints / variables – Computer solution of linear programming models • WINQSB • EXCEL • LINDO 3 Introduction to Linear Programming • A Linear Programming model seeks to maximize or minimize a linear function, subject to a set of linear constraints. • The linear model consists of the following components: – A set of decision variables. – An objective function. – A set of constraints. – SHOW FORMAT 4 • The Importance of Linear Programming – Many real static problems lend themselves to linear programming formulations. – Many real problems can be approximated by linear models. – The output generated by linear programs provides useful “what’s best” and “what-if” information. 5 Assumptions of Linear Programming • The decision variables are continuous or divisible, meaning that 3.333 eggs or 4.266 airplanes is an acceptable solution • The parameters are known with certainty • The objective function and constraints exhibit constant returns to scale (i.e., linearity) • There are no interactions between decision variables 6 Methodology of Linear Programming Determine and define the decision variables Formulate an objective function verbal characterization Mathematical characterization Formulate each constraint 7 THE GALAXY INDUSTRY PRODUCTION PROBLEM - A Prototype Example • Galaxy manufactures two toy models: – Space Ray. – Zapper. • Purpose: to maximize profits • How: By choice of product mix – How many Space Rays? – How many Zappers? • A RESOURCE ALLOCATION PROBLEM 8 Galaxy Resource Allocation Resources are limited to – 1200 pounds of special plastic available per week – 40 hours of production time per week. • All LP Models have to be formulated in the context of a production period – In this case, a week 9 • Marketing requirement – Total production cannot exceed 800 dozens. – Number of dozens of Space Rays cannot exceed number of dozens of Zappers by more than 450. • Technological input – Space Rays require 2 pounds of plastic and 3 minutes of labor per dozen. – Zappers require 1 pound of plastic and 4 minutes of labor per dozen. 10 • Current production plan calls for: – Producing as much as possible of the more profitable product, Space Ray ($8 profit per dozen). – Use resources left over to produce Zappers ($5 profit per dozen). WinQSB report is at the end. • The current production plan consists of: Space Rays = 550 dozens Zapper = 100 dozens Profit = 4900 dollars per week 11 MODEL FORMULATION • Decisions variables: – X1 = Production level of Space Rays (in dozens per week). – X2 = Production level of Zappers (in dozens per week). • Objective Function: – Weekly profit, to be maximized 12 The Objective Function Each dozen Space Rays realizes $8 in profit. Total profit from Space Rays is 8X1. Each dozen Zappers realizes $5 in profit. Total profit from Zappers is 5X2. The total profit contributions of both is 8X1 + 5X2 (The profit contributions are additive because of the linearity assumption) 13 • we have a plastics resource constraint, a production time constraint, and two marketing constraints. • PLASTIC: each dozen units of Space Rays requires 2 lbs of plastic; each dozen units of Zapper requires 1 lb of plastic and within any given week, our plastic supplier can provide 1200 lbs. 14 The Linear Programming Model Max 8X1 + 5X2 (Weekly profit) subject to 2X1 + 1X2 < = 1200 (Plastic) 3X1 + 4X2 < = 2400 (Production Time) X1 + X2 < = 800 (Total production) X1 - X2 < = 450 (Mix) Xj> = 0, j = 1,2 (Nonnegativity) 15 The Set of Feasible Solutions for Linear Programs The set of all points that satisfy all the constraints of the model is called a FEASIBLE REGION 16 Using a graphical presentation we can represent all the constraints, the objective function, and the three types of feasible points. 17 X2 1200 The plastic constraint: The Plastic constraint 2X1+X2<=1200 Total production constraint: X1+X2<=800 Infeasible 600 Production Feasible Time 3X1+4X2<=2400 Production mix constraint: X1-X2<=450 600 800 Interior points. Boundary points. Extreme points. X1 18 We now demonstrate the search for an optimal solution Start at some arbitrary profit, say profit = $2,000... Then increase the profit, if possible... X2 1200 ...and continue until it becomes infeasible 800 Profit 4, Profit = $=$5040 2, 3, 000 600 X1 400 600 800 19 1200 X2 Let’s take a closer look at the optimal point Infeasible 800 600 Feasible Feasible region region X1 400 600 800 20 Summary of the optimal solution Space Rays = 480 dozens Zappers = 240 dozens Profit = $5040 – This solution utilizes all the plastic and all the production hours. – Total production is only 720 (not 800). – Space Rays production exceeds Zapper by only 240 dozens (not 450). 21 • Extreme points and optimal solutions – If a linear programming problem has an optimal solution, it will occur at an extreme point. • Multiple optimal solutions – For multiple optimal solutions to exist, the objective function must be parallel to a constraint that defines the boundary of the feasible region. – Any weighted average of optimal solutions is also an optimal solution. 22 The Role of Sensitivity Analysis of the Optimal Solution • Is the optimal solution sensitive to changes in input parameters? • Possible reasons for asking this question: – Parameter values used were only best estimates. – Dynamic environment may cause changes. – “What-if” analysis may provide economical and operational information. 23 Sensitivity Analysis of Objective Function Coefficients. • Range of Optimality – The optimal solution will remain unchanged as long as • An objective function coefficient lies within its range of optimality • There are no changes in any other input parameters. – The value of the objective function will change if the coefficient multiplies a variable whose value is nonzero. 