Integrating the Supply Chain at Bristol

advertisement

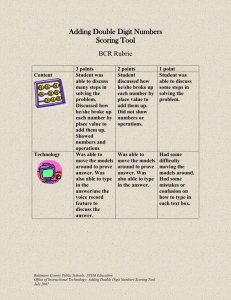

Integrating a Global Supply Chain: Essential Strategies Pharma Manufacturing Cambridge, Massachusetts June 23, 2004 Cheryl Capps Vice President Supply Chain Planning & Optimization Bristol-Myers Squibb 0 BMS: A $20B Pharmaceutical and Related Healthcare Business BMS Facts 27 Pharmaceutical plants 5 Chemical Plants 135 Markets Planned 150 + Contract Mfgs 100 + Distribution Centers 2 SAP instances, 24 BPCS instances, and 6 msc. ERP systems 6000+ SKU’s, 15000+ SRC’s Pharmaceutical Plant Chemical Plant Inventory …significant supply chain complexity 1 Our Vision Is Clear… One Plant, One Team, One Plan Seamless Integration, Flawless Execution … but what does it really mean? 2 Conceptualizing an Integrated Supply Chain is like asking a group of people to conceptualize Heaven… What does it look like? How do you get there? While everyone agrees that it’s a nice place and we should go there, that’s where the agreement ends! 3 What does Integration Mean to Us? From Every participant in the supply chain is working from a different plan Little or no visibility beyond local unit Disjointed metrics, inconsistent reporting The same data has a different meaning at every site High variability in non-CGMP processes (like planning) To One global supply chain plan Daily, global visibility of planning data Standard, global metric calculation and reporting Consistent data definitions Minimum standards for key processes Before you can optimize the supply chain, you must integrate it 4 What Capabilities are required by “Integration”? Complete visibility of — — — Consistent metrics that drive supply chain, not local performance Consistent practices — Simultaneous planning at multiple levels — Inventories Demand Plant production plans and constraints — Market and plant at the same time — Organizational alignment Tightly defined business rules for interactions between sites Practices that ensure the accuracy of critical data The same data means the same thing to everyone Global master data Integration is the ability to create and execute a single plan for the entire supply chain. 5 Why do we fail? The usual suspects: Lack of senior management support Unrealistic objectives Lack of resources Poor project management IT focus/IT led Poor change management But many companies get all of these things right and still fail to realize the desired benefits! 6 Essential Strategies Step 1: Develop a compelling case for change Step 2: Create a vivid picture of the future Step 3: Identify the gaps in capabilities between the “as is” and the “to be” state Step 4: Build a road map Step 5: Design the project Step 6: Establish change management program There are 6 essential strategies to integrating a supply chain 7 Essential Strategies Step 1: Develop a compelling case for change — — — Easy to understand Tailored to stakeholder group * Conceptual * Emotional * Financial * Technical Integrated with other key business strategies Assume that the detriments of the “as is” state are not widely understood. 8 “As-Is” Scenario Demand Data Non US Markets Bulk Sites Tolling Partners 3rd Party Mfgs Cannot balance supply and demand Finishing Sites •Long lead time •Minimum order qtys. MTO Market Orders Replenishment Orders Central Planning US Market Multiple formats systems & schedules In SAP Sites In BPCS Sites Central Planning InTransit 3rd Party Mfg Tolling Tolling Partners 3rd Party Mfg Distribution In US DC’s Market Impact •Unreliable delivery Finishing Sites SAP Sites BPCS Sites Finishing Sites Finishing Sites Supply Data Supply Chain Issue •Excessive Inventory •Resource Intensive In NonUS DC’s Manual, resource intensive, inaccurate 9 Essential Strategies Step 2: Create a vivid picture of the future — Right scope — Well defined Endpoint — Narrow enough to be manageable Broad enough to allow true integration What does success look like? Tailored to stakeholder group Detail for the “Detailed”, Simple for the “Simple” Assume that the benefits of the “to be” state are not inherently obvious 10 The Future State Process – Level 1 Demand Data Global Forecast & Net Requirements Balance Supply & Demand Statistical Tools APS System Supply Data Global Inventory & Capacity Data Suggested Network Plan Shape Supply & Demand Markets Network Planning S&OP Trade Sales Collaborative Planning MFG Sites Net Requirement Plan •One Format •One delivery system •Set calendar Purchase Orders •One Plan •Collaborative Process •Data-based decision making •Assigned Accountability •Full-picture •Real Time 11 Process Design – Level 2 “To Be” Operating Model 1.0 Determine Supply Capabilities 3.0 Balance Supply/Demand 2.0 Determine Demand Requirements 1.1 Determine Raw Material Supply 1.4 Determine Production Capacities 3.1 Consolidate Demand 3.7 Perform “What If” on NPI 2.1 Collect Customer Data and Collaborative Input 2.4 Collect Market Research / Analysis 2.7 Simulate NPI Requirements 1.2 Determine WIP and Committed Production 1.5 Determine 3rd Party Supply Capability 3.2 Load Inventories 3.8 Prepare for S&OP Meeting 2.2 Load Demand History 2.5 Collect Promotion and Deal Information 2.8 Approve Forecast 1.3 Determine Actual FG Inventory 1.6 Determine Tolling Partner Supply Capability 3.3 Review Supply Chain Performance 3.9 Conduct S&OP Meeting 2.3 Create Statistical Baseline 2.6 Develop Sales Forecast 3.4 Update Market Segmentation / Service Level Agreement 3.10 Adjust Supply Chain Tactical Plan 3.5 Update Inventory Targets 3.11Communicate Supply Side/ Demand Side Impact 3.6 Run Planning Optimization 3.12 Communicate Financial Plan Impacts 4.0 Execute Supply Plan 4.1 Create Production Schedule 4.4 Provide Tolling Partner with Product Requirements 4.2 Provide Raw Materials Requirements 4.5 Execute Production Schedule 4.3 Provide 3rd Party with Product Requirements 4.6 Perform Available To Promise (ATP) 4.7 Deployment 5.0 Shape Demand Plan 5.1 Create/ Execute Demand Plan 5.2 Resolve Financial Impacts 12 Process Design – Level 3 Example II Process Design - 1.1 1.4 Determine Production Capability Inputs Manufacturing Performance Planned Mfg Improvement Maintenance History 1.4.1 Determine production parameters based on demonstrated performance 1.4.2 Modify production parameters based on new capability 1.4.3 Estimate Maintenance needs by unit 1.4.4 Gain consensus on production capability parameters Preliminary FG Production capability profile (by site, by unit, by time period) 13 Essential Strategies Step 3: Identify the gaps in capabilities between the “as is” and the “to be” state. — Seek input from a broad base of stakeholders — Prioritize gaps based on degree of urgency and business value — Group “related gaps” Individual capability assessments and prioritization inputs provide the basis of the project plan 14 Gap Analysis Cross-Functional Input Capability Assessment Assessment of performance in relation to the To-Be Operating Model (Global Perspective with “80/20 Rule”) Capability Prioritization Prioritization of each of the To-Be Operating Model components based on Degree of Urgency and Business Value Driving Factors and Considerations - Benefit vs. Cost - Site Integration Issues - “Low Hanging Fruit” - Process Dependencies - Domestic vs. International Capabilities As-Is + Business Capability Release #1 - Current Initiatives / Activities - Technology Dependencies - Scalability - Organizational Dependencies + Business Capability Release #2 - Scope +…+ Business Capability Release #12 = To-Be Operational Model Essential Strategies Step 4: Build a Road Map — Resist the urge to ‘eat the elephant in one bite’, while insuring that the entire elephant will be eaten. — Each “bite” should be large enough to deliver value but small enough to be completed in a 6 – 12 month time frame. — At the end of each “bite” the supply chain should be in a “steady-state”. …Achieve short term gains while insuring long term results 16 Business Capability Release Plan The BCR plan can be viewed as a simple building model... BCR 11: APS Scheduling Optimization BCR 9 Supplier Integration BCR 10 Customer Integration BCR 7 APS Supply Planning BCR 6 APS Demand Planning BCR 4A Data Integration BCR 1 Demand Consolidation BCR 2 Tolling Automation BCR 5 Network Planning BCR 3 S&OP Standardization Change Management & Learning BCR 4 Inventory Visibility BCR0B - Management Tools BCR8 – Market Remediation BCR0A - Site Acceleration Optimization Phase II Extension Optimization Phase I Integration Foundation … A solid framework of tools, processes, and data 17 Essential Strategies Step 5: Design the Project — Build stakeholder ownership into the process — Integrate process technology and people — Plan for sustainability Minimize non-value add “we-they” activity Eliminate “hand-offs” where possible If you can’t integrate multiple project