24 The effects of changes in an objective function coefficient on the optimal solution 1200 X2 800 600 X1 400 600 800 25 The effects of changes in an objective function coefficient on the optimal solution 1200 X2 Range of optimality 800 600 400 600 800 X1 26 • Multiple changes – The range of optimality is valid only when a single objective function coefficient changes. – When more than one variable changes we turn to the 100% rule. This is beyond the scope of this course 27 • Reduced costs The reduced cost for a variable at its lower bound (usually zero) yields: • The amount the profit coefficient must change before the variable can take on a value above its lower bound. • Complementary slackness At the optimal solution, either a variable is at its lower bound or the reduced cost is 0. 28 29 Sensitivity Analysis of Right-Hand Side Values • Any change in a right hand side of a binding constraint will change the optimal solution. • Small change in a right-hand side of a nonbinding constraint that is less than its slack or surplus, will cause no change in the optimal solution. 30 • In sensitivity analysis of right-hand sides of constraints we are interested in the following questions: Keeping all other factors the same, how much would the optimal value of the objective function (for example, the profit) change if the right-hand side of a constraint changed by one unit? – For how many additional UNITS is this per unit change valid? – For how many fewer UNITS is this per unit change valid? 31 X2 1200 The Plastic constraint The new Plastic constraint Maximum profit = 5040 Production mix constraint 600 Production time constraint Feasible Infeasible extreme points X1 600 800 32 • Correct Interpretation of shadow prices – Sunk costs: The shadow price is the value of an extra unit of the resource, since the cost of the resource is not included in the calculation of the objective function coefficient. – Included costs: The shadow price is the premium value above the existing unit value for the resource, since the cost of the resource is included in the calculation of the objective function coefficient. 33 • Range of feasibility – The set of right - hand side values for which the same set of constraints determines the optimal extreme point. – The range over-which the same variables remain in solution (which is another way of saying that the same extreme point is the optimal extreme point) – Within the range of feasibility, shadow prices remain constant; however, the optimal objective function value and decision variable values will change if the corresponding constraint is binding 34 Other Post Optimality Changes • Addition of a constraint. • Deletion of a constraint. • Addition of a variable. • Deletion of a variable. • Changes in the left - hand side technology coefficients. 35 Models Without Optimal Solutions • Infeasibility: Occurs when a model has no feasible point. • Unboundedness: Occurs when the objective can become infinitely large. 36 Infeasibility No point, simultaneously, lies both above line 1 and below lines 2 and 3 . 2 3 1 37 Unbounded solution 38 Navy Sea Ration • A cost minimization diet problem – Mix two sea ration products: Texfoods, Calration. – Minimize the total cost of the mix. – Meet the minimum requirements of Vitamin A, Vitamin D, and Iron. 39 • Decision variables – X1 (X2) -- The number of two-ounce portions of Texfoods (Calration) product used in a serving. • The Model Cost per 2 oz. Minimize 0.60X1 + 0.50X2 Subject to 20X1 + 50X2 100 Vitamin A % Vitamin A 25X1 + 25X2 100 Vitamin D provided per 2 oz. 50X1 + 10X2 100 Iron X1, X2 0 % required 40 The Graphical solution 5 4 The Iron constraint Feasible Region Vitamin “D” constraint 2 Vitamin “A” constraint 2 4 5 41 • Summary of the optimal solution – Texfood product = 1.5 portions (= 3 ounces) Calration product = 2.5 portions (= 5 ounces) – Cost =$ 2.15 per serving. – The minimum requirements for Vitamin D and iron are met with no surplus. – The mixture provides 155% of the requirement for Vitamin A. 42 Computer Solution of Linear Programs With Any Number of Decision Variables • Linear programming software packages solve large linear models. • Most of the software packages use the algebraic technique called the Simplex algorithm. • The input to any package includes: – The objective function criterion (Max or Min). – The type of each constraint: , , . – The actual coefficients for the problem. 43 • The typical output generated from linear programming software includes: – Optimal value of the objective function. – Optimal values of the decision variables. – Reduced cost for each objective function coefficient. – Ranges of optimality for objective function coefficients. – The amount of slack or surplus in each constraint. – Shadow (or dual) prices for the constraints. – Ranges of feasibility for right-hand side values. 44 Variable and constraint name can be changed here WINQSB Input Data for the Galaxy Industries Problem Variables are restricted to >= 0 Click to solve No upper bound 45 Basis and non-basis variables • The basis variable values are free to take on values other than their lower bounds • The non-basis variables are fixed at their lower bounds (0) • THERE ARE ALWAYS AS MANY BASIS VARIABLES AS THERE ARE CONSTRAINTS, ALWAYS 46 Another problem with10 products • max 10x1 + 12 x2 + 15 x3 + 5 x4 + 8 x5 + 17x6 + 3 x7 + 9x8 + 11x10 • s.t. • 2x1 + x2 + 3x3 + x4 + 2x5 + 3x6 + x7 + 3x8 + 2x9 + x10 <= 100 • all xi >= 0 • How many basis variables? • How many products should we be making? 47 48