elements, is it reasonable to expect that you can integrate an entire supply chain? Standardize project methodology, terminology, required documents, and even presentation formats. Use every opportunity to reduce variability …Invest the time necessary to develop a robust project design 18 Project Team Structure Team Leaders Functional Process Owners Business Capability Releases Site Network Markets SourcingDistribution Logistics Planning Inventory & Database Metrics Finance Maintenance Mgmt BCR 0-A Site Acceleration BCR 0-B Management Tools BCR 1 Demand Consolidation BCR 2 Tolling Automation BCR 3 S&OP Standardization Change Mgmt & Learning • Design, build, test and deploy identified business capabilities BCR 4 Inventory Visibility BCR 5 Network Plng. BCR 6 APS Demand Plng BCR 7 APS Supply Plng BCR 8 Market Integration BCR 9 Supplier Integration BCR 10 Customer Integration • Re-design existing functional processes and organization to support BCR solutions … Build stakeholder ownership into the process 19 The Project Office Project Management Project Administration Manages Consolidation of Project Plans Reporting Measurement Resource allocation Remediation Insure adherence to process Process Integration Develop overarching process solutions Coordinate & guide teams Ensures process integration among BCR’s Technology Integration Change Management Manage evaluations & Develop and selection of implement CM technology solutions strategy and work Coordinate & guide plan teams Lead & facilitates CM Ensure technology activities integration between Directs design & BCR’s implementation of training programs to ensure knowledge transfer and development …People, process and technology integration required 20 Standard Project Methodology (Based on 12 Months) BCR Duration BCR Team M o b i l i z e 1 2 3 4 5 6 7 8 9 10 11 12 Change Management Design Build Capability Test/ Pilot Deploy Today: Week 6 of the design phase Complete - Week 5 Complete - Week 6 Weeks 7 & 8 Scope Draft process flow level 4 Integrated level 4 process flow Assumptions Business Rules Final application architecture Business Requirements Draft application architecture Final roll-out/ release plans Business scenario inventory First cut roll-out/ release plans Process Flows level 1, 2, 3. Business Tools/ Metrics Inventory Legal & Regulatory Element inventory Business Resource requirements Draft Risk Management Plan Final Risk Management plan Build/ Test Element Inventory Detailed Build/ Test plan 21 Essential Strategies Step 6: Establish Change Management Program — Engage and gain commitment from Senior leadership — Ensure employee understanding at all levels and promoting readiness and buy-in of key stakeholders — Identify and develop skills and competencies required by SC Professionals; train sites and markets — Facilitate the organizational transformation; clarify roles and accountabilities — Establish programs to recognize/reward behaviors needed to sustain the model and promote the new culture …Change Management is necessary to manage the journey and to facilitate transition to the future state. 22 Change Management Processes BCR 11: APS Scheduling Optimization BCR8 – Market Remediation BCR0A - Site Acceleration BCR 4A Integration BCR 1 Demand Consolidation CM8: CM7: CM6: CM5: CM4: CM3: CM2: CM1: BCR 7 APS Supply Planning BCR 6 APS Demand Planning BCR 2 Tolling Automation BCR 5 Network Planning BCR 3 S&OP Standardization BCR 4 Inventory Visibility BCR0B - Management Tools BCR 10 BCR 9 Supplier Integration Customer Integration Supply Chain Optimization Change Management & Learning Organizational Transformation Readiness Assessment Knowledge Transfer Performance Support & Learning Change Advocate network Communications & Stakeholder Management Build Project Team Sponsorship ... eight key change management processes leveraged. 23 Lessons Learned… Benefits are likely understated in the business case. Process must always lead technology. Don’t let the “latest whiz-bang tool” distract you from your objective. Insure that “process & technology” do not get too far ahead of “people”. Do not underestimate the effort required to integrate and remediate data. Continue to change business objectives to reflect capabilities delivered and planned. Have a low tolerance for exceptions to global standards. Link a balanced scorecard of metrics and process compliance to compensation … It’s not easy, but it is achievable! 24